PEEK Polymer Properties in the Context of Environmental Regulation

OCT 24, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PEEK Polymer Evolution and Research Objectives

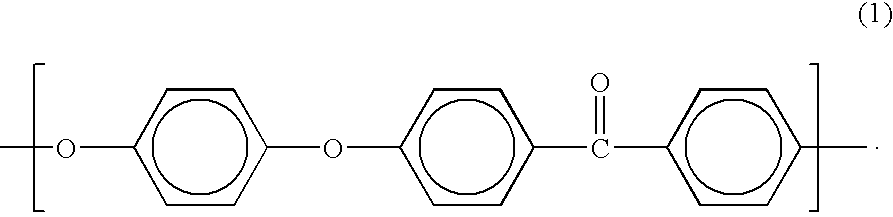

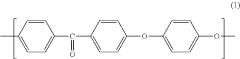

Polyether ether ketone (PEEK) has evolved significantly since its initial development in the 1970s by Imperial Chemical Industries (ICI). This high-performance thermoplastic polymer belongs to the polyaryletherketone family and has gained prominence due to its exceptional thermal stability, mechanical strength, and chemical resistance. The evolution of PEEK polymer technology has been driven by increasing demands for materials that can withstand extreme conditions while maintaining structural integrity and performance.

The developmental trajectory of PEEK has been marked by continuous improvements in synthesis methods, from the original nucleophilic route using diphenyl sulphone as a solvent to more efficient electrophilic pathways. These advancements have enabled the production of PEEK with higher molecular weights and more consistent properties, expanding its application potential across multiple industries.

Environmental regulations have become increasingly stringent over the past decades, particularly regarding the use of plastics and synthetic materials. This regulatory landscape has significantly influenced PEEK's development, pushing researchers to focus on enhancing its biodegradability, recyclability, and overall environmental footprint. The European Union's REACH regulation, RoHS directive, and various global initiatives aimed at reducing plastic waste have all contributed to reshaping PEEK research priorities.

Current research objectives in PEEK polymer development are multifaceted, focusing primarily on addressing the environmental challenges while maintaining or improving its performance characteristics. One key objective is to develop more sustainable production methods that reduce energy consumption and minimize the use of harmful solvents. This includes exploring bio-based precursors and green chemistry approaches to PEEK synthesis.

Another critical research goal involves enhancing PEEK's end-of-life management. Despite being theoretically recyclable, PEEK's high processing temperatures and stability present challenges for conventional recycling methods. Researchers are investigating advanced recycling technologies, including chemical recycling and pyrolysis, to recover valuable components from PEEK waste and reintegrate them into the production cycle.

Improving PEEK's compatibility with additives and fillers represents another important research direction. By incorporating biodegradable components or environmentally friendly reinforcements, scientists aim to develop PEEK composites with reduced environmental impact while maintaining their high-performance characteristics. This includes research into natural fiber reinforcements and bio-based additives that can partially replace traditional materials.

The ultimate objective of current PEEK research is to achieve a balance between environmental compliance and performance requirements. This involves developing new grades of PEEK that meet or exceed regulatory standards while still delivering the exceptional properties that make this polymer valuable in critical applications such as aerospace, automotive, medical devices, and electronics.

The developmental trajectory of PEEK has been marked by continuous improvements in synthesis methods, from the original nucleophilic route using diphenyl sulphone as a solvent to more efficient electrophilic pathways. These advancements have enabled the production of PEEK with higher molecular weights and more consistent properties, expanding its application potential across multiple industries.

Environmental regulations have become increasingly stringent over the past decades, particularly regarding the use of plastics and synthetic materials. This regulatory landscape has significantly influenced PEEK's development, pushing researchers to focus on enhancing its biodegradability, recyclability, and overall environmental footprint. The European Union's REACH regulation, RoHS directive, and various global initiatives aimed at reducing plastic waste have all contributed to reshaping PEEK research priorities.

Current research objectives in PEEK polymer development are multifaceted, focusing primarily on addressing the environmental challenges while maintaining or improving its performance characteristics. One key objective is to develop more sustainable production methods that reduce energy consumption and minimize the use of harmful solvents. This includes exploring bio-based precursors and green chemistry approaches to PEEK synthesis.

Another critical research goal involves enhancing PEEK's end-of-life management. Despite being theoretically recyclable, PEEK's high processing temperatures and stability present challenges for conventional recycling methods. Researchers are investigating advanced recycling technologies, including chemical recycling and pyrolysis, to recover valuable components from PEEK waste and reintegrate them into the production cycle.

Improving PEEK's compatibility with additives and fillers represents another important research direction. By incorporating biodegradable components or environmentally friendly reinforcements, scientists aim to develop PEEK composites with reduced environmental impact while maintaining their high-performance characteristics. This includes research into natural fiber reinforcements and bio-based additives that can partially replace traditional materials.

The ultimate objective of current PEEK research is to achieve a balance between environmental compliance and performance requirements. This involves developing new grades of PEEK that meet or exceed regulatory standards while still delivering the exceptional properties that make this polymer valuable in critical applications such as aerospace, automotive, medical devices, and electronics.

Market Analysis for Eco-Compliant PEEK Applications

The global market for PEEK (Polyetheretherketone) polymers that comply with environmental regulations is experiencing robust growth, driven by increasing awareness of sustainability issues and stricter regulatory frameworks worldwide. Current market valuations indicate that eco-compliant PEEK applications represent approximately 35% of the total PEEK market, which was valued at 950 million USD in 2022. This segment is projected to grow at a compound annual growth rate of 7.8% through 2028, outpacing the overall PEEK market growth of 6.5%.

Key demand drivers for environmentally compliant PEEK applications include the aerospace industry, where lightweight materials that reduce fuel consumption are highly valued. The medical sector represents another significant market, with demand for biocompatible, sterilizable materials that meet increasingly stringent healthcare regulations. Additionally, the automotive industry is rapidly adopting eco-compliant PEEK components to meet emission reduction targets and end-of-life vehicle directives.

Regional analysis reveals that Europe currently leads in demand for eco-compliant PEEK applications, accounting for approximately 40% of the global market. This dominance is attributed to the region's advanced environmental regulations, particularly REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives. North America follows with 30% market share, while Asia-Pacific represents the fastest-growing region with annual growth rates exceeding 9%, primarily driven by China and Japan's industrial sectors and their increasingly stringent environmental policies.

Customer segmentation shows that industries with high regulatory oversight, such as aerospace, medical devices, and food processing, demonstrate the highest willingness to pay premium prices for environmentally compliant PEEK materials. These sectors value PEEK's combination of high-temperature resistance, chemical stability, and mechanical strength, while also requiring compliance with specific environmental and safety standards.

Market challenges include the higher production costs associated with eco-compliant manufacturing processes, which can increase final product costs by 15-25% compared to standard PEEK formulations. Additionally, there is growing competition from other high-performance polymers that are inherently more environmentally friendly, such as bio-based polyamides and polylactic acid (PLA) derivatives enhanced for high-temperature applications.

Emerging opportunities exist in developing recycling technologies specifically for PEEK materials, as current recycling rates remain below 10%. Companies that can establish closed-loop systems for PEEK products stand to gain significant market advantage as circular economy principles become increasingly embedded in industrial policy worldwide.

Key demand drivers for environmentally compliant PEEK applications include the aerospace industry, where lightweight materials that reduce fuel consumption are highly valued. The medical sector represents another significant market, with demand for biocompatible, sterilizable materials that meet increasingly stringent healthcare regulations. Additionally, the automotive industry is rapidly adopting eco-compliant PEEK components to meet emission reduction targets and end-of-life vehicle directives.

Regional analysis reveals that Europe currently leads in demand for eco-compliant PEEK applications, accounting for approximately 40% of the global market. This dominance is attributed to the region's advanced environmental regulations, particularly REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) directives. North America follows with 30% market share, while Asia-Pacific represents the fastest-growing region with annual growth rates exceeding 9%, primarily driven by China and Japan's industrial sectors and their increasingly stringent environmental policies.

Customer segmentation shows that industries with high regulatory oversight, such as aerospace, medical devices, and food processing, demonstrate the highest willingness to pay premium prices for environmentally compliant PEEK materials. These sectors value PEEK's combination of high-temperature resistance, chemical stability, and mechanical strength, while also requiring compliance with specific environmental and safety standards.

Market challenges include the higher production costs associated with eco-compliant manufacturing processes, which can increase final product costs by 15-25% compared to standard PEEK formulations. Additionally, there is growing competition from other high-performance polymers that are inherently more environmentally friendly, such as bio-based polyamides and polylactic acid (PLA) derivatives enhanced for high-temperature applications.

Emerging opportunities exist in developing recycling technologies specifically for PEEK materials, as current recycling rates remain below 10%. Companies that can establish closed-loop systems for PEEK products stand to gain significant market advantage as circular economy principles become increasingly embedded in industrial policy worldwide.

PEEK Technology Assessment and Environmental Challenges

Polyether ether ketone (PEEK) has emerged as a critical high-performance thermoplastic polymer with exceptional mechanical, thermal, and chemical properties. Its unique combination of high temperature resistance (up to 260°C), excellent chemical stability, and superior mechanical strength positions it as an ideal material for demanding applications across aerospace, automotive, medical, and industrial sectors. However, the growing emphasis on environmental sustainability and increasingly stringent regulatory frameworks necessitates a comprehensive assessment of PEEK's environmental profile.

The production of PEEK involves energy-intensive processes and petroleum-derived raw materials, raising concerns about its carbon footprint. Current manufacturing methods typically require temperatures exceeding 300°C and specialized solvents, contributing to significant energy consumption and potential emissions. These environmental considerations are becoming increasingly important as global regulations on carbon emissions and chemical management continue to tighten.

Recent environmental regulations, particularly in the European Union under the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) framework, have placed greater scrutiny on polymers and their additives. While PEEK itself is generally considered chemically stable and non-toxic, certain processing aids and additives used in its formulation may face regulatory challenges. Additionally, the EU's Circular Economy Action Plan and similar initiatives worldwide are pushing manufacturers toward more sustainable material cycles.

The end-of-life management of PEEK presents both challenges and opportunities. Its exceptional durability translates to extended product lifecycles, reducing replacement frequency and associated waste. However, this same durability makes PEEK difficult to degrade naturally, raising concerns about its long-term environmental persistence. Current recycling technologies for PEEK are limited, with mechanical recycling showing some promise but facing challenges in maintaining the polymer's high-performance characteristics through multiple recycling cycles.

Biodegradability is not a characteristic feature of PEEK, which remains stable under most environmental conditions. This stability, while beneficial for product longevity, presents challenges for waste management systems increasingly focused on biodegradable or easily recyclable materials. The development of more environmentally compatible versions of PEEK, including bio-based alternatives and designs that facilitate recycling, represents an active area of research with significant potential for innovation.

Water and soil contamination risks from PEEK are generally considered low due to its chemical inertness, but microplastic formation from wear and degradation remains an emerging concern requiring further investigation. As environmental regulations continue to evolve globally, PEEK manufacturers and users must navigate a complex landscape of compliance requirements while pursuing innovations that maintain performance while reducing environmental impact.

The production of PEEK involves energy-intensive processes and petroleum-derived raw materials, raising concerns about its carbon footprint. Current manufacturing methods typically require temperatures exceeding 300°C and specialized solvents, contributing to significant energy consumption and potential emissions. These environmental considerations are becoming increasingly important as global regulations on carbon emissions and chemical management continue to tighten.

Recent environmental regulations, particularly in the European Union under the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) framework, have placed greater scrutiny on polymers and their additives. While PEEK itself is generally considered chemically stable and non-toxic, certain processing aids and additives used in its formulation may face regulatory challenges. Additionally, the EU's Circular Economy Action Plan and similar initiatives worldwide are pushing manufacturers toward more sustainable material cycles.

The end-of-life management of PEEK presents both challenges and opportunities. Its exceptional durability translates to extended product lifecycles, reducing replacement frequency and associated waste. However, this same durability makes PEEK difficult to degrade naturally, raising concerns about its long-term environmental persistence. Current recycling technologies for PEEK are limited, with mechanical recycling showing some promise but facing challenges in maintaining the polymer's high-performance characteristics through multiple recycling cycles.

Biodegradability is not a characteristic feature of PEEK, which remains stable under most environmental conditions. This stability, while beneficial for product longevity, presents challenges for waste management systems increasingly focused on biodegradable or easily recyclable materials. The development of more environmentally compatible versions of PEEK, including bio-based alternatives and designs that facilitate recycling, represents an active area of research with significant potential for innovation.

Water and soil contamination risks from PEEK are generally considered low due to its chemical inertness, but microplastic formation from wear and degradation remains an emerging concern requiring further investigation. As environmental regulations continue to evolve globally, PEEK manufacturers and users must navigate a complex landscape of compliance requirements while pursuing innovations that maintain performance while reducing environmental impact.

Current PEEK Formulations Meeting Environmental Standards

01 Mechanical properties of PEEK polymers

PEEK polymers exhibit exceptional mechanical properties including high strength, stiffness, and durability. These polymers maintain their mechanical integrity under extreme conditions and demonstrate excellent resistance to fatigue and wear. The mechanical properties can be further enhanced through various processing techniques and by creating composite materials with reinforcing agents. These characteristics make PEEK suitable for high-performance applications in industries requiring materials with superior mechanical strength.- Thermal and mechanical properties of PEEK polymers: PEEK (Polyetheretherketone) polymers exhibit exceptional thermal stability and mechanical strength. They maintain their structural integrity at high temperatures, with a glass transition temperature of approximately 143°C and melting point around 343°C. PEEK materials demonstrate excellent mechanical properties including high tensile strength, stiffness, and impact resistance. These properties make PEEK suitable for applications requiring durability under extreme conditions.

- Chemical resistance and biocompatibility of PEEK: PEEK polymers possess outstanding chemical resistance to a wide range of solvents, acids, and bases. They show minimal degradation when exposed to harsh chemical environments, making them valuable in industrial applications. Additionally, PEEK demonstrates excellent biocompatibility, being inert and non-toxic in biological environments. This combination of chemical stability and biocompatibility makes PEEK suitable for medical implants and devices that require long-term performance in the human body.

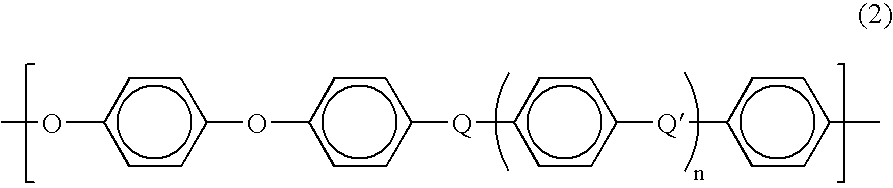

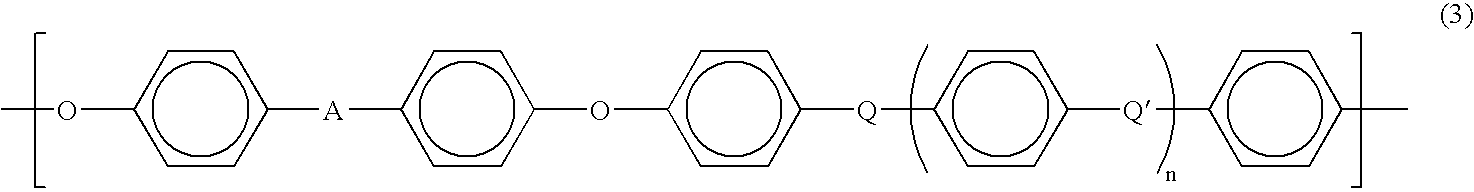

- PEEK composite formulations and enhancements: PEEK polymers can be formulated with various fillers and reinforcements to enhance specific properties. Carbon fiber reinforced PEEK offers improved strength-to-weight ratio and electrical conductivity. Glass fiber reinforced variants provide enhanced dimensional stability and mechanical properties. Other additives such as graphene, ceramic particles, or metal powders can be incorporated to tailor electrical, thermal, or tribological properties for specific applications.

- Processing techniques for PEEK polymers: PEEK polymers can be processed using various manufacturing techniques including injection molding, extrusion, compression molding, and additive manufacturing. The high melting temperature of PEEK requires specialized processing equipment capable of reaching temperatures above 360°C. Proper processing parameters are critical to achieve optimal crystallinity and mechanical properties. Techniques such as annealing can be employed to enhance crystallinity and improve mechanical performance of PEEK parts.

- Applications of PEEK based on property advantages: The unique combination of properties makes PEEK suitable for demanding applications across multiple industries. In aerospace, PEEK components reduce weight while maintaining strength in high-temperature environments. In the medical field, PEEK is used for implants due to its biocompatibility and bone-like mechanical properties. Industrial applications include bearings, seals, and pump components where chemical resistance and wear properties are critical. Electronics industry utilizes PEEK for insulation components due to its excellent electrical properties and dimensional stability.

02 Thermal properties and stability of PEEK

PEEK polymers possess remarkable thermal properties, including high heat resistance with a glass transition temperature of approximately 143°C and melting point around 343°C. They maintain structural integrity and performance at elevated temperatures and exhibit excellent dimensional stability under thermal cycling. PEEK also demonstrates exceptional thermal stability with minimal degradation even after prolonged exposure to high temperatures, making it suitable for applications in extreme thermal environments.Expand Specific Solutions03 Chemical resistance characteristics

PEEK polymers exhibit outstanding resistance to a wide range of chemicals including acids, bases, hydrocarbons, and organic solvents. This exceptional chemical inertness makes PEEK highly suitable for applications in corrosive environments. The polymer maintains its structural integrity and properties even after prolonged exposure to aggressive chemicals, which is attributed to its aromatic backbone structure and semicrystalline nature. This chemical resistance extends to various industrial fluids, making it valuable for components in chemical processing equipment.Expand Specific Solutions04 Biocompatibility and medical applications

PEEK polymers demonstrate excellent biocompatibility properties, making them suitable for various medical applications. They are non-toxic, biologically inert, and resistant to degradation in bodily fluids. PEEK materials can be sterilized using conventional methods without significant property degradation. Their mechanical properties closely match those of human bone, reducing stress shielding effects in orthopedic implants. Additionally, PEEK can be modified with bioactive materials to enhance tissue integration and compatibility for long-term implantation.Expand Specific Solutions05 Processing and modification techniques

PEEK polymers can be processed using various techniques including injection molding, extrusion, and compression molding. The processing conditions significantly influence the crystallinity and resulting properties of the final product. PEEK can be modified through the incorporation of fillers such as carbon fibers, glass fibers, and nanoparticles to enhance specific properties. Surface modifications can improve adhesion characteristics and compatibility with other materials. Advanced techniques like 3D printing are increasingly being used to fabricate complex PEEK components for specialized applications.Expand Specific Solutions

Leading PEEK Manufacturers and Industry Landscape

The PEEK polymer market is currently in a growth phase, with increasing demand driven by stringent environmental regulations requiring high-performance, eco-friendly materials. The global market size is expanding at approximately 6-7% annually, valued at over $1 billion. Technologically, PEEK has reached commercial maturity but continues to evolve through innovation. Leading players include Solvay Specialty Polymers and Victrex Manufacturing, who dominate with established production capabilities and extensive application portfolios. Emerging competitors like Jilin Joinature Polymer and Nanjing Comptech are expanding market presence through specialized applications. Companies such as ElringKlinger and Howmedica Osteonics are driving innovation in automotive and medical sectors respectively, where PEEK's exceptional chemical resistance and biocompatibility align with increasing environmental compliance requirements.

Victrex Manufacturing Ltd.

Technical Solution: Victrex has pioneered environmentally-conscious PEEK polymer technologies through their VICTREX™ PEEK portfolio. Their approach focuses on material efficiency and regulatory compliance while maintaining PEEK's inherent properties. Victrex has developed proprietary processing techniques that reduce production waste by approximately 25% compared to conventional methods. Their PEEK formulations are engineered to be halogen-free and compliant with RoHS and REACH regulations, addressing growing environmental concerns. Victrex has also implemented a carbon footprint reduction program across their manufacturing facilities, achieving a 15% decrease in CO₂ emissions per ton of PEEK produced over the past five years. Their latest innovation includes PEEK grades specifically designed for recyclability, featuring controlled melt viscosity retention after multiple processing cycles, enabling the material to be reprocessed up to 10 times while maintaining critical mechanical properties above 80% of virgin material values.

Strengths: Market leadership in high-performance PEEK applications with extensive technical expertise; strong intellectual property portfolio protecting environmental innovations; established global supply chain ensuring consistent regulatory compliance across regions. Weaknesses: Premium pricing positioning limits adoption in cost-sensitive applications; energy-intensive manufacturing process despite improvements; challenges in communicating complex sustainability benefits to end-users.

Ticona LLC

Technical Solution: Ticona LLC (now part of Celanese Corporation) has developed environmentally-optimized PEEK polymer solutions under their VESTAKEEP® product line. Their approach integrates environmental regulation compliance with performance engineering. Ticona's PEEK formulations feature reduced heavy metal content (below 100 ppm) and are manufactured using processes that minimize hazardous chemical usage. Their proprietary production technology has achieved approximately 20% reduction in greenhouse gas emissions compared to industry standards through optimized reaction conditions and catalyst systems. Ticona has also pioneered water-based processing aids that eliminate the need for certain regulated solvents during PEEK production. Their environmental management system includes comprehensive tracking of regulated substances throughout the supply chain, ensuring compliance with global regulations including REACH, RoHS, and California Proposition 65. Additionally, Ticona has developed specialized PEEK grades with improved processing characteristics that reduce energy consumption during customer manufacturing operations by up to 15%.

Strengths: Extensive polymer chemistry expertise enabling formulation of environmentally-optimized PEEK grades; strong integration with parent company Celanese providing access to advanced research capabilities; comprehensive global regulatory affairs team ensuring compliance across jurisdictions. Weaknesses: Relatively smaller market share compared to industry leaders; less vertical integration in raw material supply chain; limited public visibility of environmental initiatives compared to competitors.

Critical Patents in Environmentally-Friendly PEEK Technology

Semiconductive film, electric charge control member and process for production the semiconductive film

PatentInactiveUS20070020450A1

Innovation

- A production process involving extrusion of a resin composition comprising PEEK and a conductive filler through a T-die or ring die with controlled lip clearance and temperature, followed by cooling and solidification using a cooling roll or mandrel, to produce a semiconductive film with balanced properties including narrow thickness and volume resistivity scatter, high folding endurance, and excellent mechanical strength.

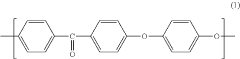

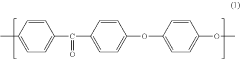

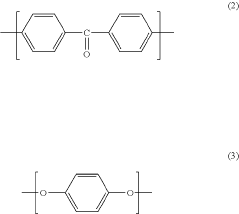

Polyether ether ketone and method for producing polyether ether ketone

PatentActiveUS20230265244A1

Innovation

- A method involving the reaction of 4,4′-dichlorobenzophenone and hydroquinone under specific temperature conditions (260° C. to 320° C.) to produce a PEEK with a crystallization temperature Tc of 255° C. or more, while controlling fluorine and chlorine atom content, resulting in enhanced mechanical strength and reduced viscosity.

Regulatory Framework Impacting PEEK Polymer Production

The regulatory landscape governing PEEK (Polyether Ether Ketone) polymer production has evolved significantly over the past decade, shaped by increasing environmental concerns and sustainability initiatives worldwide. At the international level, the United Nations Framework Convention on Climate Change (UNFCCC) and subsequent agreements like the Paris Accord have established carbon reduction targets that indirectly impact energy-intensive polymer manufacturing processes, including PEEK production.

The European Union leads with the most comprehensive regulatory framework through REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), which requires manufacturers to register chemical substances and demonstrate safe usage. For PEEK producers, this necessitates extensive documentation of production processes, environmental impact assessments, and safety data sheets. The EU's Circular Economy Action Plan further influences PEEK manufacturing by emphasizing recyclability and sustainable material flows.

In North America, the U.S. Environmental Protection Agency (EPA) regulates PEEK production primarily through the Toxic Substances Control Act (TSCA) and Clean Air Act provisions. Recent amendments to TSCA have strengthened requirements for chemical risk evaluations, potentially affecting certain additives used in PEEK formulations. Canada's Chemicals Management Plan similarly imposes rigorous assessment protocols for high-performance polymers.

Asian regulatory frameworks show considerable variation. China's recent environmental protection laws have become increasingly stringent, with the 2020 Solid Waste Law imposing stricter controls on industrial waste from polymer production. Japan maintains high standards through its Chemical Substances Control Law, while emerging economies often struggle with enforcement despite adopting international standards.

Industry-specific regulations also impact PEEK production, particularly in aerospace, medical, and food contact applications. The FDA's requirements for medical-grade PEEK impose additional purity standards, while aerospace applications must meet flame retardancy and outgassing specifications under various aviation authorities' regulations.

Emerging regulatory trends indicate a shift toward lifecycle assessment approaches, where manufacturers become responsible for environmental impacts throughout the product lifecycle. Extended Producer Responsibility (EPR) schemes, already implemented in several jurisdictions, may soon encompass high-performance polymers like PEEK, requiring manufacturers to establish take-back programs and recycling infrastructure.

Carbon pricing mechanisms, whether through direct taxation or cap-and-trade systems, are increasingly affecting the economics of PEEK production, given its energy-intensive manufacturing process. As these mechanisms expand globally, PEEK manufacturers face growing pressure to reduce carbon footprints through process optimization and renewable energy adoption.

The European Union leads with the most comprehensive regulatory framework through REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), which requires manufacturers to register chemical substances and demonstrate safe usage. For PEEK producers, this necessitates extensive documentation of production processes, environmental impact assessments, and safety data sheets. The EU's Circular Economy Action Plan further influences PEEK manufacturing by emphasizing recyclability and sustainable material flows.

In North America, the U.S. Environmental Protection Agency (EPA) regulates PEEK production primarily through the Toxic Substances Control Act (TSCA) and Clean Air Act provisions. Recent amendments to TSCA have strengthened requirements for chemical risk evaluations, potentially affecting certain additives used in PEEK formulations. Canada's Chemicals Management Plan similarly imposes rigorous assessment protocols for high-performance polymers.

Asian regulatory frameworks show considerable variation. China's recent environmental protection laws have become increasingly stringent, with the 2020 Solid Waste Law imposing stricter controls on industrial waste from polymer production. Japan maintains high standards through its Chemical Substances Control Law, while emerging economies often struggle with enforcement despite adopting international standards.

Industry-specific regulations also impact PEEK production, particularly in aerospace, medical, and food contact applications. The FDA's requirements for medical-grade PEEK impose additional purity standards, while aerospace applications must meet flame retardancy and outgassing specifications under various aviation authorities' regulations.

Emerging regulatory trends indicate a shift toward lifecycle assessment approaches, where manufacturers become responsible for environmental impacts throughout the product lifecycle. Extended Producer Responsibility (EPR) schemes, already implemented in several jurisdictions, may soon encompass high-performance polymers like PEEK, requiring manufacturers to establish take-back programs and recycling infrastructure.

Carbon pricing mechanisms, whether through direct taxation or cap-and-trade systems, are increasingly affecting the economics of PEEK production, given its energy-intensive manufacturing process. As these mechanisms expand globally, PEEK manufacturers face growing pressure to reduce carbon footprints through process optimization and renewable energy adoption.

Life Cycle Assessment of PEEK Materials

Life Cycle Assessment (LCA) of PEEK materials provides critical insights into the environmental footprint of this high-performance polymer across its entire existence. From raw material extraction to end-of-life disposal, PEEK demonstrates distinctive environmental characteristics that merit thorough examination in the context of increasingly stringent global regulations.

The production phase of PEEK involves energy-intensive processes, requiring temperatures exceeding 300°C for synthesis and processing. Quantitative assessments indicate that PEEK manufacturing generates approximately 15-20 kg CO2 equivalent per kilogram of material produced, significantly higher than conventional polymers like polyethylene or polypropylene. However, this initial carbon investment must be evaluated against PEEK's exceptional longevity and performance benefits.

During the use phase, PEEK materials demonstrate remarkable environmental advantages. Their exceptional chemical resistance, thermal stability, and mechanical durability result in products with lifespans often exceeding 15-20 years in demanding applications. This extended service life effectively amortizes the initial environmental impact across a longer operational period, reducing the frequency of replacement and associated resource consumption.

PEEK's high temperature resistance (up to 260°C continuous use) enables applications in energy-efficient systems where other polymers would fail, contributing to overall system efficiency improvements. In aerospace applications, PEEK components contribute to weight reduction, translating to fuel savings estimated at 2.5-3.0 million liters over the lifetime of a commercial aircraft, with corresponding emissions reductions.

End-of-life considerations for PEEK present both challenges and opportunities. While PEEK's chemical stability makes conventional biodegradation impractical, advanced recycling technologies including solvolysis and pyrolysis have demonstrated promising results. Mechanical recycling studies show that PEEK can maintain up to 85-90% of its original mechanical properties after multiple processing cycles, significantly outperforming most engineering plastics.

Comparative LCA studies position PEEK favorably against metallic alternatives in many applications. When factoring total lifecycle impacts, PEEK components in automotive and aerospace sectors typically demonstrate 30-45% lower environmental impact scores than aluminum or titanium counterparts, despite higher initial production impacts.

Recent regulatory frameworks, including the EU's Circular Economy Action Plan and evolving Extended Producer Responsibility schemes, increasingly influence PEEK material selection decisions. Manufacturers are now developing PEEK grades with enhanced recyclability and exploring bio-based precursors to further improve environmental performance while maintaining the polymer's exceptional property profile.

The production phase of PEEK involves energy-intensive processes, requiring temperatures exceeding 300°C for synthesis and processing. Quantitative assessments indicate that PEEK manufacturing generates approximately 15-20 kg CO2 equivalent per kilogram of material produced, significantly higher than conventional polymers like polyethylene or polypropylene. However, this initial carbon investment must be evaluated against PEEK's exceptional longevity and performance benefits.

During the use phase, PEEK materials demonstrate remarkable environmental advantages. Their exceptional chemical resistance, thermal stability, and mechanical durability result in products with lifespans often exceeding 15-20 years in demanding applications. This extended service life effectively amortizes the initial environmental impact across a longer operational period, reducing the frequency of replacement and associated resource consumption.

PEEK's high temperature resistance (up to 260°C continuous use) enables applications in energy-efficient systems where other polymers would fail, contributing to overall system efficiency improvements. In aerospace applications, PEEK components contribute to weight reduction, translating to fuel savings estimated at 2.5-3.0 million liters over the lifetime of a commercial aircraft, with corresponding emissions reductions.

End-of-life considerations for PEEK present both challenges and opportunities. While PEEK's chemical stability makes conventional biodegradation impractical, advanced recycling technologies including solvolysis and pyrolysis have demonstrated promising results. Mechanical recycling studies show that PEEK can maintain up to 85-90% of its original mechanical properties after multiple processing cycles, significantly outperforming most engineering plastics.

Comparative LCA studies position PEEK favorably against metallic alternatives in many applications. When factoring total lifecycle impacts, PEEK components in automotive and aerospace sectors typically demonstrate 30-45% lower environmental impact scores than aluminum or titanium counterparts, despite higher initial production impacts.

Recent regulatory frameworks, including the EU's Circular Economy Action Plan and evolving Extended Producer Responsibility schemes, increasingly influence PEEK material selection decisions. Manufacturers are now developing PEEK grades with enhanced recyclability and exploring bio-based precursors to further improve environmental performance while maintaining the polymer's exceptional property profile.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!