Quantify CFRP Impact Energy Withstand in Aerospace

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CFRP Impact Resistance Background and Objectives

Carbon Fiber Reinforced Polymers (CFRP) have revolutionized aerospace engineering since their introduction in the 1960s, offering exceptional strength-to-weight ratios that significantly outperform traditional metallic materials. The evolution of CFRP technology has been driven by the aerospace industry's constant pursuit of lighter, stronger, and more fuel-efficient aircraft structures. From early applications in secondary structures to today's primary airframe components, CFRP usage has expanded dramatically, now constituting up to 50% of modern aircraft by weight.

The critical challenge facing aerospace CFRP applications is their vulnerability to impact damage, which can significantly compromise structural integrity without visible surface indications. This "barely visible impact damage" (BVID) phenomenon presents unique safety concerns, as internal delaminations and matrix cracking can propagate under cyclic loading conditions typical in aerospace operations.

Current industry standards require CFRP components to maintain structural integrity after impact events ranging from tool drops during maintenance to bird strikes during flight. However, quantification methodologies vary significantly across manufacturers and regulatory bodies, creating inconsistencies in safety margins and design approaches.

The primary objective of this technical research is to develop standardized methodologies for quantifying CFRP impact energy absorption capabilities specifically tailored to aerospace applications. This includes establishing reliable testing protocols that accurately simulate real-world impact scenarios while providing reproducible data for engineering analysis and certification purposes.

Secondary objectives include mapping the relationship between impact energy levels and resulting damage morphology across various CFRP layup configurations and resin systems commonly used in aerospace. This will enable more precise prediction models for damage tolerance assessment and structural health monitoring systems development.

Recent technological advancements in non-destructive testing (NDT) techniques, including thermography, ultrasonic scanning, and X-ray computed tomography, have enhanced our ability to characterize impact damage. However, correlating these observations with actual mechanical property degradation remains challenging and requires further investigation.

The aerospace industry's transition toward more electric aircraft and sustainable aviation fuels places additional demands on CFRP structures, as these technologies often require different load paths and thermal management considerations. Understanding impact resistance in these evolving design contexts represents a frontier in CFRP research that this technical investigation aims to address.

Ultimately, quantifying CFRP impact energy withstand capabilities will enable more efficient design methodologies, potentially reducing structural weight while maintaining or improving safety margins – a critical balance for next-generation aerospace applications.

The critical challenge facing aerospace CFRP applications is their vulnerability to impact damage, which can significantly compromise structural integrity without visible surface indications. This "barely visible impact damage" (BVID) phenomenon presents unique safety concerns, as internal delaminations and matrix cracking can propagate under cyclic loading conditions typical in aerospace operations.

Current industry standards require CFRP components to maintain structural integrity after impact events ranging from tool drops during maintenance to bird strikes during flight. However, quantification methodologies vary significantly across manufacturers and regulatory bodies, creating inconsistencies in safety margins and design approaches.

The primary objective of this technical research is to develop standardized methodologies for quantifying CFRP impact energy absorption capabilities specifically tailored to aerospace applications. This includes establishing reliable testing protocols that accurately simulate real-world impact scenarios while providing reproducible data for engineering analysis and certification purposes.

Secondary objectives include mapping the relationship between impact energy levels and resulting damage morphology across various CFRP layup configurations and resin systems commonly used in aerospace. This will enable more precise prediction models for damage tolerance assessment and structural health monitoring systems development.

Recent technological advancements in non-destructive testing (NDT) techniques, including thermography, ultrasonic scanning, and X-ray computed tomography, have enhanced our ability to characterize impact damage. However, correlating these observations with actual mechanical property degradation remains challenging and requires further investigation.

The aerospace industry's transition toward more electric aircraft and sustainable aviation fuels places additional demands on CFRP structures, as these technologies often require different load paths and thermal management considerations. Understanding impact resistance in these evolving design contexts represents a frontier in CFRP research that this technical investigation aims to address.

Ultimately, quantifying CFRP impact energy withstand capabilities will enable more efficient design methodologies, potentially reducing structural weight while maintaining or improving safety margins – a critical balance for next-generation aerospace applications.

Aerospace Market Requirements for CFRP Materials

The aerospace industry demands exceptional performance from Carbon Fiber Reinforced Polymers (CFRP) materials, particularly regarding impact energy withstand capabilities. Commercial aircraft manufacturers require CFRP components that can withstand bird strikes, hail, tool drops during maintenance, and runway debris impacts while maintaining structural integrity. Boeing and Airbus specifications typically mandate that primary structures withstand impact energies ranging from 25J for interior components to 50J for exterior surfaces without catastrophic failure.

Military aerospace applications impose even more stringent requirements, with fighter aircraft CFRP components needing to withstand ballistic impacts and battlefield debris. These specifications often require impact resistance up to 100J for certain structural components, with minimal damage propagation and retention of at least 70% of original mechanical properties post-impact.

Space applications present unique challenges, with CFRP materials needing to withstand micrometeoroid impacts at orbital velocities exceeding 7 km/s. Space vehicle manufacturers require materials that can contain damage without compromising pressurized compartments, typically specifying hypervelocity impact resistance with damage containment capabilities.

Regulatory frameworks further shape these requirements, with FAA regulations (14 CFR Part 25) and EASA certifications mandating specific impact performance standards. These include the ability to withstand specified impact events without compromising airworthiness and maintaining load-bearing capability after sustaining damage within prescribed limits.

Market analysis reveals growing demand for quantifiable impact resistance metrics, with aerospace OEMs increasingly specifying Compression After Impact (CAI) strength retention of at least 80% for primary structures. The helicopter segment specifically requires CFRP materials with enhanced impact resistance for rotor blades, typically specifying materials that maintain structural integrity after impacts up to 30J while minimizing delamination area.

Emerging market trends show increasing interest in self-sensing CFRP materials that can quantify and report impact events in real-time, with major airlines expressing willingness to pay premium prices for materials that reduce maintenance inspection requirements through built-in damage detection capabilities.

Cost considerations remain significant, with aerospace manufacturers seeking balance between impact performance and manufacturing expenses. Market research indicates acceptance of 15-20% cost premiums for CFRP materials demonstrating superior quantifiable impact resistance compared to conventional composites, provided they deliver measurable reductions in maintenance costs and extended service life.

Military aerospace applications impose even more stringent requirements, with fighter aircraft CFRP components needing to withstand ballistic impacts and battlefield debris. These specifications often require impact resistance up to 100J for certain structural components, with minimal damage propagation and retention of at least 70% of original mechanical properties post-impact.

Space applications present unique challenges, with CFRP materials needing to withstand micrometeoroid impacts at orbital velocities exceeding 7 km/s. Space vehicle manufacturers require materials that can contain damage without compromising pressurized compartments, typically specifying hypervelocity impact resistance with damage containment capabilities.

Regulatory frameworks further shape these requirements, with FAA regulations (14 CFR Part 25) and EASA certifications mandating specific impact performance standards. These include the ability to withstand specified impact events without compromising airworthiness and maintaining load-bearing capability after sustaining damage within prescribed limits.

Market analysis reveals growing demand for quantifiable impact resistance metrics, with aerospace OEMs increasingly specifying Compression After Impact (CAI) strength retention of at least 80% for primary structures. The helicopter segment specifically requires CFRP materials with enhanced impact resistance for rotor blades, typically specifying materials that maintain structural integrity after impacts up to 30J while minimizing delamination area.

Emerging market trends show increasing interest in self-sensing CFRP materials that can quantify and report impact events in real-time, with major airlines expressing willingness to pay premium prices for materials that reduce maintenance inspection requirements through built-in damage detection capabilities.

Cost considerations remain significant, with aerospace manufacturers seeking balance between impact performance and manufacturing expenses. Market research indicates acceptance of 15-20% cost premiums for CFRP materials demonstrating superior quantifiable impact resistance compared to conventional composites, provided they deliver measurable reductions in maintenance costs and extended service life.

Current Limitations in CFRP Impact Energy Quantification

Despite significant advancements in Carbon Fiber Reinforced Polymer (CFRP) technology, several critical limitations persist in accurately quantifying impact energy withstand capabilities for aerospace applications. Current testing methodologies often fail to replicate the complex multi-directional loading scenarios encountered during actual service conditions. Standard impact tests typically employ simplified loading conditions that inadequately represent the combined shear, compression, and tension forces experienced during in-flight impacts.

The heterogeneous and anisotropic nature of CFRP materials creates substantial challenges for developing universally applicable quantification models. Material response varies significantly based on fiber orientation, layup sequence, and manufacturing processes, resulting in inconsistent test results across different laboratories and testing protocols. This variability undermines the reliability of impact resistance data used in aerospace design calculations.

Existing non-destructive evaluation (NDE) techniques demonstrate limited sensitivity in detecting and characterizing barely visible impact damage (BVID), which represents a significant concern for aerospace structures. Conventional ultrasonic, thermography, and radiographic methods often fail to accurately quantify the extent of internal damage, particularly delaminations and matrix cracking that can substantially reduce residual strength without visible surface indications.

Scale effects present another significant limitation, as laboratory specimens rarely match the dimensions and boundary conditions of actual aerospace components. Test results from small coupons frequently fail to translate accurately to full-scale structures due to differences in stress distribution, damage propagation mechanisms, and structural response characteristics. This scaling discrepancy introduces uncertainty in predicting real-world performance based on laboratory data.

Current analytical and numerical models for impact damage prediction exhibit limitations in capturing the complex damage initiation and propagation mechanisms in CFRP structures. Most models rely on simplifying assumptions regarding material behavior, contact conditions, and failure criteria that reduce their predictive accuracy for diverse impact scenarios encountered in aerospace applications.

Environmental factors significantly influence impact energy absorption capabilities, yet standardized testing protocols inadequately account for these effects. Temperature extremes, moisture absorption, UV exposure, and cyclic loading can substantially alter CFRP mechanical properties and damage tolerance, but these variables are rarely incorporated comprehensively into quantification methodologies.

The aerospace industry also lacks standardized metrics for comparing impact resistance across different CFRP systems. Various manufacturers and research institutions employ different parameters—such as damage area, residual strength, or energy absorption—making direct comparisons challenging and hindering the development of industry-wide design allowables for impact-resistant structures.

The heterogeneous and anisotropic nature of CFRP materials creates substantial challenges for developing universally applicable quantification models. Material response varies significantly based on fiber orientation, layup sequence, and manufacturing processes, resulting in inconsistent test results across different laboratories and testing protocols. This variability undermines the reliability of impact resistance data used in aerospace design calculations.

Existing non-destructive evaluation (NDE) techniques demonstrate limited sensitivity in detecting and characterizing barely visible impact damage (BVID), which represents a significant concern for aerospace structures. Conventional ultrasonic, thermography, and radiographic methods often fail to accurately quantify the extent of internal damage, particularly delaminations and matrix cracking that can substantially reduce residual strength without visible surface indications.

Scale effects present another significant limitation, as laboratory specimens rarely match the dimensions and boundary conditions of actual aerospace components. Test results from small coupons frequently fail to translate accurately to full-scale structures due to differences in stress distribution, damage propagation mechanisms, and structural response characteristics. This scaling discrepancy introduces uncertainty in predicting real-world performance based on laboratory data.

Current analytical and numerical models for impact damage prediction exhibit limitations in capturing the complex damage initiation and propagation mechanisms in CFRP structures. Most models rely on simplifying assumptions regarding material behavior, contact conditions, and failure criteria that reduce their predictive accuracy for diverse impact scenarios encountered in aerospace applications.

Environmental factors significantly influence impact energy absorption capabilities, yet standardized testing protocols inadequately account for these effects. Temperature extremes, moisture absorption, UV exposure, and cyclic loading can substantially alter CFRP mechanical properties and damage tolerance, but these variables are rarely incorporated comprehensively into quantification methodologies.

The aerospace industry also lacks standardized metrics for comparing impact resistance across different CFRP systems. Various manufacturers and research institutions employ different parameters—such as damage area, residual strength, or energy absorption—making direct comparisons challenging and hindering the development of industry-wide design allowables for impact-resistant structures.

Existing Impact Energy Quantification Techniques

01 Matrix modifications for improved impact resistance

Various modifications to the polymer matrix in CFRP can significantly enhance impact energy absorption. These include incorporating toughening agents, using hybrid matrices, and optimizing resin formulations to increase ductility while maintaining strength. Such modifications allow the composite to absorb more energy during impact events by controlling crack propagation and increasing the material's ability to deform before failure.- Matrix modifications for improved impact resistance: Various modifications to the polymer matrix in CFRP can significantly enhance impact energy absorption. These include incorporating toughening agents, using hybrid resin systems, and optimizing the crosslinking density of the matrix. These modifications create mechanisms for energy dissipation during impact events, allowing the composite to withstand higher impact energies without catastrophic failure. The modified matrices can better distribute stress throughout the composite structure, preventing localized damage propagation.

- Fiber architecture and orientation optimization: The arrangement and orientation of carbon fibers within the polymer matrix significantly affects impact energy absorption capabilities. Multi-directional fiber layouts, 3D fiber architectures, and strategic fiber orientation can dramatically improve impact resistance compared to unidirectional configurations. These optimized architectures create multiple load paths for energy dissipation and prevent crack propagation through the material. By tailoring fiber orientation to anticipated impact directions, CFRP structures can be designed to maximize energy absorption while maintaining structural integrity.

- Hybrid composite systems with secondary reinforcements: Incorporating secondary reinforcement materials alongside carbon fibers creates hybrid composites with enhanced impact resistance. Materials such as aramid fibers, glass fibers, or natural fibers can be strategically integrated to improve energy absorption while maintaining the high strength-to-weight ratio of CFRP. These hybrid systems often exhibit synergistic effects where the combination of materials provides better impact performance than either material alone. The secondary reinforcements typically contribute ductility and toughness while the carbon fibers maintain structural rigidity.

- Nanoparticle and nanomaterial reinforcement: The addition of nanoparticles and nanomaterials to CFRP can significantly enhance impact energy absorption. Materials such as carbon nanotubes, graphene, nanoclays, and nanosilica create multiscale reinforcement systems that address impact resistance at multiple structural levels. These nanomaterials can strengthen the fiber-matrix interface, create energy-dissipating mechanisms at the nanoscale, and improve overall toughness without significantly increasing weight. The nanoscale reinforcements help to arrest crack propagation and distribute impact forces throughout the composite structure.

- Structural design and layering strategies: Advanced structural designs and layering strategies can optimize CFRP components for maximum impact energy absorption. Techniques include sandwich structures with energy-absorbing cores, gradient structures with varying fiber densities, and strategic placement of sacrificial layers designed to absorb impact energy. These design approaches often incorporate crush zones, load-distributing elements, and progressive failure mechanisms that allow the structure to absorb significant impact energy while protecting critical components. Optimized layering sequences can be tailored to specific impact scenarios and energy levels.

02 Structural design optimization for impact resistance

The structural design of CFRP components plays a crucial role in their ability to withstand impact energy. This includes optimizing layer configurations, fiber orientations, and creating specialized geometries that distribute impact forces. Designs incorporating energy-absorbing features such as crush zones, reinforced sections, and strategic thickness variations can significantly improve the overall impact resistance of CFRP structures.Expand Specific Solutions03 Hybrid composite systems for enhanced impact performance

Combining carbon fibers with other reinforcement materials creates hybrid composites with superior impact resistance. These systems often incorporate materials like aramid, glass fibers, or natural fibers alongside carbon fibers. The hybridization leverages the complementary properties of different reinforcements, allowing for customized impact energy absorption while maintaining the lightweight advantages of CFRP.Expand Specific Solutions04 Nano-reinforcement for improved impact energy absorption

Incorporating nanomaterials into CFRP significantly enhances impact energy absorption capabilities. Nanomaterials such as carbon nanotubes, graphene, and nanoparticles create multiscale reinforcement structures that improve interfacial bonding between fibers and matrix. This nano-reinforcement strategy helps dissipate impact energy more effectively throughout the composite structure, preventing catastrophic failure under impact loads.Expand Specific Solutions05 Surface treatments and interlaminar toughening

Surface treatments of carbon fibers and interlaminar toughening techniques significantly improve the impact resistance of CFRP. These methods enhance the fiber-matrix interface strength and create energy-dissipating mechanisms between composite layers. Techniques include fiber sizing optimization, incorporation of interleaving materials, and the use of z-pinning or stitching to improve through-thickness properties and prevent delamination during impact events.Expand Specific Solutions

Leading Aerospace Manufacturers and CFRP Suppliers

The aerospace CFRP impact energy withstand market is in a growth phase, with increasing demand driven by the need for lightweight, high-performance materials in aircraft structures. The global market size is expanding significantly as commercial and military aerospace sectors adopt carbon fiber reinforced polymers for their superior strength-to-weight ratio. Technologically, the field is maturing with leading players demonstrating varied levels of expertise. Toray Industries and Hexcel Corporation lead in advanced CFRP material development, while aerospace manufacturers like Airbus Operations and Boeing integrate these materials into aircraft structures. Academic institutions such as Nanjing University of Aeronautics & Astronautics and Harbin Institute of Technology contribute significant research on impact resistance quantification methodologies. Mitsubishi Heavy Industries and SGL Carbon are advancing manufacturing processes to enhance impact energy absorption capabilities in aerospace applications.

Toray Industries, Inc.

Technical Solution: Toray Industries has developed a sophisticated material-centric approach to quantifying CFRP impact energy withstand capabilities specifically tailored for aerospace applications. Their methodology begins at the constituent material level, where they engineer carbon fiber and resin systems with optimized interfacial properties to enhance impact resistance. Toray's proprietary T800H and T1100G aerospace-grade carbon fibers feature nano-level surface treatments that significantly improve fiber-matrix adhesion, resulting in superior impact energy dissipation. Their approach includes a comprehensive characterization protocol that combines instrumented drop-weight impact testing with acoustic emission analysis to correlate energy absorption with specific failure mechanisms. Toray has pioneered the development of toughened resin systems with nano-modified matrices that demonstrate up to 40% improvement in impact resistance compared to conventional aerospace epoxies. Their quantification methodology incorporates both quasi-static and dynamic testing across multiple temperature ranges (-55°C to 80°C) to establish performance envelopes relevant to aerospace operational conditions. Additionally, Toray employs micro-CT scanning and digital image correlation during impact events to visualize and quantify internal damage progression, providing crucial data for their predictive models.

Strengths: Toray's material-focused approach allows for fundamental improvements in impact resistance at the constituent level, providing advantages that cascade through all applications. Their extensive material database enables precise tailoring of CFRP systems for specific impact requirements. Weaknesses: Their methodology sometimes emphasizes material performance over structural design considerations, potentially overlooking system-level optimization opportunities. Implementation requires close partnership with Toray for material selection and processing parameters.

Airbus Operations GmbH

Technical Solution: Airbus Operations GmbH has developed a comprehensive impact energy quantification framework for CFRP aerospace structures that combines experimental testing with advanced numerical simulation. Their approach utilizes a multi-scale modeling methodology that captures damage mechanisms at micro, meso, and macro levels. At the core of their technology is the Virtual Testing Environment (VTE), which enables simulation of various impact scenarios on CFRP components before physical prototyping. Airbus has implemented specialized instrumented impact testing facilities capable of replicating real-world impact conditions, from tool drops to bird strikes, while precisely measuring energy absorption and damage propagation. Their methodology incorporates acoustic emission monitoring during impact events to correlate energy dissipation with specific damage mechanisms in the composite structure. Airbus has also pioneered the use of thermography and ultrasonic inspection techniques to quantify post-impact damage extent, which feeds back into their predictive models to continuously improve accuracy. This integrated approach has enabled Airbus to establish design allowables for CFRP structures that optimize weight while ensuring sufficient impact resistance for aerospace certification requirements.

Strengths: Airbus's methodology benefits from extensive validation across their aircraft programs, providing robust correlation between predicted and actual impact performance. Their multi-scale approach effectively captures the complex damage mechanisms in CFRP materials. Weaknesses: The computational intensity of their full simulation framework can limit rapid design iterations, and their methods require specialized testing equipment that may not be widely accessible to smaller aerospace suppliers.

Key Innovations in CFRP Impact Testing

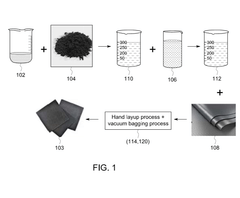

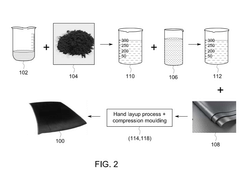

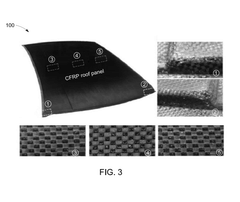

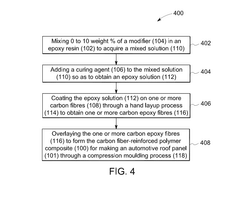

Material selection and manufacture of automotive roof panel using CFRP hybrid composite

PatentActiveIN202341035232A

Innovation

- A carbon fiber reinforced polymer composite for automotive roof panels using industrial waste carbon fiber powder, combined with epoxy resin and a curing agent, is fabricated through a hand layup and compression moulding process to reduce weight and enhance bending stiffness and impact strength.

Carbon fiber reinforced polymer assembly

PatentActiveUS9981692B2

Innovation

- An impact absorbing assembly comprising a first and second CFRP part joined by a metal part, where the metal part bends in response to impact loads, inhibiting CFRP cracking, and featuring a metal bending hinge or tubular member to enhance energy absorption, with the metal part made of ductile aluminum for superior performance.

Certification Standards for Aerospace CFRP Components

Certification standards for aerospace CFRP components are governed by stringent regulatory frameworks established by international aviation authorities. The Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) have developed comprehensive certification processes specifically for composite materials used in aircraft structures. These standards, including FAR Part 25 and CS-25, outline the requirements for demonstrating that CFRP components can withstand specified impact energies without catastrophic failure.

The certification process requires manufacturers to conduct extensive testing to quantify the impact energy absorption capabilities of CFRP structures. This includes both low-velocity impact testing (LVIT) and high-velocity impact testing (HVIT) to simulate various in-service conditions such as tool drops, bird strikes, and debris impacts. ASTM D7136 and D7137 standards provide standardized methodologies for measuring damage resistance and tolerance of composite laminates subjected to impact events.

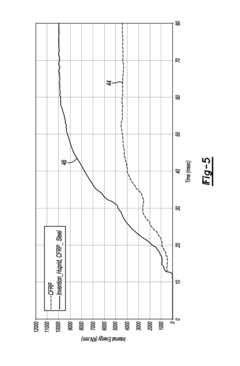

Boeing's 787 Dreamliner certification process established new precedents for CFRP certification, requiring demonstration of equivalent or superior damage tolerance compared to traditional aluminum structures. This involved over 5,000 impact tests across various energy levels to establish a comprehensive damage resistance profile. The certification data showed that CFRP components could maintain structural integrity after impacts up to 35 J/mm of thickness, significantly outperforming traditional materials.

Airworthiness directives further mandate regular inspection protocols for CFRP components, acknowledging that impact damage may not be visually apparent (barely visible impact damage or BVID). These standards require that structures maintain ultimate load capability with BVID present, and limit load capability with visible damage up to a specified threshold.

Recent updates to certification standards have incorporated probabilistic approaches to impact energy quantification, recognizing the statistical nature of impact events in service. This has led to the development of the Building Block Approach (BBA), which systematically escalates testing from coupon level to full-scale components to validate analytical models used for certification.

The standards also address environmental factors that can affect impact energy absorption, requiring testing under hot/wet conditions that typically represent worst-case scenarios for CFRP performance. Manufacturers must demonstrate that their components maintain required energy absorption capabilities after exposure to operational temperature ranges (-54°C to +71°C) and moisture saturation levels typical of service environments.

The certification process requires manufacturers to conduct extensive testing to quantify the impact energy absorption capabilities of CFRP structures. This includes both low-velocity impact testing (LVIT) and high-velocity impact testing (HVIT) to simulate various in-service conditions such as tool drops, bird strikes, and debris impacts. ASTM D7136 and D7137 standards provide standardized methodologies for measuring damage resistance and tolerance of composite laminates subjected to impact events.

Boeing's 787 Dreamliner certification process established new precedents for CFRP certification, requiring demonstration of equivalent or superior damage tolerance compared to traditional aluminum structures. This involved over 5,000 impact tests across various energy levels to establish a comprehensive damage resistance profile. The certification data showed that CFRP components could maintain structural integrity after impacts up to 35 J/mm of thickness, significantly outperforming traditional materials.

Airworthiness directives further mandate regular inspection protocols for CFRP components, acknowledging that impact damage may not be visually apparent (barely visible impact damage or BVID). These standards require that structures maintain ultimate load capability with BVID present, and limit load capability with visible damage up to a specified threshold.

Recent updates to certification standards have incorporated probabilistic approaches to impact energy quantification, recognizing the statistical nature of impact events in service. This has led to the development of the Building Block Approach (BBA), which systematically escalates testing from coupon level to full-scale components to validate analytical models used for certification.

The standards also address environmental factors that can affect impact energy absorption, requiring testing under hot/wet conditions that typically represent worst-case scenarios for CFRP performance. Manufacturers must demonstrate that their components maintain required energy absorption capabilities after exposure to operational temperature ranges (-54°C to +71°C) and moisture saturation levels typical of service environments.

Environmental Factors Affecting CFRP Impact Performance

The environmental conditions in which Carbon Fiber Reinforced Polymers (CFRP) operate significantly influence their impact resistance capabilities in aerospace applications. Temperature variations represent one of the most critical factors affecting CFRP performance. At extremely low temperatures, typically encountered at high altitudes (-55°C to -60°C), the matrix material in CFRP composites tends to become increasingly brittle, reducing the material's ability to absorb impact energy through deformation mechanisms. Conversely, at elevated temperatures (above 80°C), the polymer matrix may experience softening, potentially compromising the structural integrity and impact resistance of the composite.

Moisture absorption presents another substantial challenge for CFRP components in aerospace applications. When exposed to humid environments, CFRP materials can absorb moisture at rates of 1-2% by weight, leading to plasticization of the polymer matrix. This phenomenon reduces the glass transition temperature and interfacial bond strength between fibers and matrix, ultimately decreasing impact resistance by up to 30% in severe cases. The cyclic absorption and desorption of moisture during service can further exacerbate degradation through the creation of microcracks.

Ultraviolet (UV) radiation exposure, particularly relevant for external aerospace components, causes photodegradation of the polymer matrix through chain scission and oxidation reactions. Research indicates that prolonged UV exposure can reduce the impact energy absorption capacity of CFRP by 15-25% after extended service periods, with surface layers being most severely affected. This degradation manifests as yellowing, embrittlement, and microcracking of the matrix material.

Thermal cycling, a common condition in aerospace applications where components experience rapid temperature fluctuations during ascent and descent phases, induces internal stresses due to the mismatch in thermal expansion coefficients between fibers and matrix. Studies have documented that after 500-1000 thermal cycles, CFRP composites may exhibit a reduction in impact resistance of approximately 10-20% due to the development of microcracks and weakening of the fiber-matrix interface.

Chemical exposure represents an additional environmental concern, particularly from aviation fluids such as jet fuel, hydraulic fluids, and de-icing agents. These substances can penetrate the matrix material, causing swelling, plasticization, and in some cases, chemical degradation of the polymer chains. The resultant weakening of the matrix can reduce impact energy absorption capacity by 5-40%, depending on the specific chemical agent and exposure duration.

Erosion from airborne particles and rain impingement progressively damages the protective surface layers of CFRP components, exposing underlying material to environmental attack and creating stress concentration points that reduce impact resistance. Wind tunnel tests simulating operational conditions have demonstrated that erosion can reduce the impact performance of CFRP by up to 15% after equivalent service periods of 5-7 years.

Moisture absorption presents another substantial challenge for CFRP components in aerospace applications. When exposed to humid environments, CFRP materials can absorb moisture at rates of 1-2% by weight, leading to plasticization of the polymer matrix. This phenomenon reduces the glass transition temperature and interfacial bond strength between fibers and matrix, ultimately decreasing impact resistance by up to 30% in severe cases. The cyclic absorption and desorption of moisture during service can further exacerbate degradation through the creation of microcracks.

Ultraviolet (UV) radiation exposure, particularly relevant for external aerospace components, causes photodegradation of the polymer matrix through chain scission and oxidation reactions. Research indicates that prolonged UV exposure can reduce the impact energy absorption capacity of CFRP by 15-25% after extended service periods, with surface layers being most severely affected. This degradation manifests as yellowing, embrittlement, and microcracking of the matrix material.

Thermal cycling, a common condition in aerospace applications where components experience rapid temperature fluctuations during ascent and descent phases, induces internal stresses due to the mismatch in thermal expansion coefficients between fibers and matrix. Studies have documented that after 500-1000 thermal cycles, CFRP composites may exhibit a reduction in impact resistance of approximately 10-20% due to the development of microcracks and weakening of the fiber-matrix interface.

Chemical exposure represents an additional environmental concern, particularly from aviation fluids such as jet fuel, hydraulic fluids, and de-icing agents. These substances can penetrate the matrix material, causing swelling, plasticization, and in some cases, chemical degradation of the polymer chains. The resultant weakening of the matrix can reduce impact energy absorption capacity by 5-40%, depending on the specific chemical agent and exposure duration.

Erosion from airborne particles and rain impingement progressively damages the protective surface layers of CFRP components, exposing underlying material to environmental attack and creating stress concentration points that reduce impact resistance. Wind tunnel tests simulating operational conditions have demonstrated that erosion can reduce the impact performance of CFRP by up to 15% after equivalent service periods of 5-7 years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!