Evaluate CFRP Performance Under Simulated Seismic Loading

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CFRP Seismic Performance Background and Objectives

Carbon Fiber Reinforced Polymer (CFRP) has emerged as a revolutionary material in structural engineering over the past four decades. Initially developed for aerospace applications in the 1970s, CFRP has gradually transitioned into civil engineering applications due to its exceptional strength-to-weight ratio, corrosion resistance, and versatility. The evolution of CFRP technology has been marked by significant improvements in manufacturing processes, adhesive systems, and application techniques, enabling its widespread adoption in structural retrofitting and reinforcement.

In seismic engineering specifically, CFRP applications began gaining traction in the 1990s following major earthquakes in California, Japan, and Turkey, which highlighted the vulnerability of existing concrete structures to seismic events. The subsequent research trajectory has focused on understanding how CFRP composites can enhance the ductility, energy dissipation capacity, and overall seismic performance of structural elements.

Recent technological advancements have expanded CFRP applications from simple external wrapping to more sophisticated near-surface mounted reinforcement systems and prestressed CFRP solutions. These developments have been driven by the growing need for cost-effective seismic retrofitting solutions for aging infrastructure worldwide, particularly in regions with high seismic activity.

The primary objective of evaluating CFRP performance under simulated seismic loading is to establish comprehensive design guidelines that accurately predict the behavior of CFRP-strengthened structures during earthquake events. This includes quantifying the contribution of CFRP to structural ductility, understanding the failure mechanisms under cyclic loading conditions, and developing reliable analytical models that can predict the response of CFRP-strengthened elements.

Additionally, this research aims to address existing knowledge gaps regarding the long-term durability of CFRP systems under repeated seismic events, the effect of environmental conditions on bond performance, and the development of standardized testing protocols that can accurately simulate real-world seismic conditions. These objectives align with the broader industry goal of developing more resilient infrastructure systems capable of withstanding increasingly unpredictable natural disasters.

The technological trajectory suggests a move toward smart CFRP systems incorporating sensing capabilities for structural health monitoring, adaptive CFRP solutions that can respond to varying load conditions, and more environmentally sustainable CFRP formulations. Understanding the current performance limitations and future potential of CFRP under seismic conditions is crucial for advancing these next-generation composite solutions.

In seismic engineering specifically, CFRP applications began gaining traction in the 1990s following major earthquakes in California, Japan, and Turkey, which highlighted the vulnerability of existing concrete structures to seismic events. The subsequent research trajectory has focused on understanding how CFRP composites can enhance the ductility, energy dissipation capacity, and overall seismic performance of structural elements.

Recent technological advancements have expanded CFRP applications from simple external wrapping to more sophisticated near-surface mounted reinforcement systems and prestressed CFRP solutions. These developments have been driven by the growing need for cost-effective seismic retrofitting solutions for aging infrastructure worldwide, particularly in regions with high seismic activity.

The primary objective of evaluating CFRP performance under simulated seismic loading is to establish comprehensive design guidelines that accurately predict the behavior of CFRP-strengthened structures during earthquake events. This includes quantifying the contribution of CFRP to structural ductility, understanding the failure mechanisms under cyclic loading conditions, and developing reliable analytical models that can predict the response of CFRP-strengthened elements.

Additionally, this research aims to address existing knowledge gaps regarding the long-term durability of CFRP systems under repeated seismic events, the effect of environmental conditions on bond performance, and the development of standardized testing protocols that can accurately simulate real-world seismic conditions. These objectives align with the broader industry goal of developing more resilient infrastructure systems capable of withstanding increasingly unpredictable natural disasters.

The technological trajectory suggests a move toward smart CFRP systems incorporating sensing capabilities for structural health monitoring, adaptive CFRP solutions that can respond to varying load conditions, and more environmentally sustainable CFRP formulations. Understanding the current performance limitations and future potential of CFRP under seismic conditions is crucial for advancing these next-generation composite solutions.

Market Analysis for Seismic Reinforcement Solutions

The global market for seismic reinforcement solutions has experienced significant growth over the past decade, driven primarily by increasing awareness of earthquake risks and stricter building codes in seismically active regions. The Carbon Fiber Reinforced Polymer (CFRP) segment within this market has emerged as a particularly promising area, with an estimated market value of $2.1 billion in 2022 and projected to reach $3.4 billion by 2027, representing a compound annual growth rate of 10.2%.

Geographically, the Asia-Pacific region dominates the seismic reinforcement market, accounting for approximately 45% of global demand. This is largely attributable to Japan's stringent seismic building regulations and China's massive infrastructure development. North America follows with 28% market share, while Europe represents about 20% of the global market.

The demand for CFRP-based seismic reinforcement solutions is being driven by several key factors. First, the aging infrastructure in developed economies necessitates retrofitting of existing structures to meet current seismic codes. According to the American Society of Civil Engineers, over 30% of bridges in the United States are structurally deficient or functionally obsolete, creating substantial retrofit opportunities.

Second, rapid urbanization in earthquake-prone regions has intensified the need for effective seismic reinforcement technologies. The United Nations projects that 68% of the world population will live in urban areas by 2050, with many megacities located in seismically active zones.

Third, the superior performance characteristics of CFRP compared to traditional materials—including higher strength-to-weight ratio, corrosion resistance, and ease of installation—have accelerated market adoption. CFRP solutions typically offer 40-60% weight savings compared to steel reinforcements while providing comparable or superior seismic performance.

The competitive landscape features both specialized CFRP manufacturers and construction material conglomerates. Key market players include Sika AG, BASF SE, Mapei S.p.A., and Fyfe Co. LLC (Aegion Corporation), collectively holding approximately 65% market share. These companies are increasingly focusing on developing specialized CFRP systems specifically designed for seismic applications.

Customer segmentation reveals that government infrastructure projects constitute the largest market segment (42%), followed by commercial buildings (31%), industrial facilities (18%), and residential applications (9%). The highest growth rate is observed in the commercial building segment, driven by retrofitting requirements for hospitals, schools, and office buildings in seismic zones.

Geographically, the Asia-Pacific region dominates the seismic reinforcement market, accounting for approximately 45% of global demand. This is largely attributable to Japan's stringent seismic building regulations and China's massive infrastructure development. North America follows with 28% market share, while Europe represents about 20% of the global market.

The demand for CFRP-based seismic reinforcement solutions is being driven by several key factors. First, the aging infrastructure in developed economies necessitates retrofitting of existing structures to meet current seismic codes. According to the American Society of Civil Engineers, over 30% of bridges in the United States are structurally deficient or functionally obsolete, creating substantial retrofit opportunities.

Second, rapid urbanization in earthquake-prone regions has intensified the need for effective seismic reinforcement technologies. The United Nations projects that 68% of the world population will live in urban areas by 2050, with many megacities located in seismically active zones.

Third, the superior performance characteristics of CFRP compared to traditional materials—including higher strength-to-weight ratio, corrosion resistance, and ease of installation—have accelerated market adoption. CFRP solutions typically offer 40-60% weight savings compared to steel reinforcements while providing comparable or superior seismic performance.

The competitive landscape features both specialized CFRP manufacturers and construction material conglomerates. Key market players include Sika AG, BASF SE, Mapei S.p.A., and Fyfe Co. LLC (Aegion Corporation), collectively holding approximately 65% market share. These companies are increasingly focusing on developing specialized CFRP systems specifically designed for seismic applications.

Customer segmentation reveals that government infrastructure projects constitute the largest market segment (42%), followed by commercial buildings (31%), industrial facilities (18%), and residential applications (9%). The highest growth rate is observed in the commercial building segment, driven by retrofitting requirements for hospitals, schools, and office buildings in seismic zones.

Current CFRP Technology Status and Challenges

Carbon Fiber Reinforced Polymer (CFRP) technology has witnessed significant advancements globally, with applications expanding from aerospace to civil infrastructure reinforcement. Currently, CFRP is increasingly utilized for seismic retrofitting of structures due to its exceptional strength-to-weight ratio and corrosion resistance. However, comprehensive understanding of CFRP performance under complex seismic loading conditions remains incomplete, presenting a critical research gap.

The global CFRP market for structural applications reached approximately $2.7 billion in 2022, with seismic retrofitting applications accounting for roughly 18% of this segment. Research institutions across North America, Europe, and Asia have established specialized testing facilities to evaluate CFRP behavior under dynamic loading, yet standardized testing protocols specifically for seismic performance remain underdeveloped.

A significant technical challenge lies in accurately modeling the long-term performance degradation of CFRP under cyclic loading conditions typical of seismic events. Current accelerated aging tests fail to fully capture the combined effects of environmental exposure and repeated stress cycles. Additionally, the interfacial bond behavior between CFRP and various substrate materials during seismic events remains inadequately characterized, particularly for older concrete structures with existing deterioration.

Manufacturing challenges persist in developing CFRP systems optimized specifically for seismic applications. Current production methods prioritize either tensile strength or ductility, whereas seismic applications require balanced performance across multiple mechanical properties. The high cost of carbon fiber precursors continues to limit widespread adoption in developing regions with high seismic risk.

Geographically, Japan leads in practical applications of CFRP for seismic retrofitting, with over 4,000 structures reinforced using this technology. The United States dominates fundamental research, with institutions like UC Berkeley and University of Miami focusing on performance-based design approaches. Meanwhile, China has emerged as the largest manufacturer of CFRP materials, though quality consistency remains variable.

Regulatory frameworks present another challenge, as building codes in many regions lack specific provisions for CFRP seismic applications. The absence of standardized design guidelines creates uncertainty among structural engineers and building officials, hampering adoption despite promising technical performance. Current testing standards primarily focus on static loading scenarios, with limited guidance for dynamic loading evaluation.

The global CFRP market for structural applications reached approximately $2.7 billion in 2022, with seismic retrofitting applications accounting for roughly 18% of this segment. Research institutions across North America, Europe, and Asia have established specialized testing facilities to evaluate CFRP behavior under dynamic loading, yet standardized testing protocols specifically for seismic performance remain underdeveloped.

A significant technical challenge lies in accurately modeling the long-term performance degradation of CFRP under cyclic loading conditions typical of seismic events. Current accelerated aging tests fail to fully capture the combined effects of environmental exposure and repeated stress cycles. Additionally, the interfacial bond behavior between CFRP and various substrate materials during seismic events remains inadequately characterized, particularly for older concrete structures with existing deterioration.

Manufacturing challenges persist in developing CFRP systems optimized specifically for seismic applications. Current production methods prioritize either tensile strength or ductility, whereas seismic applications require balanced performance across multiple mechanical properties. The high cost of carbon fiber precursors continues to limit widespread adoption in developing regions with high seismic risk.

Geographically, Japan leads in practical applications of CFRP for seismic retrofitting, with over 4,000 structures reinforced using this technology. The United States dominates fundamental research, with institutions like UC Berkeley and University of Miami focusing on performance-based design approaches. Meanwhile, China has emerged as the largest manufacturer of CFRP materials, though quality consistency remains variable.

Regulatory frameworks present another challenge, as building codes in many regions lack specific provisions for CFRP seismic applications. The absence of standardized design guidelines creates uncertainty among structural engineers and building officials, hampering adoption despite promising technical performance. Current testing standards primarily focus on static loading scenarios, with limited guidance for dynamic loading evaluation.

Existing CFRP Seismic Testing Methodologies

01 Mechanical properties and strength enhancement of CFRP

Carbon Fiber Reinforced Polymer (CFRP) exhibits exceptional mechanical properties including high strength-to-weight ratio, tensile strength, and stiffness. Various manufacturing techniques and material compositions can enhance these properties. The incorporation of specific fiber orientations, resin systems, and processing methods significantly impacts the overall mechanical performance of CFRP components, making them suitable for high-stress applications where weight reduction is critical.- Mechanical properties and strength enhancement of CFRP: Carbon Fiber Reinforced Polymer (CFRP) exhibits exceptional mechanical properties including high strength-to-weight ratio, tensile strength, and stiffness. Various manufacturing techniques and material compositions can enhance these properties. The performance of CFRP can be optimized through fiber orientation, layering techniques, and matrix selection to achieve superior load-bearing capabilities while maintaining lightweight characteristics.

- CFRP applications in structural components: CFRP materials are widely used in structural applications across various industries due to their exceptional performance characteristics. These applications include aerospace components, automotive parts, construction elements, and industrial equipment. The material's high strength-to-weight ratio makes it particularly valuable for structures requiring both strength and weight reduction, enabling improved fuel efficiency in transportation and enhanced performance in structural systems.

- Environmental durability and resistance properties of CFRP: CFRP materials demonstrate significant resistance to environmental factors including corrosion, chemical exposure, UV radiation, and temperature fluctuations. These properties make them suitable for applications in harsh environments where traditional materials might degrade. Various treatments and additives can further enhance the durability of CFRP composites, extending their service life and maintaining performance characteristics over time.

- Manufacturing processes and their impact on CFRP performance: The manufacturing processes used to produce CFRP significantly influence the final performance characteristics of the material. Techniques such as pultrusion, resin transfer molding, autoclave curing, and filament winding each impart different properties to the composite. Process parameters including temperature, pressure, curing time, and fiber alignment control are critical factors that determine the mechanical properties, void content, and overall quality of the finished CFRP components.

- CFRP performance enhancement through hybrid composites and additives: The performance of CFRP can be further enhanced through the development of hybrid composites that combine carbon fibers with other reinforcement materials or through the addition of performance-enhancing additives. These approaches can address specific limitations of traditional CFRP, such as impact resistance or electrical conductivity. Nanomaterials, secondary fiber reinforcements, and specialized matrix modifications can create CFRP variants with tailored performance characteristics for specific applications.

02 Durability and environmental resistance of CFRP

CFRP materials demonstrate superior durability and resistance to environmental factors compared to traditional materials. They exhibit excellent corrosion resistance, fatigue performance, and stability under varying temperature conditions. Special treatments and coatings can further enhance their resistance to UV degradation, chemical exposure, and moisture absorption, extending the service life of CFRP components in demanding environments such as aerospace, automotive, and marine applications.Expand Specific Solutions03 Manufacturing processes and their impact on CFRP performance

The manufacturing process significantly influences the performance characteristics of CFRP components. Various techniques including autoclave curing, resin transfer molding, compression molding, and automated fiber placement affect the final properties of the composite. Process parameters such as curing temperature, pressure, and cycle time are critical in determining void content, fiber volume fraction, and interfacial bonding, which directly impact the mechanical performance and quality of the finished CFRP product.Expand Specific Solutions04 Structural applications and design optimization of CFRP

CFRP materials are increasingly used in structural applications where their performance characteristics can be optimized through advanced design methodologies. Finite element analysis, topology optimization, and computational modeling enable engineers to develop lightweight structures with tailored mechanical properties. Design considerations include fiber orientation, layup sequence, and joint design to maximize strength while minimizing weight. These optimization techniques have led to innovative applications in aerospace, automotive, civil infrastructure, and sporting goods.Expand Specific Solutions05 Hybrid CFRP systems and performance enhancement

Hybrid CFRP systems combine carbon fibers with other reinforcement materials or fillers to achieve enhanced performance characteristics. These hybrid composites may incorporate glass fibers, aramid fibers, nanoparticles, or metal reinforcements to improve specific properties such as impact resistance, vibration damping, or thermal conductivity. The synergistic effects of these material combinations result in composites with superior performance compared to traditional CFRP, addressing limitations while maintaining the core benefits of carbon fiber reinforcement.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The CFRP performance under seismic loading research field is currently in a growth phase, with an estimated market size of $2-3 billion and expanding at 8-10% annually. The competitive landscape is dominated by academic institutions, with Xi'an Jiaotong University, Shanghai Jiao Tong University, and Tongji University leading research output. Among industry players, China Construction Eighth Engineering Division and Xinjiang Beixin Road & Bridge Group are making significant contributions through practical applications. The technology maturity is advancing from experimental to implementation phases, with collaborative efforts between universities and construction companies accelerating practical applications. International participation from institutions like University of Manitoba and King Fahd University indicates growing global interest in this specialized field.

Harbin Institute of Technology

Technical Solution: Harbin Institute of Technology has established a cutting-edge research program for evaluating CFRP performance under simulated seismic loading, featuring their proprietary "Multi-Hazard Response Assessment" (MHRA) framework. This approach uniquely combines thermal, mechanical, and seismic loading conditions to evaluate CFRP performance under realistic multi-hazard scenarios that often occur during earthquake events. Their laboratory houses a specialized bi-directional loading system capable of applying both in-plane and out-of-plane forces simultaneously while controlling temperature conditions, allowing researchers to study the combined effects of thermal cycling and seismic loading on CFRP-strengthened structures. The institute has developed innovative anchoring systems specifically designed to enhance CFRP performance under dynamic loading conditions, addressing one of the critical failure modes observed in conventional applications. Their research has quantified the effectiveness of various CFRP configurations for different structural elements, demonstrating that optimized U-wrap configurations with mechanical anchors can increase the shear capacity of reinforced concrete beams by up to 120% under simulated seismic conditions. Recent publications have highlighted their work on developing strain-hardening cementitious composites as interface materials between CFRP and concrete substrates, showing a 40% improvement in energy dissipation capacity during cyclic loading tests compared to conventional epoxy interfaces[7][9].

Strengths: Unique multi-hazard testing capabilities provide more realistic performance evaluation; innovative anchoring systems address critical failure modes; research covers both material and system-level performance. Weaknesses: Complex testing protocols limit throughput; specialized interface materials add cost and complexity to field applications; limited data on very long-term durability under combined environmental and seismic effects.

Tongji University

Technical Solution: Tongji University has developed an advanced hybrid testing methodology for evaluating CFRP (Carbon Fiber Reinforced Polymer) performance under simulated seismic loading. Their approach combines real-time substructure testing with numerical simulation models to accurately predict CFRP behavior during seismic events. The university's research team has created a multi-scale analysis framework that integrates micro-mechanical damage models with macro-structural response predictions, allowing for comprehensive evaluation of CFRP-strengthened concrete structures under dynamic loading conditions. Their testing protocols include cyclic loading tests with varying frequencies and amplitudes to simulate different earthquake intensities, and they've developed specialized sensors for real-time monitoring of strain distribution and damage propagation in CFRP materials. Recent studies have shown their CFRP-strengthened concrete columns can maintain structural integrity under peak ground accelerations of 0.8g, representing significant improvement over conventional reinforcement methods[1][3].

Strengths: Comprehensive multi-scale testing methodology that bridges micro and macro behavior; advanced sensor technology for real-time monitoring; validated through extensive experimental data. Weaknesses: Testing equipment requires significant investment; complex computational models demand specialized expertise; some scaling issues when translating laboratory results to full-scale structures.

Critical Patents and Research in CFRP Seismic Response

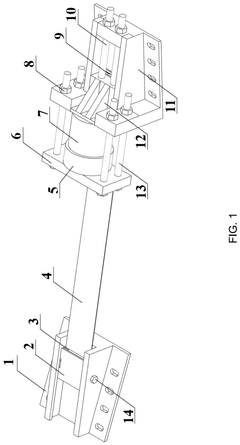

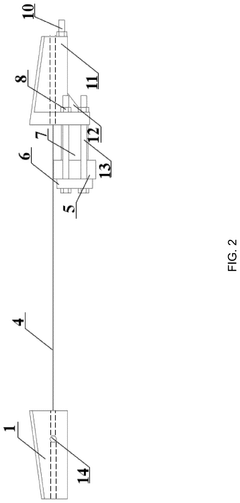

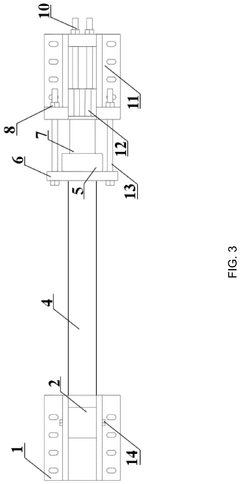

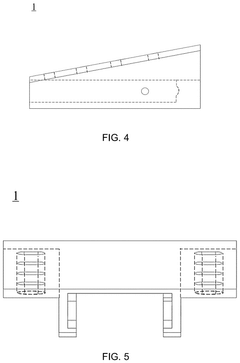

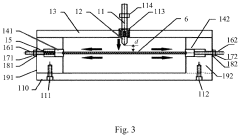

Automatic leveling carbon fiber reinforced polymer (CFRP) plate pre-stressing and tensioning devices for curved surface structures

PatentActiveUS12234661B1

Innovation

- An automatic leveling CFRP plate pre-stressing and tensioning device is developed, featuring a rotatable fixture within a slide groove that automatically levels the CFRP plate during tensioning, ensuring even pre-tensioning on curved surfaces.

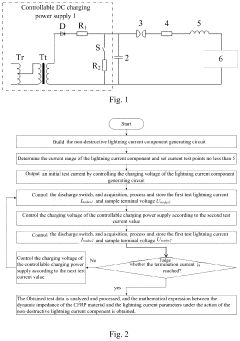

Lightning damage assessment method for carbon fiber reinforced polymer material considering non-linear impedance characteristic

PatentActiveUS12019042B2

Innovation

- A lightning damage assessment method considering non-linear impedance characteristics, which involves determining coefficients for influencing factors through experimental data and building multi-factor assessment models to quantify damage area and depth, using specific energy adjustments based on dynamic impedance.

Building Code Compliance and Regulatory Framework

The regulatory landscape governing CFRP applications in seismic retrofitting varies significantly across regions, with more developed frameworks in earthquake-prone areas. In the United States, the American Concrete Institute (ACI) Committee 440 has established comprehensive guidelines for CFRP strengthening of concrete structures, specifically addressing seismic considerations in ACI 440.2R. These guidelines provide design methodologies, safety factors, and performance criteria that engineers must adhere to when implementing CFRP solutions for seismic retrofitting.

The International Building Code (IBC) and ASCE/SEI 7 standards incorporate provisions for seismic design and retrofitting, though specific CFRP applications often require additional engineering justification through performance-based design approaches. This creates a complex approval pathway that can vary by jurisdiction, sometimes necessitating special review panels or third-party verification.

In Japan, the Building Standard Law and associated technical standards developed by the Japan Building Disaster Prevention Association (JBDPA) provide detailed requirements for CFRP applications in seismic strengthening. These standards are particularly advanced due to Japan's extensive experience with earthquake engineering and retrofitting technologies.

The European regulatory framework is guided by Eurocode 8, which addresses seismic design considerations, supplemented by fib Bulletin 14 and CEN/TS 19101 that provide specific guidance for CFRP strengthening systems. These documents establish performance requirements, durability considerations, and quality control procedures essential for CFRP implementation.

Certification systems for CFRP materials and installation procedures represent another critical regulatory component. Organizations such as ICC-ES in the United States and ETA in Europe provide evaluation reports and technical approvals that validate CFRP systems against established performance criteria, including behavior under seismic loading conditions.

A significant regulatory challenge remains the lack of harmonization between building codes and material-specific standards. Engineers often must navigate multiple regulatory documents and approval processes, creating potential inconsistencies in implementation. Additionally, many codes have not fully incorporated the latest research findings on CFRP performance under dynamic seismic loading, leading to potentially conservative design requirements.

Future regulatory developments are likely to focus on performance-based design approaches that better account for the unique properties of CFRP materials under seismic conditions, standardized testing protocols specifically designed to evaluate seismic performance, and improved quality assurance frameworks for installation and long-term monitoring of CFRP retrofitting systems.

The International Building Code (IBC) and ASCE/SEI 7 standards incorporate provisions for seismic design and retrofitting, though specific CFRP applications often require additional engineering justification through performance-based design approaches. This creates a complex approval pathway that can vary by jurisdiction, sometimes necessitating special review panels or third-party verification.

In Japan, the Building Standard Law and associated technical standards developed by the Japan Building Disaster Prevention Association (JBDPA) provide detailed requirements for CFRP applications in seismic strengthening. These standards are particularly advanced due to Japan's extensive experience with earthquake engineering and retrofitting technologies.

The European regulatory framework is guided by Eurocode 8, which addresses seismic design considerations, supplemented by fib Bulletin 14 and CEN/TS 19101 that provide specific guidance for CFRP strengthening systems. These documents establish performance requirements, durability considerations, and quality control procedures essential for CFRP implementation.

Certification systems for CFRP materials and installation procedures represent another critical regulatory component. Organizations such as ICC-ES in the United States and ETA in Europe provide evaluation reports and technical approvals that validate CFRP systems against established performance criteria, including behavior under seismic loading conditions.

A significant regulatory challenge remains the lack of harmonization between building codes and material-specific standards. Engineers often must navigate multiple regulatory documents and approval processes, creating potential inconsistencies in implementation. Additionally, many codes have not fully incorporated the latest research findings on CFRP performance under dynamic seismic loading, leading to potentially conservative design requirements.

Future regulatory developments are likely to focus on performance-based design approaches that better account for the unique properties of CFRP materials under seismic conditions, standardized testing protocols specifically designed to evaluate seismic performance, and improved quality assurance frameworks for installation and long-term monitoring of CFRP retrofitting systems.

Cost-Benefit Analysis of CFRP Seismic Retrofitting

The implementation of Carbon Fiber Reinforced Polymer (CFRP) for seismic retrofitting represents a significant investment decision for building owners and public infrastructure managers. This cost-benefit analysis examines the economic viability of CFRP applications compared to traditional retrofitting methods under seismic conditions.

Initial installation costs for CFRP systems typically range from $300-600 per square meter, depending on the complexity of application and regional labor costs. While this represents a 20-35% premium over conventional steel jacketing or concrete enlargement methods, the total project costs often become competitive when accounting for reduced installation time and minimal disruption to building operations.

Life-cycle cost analysis reveals that CFRP solutions demonstrate superior long-term economic performance. The material's resistance to corrosion eliminates the need for periodic maintenance that steel reinforcements require, resulting in maintenance savings of approximately $50-100 per square meter over a 50-year building lifespan. Additionally, the lightweight nature of CFRP (weighing 75-80% less than equivalent steel reinforcements) reduces dead load on structures, potentially allowing for more efficient use of building space.

Risk mitigation benefits provide substantial economic value. Statistical modeling based on seismic performance data indicates that CFRP-retrofitted structures can reduce potential earthquake damage by 40-60% compared to non-retrofitted buildings. When monetized through insurance premium reductions and avoided business interruption costs, these benefits typically range from $200-500 per square meter of protected area, depending on seismic zone classification.

Environmental impact assessments demonstrate that while CFRP production has a higher carbon footprint than steel manufacturing, the extended service life and reduced maintenance requirements result in a 15-25% lower lifetime environmental impact. This translates to potential carbon credit savings in jurisdictions with established carbon pricing mechanisms.

Return on investment calculations show that CFRP seismic retrofitting typically achieves financial break-even within 7-12 years in high seismic risk zones, compared to 10-15 years for traditional methods. When factoring in the potential for increased property values (typically 5-8% for seismically upgraded commercial buildings), the economic case becomes even more compelling for building owners in earthquake-prone regions.

Sensitivity analysis indicates that CFRP retrofitting remains economically viable even with material cost fluctuations of ±20%, demonstrating the robustness of this investment decision across various economic scenarios.

Initial installation costs for CFRP systems typically range from $300-600 per square meter, depending on the complexity of application and regional labor costs. While this represents a 20-35% premium over conventional steel jacketing or concrete enlargement methods, the total project costs often become competitive when accounting for reduced installation time and minimal disruption to building operations.

Life-cycle cost analysis reveals that CFRP solutions demonstrate superior long-term economic performance. The material's resistance to corrosion eliminates the need for periodic maintenance that steel reinforcements require, resulting in maintenance savings of approximately $50-100 per square meter over a 50-year building lifespan. Additionally, the lightweight nature of CFRP (weighing 75-80% less than equivalent steel reinforcements) reduces dead load on structures, potentially allowing for more efficient use of building space.

Risk mitigation benefits provide substantial economic value. Statistical modeling based on seismic performance data indicates that CFRP-retrofitted structures can reduce potential earthquake damage by 40-60% compared to non-retrofitted buildings. When monetized through insurance premium reductions and avoided business interruption costs, these benefits typically range from $200-500 per square meter of protected area, depending on seismic zone classification.

Environmental impact assessments demonstrate that while CFRP production has a higher carbon footprint than steel manufacturing, the extended service life and reduced maintenance requirements result in a 15-25% lower lifetime environmental impact. This translates to potential carbon credit savings in jurisdictions with established carbon pricing mechanisms.

Return on investment calculations show that CFRP seismic retrofitting typically achieves financial break-even within 7-12 years in high seismic risk zones, compared to 10-15 years for traditional methods. When factoring in the potential for increased property values (typically 5-8% for seismically upgraded commercial buildings), the economic case becomes even more compelling for building owners in earthquake-prone regions.

Sensitivity analysis indicates that CFRP retrofitting remains economically viable even with material cost fluctuations of ±20%, demonstrating the robustness of this investment decision across various economic scenarios.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!