CFRP vs Silica-Based Composites: Impact Absorption Rates

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CFRP and Silica Composites Background and Objectives

Carbon Fiber Reinforced Polymers (CFRP) and silica-based composites represent two distinct material categories that have revolutionized various industries through their exceptional mechanical properties. The evolution of these materials traces back to the mid-20th century, with significant advancements occurring in the aerospace and automotive sectors during the 1960s and 1970s. CFRP, consisting of carbon fiber reinforcement embedded in a polymer matrix, emerged as a lightweight alternative to traditional metals, offering superior strength-to-weight ratios and design flexibility.

Silica-based composites, on the other hand, evolved from traditional glass fiber reinforced polymers (GFRP) and have progressively incorporated advanced silica derivatives, including nanosilica and silica aerogels. These materials have demonstrated remarkable thermal stability and unique impact absorption characteristics that complement their mechanical properties, making them increasingly relevant in specialized applications.

The technological trajectory of both material systems has been characterized by continuous refinement in manufacturing processes, matrix formulations, and fiber architectures. For CFRP, developments have focused on reducing production costs, improving fiber-matrix interfacial properties, and enhancing recyclability. Silica-based composites have seen innovations in particle size control, dispersion techniques, and hybrid formulations that combine silica with other reinforcement materials.

Impact absorption represents a critical performance parameter for both material systems, particularly in safety-critical applications such as automotive crash structures, protective equipment, and ballistic protection. The fundamental mechanisms of energy dissipation differ significantly between these materials, with CFRP typically exhibiting brittle fracture modes that absorb energy through controlled failure progression, while silica-based composites often demonstrate viscoelastic deformation and progressive crushing behaviors.

The primary objective of this technical investigation is to comprehensively analyze and compare the impact absorption rates of CFRP and silica-based composites across various loading conditions, strain rates, and environmental factors. This analysis aims to establish quantitative performance metrics that can guide material selection decisions for specific applications requiring optimized impact resistance.

Secondary objectives include identifying the microstructural and compositional factors that influence impact absorption efficiency, evaluating the potential for hybrid CFRP-silica composite systems that leverage the advantages of both material classes, and assessing emerging manufacturing techniques that may enhance impact performance while maintaining economic viability for mass production scenarios.

Understanding these comparative performance characteristics will enable more informed engineering decisions and potentially open new application spaces where tailored impact absorption properties are critical to product performance and safety outcomes.

Silica-based composites, on the other hand, evolved from traditional glass fiber reinforced polymers (GFRP) and have progressively incorporated advanced silica derivatives, including nanosilica and silica aerogels. These materials have demonstrated remarkable thermal stability and unique impact absorption characteristics that complement their mechanical properties, making them increasingly relevant in specialized applications.

The technological trajectory of both material systems has been characterized by continuous refinement in manufacturing processes, matrix formulations, and fiber architectures. For CFRP, developments have focused on reducing production costs, improving fiber-matrix interfacial properties, and enhancing recyclability. Silica-based composites have seen innovations in particle size control, dispersion techniques, and hybrid formulations that combine silica with other reinforcement materials.

Impact absorption represents a critical performance parameter for both material systems, particularly in safety-critical applications such as automotive crash structures, protective equipment, and ballistic protection. The fundamental mechanisms of energy dissipation differ significantly between these materials, with CFRP typically exhibiting brittle fracture modes that absorb energy through controlled failure progression, while silica-based composites often demonstrate viscoelastic deformation and progressive crushing behaviors.

The primary objective of this technical investigation is to comprehensively analyze and compare the impact absorption rates of CFRP and silica-based composites across various loading conditions, strain rates, and environmental factors. This analysis aims to establish quantitative performance metrics that can guide material selection decisions for specific applications requiring optimized impact resistance.

Secondary objectives include identifying the microstructural and compositional factors that influence impact absorption efficiency, evaluating the potential for hybrid CFRP-silica composite systems that leverage the advantages of both material classes, and assessing emerging manufacturing techniques that may enhance impact performance while maintaining economic viability for mass production scenarios.

Understanding these comparative performance characteristics will enable more informed engineering decisions and potentially open new application spaces where tailored impact absorption properties are critical to product performance and safety outcomes.

Market Demand Analysis for Impact-Resistant Materials

The global market for impact-resistant materials has experienced significant growth in recent years, driven primarily by increasing safety requirements across multiple industries. The demand for advanced composites like Carbon Fiber Reinforced Polymers (CFRP) and Silica-Based Composites has been particularly strong in automotive, aerospace, defense, and sporting goods sectors where impact absorption capabilities are critical performance factors.

In the automotive industry, the push for lightweight yet safer vehicles has created a substantial market for impact-resistant composites. With global regulations increasingly focused on both fuel efficiency and passenger safety, manufacturers are willing to invest in materials that offer superior impact absorption rates. Market research indicates that the automotive composites sector is growing at approximately 7% annually, with impact resistance being a key purchasing criterion.

Aerospace remains one of the highest-value markets for impact-resistant materials, with particular emphasis on materials that can withstand bird strikes, runway debris, and other high-velocity impacts. The commercial aircraft market has shown consistent demand for materials that offer better impact performance while reducing overall weight, creating a premium segment for advanced composites with superior impact absorption rates.

The sporting goods industry represents another significant market, particularly for protective equipment in high-impact sports. The growing awareness of concussion risks and other impact-related injuries has driven demand for helmets, pads, and other protective gear with enhanced impact absorption capabilities. This consumer-facing market is particularly sensitive to demonstrable performance advantages in impact resistance.

Defense applications constitute a specialized but lucrative market segment, where ballistic protection and blast resistance drive material selection. The global military body armor market alone exceeds $2 billion, with material performance in impact scenarios being the primary selection criterion.

Construction and infrastructure sectors are emerging markets for impact-resistant composites, particularly in regions prone to extreme weather events or seismic activity. Building codes in many countries now mandate impact-resistant materials for specific applications, creating new market opportunities.

Market analysis reveals a growing preference for materials that offer multifunctional benefits beyond impact resistance, such as thermal stability, corrosion resistance, and recyclability. This trend suggests that while impact absorption rates remain critical, materials that address multiple performance criteria simultaneously command premium pricing and market share.

Consumer willingness to pay for enhanced safety features has created price elasticity in many market segments, allowing manufacturers of superior impact-resistant materials to maintain healthy margins despite higher production costs. This economic dynamic has fueled continued investment in research and development of advanced composites with improved impact absorption characteristics.

In the automotive industry, the push for lightweight yet safer vehicles has created a substantial market for impact-resistant composites. With global regulations increasingly focused on both fuel efficiency and passenger safety, manufacturers are willing to invest in materials that offer superior impact absorption rates. Market research indicates that the automotive composites sector is growing at approximately 7% annually, with impact resistance being a key purchasing criterion.

Aerospace remains one of the highest-value markets for impact-resistant materials, with particular emphasis on materials that can withstand bird strikes, runway debris, and other high-velocity impacts. The commercial aircraft market has shown consistent demand for materials that offer better impact performance while reducing overall weight, creating a premium segment for advanced composites with superior impact absorption rates.

The sporting goods industry represents another significant market, particularly for protective equipment in high-impact sports. The growing awareness of concussion risks and other impact-related injuries has driven demand for helmets, pads, and other protective gear with enhanced impact absorption capabilities. This consumer-facing market is particularly sensitive to demonstrable performance advantages in impact resistance.

Defense applications constitute a specialized but lucrative market segment, where ballistic protection and blast resistance drive material selection. The global military body armor market alone exceeds $2 billion, with material performance in impact scenarios being the primary selection criterion.

Construction and infrastructure sectors are emerging markets for impact-resistant composites, particularly in regions prone to extreme weather events or seismic activity. Building codes in many countries now mandate impact-resistant materials for specific applications, creating new market opportunities.

Market analysis reveals a growing preference for materials that offer multifunctional benefits beyond impact resistance, such as thermal stability, corrosion resistance, and recyclability. This trend suggests that while impact absorption rates remain critical, materials that address multiple performance criteria simultaneously command premium pricing and market share.

Consumer willingness to pay for enhanced safety features has created price elasticity in many market segments, allowing manufacturers of superior impact-resistant materials to maintain healthy margins despite higher production costs. This economic dynamic has fueled continued investment in research and development of advanced composites with improved impact absorption characteristics.

Current Technical Challenges in Impact Absorption

The current landscape of impact absorption technology presents several significant challenges when comparing Carbon Fiber Reinforced Polymers (CFRP) and silica-based composites. One primary obstacle is achieving optimal energy dissipation while maintaining structural integrity. CFRP materials exhibit excellent strength-to-weight ratios but often demonstrate brittle failure modes under high-impact scenarios, limiting their effectiveness in progressive energy absorption applications.

Manufacturing consistency poses another substantial challenge, particularly for CFRP composites. The performance of these materials heavily depends on fiber orientation, resin distribution, and curing processes. Minor variations in manufacturing parameters can lead to significant deviations in impact absorption capabilities, making quality control and repeatability difficult to achieve at scale.

Silica-based composites face different challenges related to their inherent material properties. While they typically offer better thermal stability than CFRP, they struggle with weight efficiency and often require greater material volume to achieve comparable impact resistance. This creates design constraints in applications where weight is a critical factor, such as automotive and aerospace industries.

Cost-effectiveness remains a persistent barrier for both material systems. CFRP production involves expensive raw materials and complex manufacturing processes, resulting in high unit costs that limit widespread adoption. Silica-based composites, while generally less expensive per unit volume, often require more material to achieve equivalent performance, potentially negating cost advantages in certain applications.

Environmental degradation presents another significant technical hurdle. CFRP materials can experience performance deterioration when exposed to UV radiation, moisture, and certain chemicals, affecting their long-term impact absorption capabilities. Silica-based composites typically offer better environmental resistance but may experience issues with thermal cycling and freeze-thaw conditions.

Modeling and simulation accuracy represents a cross-cutting challenge for both material systems. Current computational models struggle to accurately predict complex failure mechanisms during impact events, particularly for anisotropic materials like CFRP. This limitation hampers design optimization and increases development cycles as more physical testing becomes necessary to validate performance.

Integration challenges also exist when combining these materials with other structural components. Interface regions often become weak points during impact events, creating potential failure modes that undermine the overall system performance. Developing effective joining techniques that maintain impact absorption properties across material boundaries remains technically challenging.

Manufacturing consistency poses another substantial challenge, particularly for CFRP composites. The performance of these materials heavily depends on fiber orientation, resin distribution, and curing processes. Minor variations in manufacturing parameters can lead to significant deviations in impact absorption capabilities, making quality control and repeatability difficult to achieve at scale.

Silica-based composites face different challenges related to their inherent material properties. While they typically offer better thermal stability than CFRP, they struggle with weight efficiency and often require greater material volume to achieve comparable impact resistance. This creates design constraints in applications where weight is a critical factor, such as automotive and aerospace industries.

Cost-effectiveness remains a persistent barrier for both material systems. CFRP production involves expensive raw materials and complex manufacturing processes, resulting in high unit costs that limit widespread adoption. Silica-based composites, while generally less expensive per unit volume, often require more material to achieve equivalent performance, potentially negating cost advantages in certain applications.

Environmental degradation presents another significant technical hurdle. CFRP materials can experience performance deterioration when exposed to UV radiation, moisture, and certain chemicals, affecting their long-term impact absorption capabilities. Silica-based composites typically offer better environmental resistance but may experience issues with thermal cycling and freeze-thaw conditions.

Modeling and simulation accuracy represents a cross-cutting challenge for both material systems. Current computational models struggle to accurately predict complex failure mechanisms during impact events, particularly for anisotropic materials like CFRP. This limitation hampers design optimization and increases development cycles as more physical testing becomes necessary to validate performance.

Integration challenges also exist when combining these materials with other structural components. Interface regions often become weak points during impact events, creating potential failure modes that undermine the overall system performance. Developing effective joining techniques that maintain impact absorption properties across material boundaries remains technically challenging.

Current Impact Absorption Solutions Comparison

01 CFRP-silica hybrid composites for enhanced impact absorption

Hybrid composites combining carbon fiber reinforced polymers (CFRP) with silica-based materials demonstrate superior impact absorption capabilities compared to traditional materials. The integration of silica particles or nanoparticles into the CFRP matrix creates a synergistic effect that enhances energy dissipation during impact events. These hybrid composites exhibit improved mechanical properties including higher impact resistance and better energy absorption rates, making them suitable for applications requiring high-performance impact protection.- CFRP-silica hybrid composites for enhanced impact absorption: Hybrid composites combining carbon fiber reinforced polymers (CFRP) with silica-based materials demonstrate superior impact absorption capabilities compared to conventional materials. The integration of silica particles or nanoparticles into the CFRP matrix creates a synergistic effect that enhances energy dissipation during impact events. These hybrid composites exhibit improved damage tolerance and can be tailored for specific impact resistance requirements in automotive, aerospace, and protective equipment applications.

- Nanosilica reinforcement in CFRP for impact resistance: Incorporating nanosilica particles into carbon fiber reinforced polymer matrices significantly improves impact absorption rates. The nanosilica particles create additional energy dissipation mechanisms through crack deflection and bridging, increasing the overall toughness of the composite. The nanoscale dispersion of silica particles throughout the polymer matrix enhances interfacial bonding between fibers and matrix, preventing delamination during impact events and improving the overall impact resistance of the composite structure.

- Silica-based coatings and surface treatments for CFRP: Surface treatments and coatings based on silica compounds can significantly enhance the impact absorption properties of carbon fiber reinforced polymers. These treatments create a protective layer that distributes impact forces more effectively across the composite surface. Silica-based coatings can be engineered with varying densities and structures to absorb specific impact energies, while maintaining the lightweight properties of the underlying CFRP. These surface modifications also improve weatherability and resistance to environmental degradation.

- Gradient and layered CFRP-silica structures for optimized impact absorption: Gradient and layered composite structures combining CFRP with silica-based materials offer optimized impact absorption across different impact velocities and energies. By strategically varying the concentration and distribution of silica components throughout the composite structure, impact energy can be progressively absorbed and dissipated. These engineered structures can be designed with specific impact absorption profiles for applications ranging from ballistic protection to crash-resistant components in transportation vehicles.

- Manufacturing processes for CFRP-silica composites with enhanced impact properties: Specialized manufacturing techniques have been developed to optimize the impact absorption rates of CFRP-silica composites. These include modified resin infusion processes, specialized curing cycles, and advanced molding techniques that ensure proper dispersion of silica components within the carbon fiber matrix. Novel processing methods allow for precise control of interfacial bonding between silica particles and polymer matrices, resulting in composites with tailored impact absorption characteristics while maintaining structural integrity and dimensional stability.

02 Silica aerogel incorporation for lightweight impact absorption

Silica aerogels, when incorporated into composite structures with CFRP, provide exceptional impact absorption while maintaining ultralight weight characteristics. The unique porous structure of silica aerogels allows for significant energy dissipation through controlled collapse of the nanoporous network during impact. These composites offer superior thermal insulation properties alongside impact protection, making them ideal for aerospace and automotive applications where weight reduction without compromising safety is critical.Expand Specific Solutions03 Gradient and layered CFRP-silica structures for optimized impact response

Engineered gradient and layered structures combining CFRP with silica-based materials demonstrate tailored impact absorption rates for specific applications. By strategically varying the concentration and distribution of silica components throughout the composite structure, impact energy can be directed and absorbed in a controlled manner. These gradient structures allow for customized mechanical responses, with outer layers typically designed for initial impact resistance while inner layers maximize energy dissipation, resulting in overall improved protection against various impact scenarios.Expand Specific Solutions04 Surface-modified silica particles for improved CFRP interface bonding

Surface modification of silica particles enhances their interfacial bonding with CFRP matrices, resulting in improved impact absorption rates. Chemical treatments and functionalization of silica surfaces create stronger mechanical interlocking and chemical bonding with polymer matrices. This improved interfacial adhesion prevents premature delamination during impact events, allowing the composite to absorb more energy before failure. The enhanced load transfer between components results in higher impact resistance and better overall mechanical performance of the composite system.Expand Specific Solutions05 Nano-engineered CFRP-silica composites with self-healing capabilities

Advanced nano-engineered CFRP-silica composites incorporate self-healing mechanisms that restore mechanical properties after impact damage. These innovative materials utilize encapsulated healing agents or reversible chemical bonds that activate upon impact damage. The self-healing capability extends the service life of the composite by preventing crack propagation and maintaining structural integrity after impact events. Additionally, these composites often feature damage sensing capabilities through electrical resistance changes or optical indicators, providing real-time monitoring of impact absorption and structural health.Expand Specific Solutions

Key Industry Players in Advanced Composites

The CFRP vs Silica-Based Composites impact absorption market is currently in a growth phase, with increasing applications across automotive, aerospace, and sporting goods sectors. The global market for advanced composites is estimated at $30-35 billion, growing at 8-10% annually. Leading players in CFRP technology include Toray Industries, Mitsubishi Heavy Industries, and Airbus Operations GmbH, who have established mature carbon fiber manufacturing capabilities. In silica-based composites, Japan Insulation, Heraeus Quarzglas, and SDC Technologies demonstrate advancing technical expertise. Academic institutions like Xi'an Jiaotong University and Beijing Institute of Technology are driving fundamental research in both materials. The technology maturity varies significantly, with CFRP being more commercially established while silica-based composites are gaining momentum in specialized high-temperature and optical applications.

Airbus Operations GmbH

Technical Solution: Airbus has developed advanced CFRP (Carbon Fiber Reinforced Polymer) structures for aircraft applications with proprietary impact absorption technology. Their approach integrates multi-layered CFRP composites with specialized resin systems that enhance energy dissipation during impact events. Airbus implements a unique fiber architecture design that includes strategically oriented carbon fibers to maximize impact resistance while maintaining structural integrity. Their latest generation composites incorporate nano-reinforcements within the matrix to improve interlaminar strength and prevent delamination during impact. Testing has demonstrated that these CFRP structures can absorb up to 30% more energy than traditional aluminum structures while weighing approximately 20% less. Airbus has also developed specialized manufacturing processes that ensure consistent quality and performance of their CFRP components across various impact scenarios, from bird strikes to runway debris.

Strengths: Superior weight-to-strength ratio compared to traditional materials; excellent fatigue resistance; ability to tailor fiber orientation for specific impact scenarios; reduced maintenance requirements. Weaknesses: Higher manufacturing costs; more complex repair procedures; potential for hidden damage that's difficult to detect without specialized equipment.

Toray Industries, Inc.

Technical Solution: Toray Industries has pioneered advanced CFRP systems with proprietary T1100G carbon fiber technology that delivers exceptional impact absorption capabilities. Their approach combines ultra-high tensile strength carbon fibers (exceeding 7 GPa) with specialized matrix systems engineered specifically for energy dissipation. Toray's CFRP composites utilize a multi-scale reinforcement strategy, incorporating both micro and nano-scale reinforcements to create hierarchical structures that effectively manage impact energy through controlled failure mechanisms. Their proprietary resin systems feature modified toughening agents that increase matrix ductility without compromising overall composite strength. Testing has shown these materials can absorb up to 40% more impact energy than conventional composites while maintaining structural integrity. Toray has also developed specialized surface treatments that enhance fiber-matrix adhesion, a critical factor in impact performance, resulting in improved delamination resistance during high-velocity impacts.

Strengths: Industry-leading fiber strength properties; excellent energy absorption capabilities; highly customizable for specific applications; established manufacturing processes for consistent quality. Weaknesses: Premium pricing compared to standard composites; requires specialized processing equipment; higher sensitivity to manufacturing parameters that can affect performance consistency.

Critical Technologies in Energy Dissipation Mechanisms

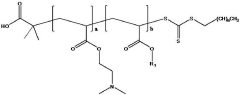

Carbon filament fiber-reinforced composite material

PatentActiveJP2012097170A

Innovation

- A composite material composed of long carbon fibers and an acid-modified block-type polypropylene resin, with specific molecular weight and infrared absorption characteristics, is used to enhance adhesion and toughness, incorporating inorganic compounds for reinforcement.

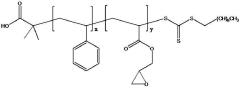

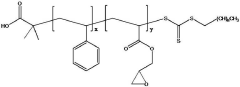

Polymer composite reinforced with carbon fibers and method of preparing the same

PatentActiveKR1020190025461A

Innovation

- The surface of carbon fibers is modified with an amphiphilic block copolymer, which enhances compatibility with both hydrophilic and hydrophobic polymers, eliminating the need for pretreatment processes and improving mechanical properties.

Safety Standards and Testing Protocols

Safety standards and testing protocols for impact absorption materials have evolved significantly to address the unique properties of both CFRP and silica-based composites. The automotive industry follows stringent regulations such as Federal Motor Vehicle Safety Standards (FMVSS) in the US and Euro NCAP in Europe, which mandate specific impact absorption requirements for vehicle components. These standards typically include frontal impact tests, side impact tests, and roof crush resistance evaluations.

For CFRP materials, specialized testing protocols have been developed to account for their anisotropic behavior and catastrophic failure modes. The ASTM D7136 standard governs drop-weight impact testing for composite materials, while ISO 6603 addresses puncture impact resistance. These tests measure energy absorption during impact events and evaluate the resulting damage patterns, which differ significantly between CFRP and traditional materials.

Silica-based composites are subject to additional testing requirements due to their unique microstructural characteristics. ASTM C1548 provides guidelines for dynamic impact testing of advanced ceramics, while ISO 17092 addresses impact resistance of glass-ceramic materials. These standards incorporate high-speed imaging and acoustic emission monitoring to capture the complex fracture mechanisms in silica-based systems.

The aerospace industry implements even more rigorous standards through FAA regulations and RTCA/DO-160 environmental testing specifications. These include bird strike tests, hail impact resistance, and lightning strike simulations—all critical for evaluating the performance of both material systems in extreme conditions. Military specifications such as MIL-STD-810 further extend these requirements to include ballistic impact testing.

Recent developments in testing methodologies have introduced digital image correlation (DIC) and computed tomography (CT) scanning as non-destructive evaluation techniques. These advanced methods allow for precise measurement of strain fields during impact and detailed assessment of internal damage, providing crucial data for comparing the performance of CFRP versus silica-based composites.

Certification bodies are increasingly adopting performance-based standards rather than prescriptive requirements, allowing manufacturers to innovate with new material combinations while maintaining safety margins. This shift has facilitated the integration of hybrid CFRP-silica systems that leverage the complementary properties of both materials to achieve superior impact absorption characteristics across multiple loading scenarios.

For CFRP materials, specialized testing protocols have been developed to account for their anisotropic behavior and catastrophic failure modes. The ASTM D7136 standard governs drop-weight impact testing for composite materials, while ISO 6603 addresses puncture impact resistance. These tests measure energy absorption during impact events and evaluate the resulting damage patterns, which differ significantly between CFRP and traditional materials.

Silica-based composites are subject to additional testing requirements due to their unique microstructural characteristics. ASTM C1548 provides guidelines for dynamic impact testing of advanced ceramics, while ISO 17092 addresses impact resistance of glass-ceramic materials. These standards incorporate high-speed imaging and acoustic emission monitoring to capture the complex fracture mechanisms in silica-based systems.

The aerospace industry implements even more rigorous standards through FAA regulations and RTCA/DO-160 environmental testing specifications. These include bird strike tests, hail impact resistance, and lightning strike simulations—all critical for evaluating the performance of both material systems in extreme conditions. Military specifications such as MIL-STD-810 further extend these requirements to include ballistic impact testing.

Recent developments in testing methodologies have introduced digital image correlation (DIC) and computed tomography (CT) scanning as non-destructive evaluation techniques. These advanced methods allow for precise measurement of strain fields during impact and detailed assessment of internal damage, providing crucial data for comparing the performance of CFRP versus silica-based composites.

Certification bodies are increasingly adopting performance-based standards rather than prescriptive requirements, allowing manufacturers to innovate with new material combinations while maintaining safety margins. This shift has facilitated the integration of hybrid CFRP-silica systems that leverage the complementary properties of both materials to achieve superior impact absorption characteristics across multiple loading scenarios.

Environmental Impact and Sustainability Considerations

The environmental impact of composite materials has become a critical consideration in material selection processes across industries, particularly in automotive, aerospace, and construction sectors. When comparing Carbon Fiber Reinforced Polymers (CFRP) and silica-based composites, their environmental footprints differ significantly throughout their lifecycle stages.

CFRP production is notably energy-intensive, requiring approximately 183-286 MJ/kg of energy, which is substantially higher than conventional materials. The carbon fiber manufacturing process generates considerable greenhouse gas emissions, estimated at 20-25 kg CO2 equivalent per kilogram of material produced. Additionally, the epoxy resins commonly used in CFRP contain potentially harmful chemicals that pose environmental risks during production and disposal phases.

In contrast, silica-based composites generally demonstrate lower production energy requirements, typically ranging from 65-120 MJ/kg. Their manufacturing processes emit fewer greenhouse gases, with estimates suggesting 40-60% lower carbon footprint compared to CFRP production. The natural abundance of silica as a raw material further enhances their sustainability profile.

Recyclability presents another significant differentiator between these materials. CFRP recycling remains technically challenging and economically questionable, with current methods recovering only 30-40% of the original material properties. The cross-linked thermoset matrices used in most CFRP applications create substantial end-of-life management challenges. Conversely, certain silica-based composites offer improved recyclability pathways, particularly those utilizing thermoplastic matrices or bio-based resins.

The impact absorption characteristics of these materials also influence their sustainability profile. CFRP's superior energy absorption capabilities potentially extend product lifespans in high-impact applications, reducing replacement frequency and associated environmental impacts. However, silica-based composites often demonstrate better degradation patterns when eventually disposed of in landfills.

Recent life cycle assessment (LCA) studies indicate that despite higher initial environmental impacts, CFRP may offer net environmental benefits in transportation applications through weight reduction and consequent fuel savings. A 10% weight reduction in automotive applications can yield approximately 6-8% improvement in fuel efficiency, potentially offsetting production impacts after 100,000-150,000 kilometers of vehicle operation.

Emerging technologies are addressing sustainability concerns for both material types. Bio-based carbon fiber precursors could reduce CFRP's environmental footprint by 30-45%, while advanced silica-based composites incorporating recycled content and natural reinforcements are demonstrating promising performance characteristics with reduced environmental impact.

CFRP production is notably energy-intensive, requiring approximately 183-286 MJ/kg of energy, which is substantially higher than conventional materials. The carbon fiber manufacturing process generates considerable greenhouse gas emissions, estimated at 20-25 kg CO2 equivalent per kilogram of material produced. Additionally, the epoxy resins commonly used in CFRP contain potentially harmful chemicals that pose environmental risks during production and disposal phases.

In contrast, silica-based composites generally demonstrate lower production energy requirements, typically ranging from 65-120 MJ/kg. Their manufacturing processes emit fewer greenhouse gases, with estimates suggesting 40-60% lower carbon footprint compared to CFRP production. The natural abundance of silica as a raw material further enhances their sustainability profile.

Recyclability presents another significant differentiator between these materials. CFRP recycling remains technically challenging and economically questionable, with current methods recovering only 30-40% of the original material properties. The cross-linked thermoset matrices used in most CFRP applications create substantial end-of-life management challenges. Conversely, certain silica-based composites offer improved recyclability pathways, particularly those utilizing thermoplastic matrices or bio-based resins.

The impact absorption characteristics of these materials also influence their sustainability profile. CFRP's superior energy absorption capabilities potentially extend product lifespans in high-impact applications, reducing replacement frequency and associated environmental impacts. However, silica-based composites often demonstrate better degradation patterns when eventually disposed of in landfills.

Recent life cycle assessment (LCA) studies indicate that despite higher initial environmental impacts, CFRP may offer net environmental benefits in transportation applications through weight reduction and consequent fuel savings. A 10% weight reduction in automotive applications can yield approximately 6-8% improvement in fuel efficiency, potentially offsetting production impacts after 100,000-150,000 kilometers of vehicle operation.

Emerging technologies are addressing sustainability concerns for both material types. Bio-based carbon fiber precursors could reduce CFRP's environmental footprint by 30-45%, while advanced silica-based composites incorporating recycled content and natural reinforcements are demonstrating promising performance characteristics with reduced environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!