Evaluating CFRP Fatigue Behavior Under Real World Cycling

SEP 17, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CFRP Fatigue Background and Research Objectives

Carbon Fiber Reinforced Polymers (CFRP) have emerged as revolutionary materials in various industries due to their exceptional strength-to-weight ratio, corrosion resistance, and design flexibility. The evolution of CFRP technology dates back to the 1960s, initially developed for aerospace applications. Over subsequent decades, these materials have penetrated numerous sectors including automotive, sporting goods, and civil infrastructure, with the cycling industry representing a significant growth area.

The fatigue behavior of CFRP components presents unique challenges compared to traditional metallic materials. Unlike metals that typically exhibit predictable fatigue patterns, CFRP materials demonstrate complex damage mechanisms including matrix cracking, delamination, fiber breakage, and interfacial debonding. These mechanisms often interact synergistically, making fatigue life prediction particularly challenging.

Recent technological advancements have enabled more sophisticated analysis of CFRP fatigue behavior, including non-destructive testing methods, digital image correlation, acoustic emission monitoring, and advanced computational modeling. However, a significant gap exists between laboratory testing conditions and real-world cycling environments, where components experience variable loading patterns, environmental exposures, and impact events.

The cycling industry has witnessed a dramatic increase in CFRP adoption, with carbon fiber frames, wheels, handlebars, and other components becoming standard in high-performance bicycles. This trend has intensified the need for comprehensive understanding of fatigue behavior under actual riding conditions, as component failures can lead to serious safety concerns and liability issues for manufacturers.

Current research predominantly focuses on constant amplitude fatigue testing under controlled laboratory conditions, which fails to capture the complex loading scenarios encountered during real-world cycling. These include variable amplitude loading, environmental factors (temperature, humidity, UV exposure), impact events, and the cumulative effects of these factors over a product's lifetime.

The primary objective of this research is to develop a comprehensive methodology for evaluating CFRP fatigue behavior under conditions that accurately simulate real-world cycling scenarios. This includes establishing testing protocols that incorporate variable loading patterns derived from actual riding data, environmental conditioning that reflects diverse usage conditions, and impact testing that mimics common riding incidents.

Secondary objectives include identifying key fatigue damage mechanisms specific to cycling applications, developing predictive models that correlate laboratory testing with field performance, and establishing design guidelines that enhance the fatigue resistance of CFRP cycling components. The ultimate goal is to bridge the gap between laboratory testing and real-world performance, enabling manufacturers to design safer, more durable CFRP components while optimizing material usage and manufacturing processes.

The fatigue behavior of CFRP components presents unique challenges compared to traditional metallic materials. Unlike metals that typically exhibit predictable fatigue patterns, CFRP materials demonstrate complex damage mechanisms including matrix cracking, delamination, fiber breakage, and interfacial debonding. These mechanisms often interact synergistically, making fatigue life prediction particularly challenging.

Recent technological advancements have enabled more sophisticated analysis of CFRP fatigue behavior, including non-destructive testing methods, digital image correlation, acoustic emission monitoring, and advanced computational modeling. However, a significant gap exists between laboratory testing conditions and real-world cycling environments, where components experience variable loading patterns, environmental exposures, and impact events.

The cycling industry has witnessed a dramatic increase in CFRP adoption, with carbon fiber frames, wheels, handlebars, and other components becoming standard in high-performance bicycles. This trend has intensified the need for comprehensive understanding of fatigue behavior under actual riding conditions, as component failures can lead to serious safety concerns and liability issues for manufacturers.

Current research predominantly focuses on constant amplitude fatigue testing under controlled laboratory conditions, which fails to capture the complex loading scenarios encountered during real-world cycling. These include variable amplitude loading, environmental factors (temperature, humidity, UV exposure), impact events, and the cumulative effects of these factors over a product's lifetime.

The primary objective of this research is to develop a comprehensive methodology for evaluating CFRP fatigue behavior under conditions that accurately simulate real-world cycling scenarios. This includes establishing testing protocols that incorporate variable loading patterns derived from actual riding data, environmental conditioning that reflects diverse usage conditions, and impact testing that mimics common riding incidents.

Secondary objectives include identifying key fatigue damage mechanisms specific to cycling applications, developing predictive models that correlate laboratory testing with field performance, and establishing design guidelines that enhance the fatigue resistance of CFRP cycling components. The ultimate goal is to bridge the gap between laboratory testing and real-world performance, enabling manufacturers to design safer, more durable CFRP components while optimizing material usage and manufacturing processes.

Market Analysis of CFRP in Cycling Industry

The Carbon Fiber Reinforced Polymer (CFRP) market in the cycling industry has experienced remarkable growth over the past decade, transforming from a niche material used exclusively in professional racing to a mainstream component in mid-to-high-end consumer bicycles. The global CFRP cycling components market was valued at approximately $2.1 billion in 2022, with projections indicating a compound annual growth rate of 7.8% through 2028.

Consumer demand for CFRP cycling products is primarily driven by the material's exceptional strength-to-weight ratio, which provides significant performance advantages in competitive and recreational cycling. Market research indicates that weight reduction remains the primary purchasing factor for 68% of serious cyclists, followed by improved ride quality (52%) and aesthetic appeal (41%). This demand profile has expanded beyond traditional road cycling into mountain biking, gravel riding, and e-bike segments.

Regional market analysis reveals that Europe continues to dominate CFRP cycling consumption, accounting for 42% of global market share, followed by North America (31%) and Asia-Pacific (22%). However, the Asia-Pacific region, particularly China and Taiwan, is experiencing the fastest growth rate at 9.3% annually, reflecting both increased local consumption and manufacturing capacity.

The price sensitivity analysis demonstrates a bifurcation in the market. Premium CFRP components command price premiums of 150-300% over aluminum alternatives, while mid-range CFRP products have seen price compression of approximately 15% over the past five years due to manufacturing efficiencies and increased competition. This price compression has expanded the addressable market significantly.

Durability concerns represent a critical market constraint, with 73% of potential CFRP bicycle purchasers citing concerns about long-term reliability and crash resistance. This highlights the commercial importance of advancements in fatigue behavior evaluation and testing methodologies under real-world cycling conditions.

Market forecasts indicate that CFRP adoption will continue to penetrate deeper into mid-range bicycle segments, with the $1,000-2,500 bicycle category expected to increase CFRP component usage by 35% by 2026. Additionally, emerging applications in urban mobility solutions and e-bikes represent significant growth vectors, with the e-bike segment projected to become the fastest-growing application for CFRP components at 12.4% annual growth.

Consumer awareness of sustainability issues is reshaping market dynamics, with 58% of cycling enthusiasts expressing interest in recycled or recyclable carbon fiber options. This trend is driving investment in circular economy solutions for CFRP in the cycling industry, potentially creating new market segments and competitive advantages for early adopters.

Consumer demand for CFRP cycling products is primarily driven by the material's exceptional strength-to-weight ratio, which provides significant performance advantages in competitive and recreational cycling. Market research indicates that weight reduction remains the primary purchasing factor for 68% of serious cyclists, followed by improved ride quality (52%) and aesthetic appeal (41%). This demand profile has expanded beyond traditional road cycling into mountain biking, gravel riding, and e-bike segments.

Regional market analysis reveals that Europe continues to dominate CFRP cycling consumption, accounting for 42% of global market share, followed by North America (31%) and Asia-Pacific (22%). However, the Asia-Pacific region, particularly China and Taiwan, is experiencing the fastest growth rate at 9.3% annually, reflecting both increased local consumption and manufacturing capacity.

The price sensitivity analysis demonstrates a bifurcation in the market. Premium CFRP components command price premiums of 150-300% over aluminum alternatives, while mid-range CFRP products have seen price compression of approximately 15% over the past five years due to manufacturing efficiencies and increased competition. This price compression has expanded the addressable market significantly.

Durability concerns represent a critical market constraint, with 73% of potential CFRP bicycle purchasers citing concerns about long-term reliability and crash resistance. This highlights the commercial importance of advancements in fatigue behavior evaluation and testing methodologies under real-world cycling conditions.

Market forecasts indicate that CFRP adoption will continue to penetrate deeper into mid-range bicycle segments, with the $1,000-2,500 bicycle category expected to increase CFRP component usage by 35% by 2026. Additionally, emerging applications in urban mobility solutions and e-bikes represent significant growth vectors, with the e-bike segment projected to become the fastest-growing application for CFRP components at 12.4% annual growth.

Consumer awareness of sustainability issues is reshaping market dynamics, with 58% of cycling enthusiasts expressing interest in recycled or recyclable carbon fiber options. This trend is driving investment in circular economy solutions for CFRP in the cycling industry, potentially creating new market segments and competitive advantages for early adopters.

Current Challenges in CFRP Fatigue Testing

The evaluation of Carbon Fiber Reinforced Polymer (CFRP) fatigue behavior under real-world cycling conditions presents several significant challenges that impede accurate assessment and prediction of material performance. Traditional fatigue testing methodologies often fail to capture the complex loading scenarios encountered in actual cycling applications, leading to potential discrepancies between laboratory results and field performance.

One primary challenge lies in the multi-axial stress states that CFRP components experience during cycling. Unlike conventional uniaxial fatigue tests, real-world cycling subjects materials to complex combinations of tension, compression, bending, and torsion simultaneously. Current testing protocols struggle to replicate these intricate stress interactions, particularly the transient loading patterns that occur during acceleration, braking, and cornering maneuvers.

Environmental factors present another substantial hurdle in CFRP fatigue testing. Cycling components are exposed to varying temperature gradients, humidity levels, UV radiation, and chemical contaminants such as road salts and lubricants. These environmental variables can significantly alter the fatigue response of composite materials, yet incorporating them systematically into accelerated testing regimes remains problematic due to the difficulty in establishing standardized environmental cycling protocols.

The anisotropic nature of CFRP materials further complicates fatigue assessment. Fiber orientation, layup sequence, and manufacturing variations introduce directional dependencies in fatigue behavior that are challenging to characterize comprehensively. Current testing methodologies often oversimplify these complexities, focusing on principal loading directions while neglecting off-axis fatigue responses that may become critical under real cycling conditions.

Scale effects represent another significant challenge. Laboratory specimens typically differ in size and geometry from actual components, raising questions about the validity of scaling fatigue data from coupon-level tests to full-scale structures. The presence of geometric features such as joints, transitions, and mounting points—common in cycling components—creates stress concentrations that dramatically influence fatigue life but are difficult to incorporate into standardized test methods.

Time-dependent phenomena also pose substantial challenges. The viscoelastic behavior of polymer matrices in CFRP leads to creep, stress relaxation, and frequency-dependent responses that affect long-term performance. Accelerated testing protocols struggle to account for these time-dependent effects without introducing artificial aging mechanisms that may not accurately represent real-world degradation pathways.

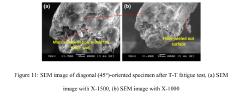

Finally, damage detection and progression monitoring during fatigue testing remains problematic. Non-destructive evaluation techniques often lack the sensitivity to detect early-stage damage in CFRP materials, particularly internal delaminations and matrix microcracking that precede catastrophic failure. This limitation hinders the development of reliable fatigue life prediction models based on damage accumulation approaches.

One primary challenge lies in the multi-axial stress states that CFRP components experience during cycling. Unlike conventional uniaxial fatigue tests, real-world cycling subjects materials to complex combinations of tension, compression, bending, and torsion simultaneously. Current testing protocols struggle to replicate these intricate stress interactions, particularly the transient loading patterns that occur during acceleration, braking, and cornering maneuvers.

Environmental factors present another substantial hurdle in CFRP fatigue testing. Cycling components are exposed to varying temperature gradients, humidity levels, UV radiation, and chemical contaminants such as road salts and lubricants. These environmental variables can significantly alter the fatigue response of composite materials, yet incorporating them systematically into accelerated testing regimes remains problematic due to the difficulty in establishing standardized environmental cycling protocols.

The anisotropic nature of CFRP materials further complicates fatigue assessment. Fiber orientation, layup sequence, and manufacturing variations introduce directional dependencies in fatigue behavior that are challenging to characterize comprehensively. Current testing methodologies often oversimplify these complexities, focusing on principal loading directions while neglecting off-axis fatigue responses that may become critical under real cycling conditions.

Scale effects represent another significant challenge. Laboratory specimens typically differ in size and geometry from actual components, raising questions about the validity of scaling fatigue data from coupon-level tests to full-scale structures. The presence of geometric features such as joints, transitions, and mounting points—common in cycling components—creates stress concentrations that dramatically influence fatigue life but are difficult to incorporate into standardized test methods.

Time-dependent phenomena also pose substantial challenges. The viscoelastic behavior of polymer matrices in CFRP leads to creep, stress relaxation, and frequency-dependent responses that affect long-term performance. Accelerated testing protocols struggle to account for these time-dependent effects without introducing artificial aging mechanisms that may not accurately represent real-world degradation pathways.

Finally, damage detection and progression monitoring during fatigue testing remains problematic. Non-destructive evaluation techniques often lack the sensitivity to detect early-stage damage in CFRP materials, particularly internal delaminations and matrix microcracking that precede catastrophic failure. This limitation hinders the development of reliable fatigue life prediction models based on damage accumulation approaches.

Established Methodologies for CFRP Fatigue Assessment

01 Fatigue testing methods for CFRP

Various testing methods are employed to evaluate the fatigue behavior of carbon fiber reinforced polymers. These include cyclic loading tests, stress-strain analysis, and accelerated aging procedures to determine long-term durability. Advanced monitoring techniques are used to detect microscopic damage initiation and propagation during fatigue testing, providing insights into failure mechanisms and lifetime prediction of CFRP structures.- Fatigue behavior improvement through matrix modification: The fatigue performance of CFRP can be enhanced by modifying the polymer matrix composition. Various additives and reinforcement materials can be incorporated into the matrix to improve its resistance to cyclic loading. These modifications can include the addition of nanoparticles, elastomeric compounds, or specialized resins that increase the toughness and crack resistance of the composite, thereby extending its fatigue life under repeated stress conditions.

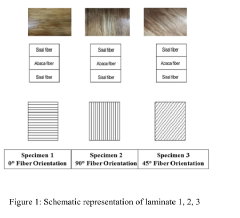

- Fiber orientation and layup design for fatigue resistance: The arrangement and orientation of carbon fibers within the polymer matrix significantly impact the fatigue behavior of CFRP composites. Strategic fiber layup designs can distribute stress more effectively and prevent crack propagation. Multi-directional fiber orientations can be implemented to address fatigue loading from various directions, while specialized weaving patterns can enhance the interlaminar strength, which is crucial for resisting delamination during cyclic loading conditions.

- Interface treatment between fiber and matrix: The interface between carbon fibers and the polymer matrix is critical for fatigue performance. Various surface treatments and sizing agents can be applied to carbon fibers to improve adhesion with the matrix, enhancing load transfer and preventing interfacial debonding during cyclic loading. These treatments modify the chemical compatibility between fibers and matrix, creating stronger bonds that resist fatigue-induced degradation and extend the composite's service life under repeated stress conditions.

- Testing and characterization methods for CFRP fatigue: Specialized testing methodologies have been developed to accurately characterize the fatigue behavior of CFRP composites. These include cyclic loading tests, acoustic emission monitoring, thermographic analysis, and advanced non-destructive evaluation techniques. Such methods help in understanding fatigue damage initiation and progression, allowing for better prediction of service life and development of more fatigue-resistant CFRP formulations and structures.

- Environmental factors affecting CFRP fatigue performance: Environmental conditions significantly impact the fatigue behavior of CFRP composites. Factors such as temperature fluctuations, moisture absorption, UV exposure, and chemical exposure can accelerate fatigue damage. Protective coatings, specialized matrix formulations, and environmental barrier systems can be incorporated into CFRP components to mitigate these effects and maintain fatigue resistance in challenging operational environments.

02 Structural design improvements for fatigue resistance

Innovative structural designs can significantly enhance the fatigue resistance of CFRP components. These include optimized fiber orientation patterns, strategic placement of reinforcement layers, and specialized joint designs that minimize stress concentrations. Structural modifications such as tapered edges, integrated stiffeners, and hybrid material combinations help distribute loads more evenly, thereby extending the fatigue life of CFRP structures under cyclic loading conditions.Expand Specific Solutions03 Matrix modification techniques for improved fatigue performance

The polymer matrix in CFRP can be modified to enhance fatigue resistance through various techniques. These include incorporation of nano-additives, toughening agents, and self-healing components that prevent crack propagation. Chemical modifications to the resin system can improve fiber-matrix interfacial bonding, increase damage tolerance, and reduce moisture sensitivity, all contributing to superior fatigue performance under various environmental conditions.Expand Specific Solutions04 Environmental factors affecting CFRP fatigue behavior

Environmental conditions significantly impact the fatigue performance of CFRP materials. Factors such as temperature fluctuations, humidity, UV exposure, and chemical exposure can accelerate degradation mechanisms and reduce fatigue life. Understanding these environmental effects is crucial for developing protective measures, such as specialized coatings and treatments, to maintain the structural integrity of CFRP components under real-world service conditions.Expand Specific Solutions05 Monitoring and prediction systems for CFRP fatigue life

Advanced monitoring and prediction systems have been developed to assess and forecast the fatigue behavior of CFRP structures. These include embedded sensor networks, acoustic emission detection systems, and digital twin technologies that provide real-time data on structural health. Predictive algorithms and machine learning models analyze this data to estimate remaining service life, optimize maintenance schedules, and prevent catastrophic failures in critical CFRP applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The CFRP fatigue behavior evaluation market is in a growth phase, driven by increasing demand for lightweight materials in aerospace, automotive, and renewable energy sectors. The market is expected to expand significantly due to the rising adoption of carbon fiber composites in critical applications requiring cyclical loading resistance. Boeing and Rolls-Royce lead in aerospace applications, while GE, Siemens Energy, and Mitsubishi Heavy Industries dominate in energy sector implementations. Academic institutions like Northwestern Polytechnical University, Beihang University, and Purdue Research Foundation are advancing fundamental research, creating a competitive landscape where industry-academia collaboration is crucial for innovation. The technology is approaching maturity in aerospace but remains in development for newer applications like cycling sports equipment, where companies like Mavic are exploring performance boundaries.

The Boeing Co.

Technical Solution: Boeing has developed comprehensive testing protocols for evaluating CFRP fatigue behavior under real-world cycling conditions, particularly for aerospace applications. Their approach combines accelerated fatigue testing with digital twin modeling to predict composite material degradation over time. Boeing's methodology incorporates multi-scale testing from coupon to full-scale component level, with specialized environmental chambers that simulate altitude, temperature, and humidity variations encountered during flight cycles. Their proprietary BVID (Barely Visible Impact Damage) assessment protocol specifically evaluates how micro-damages accumulate during cyclic loading, using advanced non-destructive inspection techniques including thermography and ultrasonic scanning to detect subsurface damage progression. Boeing has also pioneered the integration of embedded fiber optic sensors within CFRP structures to enable real-time structural health monitoring during cyclic loading tests.

Strengths: Industry-leading expertise in aerospace-grade CFRP testing with access to extensive historical fatigue data. Advanced facilities for full-scale component testing under complex environmental conditions. Weaknesses: Testing methodologies are primarily optimized for aerospace applications and may require adaptation for other industries. High costs associated with their comprehensive testing approach.

Vrije Universiteit Brussel

Technical Solution: Vrije Universiteit Brussel (VUB) has developed a comprehensive research program for evaluating CFRP fatigue behavior under real-world cycling conditions, with particular focus on bicycle and sports equipment applications. Their methodology combines experimental testing with advanced numerical modeling to characterize damage initiation and propagation. VUB's approach incorporates multi-scale testing from material coupon to full component level, with specialized test rigs that can replicate complex loading patterns experienced during actual cycling activities. Their research utilizes Digital Image Correlation (DIC) and Acoustic Emission (AE) monitoring during fatigue testing to identify damage mechanisms and progression in real-time. VUB has pioneered the development of fatigue master curves that account for the viscoelastic behavior of the polymer matrix in CFRP under different loading frequencies and environmental conditions. Their testing protocols include environmental chambers that simulate temperature variations, humidity cycling, and UV exposure to provide more realistic lifetime predictions. VUB researchers have established correlations between manufacturing parameters (fiber orientation, cure cycles, void content) and fatigue performance through extensive experimental campaigns.

Strengths: Strong academic research foundation with extensive publications on CFRP fatigue behavior. Specialized expertise in sports equipment applications, particularly cycling components. Weaknesses: As an academic institution, may have limited facilities for full-scale industrial testing compared to large corporations. Research may be more theoretical and less immediately applicable to production environments.

Critical Patents and Literature on CFRP Cycling Applications

Fatigue and creep behavior of abaca-sisal natural fiber-reinforced polymeric composites

PatentPendingIN202341068508A

Innovation

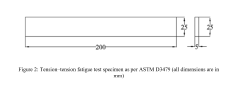

- The use of hybrid composites with Cissus quadrangularis fibers in combination with epoxy resin, oriented in specific configurations (0°, 45°, and 90°) to create specimens that demonstrate improved mechanical, thermal, and tribological properties, and undergo tension-tension, compression-compression, flexural creep, and tensile creep tests to evaluate fatigue behavior.

Environmental Factors Affecting CFRP Performance

Carbon Fiber Reinforced Polymers (CFRP) exhibit significant sensitivity to environmental conditions, which directly impacts their fatigue behavior during cycling applications. Temperature variations represent a primary environmental factor affecting CFRP performance. Under elevated temperatures, the polymer matrix may experience softening, reducing the composite's overall stiffness and potentially accelerating fatigue damage accumulation. Conversely, low temperatures can induce matrix embrittlement, increasing the risk of microcrack formation at lower stress thresholds than typically observed under standard conditions.

Moisture absorption constitutes another critical environmental factor. CFRP materials can absorb moisture from humid environments, leading to plasticization of the polymer matrix and potential hydrolysis of the fiber-matrix interface. Research indicates that moisture ingress can reduce the glass transition temperature of the composite by up to 30°C, significantly altering its mechanical properties during cycling applications. The rate of moisture absorption correlates strongly with ambient humidity levels, temperature, and the specific resin system employed.

Ultraviolet (UV) radiation exposure presents a particular challenge for CFRP components used in outdoor cycling applications. Prolonged UV exposure can degrade the polymer matrix through photo-oxidation processes, resulting in surface embrittlement, discoloration, and reduced mechanical properties. Studies have demonstrated that UV-induced degradation can accelerate fatigue crack initiation by creating surface defects that serve as stress concentration points during cyclic loading.

Chemical exposure from road contaminants, including de-icing salts, automotive fluids, and acidic rain, can significantly impact CFRP durability. These substances may penetrate the composite structure, particularly at cut edges or damaged areas, potentially causing localized degradation of the fiber-matrix interface. Salt solutions are especially problematic as they can facilitate galvanic corrosion when CFRP is used in conjunction with metallic components in bicycle frames or components.

Thermal cycling effects warrant special consideration in real-world applications. The significant difference in thermal expansion coefficients between carbon fibers and polymer matrices generates internal stresses during temperature fluctuations. These thermally-induced stresses, when combined with mechanical cycling loads, can accelerate damage accumulation through a phenomenon known as thermo-mechanical fatigue. This effect becomes particularly relevant for components experiencing both daily temperature variations and mechanical cycling.

Synergistic interactions between multiple environmental factors often produce more severe degradation than individual factors acting independently. For instance, the combination of moisture and elevated temperature can accelerate chemical aging processes, while simultaneous UV exposure and humidity can enhance surface degradation rates. These complex interactions necessitate comprehensive testing protocols that accurately simulate real-world multi-factor environmental conditions when evaluating CFRP fatigue performance for cycling applications.

Moisture absorption constitutes another critical environmental factor. CFRP materials can absorb moisture from humid environments, leading to plasticization of the polymer matrix and potential hydrolysis of the fiber-matrix interface. Research indicates that moisture ingress can reduce the glass transition temperature of the composite by up to 30°C, significantly altering its mechanical properties during cycling applications. The rate of moisture absorption correlates strongly with ambient humidity levels, temperature, and the specific resin system employed.

Ultraviolet (UV) radiation exposure presents a particular challenge for CFRP components used in outdoor cycling applications. Prolonged UV exposure can degrade the polymer matrix through photo-oxidation processes, resulting in surface embrittlement, discoloration, and reduced mechanical properties. Studies have demonstrated that UV-induced degradation can accelerate fatigue crack initiation by creating surface defects that serve as stress concentration points during cyclic loading.

Chemical exposure from road contaminants, including de-icing salts, automotive fluids, and acidic rain, can significantly impact CFRP durability. These substances may penetrate the composite structure, particularly at cut edges or damaged areas, potentially causing localized degradation of the fiber-matrix interface. Salt solutions are especially problematic as they can facilitate galvanic corrosion when CFRP is used in conjunction with metallic components in bicycle frames or components.

Thermal cycling effects warrant special consideration in real-world applications. The significant difference in thermal expansion coefficients between carbon fibers and polymer matrices generates internal stresses during temperature fluctuations. These thermally-induced stresses, when combined with mechanical cycling loads, can accelerate damage accumulation through a phenomenon known as thermo-mechanical fatigue. This effect becomes particularly relevant for components experiencing both daily temperature variations and mechanical cycling.

Synergistic interactions between multiple environmental factors often produce more severe degradation than individual factors acting independently. For instance, the combination of moisture and elevated temperature can accelerate chemical aging processes, while simultaneous UV exposure and humidity can enhance surface degradation rates. These complex interactions necessitate comprehensive testing protocols that accurately simulate real-world multi-factor environmental conditions when evaluating CFRP fatigue performance for cycling applications.

Safety Standards and Certification Requirements

The regulatory landscape for Carbon Fiber Reinforced Polymer (CFRP) components in cycling applications is complex and continuously evolving. Currently, several international standards govern the safety certification of CFRP bicycle components, with ISO 4210 series serving as the primary global benchmark. These standards establish minimum safety and performance requirements for bicycles, including specific testing protocols for CFRP components under fatigue conditions.

In the United States, the Consumer Product Safety Commission (CPSC) enforces additional requirements that manufacturers must meet before bringing CFRP cycling products to market. The European Union implements the EN 14781 standard for racing bicycles and EN 15194 for electrically power-assisted cycles, both containing specific provisions for composite materials testing and certification.

Testing methodologies prescribed by these standards typically include accelerated fatigue testing, impact resistance evaluation, and structural integrity assessment. However, a significant limitation exists in the correlation between laboratory testing conditions and real-world cycling environments. Current standards often employ simplified loading patterns that fail to accurately represent the complex, multi-directional stress states experienced during actual riding conditions.

Certification processes generally require manufacturers to submit CFRP components for third-party testing at accredited facilities. These facilities conduct standardized tests including cyclic loading to simulate repeated stress, environmental conditioning to assess performance under various temperature and humidity conditions, and destructive testing to determine ultimate failure modes.

Recent developments in certification requirements have begun addressing the unique fatigue characteristics of CFRP materials. The ASTM D7791 standard specifically focuses on fatigue testing of polymer matrix composite materials, providing more relevant testing protocols for bicycle components. Additionally, the UCI (Union Cycliste Internationale) has implemented specific approval procedures for CFRP frames and components used in professional competition.

A notable gap in current standards is the limited consideration of long-term environmental exposure effects on CFRP fatigue behavior. Ultraviolet radiation, temperature cycling, and moisture exposure can significantly alter the material properties over time, yet standardized testing rarely accounts for these factors comprehensively.

Industry stakeholders are advocating for more sophisticated certification requirements that incorporate real-world usage data collected through instrumented field testing. This approach would enable standards to evolve toward more representative testing protocols that better predict actual component lifespan and failure modes under authentic cycling conditions.

In the United States, the Consumer Product Safety Commission (CPSC) enforces additional requirements that manufacturers must meet before bringing CFRP cycling products to market. The European Union implements the EN 14781 standard for racing bicycles and EN 15194 for electrically power-assisted cycles, both containing specific provisions for composite materials testing and certification.

Testing methodologies prescribed by these standards typically include accelerated fatigue testing, impact resistance evaluation, and structural integrity assessment. However, a significant limitation exists in the correlation between laboratory testing conditions and real-world cycling environments. Current standards often employ simplified loading patterns that fail to accurately represent the complex, multi-directional stress states experienced during actual riding conditions.

Certification processes generally require manufacturers to submit CFRP components for third-party testing at accredited facilities. These facilities conduct standardized tests including cyclic loading to simulate repeated stress, environmental conditioning to assess performance under various temperature and humidity conditions, and destructive testing to determine ultimate failure modes.

Recent developments in certification requirements have begun addressing the unique fatigue characteristics of CFRP materials. The ASTM D7791 standard specifically focuses on fatigue testing of polymer matrix composite materials, providing more relevant testing protocols for bicycle components. Additionally, the UCI (Union Cycliste Internationale) has implemented specific approval procedures for CFRP frames and components used in professional competition.

A notable gap in current standards is the limited consideration of long-term environmental exposure effects on CFRP fatigue behavior. Ultraviolet radiation, temperature cycling, and moisture exposure can significantly alter the material properties over time, yet standardized testing rarely accounts for these factors comprehensively.

Industry stakeholders are advocating for more sophisticated certification requirements that incorporate real-world usage data collected through instrumented field testing. This approach would enable standards to evolve toward more representative testing protocols that better predict actual component lifespan and failure modes under authentic cycling conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!