Analysis of PEEK Polymer Coating Techniques for Corrosion Resistance

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PEEK Coating Technology Background and Objectives

Polyetheretherketone (PEEK) has emerged as a revolutionary polymer in the field of corrosion protection since its commercial introduction in the 1980s. This high-performance thermoplastic belongs to the polyaryletherketone family and has gained significant attention due to its exceptional chemical resistance, thermal stability, and mechanical properties. The evolution of PEEK coating technology has been driven by increasing demands for durable protection solutions in aggressive environments where traditional materials fail.

The historical development of PEEK coatings can be traced through several key milestones. Initially utilized in aerospace and semiconductor industries, PEEK's application scope has progressively expanded to include oil and gas, chemical processing, automotive, and medical sectors. This expansion correlates with advancements in polymer science and coating application techniques, particularly in the areas of powder coating, electrostatic deposition, and thermal spray methods.

Current technological trends in PEEK coating development focus on enhancing adhesion properties, improving thickness uniformity, and developing composite PEEK formulations with enhanced functionality. The incorporation of nanoparticles and the development of PEEK-based hybrid coatings represent cutting-edge approaches aimed at addressing specific performance requirements in corrosion protection.

The primary objective of PEEK coating technology research is to establish optimal application methodologies that maximize corrosion resistance while maintaining cost-effectiveness and processability. This includes investigating the relationship between processing parameters and coating performance, understanding degradation mechanisms in various environments, and developing standardized testing protocols for quality assurance.

Secondary objectives include reducing environmental impact through the development of solvent-free application techniques, improving coating repairability in field conditions, and extending service life predictions through accelerated testing methodologies. These objectives align with broader industry goals of sustainability and total cost of ownership reduction.

The technical challenges driving innovation in this field include achieving uniform coating thickness on complex geometries, enhancing adhesion to diverse substrate materials, and maintaining performance integrity under extreme temperature cycling. Additionally, researchers are addressing the need for non-destructive evaluation methods to assess coating quality and developing predictive models for long-term performance in specific corrosive environments.

As industrial requirements for corrosion protection become increasingly stringent, PEEK coating technology continues to evolve, with particular emphasis on customized solutions for specific operational environments and integration with complementary protection systems. The trajectory of development suggests a growing convergence of polymer science, surface engineering, and computational modeling to optimize coating performance and application efficiency.

The historical development of PEEK coatings can be traced through several key milestones. Initially utilized in aerospace and semiconductor industries, PEEK's application scope has progressively expanded to include oil and gas, chemical processing, automotive, and medical sectors. This expansion correlates with advancements in polymer science and coating application techniques, particularly in the areas of powder coating, electrostatic deposition, and thermal spray methods.

Current technological trends in PEEK coating development focus on enhancing adhesion properties, improving thickness uniformity, and developing composite PEEK formulations with enhanced functionality. The incorporation of nanoparticles and the development of PEEK-based hybrid coatings represent cutting-edge approaches aimed at addressing specific performance requirements in corrosion protection.

The primary objective of PEEK coating technology research is to establish optimal application methodologies that maximize corrosion resistance while maintaining cost-effectiveness and processability. This includes investigating the relationship between processing parameters and coating performance, understanding degradation mechanisms in various environments, and developing standardized testing protocols for quality assurance.

Secondary objectives include reducing environmental impact through the development of solvent-free application techniques, improving coating repairability in field conditions, and extending service life predictions through accelerated testing methodologies. These objectives align with broader industry goals of sustainability and total cost of ownership reduction.

The technical challenges driving innovation in this field include achieving uniform coating thickness on complex geometries, enhancing adhesion to diverse substrate materials, and maintaining performance integrity under extreme temperature cycling. Additionally, researchers are addressing the need for non-destructive evaluation methods to assess coating quality and developing predictive models for long-term performance in specific corrosive environments.

As industrial requirements for corrosion protection become increasingly stringent, PEEK coating technology continues to evolve, with particular emphasis on customized solutions for specific operational environments and integration with complementary protection systems. The trajectory of development suggests a growing convergence of polymer science, surface engineering, and computational modeling to optimize coating performance and application efficiency.

Market Demand Analysis for Corrosion-Resistant Coatings

The global market for corrosion-resistant coatings has been experiencing significant growth, driven by increasing awareness of the economic impact of corrosion across various industries. The annual cost of corrosion worldwide is estimated at $2.5 trillion, representing approximately 3.4% of global GDP, creating substantial demand for effective protective solutions like PEEK polymer coatings.

The oil and gas sector remains the largest consumer of corrosion-resistant coatings, accounting for roughly 28% of the market share. This industry faces severe corrosion challenges due to exposure to harsh chemicals, extreme temperatures, and high-pressure environments. PEEK coatings offer exceptional resistance to these conditions, making them increasingly attractive despite their higher initial cost compared to traditional solutions.

Aerospace and automotive industries collectively represent another 23% of market demand, where lightweight yet durable materials are essential for improving fuel efficiency while maintaining structural integrity. The chemical processing industry contributes approximately 18% to the market, requiring materials that can withstand aggressive chemical environments without degradation or contamination.

Market analysis indicates a compound annual growth rate (CAGR) of 5.8% for specialized high-performance polymer coatings like PEEK through 2028, outpacing the overall corrosion-resistant coatings market growth of 4.7%. This accelerated growth reflects the increasing preference for long-term performance over initial investment costs.

Regional demand patterns show North America and Europe currently dominating the high-performance polymer coatings market with 32% and 28% shares respectively. However, the Asia-Pacific region is experiencing the fastest growth at 7.2% annually, driven by rapid industrialization in China and India, alongside stringent environmental regulations limiting traditional coating technologies.

Customer requirements are evolving beyond mere corrosion protection to include additional functionalities such as electrical insulation, thermal stability, and reduced friction. This multi-functionality demand is particularly evident in electronics and medical device manufacturing, where PEEK's biocompatibility and sterilization resistance provide significant advantages.

Environmental regulations continue to shape market dynamics, with increasing restrictions on volatile organic compounds (VOCs) and heavy metals in coating formulations. PEEK-based solutions, being environmentally friendly alternatives to traditional coatings containing chromates and other hazardous substances, are benefiting from this regulatory trend.

The total addressable market for high-performance polymer coatings is projected to reach $17.3 billion by 2030, with PEEK-based formulations expected to capture an increasing portion due to their superior performance characteristics and growing cost-effectiveness as manufacturing processes improve and economies of scale develop.

The oil and gas sector remains the largest consumer of corrosion-resistant coatings, accounting for roughly 28% of the market share. This industry faces severe corrosion challenges due to exposure to harsh chemicals, extreme temperatures, and high-pressure environments. PEEK coatings offer exceptional resistance to these conditions, making them increasingly attractive despite their higher initial cost compared to traditional solutions.

Aerospace and automotive industries collectively represent another 23% of market demand, where lightweight yet durable materials are essential for improving fuel efficiency while maintaining structural integrity. The chemical processing industry contributes approximately 18% to the market, requiring materials that can withstand aggressive chemical environments without degradation or contamination.

Market analysis indicates a compound annual growth rate (CAGR) of 5.8% for specialized high-performance polymer coatings like PEEK through 2028, outpacing the overall corrosion-resistant coatings market growth of 4.7%. This accelerated growth reflects the increasing preference for long-term performance over initial investment costs.

Regional demand patterns show North America and Europe currently dominating the high-performance polymer coatings market with 32% and 28% shares respectively. However, the Asia-Pacific region is experiencing the fastest growth at 7.2% annually, driven by rapid industrialization in China and India, alongside stringent environmental regulations limiting traditional coating technologies.

Customer requirements are evolving beyond mere corrosion protection to include additional functionalities such as electrical insulation, thermal stability, and reduced friction. This multi-functionality demand is particularly evident in electronics and medical device manufacturing, where PEEK's biocompatibility and sterilization resistance provide significant advantages.

Environmental regulations continue to shape market dynamics, with increasing restrictions on volatile organic compounds (VOCs) and heavy metals in coating formulations. PEEK-based solutions, being environmentally friendly alternatives to traditional coatings containing chromates and other hazardous substances, are benefiting from this regulatory trend.

The total addressable market for high-performance polymer coatings is projected to reach $17.3 billion by 2030, with PEEK-based formulations expected to capture an increasing portion due to their superior performance characteristics and growing cost-effectiveness as manufacturing processes improve and economies of scale develop.

Current State and Challenges in PEEK Polymer Coating

PEEK (Polyetheretherketone) polymer coatings have emerged as a significant advancement in corrosion protection technologies globally. Currently, the application of PEEK coatings is predominantly achieved through several established techniques including powder coating, electrostatic spraying, and thermal spraying methods. Each technique offers distinct advantages in terms of coating thickness control, adhesion properties, and surface finish quality. The powder coating method has gained particular prominence due to its relatively straightforward application process and environmental friendliness, eliminating the need for volatile organic compounds.

Despite these advancements, the industry faces substantial technical challenges in PEEK coating applications. A primary obstacle remains the high processing temperature requirement (typically 370-400°C) necessary for proper PEEK melting and adhesion, which limits substrate compatibility and increases energy consumption. This temperature constraint restricts application on temperature-sensitive materials and contributes significantly to production costs.

Adhesion quality between PEEK coatings and various substrate materials presents another persistent challenge. Current surface preparation techniques, including mechanical abrasion, chemical treatments, and plasma modification, often yield inconsistent results across different substrate materials, particularly with non-metallic surfaces. The development of universal surface preparation protocols remains elusive.

Coating thickness uniformity continues to be problematic, especially for components with complex geometries or internal surfaces. Current application methods struggle to deliver consistent coating thickness across irregular shapes, leading to potential weak points in corrosion protection. Advanced application technologies capable of addressing these geometric challenges are still under development.

The durability of PEEK coatings under extreme conditions represents another significant challenge. While PEEK demonstrates excellent chemical resistance, its performance under combined stressors—such as simultaneous exposure to high temperatures, mechanical abrasion, and corrosive chemicals—requires further optimization. Current formulations may exhibit degradation under such extreme multi-factor environments.

Geographically, PEEK coating technology development is concentrated primarily in North America, Western Europe, and East Asia, with the United States, Germany, Japan, and China leading research efforts. This concentration has created disparities in technology access and implementation capabilities across different regions. Developing economies face particular challenges in adopting these advanced coating technologies due to cost barriers and technical expertise limitations.

Cost factors remain a significant impediment to widespread adoption. The high price of raw PEEK materials, coupled with energy-intensive application processes, results in substantially higher implementation costs compared to traditional coating solutions. This economic barrier has limited market penetration, particularly in price-sensitive industries and regions.

Despite these advancements, the industry faces substantial technical challenges in PEEK coating applications. A primary obstacle remains the high processing temperature requirement (typically 370-400°C) necessary for proper PEEK melting and adhesion, which limits substrate compatibility and increases energy consumption. This temperature constraint restricts application on temperature-sensitive materials and contributes significantly to production costs.

Adhesion quality between PEEK coatings and various substrate materials presents another persistent challenge. Current surface preparation techniques, including mechanical abrasion, chemical treatments, and plasma modification, often yield inconsistent results across different substrate materials, particularly with non-metallic surfaces. The development of universal surface preparation protocols remains elusive.

Coating thickness uniformity continues to be problematic, especially for components with complex geometries or internal surfaces. Current application methods struggle to deliver consistent coating thickness across irregular shapes, leading to potential weak points in corrosion protection. Advanced application technologies capable of addressing these geometric challenges are still under development.

The durability of PEEK coatings under extreme conditions represents another significant challenge. While PEEK demonstrates excellent chemical resistance, its performance under combined stressors—such as simultaneous exposure to high temperatures, mechanical abrasion, and corrosive chemicals—requires further optimization. Current formulations may exhibit degradation under such extreme multi-factor environments.

Geographically, PEEK coating technology development is concentrated primarily in North America, Western Europe, and East Asia, with the United States, Germany, Japan, and China leading research efforts. This concentration has created disparities in technology access and implementation capabilities across different regions. Developing economies face particular challenges in adopting these advanced coating technologies due to cost barriers and technical expertise limitations.

Cost factors remain a significant impediment to widespread adoption. The high price of raw PEEK materials, coupled with energy-intensive application processes, results in substantially higher implementation costs compared to traditional coating solutions. This economic barrier has limited market penetration, particularly in price-sensitive industries and regions.

Current PEEK Coating Application Techniques

01 PEEK coating composition for corrosion resistance

Polyetheretherketone (PEEK) polymer can be formulated into specialized coating compositions that provide excellent corrosion resistance for various substrates. These compositions often include PEEK as the primary polymer matrix combined with specific additives that enhance adhesion and corrosion protection properties. The formulations may incorporate cross-linking agents, stabilizers, and other polymeric components to create a durable protective barrier against corrosive environments.- PEEK coating composition for corrosion resistance: Polyetheretherketone (PEEK) polymer can be formulated into specialized coating compositions to enhance corrosion resistance. These formulations may include additives, fillers, or modified PEEK polymers that improve adhesion to substrates and provide superior protection against corrosive environments. The coating compositions are designed to maintain their protective properties even under harsh chemical and temperature conditions, making them suitable for industrial applications where metal components are exposed to corrosive agents.

- Application methods for PEEK corrosion-resistant coatings: Various techniques can be employed to apply PEEK coatings for corrosion protection, including electrostatic spraying, powder coating, and thermal spraying methods. The application process significantly influences the coating's performance, with parameters such as pre-treatment of the substrate surface, application temperature, and curing conditions being critical factors. Proper application ensures optimal adhesion, uniform thickness, and maximum corrosion resistance properties of the PEEK coating.

- Modified PEEK polymers with enhanced corrosion resistance: Chemical modification of PEEK polymers can significantly improve their corrosion resistance properties. These modifications may include incorporating functional groups, creating copolymers, or blending with other materials to enhance specific properties. Modified PEEK formulations can offer superior resistance to specific corrosive environments, such as acidic or alkaline conditions, high-temperature settings, or environments with aggressive chemicals, while maintaining the inherent mechanical properties of the base polymer.

- PEEK composite coatings for specialized corrosion protection: PEEK-based composite coatings combine the polymer with other materials such as carbon fibers, glass fibers, or ceramic particles to create enhanced corrosion-resistant systems. These composites can provide multifunctional protection, offering not only corrosion resistance but also improved wear resistance, thermal stability, and mechanical strength. The synergistic effect of the components results in superior protection for substrates in extreme environments where conventional coatings would fail.

- Testing and performance evaluation of PEEK corrosion-resistant coatings: Various methods are employed to evaluate the corrosion resistance performance of PEEK coatings, including electrochemical impedance spectroscopy, salt spray testing, and immersion tests in corrosive media. These testing protocols help determine the coating's effectiveness, durability, and lifespan under specific environmental conditions. Performance evaluation is crucial for validating the protective capabilities of PEEK coatings and ensuring they meet industry standards and application requirements before implementation in critical infrastructure or components.

02 PEEK composite coatings with reinforcing materials

PEEK polymer coatings can be enhanced by incorporating reinforcing materials such as carbon fibers, glass fibers, or ceramic particles to improve mechanical properties while maintaining corrosion resistance. These composite coatings provide superior wear resistance and mechanical strength compared to pure PEEK coatings, making them suitable for applications in harsh environments. The reinforcing materials create a more robust barrier against corrosive agents while improving the overall durability of the coating.Expand Specific Solutions03 Surface treatment methods for PEEK coatings

Various surface treatment methods can be applied to PEEK coatings to enhance their corrosion resistance properties. These methods include plasma treatment, chemical etching, and surface functionalization techniques that improve adhesion to substrates and create a more effective barrier against corrosive elements. Surface treatments can modify the surface energy of PEEK coatings, creating stronger bonds with the substrate and reducing the potential for coating delamination in corrosive environments.Expand Specific Solutions04 PEEK coating application techniques for corrosion protection

Specialized application techniques for PEEK coatings have been developed to maximize corrosion protection. These include electrostatic powder coating, fluidized bed coating, and thermal spray methods that ensure uniform coverage and optimal adhesion to substrates. The application method significantly impacts the coating's performance, with techniques that produce dense, void-free coatings providing superior corrosion resistance. Controlled cooling rates and post-application heat treatments can further enhance the crystallinity and protective properties of PEEK coatings.Expand Specific Solutions05 PEEK coatings for specific corrosive environments

PEEK polymer coatings can be specifically formulated to resist particular corrosive environments, such as acidic, alkaline, or high-temperature conditions. These specialized formulations may include specific additives or modified PEEK polymers that enhance resistance to targeted corrosive agents. For marine applications, PEEK coatings may incorporate biocides to prevent biofouling while maintaining corrosion resistance. In chemical processing industries, PEEK coatings can be modified to withstand specific chemical exposures while providing long-term protection.Expand Specific Solutions

Major Industry Players in PEEK Coating Solutions

The PEEK polymer coating market for corrosion resistance is currently in a growth phase, with increasing adoption across aerospace, medical, and industrial sectors. The global market size is estimated to exceed $1 billion, driven by demand for high-performance materials in harsh environments. Technologically, the field shows varying maturity levels, with established players like Victrex Manufacturing and Solvay Specialty Polymers leading innovation through advanced formulation techniques. Emerging competitors include Jilin Joinature Polymer and Korea Engineering Plastics, who are developing specialized applications. PetroChina and Kingfa Sci. & Tech. are expanding capabilities in industrial-scale production, while research institutions like Changsha University and Kobe University contribute to fundamental advancements in coating methodologies and performance enhancement.

Solvay Specialty Polymers USA LLC

Technical Solution: Solvay has developed advanced PEEK polymer coating techniques focusing on their KetaSpire® PEEK products. Their approach involves a proprietary plasma-enhanced chemical vapor deposition (PECVD) method that creates uniform, thin PEEK coatings with exceptional adhesion properties. The process incorporates nano-silica particles into the PEEK matrix, enhancing both mechanical strength and corrosion resistance. Their technology enables application of PEEK coatings at lower processing temperatures (around 340°C compared to traditional 380-400°C), which expands compatibility with temperature-sensitive substrates. Solvay's method also includes a post-application thermal treatment that optimizes crystallinity levels to 35-40%, balancing chemical resistance with flexibility. Their coatings demonstrate superior resistance to aggressive chemicals including H2S, CO2, and chlorides commonly found in oil and gas environments, with documented protection at temperatures up to 260°C and pressures exceeding 20,000 psi.

Strengths: Superior chemical resistance across a broad pH spectrum (1-14); excellent thermal stability allowing continuous operation in high-temperature environments; reduced processing temperatures expanding substrate compatibility. Weaknesses: Higher initial cost compared to conventional coatings; requires specialized application equipment; potential challenges with coating complex geometries uniformly.

Victrex Manufacturing Ltd.

Technical Solution: Victrex has pioneered PEEK coating solutions through their VICOTE® coating systems specifically engineered for extreme corrosion resistance applications. Their technology utilizes an electrostatic powder application method with proprietary particle size distribution (typically 20-50 μm) that enables exceptional edge coverage and uniform thickness control. The company has developed a multi-layer application technique that incorporates a primer layer with modified PEEK chemistry to enhance adhesion to various substrates including metals, ceramics, and composites. Victrex's PEEK coatings feature a unique cross-linking mechanism activated during the curing process, which significantly improves chemical resistance while maintaining flexibility. Their coatings demonstrate exceptional resistance to hydrolysis, with less than 0.5% weight gain after 5000 hours of hot water immersion at 200°C. The technology also incorporates UV stabilizers that extend coating lifetime in outdoor applications by preventing degradation from solar radiation, making it particularly valuable for marine and offshore equipment exposed to harsh environments.

Strengths: Exceptional adhesion properties across diverse substrate materials; superior resistance to hydrolysis and salt spray (>10,000 hours in ASTM B117 testing); excellent wear resistance with low friction coefficient. Weaknesses: Relatively high processing temperatures required for optimal performance; more complex application process compared to conventional coatings; higher material costs than standard industrial coatings.

Key Technical Innovations in PEEK Polymer Coatings

Coating composition having improved corrosion-resistantand abrasion-resistant properties and goods coated bythe coating composition

PatentInactiveKR1020060091391A

Innovation

- A coating composition comprising polyether ether ketone (PEEK) resin, a polyhydric alcohol, a nonionic surfactant, an organic titanium compound, and a solvent, which forms a smooth, continuous film with excellent adhesion and resistance to corrosion and abrasion, preventing pinholes through crosslinking and thermal shrinkage control.

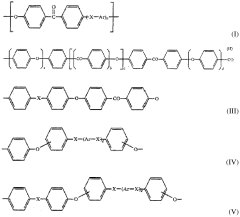

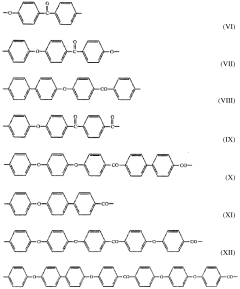

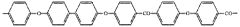

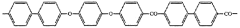

Cross-linkable poly(aryl ether ketone)s and articles made therefrom

PatentWO2009021999A1

Innovation

- Development of cross-linkable poly(aryl ether ketone)s with more than 50 wt.% of recurring units featuring carbonyl groups between arylene groups, which can be prepared through nucleophilic or electrophilic polymerization methods, allowing for the creation of thermally stable, two-dimensional shaped articles with improved mechanical and chemical resistance.

Environmental Impact Assessment of PEEK Coating Processes

The environmental impact of PEEK coating processes must be thoroughly evaluated as industries increasingly adopt these advanced polymer solutions for corrosion resistance. Traditional coating methods often involve hazardous chemicals and significant energy consumption, making environmental assessment critical for sustainable implementation.

PEEK coating processes generally demonstrate favorable environmental profiles compared to conventional metal coatings or chrome plating. The primary environmental advantages include the elimination of hexavalent chromium and other heavy metals commonly used in traditional corrosion-resistant coatings, which are known environmental pollutants and carcinogens. Additionally, PEEK coatings typically have longer service lives, reducing the frequency of reapplication and associated environmental impacts.

However, several environmental concerns remain significant. The production of PEEK raw materials requires substantial energy input, with manufacturing temperatures reaching 400°C. This energy-intensive process contributes to greenhouse gas emissions when non-renewable energy sources are utilized. Solvent-based PEEK coating methods may release volatile organic compounds (VOCs) during application and curing, potentially contributing to air pollution and ozone depletion if not properly controlled.

Waste management presents another environmental challenge. Process residues, unused materials, and end-of-life coated products require appropriate disposal protocols. While PEEK itself is thermally recyclable, coated composite products often prove difficult to separate for recycling, potentially increasing landfill burden.

Water usage and potential contamination vary significantly between different PEEK coating techniques. Electrophoretic deposition methods consume substantial water resources and may introduce contaminated wastewater requiring treatment before discharge. Powder coating approaches generally demonstrate better water conservation profiles but may generate particulate emissions requiring filtration.

Recent advancements in PEEK coating technologies show promising environmental improvements. Water-based PEEK suspensions are reducing solvent requirements, while energy-efficient curing methods like UV-assisted processing are lowering the carbon footprint of application processes. Additionally, closed-loop systems for powder recovery in spray applications have significantly reduced material waste in industrial settings.

Life cycle assessment (LCA) studies indicate that despite energy-intensive production, PEEK coatings often demonstrate net environmental benefits when considering their extended service life and elimination of hazardous substances. However, comprehensive cradle-to-grave analyses remain limited, highlighting the need for further research to quantify environmental trade-offs across different application scenarios and coating techniques.

PEEK coating processes generally demonstrate favorable environmental profiles compared to conventional metal coatings or chrome plating. The primary environmental advantages include the elimination of hexavalent chromium and other heavy metals commonly used in traditional corrosion-resistant coatings, which are known environmental pollutants and carcinogens. Additionally, PEEK coatings typically have longer service lives, reducing the frequency of reapplication and associated environmental impacts.

However, several environmental concerns remain significant. The production of PEEK raw materials requires substantial energy input, with manufacturing temperatures reaching 400°C. This energy-intensive process contributes to greenhouse gas emissions when non-renewable energy sources are utilized. Solvent-based PEEK coating methods may release volatile organic compounds (VOCs) during application and curing, potentially contributing to air pollution and ozone depletion if not properly controlled.

Waste management presents another environmental challenge. Process residues, unused materials, and end-of-life coated products require appropriate disposal protocols. While PEEK itself is thermally recyclable, coated composite products often prove difficult to separate for recycling, potentially increasing landfill burden.

Water usage and potential contamination vary significantly between different PEEK coating techniques. Electrophoretic deposition methods consume substantial water resources and may introduce contaminated wastewater requiring treatment before discharge. Powder coating approaches generally demonstrate better water conservation profiles but may generate particulate emissions requiring filtration.

Recent advancements in PEEK coating technologies show promising environmental improvements. Water-based PEEK suspensions are reducing solvent requirements, while energy-efficient curing methods like UV-assisted processing are lowering the carbon footprint of application processes. Additionally, closed-loop systems for powder recovery in spray applications have significantly reduced material waste in industrial settings.

Life cycle assessment (LCA) studies indicate that despite energy-intensive production, PEEK coatings often demonstrate net environmental benefits when considering their extended service life and elimination of hazardous substances. However, comprehensive cradle-to-grave analyses remain limited, highlighting the need for further research to quantify environmental trade-offs across different application scenarios and coating techniques.

Cost-Benefit Analysis of PEEK vs Alternative Coatings

When evaluating PEEK polymer coatings for corrosion resistance applications, cost considerations play a crucial role in determining overall feasibility. Initial investment for PEEK coating systems typically ranges from $50,000 to $200,000, significantly higher than traditional epoxy ($15,000-$40,000) or polyurethane systems ($20,000-$60,000). The material cost of PEEK powder itself averages $80-120 per kilogram, compared to $15-30 for epoxy resins and $25-45 for polyurethane compounds.

Application costs also differ substantially, with PEEK requiring specialized equipment and processing temperatures of 340-400°C, resulting in higher energy consumption. Labor costs for PEEK application average $45-65 per hour versus $30-45 for conventional coatings due to the technical expertise required. However, lifecycle analysis reveals compelling long-term advantages for PEEK coatings.

The extended service life of PEEK coatings—typically 15-20 years compared to 5-8 years for epoxies and 7-10 years for polyurethanes—creates significant maintenance savings. Downtime reduction represents another major economic benefit, with PEEK-coated components requiring replacement or maintenance approximately 60% less frequently than alternatives.

Environmental cost factors increasingly influence coating selection decisions. PEEK's minimal VOC emissions during application and excellent recyclability provide both regulatory compliance benefits and reduced environmental remediation costs. Additionally, PEEK's superior chemical resistance eliminates the need for secondary containment systems in many applications, generating further cost savings.

Risk assessment calculations demonstrate that while PEEK's initial installation costs average 2.5-3.5 times higher than conventional coatings, the total cost of ownership over a 15-year period is approximately 30-40% lower. This calculation factors in reduced maintenance interventions, extended replacement cycles, and decreased operational disruptions.

Industry-specific return on investment varies considerably. Oil and gas applications show the fastest ROI (typically 2.5-3.5 years), followed by chemical processing (3-4 years) and marine applications (3.5-5 years). The aerospace sector, despite longer ROI periods (4-6 years), often prioritizes PEEK for its weight reduction benefits and exceptional performance in extreme environments.

Recent advancements in application technologies, including electrostatic spray systems optimized for PEEK, are gradually reducing installation costs, further improving the cost-benefit ratio and expanding potential application scenarios across industries.

Application costs also differ substantially, with PEEK requiring specialized equipment and processing temperatures of 340-400°C, resulting in higher energy consumption. Labor costs for PEEK application average $45-65 per hour versus $30-45 for conventional coatings due to the technical expertise required. However, lifecycle analysis reveals compelling long-term advantages for PEEK coatings.

The extended service life of PEEK coatings—typically 15-20 years compared to 5-8 years for epoxies and 7-10 years for polyurethanes—creates significant maintenance savings. Downtime reduction represents another major economic benefit, with PEEK-coated components requiring replacement or maintenance approximately 60% less frequently than alternatives.

Environmental cost factors increasingly influence coating selection decisions. PEEK's minimal VOC emissions during application and excellent recyclability provide both regulatory compliance benefits and reduced environmental remediation costs. Additionally, PEEK's superior chemical resistance eliminates the need for secondary containment systems in many applications, generating further cost savings.

Risk assessment calculations demonstrate that while PEEK's initial installation costs average 2.5-3.5 times higher than conventional coatings, the total cost of ownership over a 15-year period is approximately 30-40% lower. This calculation factors in reduced maintenance interventions, extended replacement cycles, and decreased operational disruptions.

Industry-specific return on investment varies considerably. Oil and gas applications show the fastest ROI (typically 2.5-3.5 years), followed by chemical processing (3-4 years) and marine applications (3.5-5 years). The aerospace sector, despite longer ROI periods (4-6 years), often prioritizes PEEK for its weight reduction benefits and exceptional performance in extreme environments.

Recent advancements in application technologies, including electrostatic spray systems optimized for PEEK, are gradually reducing installation costs, further improving the cost-benefit ratio and expanding potential application scenarios across industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!