How to Reduce Modal Damping in CFRP Panels

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CFRP Modal Damping Background and Objectives

Carbon Fiber Reinforced Polymer (CFRP) composites have emerged as revolutionary materials in aerospace, automotive, and construction industries due to their exceptional strength-to-weight ratio, corrosion resistance, and design flexibility. Since their commercial introduction in the 1960s, CFRP applications have expanded dramatically, particularly in structures requiring high performance under dynamic loading conditions. The evolution of CFRP technology has been marked by continuous improvements in manufacturing processes, fiber architectures, and matrix formulations.

Modal damping in CFRP panels represents a critical area of research that has gained significant attention over the past two decades. This property refers to the material's ability to dissipate vibrational energy, which directly impacts structural performance, noise characteristics, and fatigue life. Historically, CFRP structures have exhibited relatively high damping compared to metallic counterparts, which has been advantageous for many applications requiring vibration suppression.

However, certain advanced applications—particularly in precision instruments, aerospace structures, and high-frequency response systems—require minimal modal damping to maintain dimensional stability and precise dynamic response. The inherent viscoelastic behavior of polymer matrices in CFRP contributes significantly to energy dissipation, creating a fundamental challenge when low damping is desired while maintaining the material's other beneficial properties.

Recent technological trends indicate a growing demand for CFRP panels with tailored damping characteristics, specifically the ability to reduce damping in targeted frequency ranges while maintaining structural integrity. This capability would enable more precise control of structural dynamics in applications such as optical benches, satellite structures, and scientific instruments where dimensional stability under dynamic loading is paramount.

The primary technical objective of this research is to develop methodologies and material systems that can effectively reduce modal damping in CFRP panels without compromising their mechanical properties. Specifically, we aim to achieve a 30-50% reduction in damping ratio across relevant frequency ranges (typically 10-1000 Hz) while maintaining or improving stiffness-to-weight ratios.

Secondary objectives include developing predictive models for damping behavior in modified CFRP systems, establishing design guidelines for low-damping composite structures, and creating testing protocols that accurately characterize damping properties across various environmental conditions. The ultimate goal is to enable a new generation of CFRP structures with precisely engineered dynamic response characteristics, expanding the application envelope of these advanced materials into domains previously dominated by traditional materials like ceramics and metals.

Modal damping in CFRP panels represents a critical area of research that has gained significant attention over the past two decades. This property refers to the material's ability to dissipate vibrational energy, which directly impacts structural performance, noise characteristics, and fatigue life. Historically, CFRP structures have exhibited relatively high damping compared to metallic counterparts, which has been advantageous for many applications requiring vibration suppression.

However, certain advanced applications—particularly in precision instruments, aerospace structures, and high-frequency response systems—require minimal modal damping to maintain dimensional stability and precise dynamic response. The inherent viscoelastic behavior of polymer matrices in CFRP contributes significantly to energy dissipation, creating a fundamental challenge when low damping is desired while maintaining the material's other beneficial properties.

Recent technological trends indicate a growing demand for CFRP panels with tailored damping characteristics, specifically the ability to reduce damping in targeted frequency ranges while maintaining structural integrity. This capability would enable more precise control of structural dynamics in applications such as optical benches, satellite structures, and scientific instruments where dimensional stability under dynamic loading is paramount.

The primary technical objective of this research is to develop methodologies and material systems that can effectively reduce modal damping in CFRP panels without compromising their mechanical properties. Specifically, we aim to achieve a 30-50% reduction in damping ratio across relevant frequency ranges (typically 10-1000 Hz) while maintaining or improving stiffness-to-weight ratios.

Secondary objectives include developing predictive models for damping behavior in modified CFRP systems, establishing design guidelines for low-damping composite structures, and creating testing protocols that accurately characterize damping properties across various environmental conditions. The ultimate goal is to enable a new generation of CFRP structures with precisely engineered dynamic response characteristics, expanding the application envelope of these advanced materials into domains previously dominated by traditional materials like ceramics and metals.

Market Analysis for Low-Damping CFRP Applications

The global market for low-damping Carbon Fiber Reinforced Polymer (CFRP) panels is experiencing significant growth, driven primarily by aerospace, automotive, and precision engineering sectors where vibration control is critical. Current market estimates value the specialized low-damping CFRP segment at approximately $2.3 billion, with projections indicating a compound annual growth rate of 7.8% through 2028.

Aerospace remains the dominant application sector, accounting for nearly 42% of the market demand. This is attributed to the industry's stringent requirements for materials that can maintain structural integrity while allowing controlled vibration responses in wings, fuselages, and satellite components. The space industry subset shows particularly strong growth potential, with increasing demand for ultra-lightweight structures with precisely engineered damping properties for orbital applications.

The automotive sector represents the fastest-growing segment, particularly in high-performance and electric vehicle applications. Formula 1 and other motorsport categories have pioneered the use of low-damping CFRP components to optimize vehicle dynamics and energy transfer. This technology is now cascading into premium production vehicles, where manufacturers seek to balance NVH (Noise, Vibration, Harshness) characteristics with structural performance.

Scientific instrumentation and precision engineering applications constitute a smaller but premium market segment. These applications include optical benches, measurement platforms, and testing equipment where unwanted damping can interfere with measurement accuracy or system performance. This segment values customized solutions and typically generates higher margins despite lower volume.

Regional analysis shows North America and Europe leading in market adoption, collectively representing 68% of global demand. However, Asia-Pacific markets, particularly Japan, South Korea, and China, are showing accelerated growth rates as their aerospace and high-performance automotive sectors expand.

Customer requirements analysis reveals a clear segmentation between applications requiring ultra-low damping (primarily aerospace and scientific) versus those seeking optimized or tunable damping characteristics (automotive and industrial). This bifurcation is creating distinct product development pathways and specialized market niches.

Market barriers include high material costs, complex manufacturing processes, and limited standardization. The premium for low-damping CFRP materials averages 30-45% above standard CFRP formulations, restricting widespread adoption to high-value applications where performance benefits justify the cost premium.

Future market expansion will likely be driven by innovations in nano-reinforcement technologies, automated manufacturing processes, and computational design tools that enable more precise damping characteristic engineering. As production scales increase and manufacturing technologies mature, gradual price reductions are expected to open additional market segments in consumer electronics, sporting goods, and medical devices.

Aerospace remains the dominant application sector, accounting for nearly 42% of the market demand. This is attributed to the industry's stringent requirements for materials that can maintain structural integrity while allowing controlled vibration responses in wings, fuselages, and satellite components. The space industry subset shows particularly strong growth potential, with increasing demand for ultra-lightweight structures with precisely engineered damping properties for orbital applications.

The automotive sector represents the fastest-growing segment, particularly in high-performance and electric vehicle applications. Formula 1 and other motorsport categories have pioneered the use of low-damping CFRP components to optimize vehicle dynamics and energy transfer. This technology is now cascading into premium production vehicles, where manufacturers seek to balance NVH (Noise, Vibration, Harshness) characteristics with structural performance.

Scientific instrumentation and precision engineering applications constitute a smaller but premium market segment. These applications include optical benches, measurement platforms, and testing equipment where unwanted damping can interfere with measurement accuracy or system performance. This segment values customized solutions and typically generates higher margins despite lower volume.

Regional analysis shows North America and Europe leading in market adoption, collectively representing 68% of global demand. However, Asia-Pacific markets, particularly Japan, South Korea, and China, are showing accelerated growth rates as their aerospace and high-performance automotive sectors expand.

Customer requirements analysis reveals a clear segmentation between applications requiring ultra-low damping (primarily aerospace and scientific) versus those seeking optimized or tunable damping characteristics (automotive and industrial). This bifurcation is creating distinct product development pathways and specialized market niches.

Market barriers include high material costs, complex manufacturing processes, and limited standardization. The premium for low-damping CFRP materials averages 30-45% above standard CFRP formulations, restricting widespread adoption to high-value applications where performance benefits justify the cost premium.

Future market expansion will likely be driven by innovations in nano-reinforcement technologies, automated manufacturing processes, and computational design tools that enable more precise damping characteristic engineering. As production scales increase and manufacturing technologies mature, gradual price reductions are expected to open additional market segments in consumer electronics, sporting goods, and medical devices.

Current Challenges in CFRP Modal Damping Reduction

Carbon Fiber Reinforced Polymer (CFRP) panels exhibit inherently high damping characteristics, which can be problematic in applications requiring precise vibration control or energy harvesting. The primary challenge in reducing modal damping in CFRP panels stems from the viscoelastic nature of the polymer matrix, which dissipates vibrational energy through internal friction mechanisms.

Material composition presents a significant hurdle, as the interface between carbon fibers and the polymer matrix creates numerous energy dissipation pathways. The heterogeneous microstructure of CFRP leads to complex damping behavior that varies with frequency, temperature, and strain amplitude, making systematic reduction approaches difficult to implement.

Manufacturing inconsistencies further complicate damping reduction efforts. Variations in fiber orientation, void content, and cure cycles can significantly alter the damping properties of seemingly identical panels. The lack of standardized manufacturing protocols specifically optimized for low damping applications creates reproducibility issues in research and industrial settings.

Temperature dependency poses another substantial challenge. CFRP damping characteristics change dramatically across operational temperature ranges, with most polymer matrices exhibiting increased viscoelastic behavior at elevated temperatures. This temperature sensitivity makes it difficult to maintain consistent low damping performance across varying environmental conditions.

Structural design constraints often conflict with damping reduction goals. Many applications require specific stiffness-to-weight ratios or strength parameters that limit the design space available for damping optimization. Engineers frequently face trade-offs between mechanical performance and vibration characteristics.

Current analytical models inadequately predict damping behavior in complex CFRP structures. While finite element methods can reasonably estimate natural frequencies, they struggle to accurately model damping mechanisms, particularly in multi-layered or complex geometries. This modeling gap hinders efficient design iteration and optimization.

Non-destructive evaluation techniques for damping properties remain limited. Unlike stiffness or strength parameters, damping characteristics are challenging to measure precisely without specialized equipment, making quality control and verification processes cumbersome and expensive.

The interdisciplinary nature of the problem requires expertise across materials science, structural dynamics, and manufacturing engineering. Few research teams possess the comprehensive knowledge needed to address all aspects of CFRP damping reduction simultaneously, leading to fragmented approaches that solve only portions of the overall challenge.

Material composition presents a significant hurdle, as the interface between carbon fibers and the polymer matrix creates numerous energy dissipation pathways. The heterogeneous microstructure of CFRP leads to complex damping behavior that varies with frequency, temperature, and strain amplitude, making systematic reduction approaches difficult to implement.

Manufacturing inconsistencies further complicate damping reduction efforts. Variations in fiber orientation, void content, and cure cycles can significantly alter the damping properties of seemingly identical panels. The lack of standardized manufacturing protocols specifically optimized for low damping applications creates reproducibility issues in research and industrial settings.

Temperature dependency poses another substantial challenge. CFRP damping characteristics change dramatically across operational temperature ranges, with most polymer matrices exhibiting increased viscoelastic behavior at elevated temperatures. This temperature sensitivity makes it difficult to maintain consistent low damping performance across varying environmental conditions.

Structural design constraints often conflict with damping reduction goals. Many applications require specific stiffness-to-weight ratios or strength parameters that limit the design space available for damping optimization. Engineers frequently face trade-offs between mechanical performance and vibration characteristics.

Current analytical models inadequately predict damping behavior in complex CFRP structures. While finite element methods can reasonably estimate natural frequencies, they struggle to accurately model damping mechanisms, particularly in multi-layered or complex geometries. This modeling gap hinders efficient design iteration and optimization.

Non-destructive evaluation techniques for damping properties remain limited. Unlike stiffness or strength parameters, damping characteristics are challenging to measure precisely without specialized equipment, making quality control and verification processes cumbersome and expensive.

The interdisciplinary nature of the problem requires expertise across materials science, structural dynamics, and manufacturing engineering. Few research teams possess the comprehensive knowledge needed to address all aspects of CFRP damping reduction simultaneously, leading to fragmented approaches that solve only portions of the overall challenge.

Existing Methods for Modal Damping Reduction

01 Viscoelastic materials for CFRP panel damping

Viscoelastic materials can be incorporated into CFRP panels to enhance modal damping properties. These materials convert vibrational energy into heat through molecular friction, effectively reducing resonance and vibration amplitude. The viscoelastic layer can be applied as a core material in sandwich structures or as a surface treatment, providing significant improvement in damping ratio while maintaining the structural integrity and lightweight properties of the composite panels.- Viscoelastic materials for CFRP panel damping: Viscoelastic materials can be incorporated into CFRP panels to enhance modal damping properties. These materials convert vibrational energy into heat through molecular friction, effectively reducing resonance and improving structural stability. The viscoelastic layer can be applied as a core material in sandwich structures or as a surface treatment, providing significant damping without substantially increasing weight or compromising the mechanical advantages of CFRP.

- Constrained layer damping systems for composite panels: Constrained layer damping (CLD) systems involve sandwiching a viscoelastic material between the CFRP panel and a constraining layer. When the structure vibrates, the viscoelastic material experiences shear deformation, dissipating energy and increasing modal damping. This technique is particularly effective for thin CFRP panels where flexural vibrations are predominant. The constraining layer can be made of various materials including metals or additional composite layers, optimized for specific frequency ranges.

- Nano-enhanced damping treatments for CFRP structures: Incorporating nanomaterials such as carbon nanotubes, graphene, or nanoparticles into the matrix of CFRP panels can significantly improve modal damping characteristics. These nanomaterials create additional energy dissipation mechanisms at the microscale through interfacial friction and viscoelastic effects. The nano-enhanced composites demonstrate improved damping across a wider frequency range while maintaining or even enhancing the mechanical properties of the base CFRP material.

- Hybrid fiber reinforcement for improved damping: Combining carbon fibers with other types of fibers (such as aramid, glass, or natural fibers) in CFRP panels creates hybrid composites with enhanced damping properties. The different mechanical properties of various fiber types lead to micro-scale relative movements under vibration, resulting in energy dissipation through friction and viscoelastic effects. This approach allows for tailoring the damping characteristics while maintaining high specific strength and stiffness required for structural applications.

- Active and semi-active damping systems for CFRP panels: Advanced damping solutions for CFRP panels incorporate active or semi-active systems using piezoelectric materials, magnetorheological fluids, or shape memory alloys. These systems can adapt to changing vibration conditions by altering their stiffness or damping properties in response to electrical, magnetic, or thermal stimuli. Sensors detect panel vibrations and control systems adjust the damping response accordingly, providing optimal modal damping across various operating conditions and frequencies.

02 Constrained layer damping systems for CFRP structures

Constrained layer damping (CLD) systems consist of a viscoelastic material layer sandwiched between the CFRP panel and a constraining layer. When the structure vibrates, the viscoelastic material experiences shear deformation, dissipating energy and increasing modal damping. This approach is particularly effective for thin CFRP panels where flexural vibrations are predominant. The constraining layer can be made of various materials including metals or other composite materials to optimize the damping performance across different frequency ranges.Expand Specific Solutions03 Nano-enhanced damping treatments for CFRP panels

Incorporating nanomaterials such as carbon nanotubes, graphene, or nanoparticles into the matrix of CFRP panels can significantly improve modal damping characteristics. These nanomaterials create additional energy dissipation mechanisms at the microscale through interfacial friction and viscoelastic effects. The nano-enhanced composites exhibit improved damping performance while maintaining or even enhancing the mechanical properties of the panels. This approach allows for damping improvement without substantial weight increase or structural modification.Expand Specific Solutions04 Hybrid fiber reinforcement for improved damping

Combining carbon fibers with other types of fibers (such as glass, aramid, or natural fibers) in CFRP panels creates hybrid composites with enhanced damping properties. The different elastic properties of various fiber types lead to stress concentrations and micro-movements at the interfaces during vibration, resulting in energy dissipation through friction. This hybrid approach allows engineers to tailor the damping characteristics while maintaining the high strength-to-weight ratio that makes CFRP attractive for structural applications.Expand Specific Solutions05 Active and semi-active damping systems for CFRP panels

Active and semi-active damping systems incorporate sensors, controllers, and actuators to dynamically counteract vibrations in CFRP panels. These systems can detect vibrations in real-time and apply opposing forces to dampen the modal response. Piezoelectric materials, shape memory alloys, or magnetorheological fluids can be integrated into CFRP structures to provide controllable damping capabilities. This approach is particularly valuable for applications where damping requirements vary with operating conditions or where traditional passive damping methods are insufficient.Expand Specific Solutions

Leading Organizations in CFRP Damping Research

The modal damping reduction in CFRP panels market is in an emerging growth phase, with increasing applications across aerospace and automotive industries. The market size is expanding as lightweight composite materials gain prominence in high-performance applications. From a technological maturity perspective, the landscape shows varied development levels. Aerospace leaders like Airbus Operations GmbH and Boeing Co. demonstrate advanced capabilities in CFRP vibration control, while materials specialists such as SGL Carbon SE, Toray Industries, and Mitsubishi Electric Corp. focus on innovative composite formulations. Automotive manufacturers including Honda, Nissan, and Mazda are increasingly adopting these technologies for weight reduction and performance enhancement. The competitive environment features cross-industry collaboration between materials science companies and end-users to overcome the inherent damping challenges in carbon fiber reinforced polymer structures.

Airbus Operations GmbH

Technical Solution: Airbus has pioneered the development of integrated damping solutions for CFRP panels through their Advanced Composite Structures program. Their approach focuses on nano-modified resin systems that incorporate carbon nanotubes (CNTs) and graphene to enhance the inherent damping properties of the matrix material without compromising mechanical strength. Research shows their nano-enhanced CFRP panels exhibit 25-30% higher loss factors compared to conventional composites. Additionally, Airbus has developed a proprietary interleaving technology called DAMP+ that introduces specialized non-woven thermoplastic veils between CFRP plies, creating microscopic friction interfaces that convert vibrational energy to heat. This technique has been successfully implemented in A350 XWB components, reducing vibration amplitudes by up to 35% while adding less than 5% to the overall weight.

Strengths: Solutions are fully integrated into the composite structure without additional layers, maintaining aerodynamic profiles and structural efficiency. Their approaches are compatible with existing manufacturing processes. Weaknesses: Nano-modified resins require precise dispersion techniques and quality control measures that increase production complexity and cost.

Toray Industries, Inc.

Technical Solution: Toray has developed innovative fiber-matrix interface engineering techniques to reduce modal damping in CFRP panels. Their approach focuses on optimizing the molecular structure of sizing agents applied to carbon fibers to create controlled interfacial bonding with the matrix resin. This "tunable interface" technology allows for precise control of energy dissipation mechanisms at the microscale. Toray's research demonstrates that their engineered interfaces can increase the loss factor by up to 45% compared to conventional CFRP systems. Additionally, they've pioneered hybrid fabric architectures incorporating viscoelastic fibers alongside carbon fibers in specific orientations to target damping in preferred directions. Their TORELINA® PPS-based composites feature specially formulated thermoplastic matrices with inherently higher damping characteristics while maintaining high temperature performance and chemical resistance. These materials have shown particular effectiveness in reducing vibrations in the 500-2000 Hz range, which is critical for many industrial applications.

Strengths: Solutions are integrated at the material level, requiring no additional manufacturing steps or weight penalties. Their approach offers excellent durability and environmental resistance. Weaknesses: Requires specialized fiber treatments and precise process control during composite manufacturing, potentially limiting application in facilities without advanced capabilities.

Key Technical Innovations in CFRP Damping Control

Carbon fiber-reinforced plastic molding

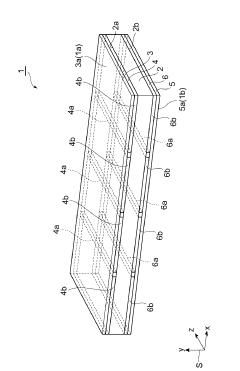

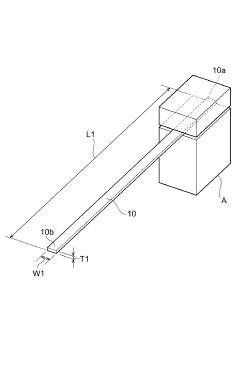

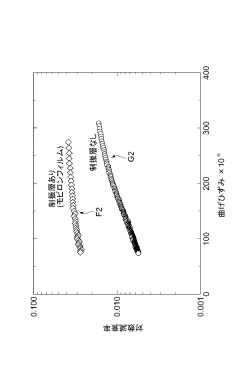

PatentInactiveJP2012162062A

Innovation

- A carbon fiber reinforced plastic molded article with a first and second carbon fiber reinforced plastic layer, and a first and second damping layer with voids intersecting the orientation direction of the carbon fibers, arranged to relieve stress and improve vibration damping.

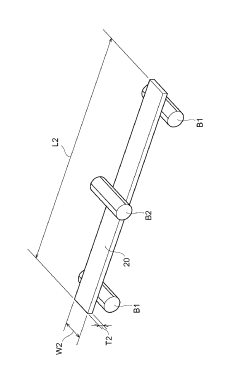

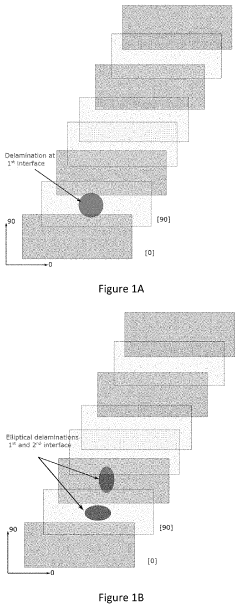

Bio-inspired composite laminate design with high out-of-plane strength and ductility

PatentActiveUS11207867B1

Innovation

- Bio-inspired CFRP composite laminates are designed with intentionally introduced delaminations at specific positions and sizes during the lamination process to control crack propagation and enhance ductility, featuring a pseudo-ductile response with increased failure strain and energy absorption.

Material Science Advancements for CFRP Optimization

Recent advancements in material science have opened new pathways for optimizing Carbon Fiber Reinforced Polymer (CFRP) panels to address modal damping challenges. The evolution of nano-enhanced matrices represents a significant breakthrough, with researchers incorporating carbon nanotubes (CNTs) and graphene into traditional epoxy systems. These nanomaterials create hierarchical reinforcement structures that effectively dissipate vibrational energy while maintaining the high stiffness-to-weight ratio that makes CFRPs attractive for aerospace and automotive applications.

Viscoelastic interlayers have emerged as another promising approach, where strategically placed viscoelastic materials between carbon fiber plies create constrained layer damping effects. When subjected to vibration, these layers experience shear deformation, converting mechanical energy into heat through molecular friction. Advanced manufacturing techniques now allow for precise placement of these interlayers at locations of maximum modal strain energy, optimizing damping without significant weight penalties.

Hybrid fiber architectures represent a paradigm shift in CFRP design philosophy. By integrating different fiber types (such as glass, aramid, or natural fibers) with traditional carbon fibers, engineers can tailor the damping characteristics of composite panels. These hybrid systems leverage the inherent damping properties of alternative fibers while maintaining much of the structural performance of pure carbon fiber systems.

Biomimetic design principles have inspired novel fiber arrangements that mimic natural structures with excellent vibration damping properties. For instance, hierarchical structures inspired by bamboo or palm trees incorporate varying fiber orientations and densities throughout the laminate thickness, creating mechanical impedance mismatches that trap and dissipate vibrational energy.

Functional additives represent another frontier in CFRP optimization. Phase-change materials, shape memory polymers, and magnetorheological particles embedded within the matrix can provide adaptive damping responses to different vibration frequencies and amplitudes. These smart materials can be engineered to respond dynamically to changing environmental conditions or loading scenarios.

Manufacturing innovations such as automated fiber placement with variable stiffness paths allow for spatially optimized fiber orientations that can be precisely engineered to target specific vibration modes. This approach enables designers to create panels with locally tailored properties that address modal damping challenges while maintaining overall structural integrity and performance requirements.

Viscoelastic interlayers have emerged as another promising approach, where strategically placed viscoelastic materials between carbon fiber plies create constrained layer damping effects. When subjected to vibration, these layers experience shear deformation, converting mechanical energy into heat through molecular friction. Advanced manufacturing techniques now allow for precise placement of these interlayers at locations of maximum modal strain energy, optimizing damping without significant weight penalties.

Hybrid fiber architectures represent a paradigm shift in CFRP design philosophy. By integrating different fiber types (such as glass, aramid, or natural fibers) with traditional carbon fibers, engineers can tailor the damping characteristics of composite panels. These hybrid systems leverage the inherent damping properties of alternative fibers while maintaining much of the structural performance of pure carbon fiber systems.

Biomimetic design principles have inspired novel fiber arrangements that mimic natural structures with excellent vibration damping properties. For instance, hierarchical structures inspired by bamboo or palm trees incorporate varying fiber orientations and densities throughout the laminate thickness, creating mechanical impedance mismatches that trap and dissipate vibrational energy.

Functional additives represent another frontier in CFRP optimization. Phase-change materials, shape memory polymers, and magnetorheological particles embedded within the matrix can provide adaptive damping responses to different vibration frequencies and amplitudes. These smart materials can be engineered to respond dynamically to changing environmental conditions or loading scenarios.

Manufacturing innovations such as automated fiber placement with variable stiffness paths allow for spatially optimized fiber orientations that can be precisely engineered to target specific vibration modes. This approach enables designers to create panels with locally tailored properties that address modal damping challenges while maintaining overall structural integrity and performance requirements.

Vibration Testing Standards for CFRP Panels

Vibration testing standards for CFRP (Carbon Fiber Reinforced Polymer) panels are essential for ensuring structural integrity and performance in various applications. These standards provide systematic methodologies for evaluating the dynamic behavior of composite structures, particularly focusing on modal damping characteristics which are critical for reducing unwanted vibrations.

The primary international standards governing vibration testing of composite materials include ISO 7626, which outlines methods for determining frequency response functions, and ASTM E756, which specifically addresses measuring vibration-damping properties. For aerospace applications, standards such as RTCA DO-160 and MIL-STD-810 provide comprehensive testing protocols that address environmental conditions alongside vibration performance.

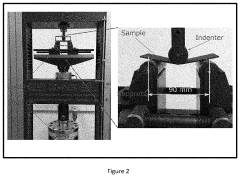

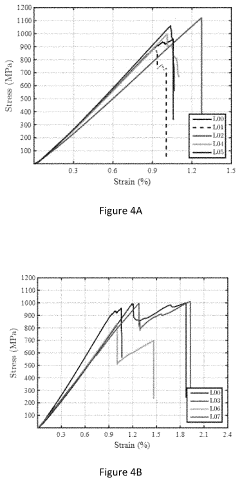

Testing methodologies typically involve modal analysis techniques, including impact hammer testing and shaker excitation methods. These approaches allow for precise measurement of natural frequencies, mode shapes, and damping ratios in CFRP panels. The standards prescribe specific sensor placement strategies, excitation methods, and data acquisition parameters to ensure reproducible results across different testing facilities.

For CFRP panels specifically, standards emphasize the importance of boundary condition control during testing. Fixed-free, free-free, and clamped configurations are commonly specified, with detailed requirements for fixture design to minimize unwanted constraints that could affect modal parameters. Temperature and humidity control are also mandated, as composite materials exhibit significant property variations with environmental conditions.

Signal processing requirements within these standards have evolved significantly, now incorporating advanced techniques such as the Half-Power Bandwidth Method, Logarithmic Decrement Method, and Complex Mode Indicator Function (CMIF) for accurate damping estimation. These methods help address the challenges of measuring the typically low damping values in CFRP structures.

Recent updates to testing standards have begun to address the anisotropic nature of CFRP materials, requiring directional testing protocols that account for fiber orientation effects on vibration characteristics. Additionally, standards now increasingly incorporate provisions for non-destructive evaluation during vibration testing, allowing for simultaneous assessment of structural integrity and dynamic performance.

Compliance with these standards is particularly crucial when developing damping reduction strategies for CFRP panels, as they provide the baseline measurement protocols against which improvements can be quantitatively assessed. They ensure that any modifications to layup configurations, matrix formulations, or damping treatments can be evaluated consistently and reliably across the industry.

The primary international standards governing vibration testing of composite materials include ISO 7626, which outlines methods for determining frequency response functions, and ASTM E756, which specifically addresses measuring vibration-damping properties. For aerospace applications, standards such as RTCA DO-160 and MIL-STD-810 provide comprehensive testing protocols that address environmental conditions alongside vibration performance.

Testing methodologies typically involve modal analysis techniques, including impact hammer testing and shaker excitation methods. These approaches allow for precise measurement of natural frequencies, mode shapes, and damping ratios in CFRP panels. The standards prescribe specific sensor placement strategies, excitation methods, and data acquisition parameters to ensure reproducible results across different testing facilities.

For CFRP panels specifically, standards emphasize the importance of boundary condition control during testing. Fixed-free, free-free, and clamped configurations are commonly specified, with detailed requirements for fixture design to minimize unwanted constraints that could affect modal parameters. Temperature and humidity control are also mandated, as composite materials exhibit significant property variations with environmental conditions.

Signal processing requirements within these standards have evolved significantly, now incorporating advanced techniques such as the Half-Power Bandwidth Method, Logarithmic Decrement Method, and Complex Mode Indicator Function (CMIF) for accurate damping estimation. These methods help address the challenges of measuring the typically low damping values in CFRP structures.

Recent updates to testing standards have begun to address the anisotropic nature of CFRP materials, requiring directional testing protocols that account for fiber orientation effects on vibration characteristics. Additionally, standards now increasingly incorporate provisions for non-destructive evaluation during vibration testing, allowing for simultaneous assessment of structural integrity and dynamic performance.

Compliance with these standards is particularly crucial when developing damping reduction strategies for CFRP panels, as they provide the baseline measurement protocols against which improvements can be quantitatively assessed. They ensure that any modifications to layup configurations, matrix formulations, or damping treatments can be evaluated consistently and reliably across the industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!