Analysis of dual-fuel V16 engines aligning with sustainable transport goals

AUG 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Dual-Fuel V16 Engine Evolution and Objectives

The evolution of dual-fuel V16 engines represents a significant milestone in the pursuit of sustainable transport solutions. These engines, which can operate on both conventional diesel fuel and alternative fuels such as natural gas or hydrogen, have emerged as a promising technology to address the growing environmental concerns in the transportation sector.

The development of dual-fuel V16 engines can be traced back to the early 2000s when the need for cleaner and more efficient power sources became increasingly apparent. Initially, these engines were primarily designed for marine applications, where the demand for high power output and long-range capabilities was paramount. Over time, the technology has been adapted and refined for use in other heavy-duty applications, including locomotives and stationary power generation.

The primary objective of dual-fuel V16 engine technology is to reduce greenhouse gas emissions and particulate matter while maintaining or improving engine performance. By utilizing a combination of diesel and cleaner-burning fuels, these engines aim to strike a balance between environmental sustainability and operational efficiency. This aligns closely with global efforts to mitigate climate change and improve air quality in urban areas.

Another key goal in the evolution of dual-fuel V16 engines is to enhance fuel flexibility. As the availability and cost of different fuel types can vary significantly across regions and over time, the ability to switch between fuel sources provides operators with greater adaptability and potential cost savings. This flexibility also supports the gradual transition towards more sustainable fuel options as infrastructure and supply chains develop.

Improving engine efficiency and reducing fuel consumption remain critical objectives in the ongoing development of dual-fuel V16 engines. Engineers and researchers are continually working to optimize combustion processes, enhance fuel injection systems, and integrate advanced control technologies to maximize energy utilization and minimize waste.

As the transportation industry faces increasingly stringent emissions regulations, dual-fuel V16 engines are being designed to meet and exceed these standards. This involves not only reducing CO2 emissions but also addressing other pollutants such as nitrogen oxides (NOx) and sulfur oxides (SOx). The integration of advanced aftertreatment systems and the exploration of novel combustion strategies are key focus areas in achieving these environmental targets.

Looking ahead, the evolution of dual-fuel V16 engines is expected to continue, with a growing emphasis on compatibility with renewable fuels and the potential for full electrification. Research is underway to explore the use of biofuels, synthetic fuels, and hydrogen as primary energy sources, further reducing the carbon footprint of these powerful engines. Additionally, the integration of hybrid technologies and energy recovery systems is being investigated to push the boundaries of efficiency and environmental performance.

The development of dual-fuel V16 engines can be traced back to the early 2000s when the need for cleaner and more efficient power sources became increasingly apparent. Initially, these engines were primarily designed for marine applications, where the demand for high power output and long-range capabilities was paramount. Over time, the technology has been adapted and refined for use in other heavy-duty applications, including locomotives and stationary power generation.

The primary objective of dual-fuel V16 engine technology is to reduce greenhouse gas emissions and particulate matter while maintaining or improving engine performance. By utilizing a combination of diesel and cleaner-burning fuels, these engines aim to strike a balance between environmental sustainability and operational efficiency. This aligns closely with global efforts to mitigate climate change and improve air quality in urban areas.

Another key goal in the evolution of dual-fuel V16 engines is to enhance fuel flexibility. As the availability and cost of different fuel types can vary significantly across regions and over time, the ability to switch between fuel sources provides operators with greater adaptability and potential cost savings. This flexibility also supports the gradual transition towards more sustainable fuel options as infrastructure and supply chains develop.

Improving engine efficiency and reducing fuel consumption remain critical objectives in the ongoing development of dual-fuel V16 engines. Engineers and researchers are continually working to optimize combustion processes, enhance fuel injection systems, and integrate advanced control technologies to maximize energy utilization and minimize waste.

As the transportation industry faces increasingly stringent emissions regulations, dual-fuel V16 engines are being designed to meet and exceed these standards. This involves not only reducing CO2 emissions but also addressing other pollutants such as nitrogen oxides (NOx) and sulfur oxides (SOx). The integration of advanced aftertreatment systems and the exploration of novel combustion strategies are key focus areas in achieving these environmental targets.

Looking ahead, the evolution of dual-fuel V16 engines is expected to continue, with a growing emphasis on compatibility with renewable fuels and the potential for full electrification. Research is underway to explore the use of biofuels, synthetic fuels, and hydrogen as primary energy sources, further reducing the carbon footprint of these powerful engines. Additionally, the integration of hybrid technologies and energy recovery systems is being investigated to push the boundaries of efficiency and environmental performance.

Market Demand for Sustainable Heavy-Duty Engines

The market demand for sustainable heavy-duty engines, particularly dual-fuel V16 engines, has been steadily increasing in recent years. This growth is driven by a combination of environmental regulations, economic factors, and technological advancements in the transport sector. As governments worldwide implement stricter emissions standards, fleet operators and manufacturers are seeking more sustainable alternatives to traditional diesel engines.

The heavy-duty transport sector, including long-haul trucking, marine shipping, and industrial applications, represents a significant portion of global fuel consumption and emissions. Dual-fuel V16 engines, which can operate on a combination of diesel and cleaner-burning fuels such as natural gas or hydrogen, offer a promising solution to reduce carbon footprint while maintaining the power and reliability required for heavy-duty operations.

Market research indicates that the global sustainable heavy-duty engine market is expected to grow substantially over the next decade. This growth is particularly pronounced in regions with well-developed natural gas infrastructure or those investing heavily in hydrogen fuel technologies. North America, Europe, and parts of Asia are leading this transition, with major fleet operators expressing interest in adopting dual-fuel technologies.

The demand is further bolstered by the potential cost savings associated with dual-fuel engines. While initial investment costs may be higher, the ability to switch between fuels based on availability and price can lead to significant operational cost reductions over the engine's lifetime. This flexibility is especially attractive in markets with volatile fuel prices or those transitioning towards more sustainable fuel sources.

Moreover, the push for sustainable transport solutions is not limited to on-road vehicles. The marine sector, facing increasing pressure to reduce emissions, is also showing growing interest in dual-fuel V16 engines for large vessels. This expansion of the market into various transport segments is creating new opportunities for engine manufacturers and technology providers.

However, the market demand is not without challenges. The availability of alternative fuels, the need for infrastructure development, and the higher initial costs of dual-fuel engines compared to traditional diesel engines are factors that could potentially slow adoption rates. Despite these challenges, the long-term benefits and alignment with sustainable transport goals continue to drive market growth.

As the technology matures and becomes more cost-effective, industry analysts predict a significant shift towards dual-fuel and other sustainable engine technologies in the heavy-duty transport sector. This transition is expected to accelerate as more countries implement carbon reduction targets and incentivize the adoption of cleaner transport solutions.

The heavy-duty transport sector, including long-haul trucking, marine shipping, and industrial applications, represents a significant portion of global fuel consumption and emissions. Dual-fuel V16 engines, which can operate on a combination of diesel and cleaner-burning fuels such as natural gas or hydrogen, offer a promising solution to reduce carbon footprint while maintaining the power and reliability required for heavy-duty operations.

Market research indicates that the global sustainable heavy-duty engine market is expected to grow substantially over the next decade. This growth is particularly pronounced in regions with well-developed natural gas infrastructure or those investing heavily in hydrogen fuel technologies. North America, Europe, and parts of Asia are leading this transition, with major fleet operators expressing interest in adopting dual-fuel technologies.

The demand is further bolstered by the potential cost savings associated with dual-fuel engines. While initial investment costs may be higher, the ability to switch between fuels based on availability and price can lead to significant operational cost reductions over the engine's lifetime. This flexibility is especially attractive in markets with volatile fuel prices or those transitioning towards more sustainable fuel sources.

Moreover, the push for sustainable transport solutions is not limited to on-road vehicles. The marine sector, facing increasing pressure to reduce emissions, is also showing growing interest in dual-fuel V16 engines for large vessels. This expansion of the market into various transport segments is creating new opportunities for engine manufacturers and technology providers.

However, the market demand is not without challenges. The availability of alternative fuels, the need for infrastructure development, and the higher initial costs of dual-fuel engines compared to traditional diesel engines are factors that could potentially slow adoption rates. Despite these challenges, the long-term benefits and alignment with sustainable transport goals continue to drive market growth.

As the technology matures and becomes more cost-effective, industry analysts predict a significant shift towards dual-fuel and other sustainable engine technologies in the heavy-duty transport sector. This transition is expected to accelerate as more countries implement carbon reduction targets and incentivize the adoption of cleaner transport solutions.

Technical Challenges in Dual-Fuel V16 Engine Development

The development of dual-fuel V16 engines aligned with sustainable transport goals faces several significant technical challenges. One of the primary hurdles is achieving optimal fuel mixing and combustion efficiency. The complex interaction between two different fuel types, typically diesel and natural gas, requires sophisticated engine management systems to ensure proper fuel ratios and timing across a wide range of operating conditions.

Another major challenge lies in the thermal management of these large, powerful engines. The dual-fuel combustion process can lead to increased thermal loads, necessitating advanced cooling systems and materials that can withstand higher temperatures without compromising engine longevity or performance. This is particularly crucial for maintaining the structural integrity of engine components and preventing premature wear.

Emissions control presents a formidable challenge in dual-fuel V16 engines. While the use of natural gas can reduce CO2 emissions compared to traditional diesel engines, the combustion of dual fuels can lead to increased NOx emissions under certain conditions. Engineers must develop innovative aftertreatment systems and combustion strategies to meet increasingly stringent emission standards while maintaining engine efficiency and power output.

The complexity of the fuel delivery system poses another significant technical hurdle. Designing a system that can accurately meter and deliver two different fuel types, often with vastly different physical properties, requires precision engineering and advanced control algorithms. This system must also be robust enough to handle variations in fuel quality and composition, which can be significant, especially for natural gas.

Durability and reliability remain critical concerns in the development of dual-fuel V16 engines. The alternating use of different fuels can lead to increased wear on engine components, particularly in the fuel injection system and combustion chamber. Engineers must develop materials and designs that can withstand the unique stresses imposed by dual-fuel operation over extended periods.

Lastly, the challenge of optimizing engine performance across different fuel mixtures and operating conditions is considerable. Achieving consistent power output, fuel efficiency, and emissions performance when switching between fuel types or operating on varying fuel ratios requires sophisticated control strategies and extensive calibration work. This optimization process is further complicated by the need to maintain performance across a wide range of environmental conditions and load profiles typical of heavy-duty transport applications.

Another major challenge lies in the thermal management of these large, powerful engines. The dual-fuel combustion process can lead to increased thermal loads, necessitating advanced cooling systems and materials that can withstand higher temperatures without compromising engine longevity or performance. This is particularly crucial for maintaining the structural integrity of engine components and preventing premature wear.

Emissions control presents a formidable challenge in dual-fuel V16 engines. While the use of natural gas can reduce CO2 emissions compared to traditional diesel engines, the combustion of dual fuels can lead to increased NOx emissions under certain conditions. Engineers must develop innovative aftertreatment systems and combustion strategies to meet increasingly stringent emission standards while maintaining engine efficiency and power output.

The complexity of the fuel delivery system poses another significant technical hurdle. Designing a system that can accurately meter and deliver two different fuel types, often with vastly different physical properties, requires precision engineering and advanced control algorithms. This system must also be robust enough to handle variations in fuel quality and composition, which can be significant, especially for natural gas.

Durability and reliability remain critical concerns in the development of dual-fuel V16 engines. The alternating use of different fuels can lead to increased wear on engine components, particularly in the fuel injection system and combustion chamber. Engineers must develop materials and designs that can withstand the unique stresses imposed by dual-fuel operation over extended periods.

Lastly, the challenge of optimizing engine performance across different fuel mixtures and operating conditions is considerable. Achieving consistent power output, fuel efficiency, and emissions performance when switching between fuel types or operating on varying fuel ratios requires sophisticated control strategies and extensive calibration work. This optimization process is further complicated by the need to maintain performance across a wide range of environmental conditions and load profiles typical of heavy-duty transport applications.

Current Dual-Fuel V16 Engine Solutions

01 Dual-fuel system design for V16 engines

Dual-fuel systems for V16 engines allow for the use of two different types of fuel, typically diesel and natural gas. This design incorporates specialized fuel injection systems, combustion chamber modifications, and engine control units to optimize performance and efficiency while reducing emissions. The system can switch between fuels or use them simultaneously, depending on operating conditions and fuel availability.- Dual-fuel system design for V16 engines: Dual-fuel systems for V16 engines allow for the use of two different types of fuel, typically diesel and natural gas. This design incorporates specialized fuel injection systems, combustion chamber modifications, and engine control units to optimize performance and efficiency while reducing emissions. The system can switch between fuels or use them simultaneously, providing flexibility in fuel choice and potentially reducing operating costs.

- Fuel injection and mixing strategies: Advanced fuel injection and mixing strategies are crucial for dual-fuel V16 engines. These may include high-pressure direct injection systems for both fuels, pre-chamber designs for improved ignition, and sophisticated fuel mixing techniques to ensure optimal combustion. Such strategies aim to maximize engine efficiency, power output, and emissions control across various operating conditions.

- Emissions reduction technologies: Dual-fuel V16 engines often incorporate advanced emissions reduction technologies to meet stringent environmental regulations. These may include exhaust gas recirculation (EGR) systems, selective catalytic reduction (SCR), particulate filters, and advanced aftertreatment systems. The combination of dual-fuel operation and these technologies can significantly reduce NOx, particulate matter, and greenhouse gas emissions.

- Engine control and monitoring systems: Sophisticated engine control and monitoring systems are essential for managing the complex operation of dual-fuel V16 engines. These systems typically include advanced electronic control units (ECUs), sensors for real-time monitoring of engine parameters, and adaptive control algorithms. They optimize fuel mixture, ignition timing, and other operational aspects to ensure efficient and reliable performance across various load conditions and fuel compositions.

- Thermal management and cooling systems: Effective thermal management and cooling systems are critical for dual-fuel V16 engines due to the high power output and varied combustion characteristics of different fuels. These systems may include advanced coolant circulation designs, intercooling for turbocharged variants, and innovative materials for improved heat dissipation. Proper thermal management ensures engine longevity, maintains efficiency, and supports consistent performance across different fuel modes.

02 Fuel injection and mixing strategies

Advanced fuel injection and mixing strategies are crucial for dual-fuel V16 engines. These include high-pressure direct injection systems for both fuels, pre-chamber designs for improved ignition, and sophisticated fuel mixing techniques to ensure optimal combustion. The goal is to achieve the right balance of fuel types and air-fuel ratios across various engine loads and speeds.Expand Specific Solutions03 Emissions control and aftertreatment systems

Dual-fuel V16 engines require specialized emissions control and aftertreatment systems to meet stringent environmental regulations. These may include selective catalytic reduction (SCR), exhaust gas recirculation (EGR), particulate filters, and oxidation catalysts. The systems are designed to effectively reduce NOx, particulate matter, and other pollutants associated with both diesel and natural gas combustion.Expand Specific Solutions04 Engine control and monitoring systems

Sophisticated engine control and monitoring systems are essential for managing the complexities of dual-fuel operation in V16 engines. These systems incorporate advanced sensors, actuators, and control algorithms to optimize fuel selection, injection timing, and combustion parameters. They also provide real-time monitoring of engine performance, emissions, and component health to ensure efficient and reliable operation.Expand Specific Solutions05 Thermal management and cooling systems

Effective thermal management and cooling systems are critical for dual-fuel V16 engines due to the different combustion characteristics of diesel and natural gas. These systems may include advanced coolant circulation designs, intercoolers, and oil cooling systems to maintain optimal operating temperatures across various engine components. Proper thermal management ensures engine longevity, efficiency, and consistent performance across different fuel modes.Expand Specific Solutions

Key Players in Dual-Fuel Engine Manufacturing

The dual-fuel V16 engine market is in a growth phase, driven by increasing demand for sustainable transport solutions. The market size is expanding as more industries seek to reduce emissions while maintaining high-performance capabilities. Technologically, the field is advancing rapidly, with companies like Mercedes-Benz Group AG, GM Global Technology Operations LLC, and Rolls-Royce Plc leading innovation. These firms are investing heavily in R&D to improve efficiency, reduce emissions, and enhance power output. Academic institutions such as Harbin Engineering University and Tianjin University are contributing to technological advancements through research partnerships. The competitive landscape is diverse, with traditional automotive manufacturers, specialized engine developers, and new entrants all vying for market share in this evolving sector.

Mercedes-Benz Group AG

Technical Solution: Mercedes-Benz has developed a dual-fuel V16 engine concept that combines hydrogen and diesel combustion. This innovative approach utilizes direct hydrogen injection into the combustion chamber, alongside traditional diesel injection. The system dynamically adjusts the fuel ratio based on operating conditions, optimizing performance and emissions. Advanced engine management software ensures seamless transition between fuel types, while a specially designed turbocharger system enhances overall efficiency. The engine incorporates high-pressure hydrogen storage and delivery systems, integrated with Mercedes' existing BlueTec emissions control technology[1][3]. This dual-fuel strategy allows for significant CO2 reduction while maintaining the power and reliability expected from large displacement engines.

Strengths: Flexibility in fuel usage, reduced CO2 emissions, leverages existing diesel engine technology. Weaknesses: Requires hydrogen infrastructure, potential higher initial costs, complexity in engine management.

GM Global Technology Operations LLC

Technical Solution: GM has developed a dual-fuel V16 engine technology focusing on natural gas and diesel combustion. Their system employs a high-pressure direct injection of natural gas, complemented by pilot diesel injection for ignition. The engine features advanced electronic control units that optimize the fuel mixture ratio in real-time, based on load demands and emissions targets. GM's design incorporates a variable geometry turbocharger to enhance low-end torque and high-end power. The combustion chamber is specially designed to promote efficient mixing of the two fuels, with piston bowl geometry optimized for dual-fuel operation. Additionally, GM has implemented a sophisticated exhaust gas recirculation (EGR) system to further reduce NOx emissions[2][5]. This technology aims to provide a bridge between conventional diesel engines and future zero-emission powertrains.

Strengths: Utilizes widely available natural gas, reduces dependence on diesel, lower emissions compared to pure diesel. Weaknesses: Requires dual fuel storage systems, potential power loss compared to pure diesel operation, complexity in fuel system management.

Innovative Dual-Fuel Combustion Technologies

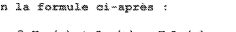

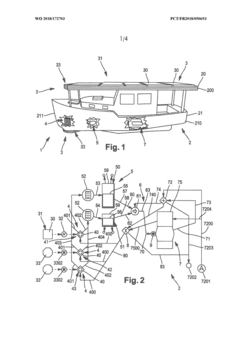

Two-stroke internal combustion engine

PatentWO2018172703A1

Innovation

- A two-stroke internal combustion engine powered by a hydrogen-oxygen gas mixture, utilizing photovoltaic panels, wind generators, and tidal turbines to produce electricity, with an exhaust gas recycling system that captures and re-injects unconsumed fuel, and a multidirectional fluid flow capture system to optimize energy capture from various orientations.

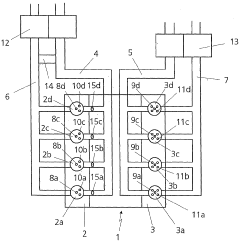

Internal combustion engine comprising deactivatable cylinders

PatentWO2003067059A1

Innovation

- The engine is designed with two banks of cylinders, where high-load cylinders can be switched off during part-load operations and equipped with higher fuel flow injectors and lower compression ratios for increased power, while low-load cylinders are optimized for reduced emissions with systems like exhaust gas recirculation and intake port shutdowns, allowing for efficient fuel use and emission control.

Emissions Regulations Impact on Engine Development

Emissions regulations have become a driving force in the development of dual-fuel V16 engines, significantly influencing design choices and technological advancements. The push for sustainable transport has led to increasingly stringent emission standards worldwide, forcing engine manufacturers to adapt their strategies and invest heavily in cleaner technologies.

The impact of these regulations is particularly evident in the evolution of dual-fuel V16 engines. These large, powerful engines, typically used in marine and stationary power applications, have been under pressure to reduce their environmental footprint. The dual-fuel capability, allowing the use of both traditional diesel and cleaner alternative fuels like natural gas, has emerged as a key solution to meet emission targets while maintaining performance.

Regulatory bodies such as the International Maritime Organization (IMO) have set ambitious goals for reducing greenhouse gas emissions from ships. The IMO's strategy aims to cut CO2 emissions from international shipping by at least 40% by 2030, compared to 2008 levels. This has spurred innovation in V16 engine design, with manufacturers focusing on improving fuel efficiency and reducing emissions across both fuel types.

The development of advanced exhaust after-treatment systems has been crucial in meeting these regulations. Selective Catalytic Reduction (SCR) technology, for instance, has been widely adopted to reduce NOx emissions. Dual-fuel V16 engines have also seen improvements in fuel injection systems and combustion chamber designs to optimize the burning of both diesel and gas fuels, resulting in lower particulate matter and CO2 emissions.

Moreover, emissions regulations have accelerated the integration of digital technologies in engine management systems. Advanced sensors and control algorithms now allow for real-time monitoring and adjustment of engine parameters, ensuring optimal performance and emissions compliance across varying operating conditions. This has led to the development of "smart" V16 engines capable of adapting to different fuel qualities and environmental conditions.

The regulatory landscape has also influenced the adoption of alternative fuels in V16 engines. Liquefied Natural Gas (LNG) has gained prominence as a cleaner alternative to diesel, with many dual-fuel V16 engines now optimized for LNG operation. This shift has required significant investments in fuel storage and delivery systems, as well as modifications to engine components to handle the different combustion characteristics of gas fuels.

As emissions regulations continue to evolve, the development of dual-fuel V16 engines is likely to focus increasingly on zero-emission technologies. This may include the integration of hydrogen fuel capabilities or the development of hybrid systems that combine internal combustion with electric propulsion. The ongoing regulatory pressure ensures that innovation in this field will remain a priority for engine manufacturers, driving the transition towards more sustainable transport solutions.

The impact of these regulations is particularly evident in the evolution of dual-fuel V16 engines. These large, powerful engines, typically used in marine and stationary power applications, have been under pressure to reduce their environmental footprint. The dual-fuel capability, allowing the use of both traditional diesel and cleaner alternative fuels like natural gas, has emerged as a key solution to meet emission targets while maintaining performance.

Regulatory bodies such as the International Maritime Organization (IMO) have set ambitious goals for reducing greenhouse gas emissions from ships. The IMO's strategy aims to cut CO2 emissions from international shipping by at least 40% by 2030, compared to 2008 levels. This has spurred innovation in V16 engine design, with manufacturers focusing on improving fuel efficiency and reducing emissions across both fuel types.

The development of advanced exhaust after-treatment systems has been crucial in meeting these regulations. Selective Catalytic Reduction (SCR) technology, for instance, has been widely adopted to reduce NOx emissions. Dual-fuel V16 engines have also seen improvements in fuel injection systems and combustion chamber designs to optimize the burning of both diesel and gas fuels, resulting in lower particulate matter and CO2 emissions.

Moreover, emissions regulations have accelerated the integration of digital technologies in engine management systems. Advanced sensors and control algorithms now allow for real-time monitoring and adjustment of engine parameters, ensuring optimal performance and emissions compliance across varying operating conditions. This has led to the development of "smart" V16 engines capable of adapting to different fuel qualities and environmental conditions.

The regulatory landscape has also influenced the adoption of alternative fuels in V16 engines. Liquefied Natural Gas (LNG) has gained prominence as a cleaner alternative to diesel, with many dual-fuel V16 engines now optimized for LNG operation. This shift has required significant investments in fuel storage and delivery systems, as well as modifications to engine components to handle the different combustion characteristics of gas fuels.

As emissions regulations continue to evolve, the development of dual-fuel V16 engines is likely to focus increasingly on zero-emission technologies. This may include the integration of hydrogen fuel capabilities or the development of hybrid systems that combine internal combustion with electric propulsion. The ongoing regulatory pressure ensures that innovation in this field will remain a priority for engine manufacturers, driving the transition towards more sustainable transport solutions.

Economic Viability of Dual-Fuel V16 Engines

The economic viability of dual-fuel V16 engines in the context of sustainable transport goals is a complex issue that requires careful analysis. These engines, which can operate on both traditional fossil fuels and alternative fuels such as natural gas or hydrogen, present both opportunities and challenges in terms of financial feasibility and environmental impact.

From a cost perspective, dual-fuel V16 engines often require a higher initial investment compared to traditional single-fuel engines. This is due to the more complex fuel delivery systems and engine management technologies required to handle multiple fuel types. However, this upfront cost can potentially be offset by lower operational expenses over the engine's lifetime, particularly if alternative fuels are more economically advantageous in certain regions or market conditions.

The flexibility of dual-fuel engines can provide a significant economic advantage in volatile fuel markets. By allowing operators to switch between fuel types based on availability and price, these engines can help mitigate the risk of fuel price fluctuations and supply chain disruptions. This adaptability can lead to substantial cost savings over time, especially for long-haul transportation and heavy-duty applications where fuel costs represent a significant portion of operational expenses.

Maintenance costs for dual-fuel V16 engines may be higher due to their increased complexity. However, advancements in engine design and materials have improved reliability and reduced maintenance intervals, potentially offsetting some of these additional costs. Furthermore, as the technology matures and becomes more widespread, economies of scale are likely to drive down both production and maintenance costs.

From an environmental standpoint, dual-fuel V16 engines can contribute to meeting sustainable transport goals by reducing greenhouse gas emissions and particulate matter when operating on cleaner alternative fuels. This alignment with sustainability objectives may provide economic benefits through compliance with emissions regulations, avoiding potential fines or restrictions, and accessing incentives or subsidies designed to promote cleaner transportation technologies.

The long-term economic viability of dual-fuel V16 engines will depend on several factors, including the development of infrastructure for alternative fuels, evolving emissions regulations, and technological advancements in competing propulsion systems such as full electric or hydrogen fuel cell technologies. As the transportation sector continues to prioritize sustainability, the ability of dual-fuel engines to serve as a transitional technology may enhance their economic appeal, providing a bridge between conventional fossil fuel-based systems and future zero-emission solutions.

From a cost perspective, dual-fuel V16 engines often require a higher initial investment compared to traditional single-fuel engines. This is due to the more complex fuel delivery systems and engine management technologies required to handle multiple fuel types. However, this upfront cost can potentially be offset by lower operational expenses over the engine's lifetime, particularly if alternative fuels are more economically advantageous in certain regions or market conditions.

The flexibility of dual-fuel engines can provide a significant economic advantage in volatile fuel markets. By allowing operators to switch between fuel types based on availability and price, these engines can help mitigate the risk of fuel price fluctuations and supply chain disruptions. This adaptability can lead to substantial cost savings over time, especially for long-haul transportation and heavy-duty applications where fuel costs represent a significant portion of operational expenses.

Maintenance costs for dual-fuel V16 engines may be higher due to their increased complexity. However, advancements in engine design and materials have improved reliability and reduced maintenance intervals, potentially offsetting some of these additional costs. Furthermore, as the technology matures and becomes more widespread, economies of scale are likely to drive down both production and maintenance costs.

From an environmental standpoint, dual-fuel V16 engines can contribute to meeting sustainable transport goals by reducing greenhouse gas emissions and particulate matter when operating on cleaner alternative fuels. This alignment with sustainability objectives may provide economic benefits through compliance with emissions regulations, avoiding potential fines or restrictions, and accessing incentives or subsidies designed to promote cleaner transportation technologies.

The long-term economic viability of dual-fuel V16 engines will depend on several factors, including the development of infrastructure for alternative fuels, evolving emissions regulations, and technological advancements in competing propulsion systems such as full electric or hydrogen fuel cell technologies. As the transportation sector continues to prioritize sustainability, the ability of dual-fuel engines to serve as a transitional technology may enhance their economic appeal, providing a bridge between conventional fossil fuel-based systems and future zero-emission solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!