Why Are PEEK Polymer Properties Vital in 3D Printing Industries?

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PEEK Polymer Evolution and Objectives

Polyether ether ketone (PEEK) has emerged as a revolutionary material in the additive manufacturing landscape, representing a significant advancement from traditional polymers used in 3D printing. First synthesized in the late 1970s by Imperial Chemical Industries (ICI), PEEK was initially developed for aerospace and automotive applications due to its exceptional thermal stability and mechanical properties. The evolution of PEEK polymer technology has been marked by continuous improvements in processing techniques and formulation, enabling its transition from conventional manufacturing methods to advanced 3D printing applications.

The historical trajectory of PEEK in additive manufacturing began in the early 2000s when researchers started exploring high-performance polymers for industrial 3D printing applications. This exploration was driven by the limitations of conventional thermoplastics like ABS and PLA, which could not meet the demanding requirements of functional end-use parts in critical industries. The technical evolution accelerated around 2010-2015 when specialized 3D printing systems capable of processing high-temperature polymers were developed, opening new possibilities for PEEK utilization.

Current technological advancements focus on enhancing PEEK's printability while maintaining its inherent superior properties. This includes the development of specialized PEEK filaments with optimized melt flow characteristics, composite PEEK materials reinforced with carbon or glass fibers, and modified printing parameters to ensure consistent layer adhesion and minimal warping. These innovations aim to address the challenging processing requirements of PEEK, which demands precise temperature control and specialized printing environments.

The primary objective of PEEK polymer development in 3D printing industries is to enable the production of high-performance functional components that can withstand extreme operating conditions. This includes parts exposed to high temperatures (up to 260°C continuous use), aggressive chemicals, and significant mechanical stress. Additionally, there is a growing focus on biocompatible PEEK formulations for medical applications, particularly in implantable devices and surgical instruments.

Future development goals include improving the cost-effectiveness of PEEK 3D printing processes, expanding the range of compatible printing technologies beyond fused filament fabrication (FFF) to include selective laser sintering (SLS) and other methods, and developing hybrid PEEK materials with enhanced properties. Research is also directed toward reducing the energy consumption associated with PEEK processing while maintaining its exceptional performance characteristics.

The strategic importance of PEEK in additive manufacturing lies in its potential to bridge the gap between prototype production and functional end-use parts, particularly in industries where performance cannot be compromised. As manufacturing trends continue to shift toward customization and on-demand production, PEEK's role in enabling high-performance 3D printed components is expected to grow substantially, driving further innovation in this specialized polymer technology.

The historical trajectory of PEEK in additive manufacturing began in the early 2000s when researchers started exploring high-performance polymers for industrial 3D printing applications. This exploration was driven by the limitations of conventional thermoplastics like ABS and PLA, which could not meet the demanding requirements of functional end-use parts in critical industries. The technical evolution accelerated around 2010-2015 when specialized 3D printing systems capable of processing high-temperature polymers were developed, opening new possibilities for PEEK utilization.

Current technological advancements focus on enhancing PEEK's printability while maintaining its inherent superior properties. This includes the development of specialized PEEK filaments with optimized melt flow characteristics, composite PEEK materials reinforced with carbon or glass fibers, and modified printing parameters to ensure consistent layer adhesion and minimal warping. These innovations aim to address the challenging processing requirements of PEEK, which demands precise temperature control and specialized printing environments.

The primary objective of PEEK polymer development in 3D printing industries is to enable the production of high-performance functional components that can withstand extreme operating conditions. This includes parts exposed to high temperatures (up to 260°C continuous use), aggressive chemicals, and significant mechanical stress. Additionally, there is a growing focus on biocompatible PEEK formulations for medical applications, particularly in implantable devices and surgical instruments.

Future development goals include improving the cost-effectiveness of PEEK 3D printing processes, expanding the range of compatible printing technologies beyond fused filament fabrication (FFF) to include selective laser sintering (SLS) and other methods, and developing hybrid PEEK materials with enhanced properties. Research is also directed toward reducing the energy consumption associated with PEEK processing while maintaining its exceptional performance characteristics.

The strategic importance of PEEK in additive manufacturing lies in its potential to bridge the gap between prototype production and functional end-use parts, particularly in industries where performance cannot be compromised. As manufacturing trends continue to shift toward customization and on-demand production, PEEK's role in enabling high-performance 3D printed components is expected to grow substantially, driving further innovation in this specialized polymer technology.

3D Printing Market Demand for High-Performance Polymers

The 3D printing industry has witnessed a significant shift towards high-performance polymers, driven by increasing demands for functional end-use parts rather than just prototypes. This evolution has created a substantial market for advanced materials like PEEK (Polyether Ether Ketone), which offers exceptional mechanical, thermal, and chemical properties. The global market for high-performance 3D printing polymers was valued at approximately $94 million in 2022 and is projected to grow at a compound annual growth rate of 20.5% through 2030.

Several key industries are fueling this demand growth. The aerospace sector requires lightweight yet durable components that can withstand extreme conditions, making PEEK an ideal candidate for replacing metal parts while reducing overall weight. Major aerospace manufacturers have reported weight reductions of up to 65% when substituting traditional metal components with PEEK-printed alternatives.

The healthcare industry represents another significant market driver, with demand for biocompatible materials for implants, surgical instruments, and medical devices. PEEK's biocompatibility, sterilizability, and bone-like mechanical properties have positioned it as a premium material for patient-specific implants and surgical guides. The medical 3D printing market segment utilizing high-performance polymers has been growing at nearly 24% annually.

Automotive and industrial manufacturing sectors are increasingly adopting high-performance polymers for functional prototypes, tooling, and end-use parts. These industries value PEEK's ability to replace metal components in high-temperature environments while offering chemical resistance and dimensional stability. The automotive sector alone accounts for approximately 18% of the high-performance polymer consumption in 3D printing applications.

Consumer electronics manufacturers are exploring PEEK for specialized components requiring precise tolerances and electrical insulation properties. This sector has shown particular interest in PEEK composites that offer enhanced electrical properties while maintaining thermal stability.

Regional analysis indicates North America currently leads the market for high-performance 3D printing polymers, accounting for roughly 42% of global consumption, followed by Europe at 35% and Asia-Pacific at 20%. However, the Asia-Pacific region is expected to demonstrate the fastest growth rate over the next five years due to rapid industrialization and increasing adoption of advanced manufacturing technologies.

The premium pricing of PEEK materials (typically $500-800 per kilogram) has historically limited widespread adoption. However, as manufacturing processes improve and economies of scale develop, price sensitivity is gradually decreasing, particularly in high-value applications where performance requirements justify the material cost.

Several key industries are fueling this demand growth. The aerospace sector requires lightweight yet durable components that can withstand extreme conditions, making PEEK an ideal candidate for replacing metal parts while reducing overall weight. Major aerospace manufacturers have reported weight reductions of up to 65% when substituting traditional metal components with PEEK-printed alternatives.

The healthcare industry represents another significant market driver, with demand for biocompatible materials for implants, surgical instruments, and medical devices. PEEK's biocompatibility, sterilizability, and bone-like mechanical properties have positioned it as a premium material for patient-specific implants and surgical guides. The medical 3D printing market segment utilizing high-performance polymers has been growing at nearly 24% annually.

Automotive and industrial manufacturing sectors are increasingly adopting high-performance polymers for functional prototypes, tooling, and end-use parts. These industries value PEEK's ability to replace metal components in high-temperature environments while offering chemical resistance and dimensional stability. The automotive sector alone accounts for approximately 18% of the high-performance polymer consumption in 3D printing applications.

Consumer electronics manufacturers are exploring PEEK for specialized components requiring precise tolerances and electrical insulation properties. This sector has shown particular interest in PEEK composites that offer enhanced electrical properties while maintaining thermal stability.

Regional analysis indicates North America currently leads the market for high-performance 3D printing polymers, accounting for roughly 42% of global consumption, followed by Europe at 35% and Asia-Pacific at 20%. However, the Asia-Pacific region is expected to demonstrate the fastest growth rate over the next five years due to rapid industrialization and increasing adoption of advanced manufacturing technologies.

The premium pricing of PEEK materials (typically $500-800 per kilogram) has historically limited widespread adoption. However, as manufacturing processes improve and economies of scale develop, price sensitivity is gradually decreasing, particularly in high-value applications where performance requirements justify the material cost.

PEEK Technical Limitations and Development Challenges

Despite PEEK's exceptional properties making it an attractive material for 3D printing applications, several significant technical limitations and development challenges persist. The high melting point of PEEK (approximately 343°C) necessitates specialized printing equipment capable of reaching and maintaining these elevated temperatures consistently. Standard FDM printers typically operate at temperatures below 300°C, requiring substantial modifications or purpose-built systems for PEEK processing.

Thermal management presents another critical challenge. PEEK exhibits a high crystallinity rate and is prone to warping and internal stress accumulation during cooling. The substantial temperature gradient between the printing temperature and ambient conditions leads to dimensional instability and potential part failure. This necessitates carefully controlled cooling environments and heated build chambers (typically maintained at 120-130°C) to ensure proper crystallization and prevent thermal stress.

Layer adhesion remains problematic due to PEEK's inherent properties. The material's high viscosity in molten state impedes complete fusion between layers, resulting in anisotropic mechanical properties where the Z-axis strength can be significantly lower than the XY-plane strength. This limitation restricts the use of PEEK-printed parts in applications requiring uniform mechanical performance in all directions.

The material's sensitivity to processing parameters creates a narrow processing window. Minor variations in temperature, cooling rate, or printing speed can dramatically affect the crystallinity, mechanical properties, and overall part quality. This sensitivity demands precise control systems and extensive parameter optimization for each specific application.

Cost factors further constrain PEEK adoption in 3D printing. High-grade PEEK filament typically costs $400-800 per kilogram, approximately 20-40 times more expensive than standard thermoplastics like PLA or ABS. Additionally, the specialized equipment required for processing PEEK represents a significant capital investment, with industrial-grade PEEK-capable printers often exceeding $50,000.

Post-processing challenges also exist. PEEK's chemical resistance, while beneficial for end-use applications, makes post-processing treatments difficult. Traditional solvent smoothing techniques used with other thermoplastics prove ineffective with PEEK, necessitating mechanical post-processing methods that can introduce new stresses or dimensional inaccuracies.

The development of PEEK composites (such as carbon fiber or glass fiber reinforced variants) introduces additional complexities related to nozzle wear, fiber orientation control, and maintaining consistent material flow during printing, further complicating the already challenging processing parameters.

Thermal management presents another critical challenge. PEEK exhibits a high crystallinity rate and is prone to warping and internal stress accumulation during cooling. The substantial temperature gradient between the printing temperature and ambient conditions leads to dimensional instability and potential part failure. This necessitates carefully controlled cooling environments and heated build chambers (typically maintained at 120-130°C) to ensure proper crystallization and prevent thermal stress.

Layer adhesion remains problematic due to PEEK's inherent properties. The material's high viscosity in molten state impedes complete fusion between layers, resulting in anisotropic mechanical properties where the Z-axis strength can be significantly lower than the XY-plane strength. This limitation restricts the use of PEEK-printed parts in applications requiring uniform mechanical performance in all directions.

The material's sensitivity to processing parameters creates a narrow processing window. Minor variations in temperature, cooling rate, or printing speed can dramatically affect the crystallinity, mechanical properties, and overall part quality. This sensitivity demands precise control systems and extensive parameter optimization for each specific application.

Cost factors further constrain PEEK adoption in 3D printing. High-grade PEEK filament typically costs $400-800 per kilogram, approximately 20-40 times more expensive than standard thermoplastics like PLA or ABS. Additionally, the specialized equipment required for processing PEEK represents a significant capital investment, with industrial-grade PEEK-capable printers often exceeding $50,000.

Post-processing challenges also exist. PEEK's chemical resistance, while beneficial for end-use applications, makes post-processing treatments difficult. Traditional solvent smoothing techniques used with other thermoplastics prove ineffective with PEEK, necessitating mechanical post-processing methods that can introduce new stresses or dimensional inaccuracies.

The development of PEEK composites (such as carbon fiber or glass fiber reinforced variants) introduces additional complexities related to nozzle wear, fiber orientation control, and maintaining consistent material flow during printing, further complicating the already challenging processing parameters.

Current PEEK Processing Methods for Additive Manufacturing

01 Thermal and mechanical properties of PEEK polymers

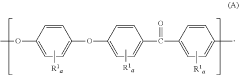

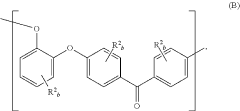

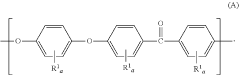

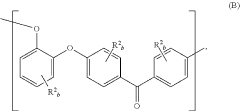

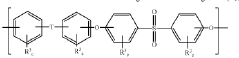

PEEK (Polyetheretherketone) polymers exhibit exceptional thermal stability and mechanical strength. They maintain their structural integrity at high temperatures, with a glass transition temperature of approximately 143°C and melting point around 343°C. PEEK materials demonstrate excellent mechanical properties including high tensile strength, stiffness, and impact resistance. These properties make PEEK suitable for applications requiring durability under extreme conditions.- Thermal and mechanical properties of PEEK polymers: PEEK (Polyether ether ketone) polymers exhibit exceptional thermal stability and mechanical strength. They maintain their structural integrity at high temperatures, with a glass transition temperature of approximately 143°C and melting point around 343°C. PEEK materials demonstrate excellent mechanical properties including high tensile strength, stiffness, and impact resistance, making them suitable for demanding applications in aerospace, automotive, and industrial sectors.

- Chemical resistance and biocompatibility of PEEK: PEEK polymers possess outstanding chemical resistance to a wide range of solvents, acids, and bases, making them highly stable in harsh chemical environments. They do not degrade significantly when exposed to hydrolysis, oxidation, or radiation. Additionally, PEEK materials demonstrate excellent biocompatibility, low toxicity, and bioinertness, which makes them suitable for medical implants and devices that require long-term contact with body tissues and fluids.

- PEEK composite formulations and enhancements: PEEK polymers can be enhanced through the incorporation of various fillers and reinforcements such as carbon fibers, glass fibers, and ceramic particles. These composite formulations significantly improve mechanical properties, wear resistance, and dimensional stability. Modified PEEK composites can achieve tailored properties for specific applications, including increased stiffness, reduced friction, improved electrical conductivity, or enhanced tribological performance.

- Processing techniques and manufacturability of PEEK: PEEK polymers can be processed using various manufacturing techniques including injection molding, extrusion, compression molding, and additive manufacturing. The high melting temperature requires specialized processing equipment capable of reaching temperatures above 360°C. PEEK materials exhibit excellent dimensional stability during processing with minimal shrinkage and warpage. The polymer's flow characteristics can be optimized through proper drying procedures and processing parameters to ensure high-quality finished parts.

- Electrical and thermal insulation properties of PEEK: PEEK polymers demonstrate excellent electrical insulation properties with high dielectric strength and volume resistivity. They maintain their electrical insulation characteristics across a wide temperature range and in various environmental conditions. PEEK materials also exhibit low thermal conductivity, making them effective thermal insulators in applications requiring heat management. These properties make PEEK suitable for electrical components, connectors, and insulation in high-temperature and high-voltage applications.

02 Chemical resistance and biocompatibility of PEEK

PEEK polymers possess outstanding chemical resistance to a wide range of solvents, acids, and bases. They show minimal degradation when exposed to harsh chemical environments, making them ideal for applications in aggressive settings. Additionally, PEEK demonstrates excellent biocompatibility, with low toxicity and minimal inflammatory response when in contact with biological tissues. This combination of chemical resistance and biocompatibility makes PEEK suitable for medical implants and devices.Expand Specific Solutions03 PEEK composite formulations and enhanced properties

PEEK can be formulated into composites by incorporating various fillers such as carbon fibers, glass fibers, and ceramic particles. These composites exhibit enhanced mechanical properties, including improved stiffness, strength, and wear resistance compared to unfilled PEEK. The addition of specific fillers can also impart additional functionalities such as electrical conductivity, thermal conductivity, or reduced friction coefficient, expanding the application range of PEEK-based materials.Expand Specific Solutions04 Processing characteristics of PEEK polymers

PEEK polymers can be processed using various techniques including injection molding, extrusion, and compression molding. The processing of PEEK requires high temperatures (typically 370-400°C) due to its high melting point. PEEK exhibits excellent dimensional stability during processing with minimal shrinkage. The material maintains its properties after multiple processing cycles, demonstrating good recyclability. Special processing considerations include proper drying to prevent hydrolysis and careful temperature control to avoid degradation.Expand Specific Solutions05 Specialized applications of PEEK based on its properties

The unique combination of properties makes PEEK suitable for specialized applications across multiple industries. In aerospace, PEEK components replace metal parts for weight reduction while maintaining strength. In the medical field, PEEK is used for implants due to its biocompatibility and radiolucency. For oil and gas applications, PEEK components withstand high pressure, temperature, and corrosive environments. In electronics, PEEK serves as an insulator with excellent dimensional stability. The material's resistance to radiation and sterilization methods further expands its application potential.Expand Specific Solutions

Leading Manufacturers and Suppliers in PEEK 3D Printing

The PEEK polymer market in 3D printing is experiencing rapid growth, currently transitioning from early adoption to mainstream industrial implementation. The global market for PEEK in additive manufacturing is expanding at approximately 15-20% annually, driven by increasing demand for high-performance materials in aerospace, medical, and industrial applications. Leading companies like Solvay Specialty Polymers and Victrex Manufacturing have established dominant positions through extensive R&D investments and proprietary formulations, while emerging players such as Arevo and Shaanxi Jugao-AM Technology are introducing innovative applications. Academic institutions including Dalian Maritime University and IIT Bombay are advancing fundamental research, collaborating with industry to overcome technical challenges in processing temperature control and layer adhesion, gradually improving the technology's commercial viability across multiple sectors.

Solvay Specialty Polymers USA LLC

Technical Solution: Solvay has developed KetaSpire® PEEK polymers specifically engineered for 3D printing applications. Their technology focuses on optimizing the polymer's crystallization behavior during the printing process, which is crucial for achieving high mechanical performance. Solvay's PEEK filaments incorporate proprietary additives that enhance layer adhesion while maintaining the inherent chemical resistance of PEEK. Their materials are processed using modified FFF (Fused Filament Fabrication) technology with carefully controlled chamber temperatures (>120°C) and nozzle temperatures (380-420°C) to ensure proper crystallization and prevent warping. The company has also developed specialized surface treatments to improve bed adhesion during printing, addressing one of the most common challenges with high-temperature polymers[1]. Solvay's PEEK materials demonstrate exceptional thermal stability up to 260°C and maintain mechanical properties even after thousands of hours of heat aging.

Strengths: Superior chemical resistance against aggressive fluids and excellent mechanical properties retention at high temperatures. Their formulations offer enhanced printability with reduced warping compared to standard PEEK. Weaknesses: Requires specialized high-temperature printers with heated chambers, making the technology less accessible to smaller manufacturers. Higher material costs compared to conventional polymers limit mass adoption.

Victrex Manufacturing Ltd.

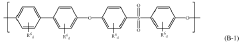

Technical Solution: Victrex has pioneered PAEK (polyaryletherketone) polymer solutions for additive manufacturing through their VICTREX AM™ PEEK filament technology. Their approach focuses on optimizing the polymer's molecular weight and distribution specifically for the layer-by-layer deposition process of 3D printing. Victrex's PEEK filaments feature a carefully controlled semi-crystalline structure that balances processability with mechanical performance. Their technology incorporates proprietary nucleating agents that promote uniform crystallization during the cooling phase, resulting in parts with isotropic properties and minimal internal stresses. The company has developed specialized printing parameters including precise thermal profiles that maintain the material between its glass transition (143°C) and crystallization temperatures during deposition, followed by controlled cooling to maximize crystallinity[2]. Victrex's PEEK materials demonstrate exceptional Z-direction strength, addressing one of the key weaknesses in FFF printed parts, with interlayer strength reaching up to 80% of injection molded equivalents.

Strengths: Exceptional mechanical properties with tensile strengths exceeding 90 MPa and continuous service temperature of 260°C. Their materials offer superior resistance to hydrolysis and radiation, making them ideal for medical and aerospace applications. Weaknesses: Requires very high printing temperatures (380-400°C) and heated chambers, limiting compatibility with many commercial printers. The material's high crystallinity can lead to significant warping if cooling is not precisely controlled.

Critical Patents and Research in PEEK Polymer Science

Additive manufacturing method for making a three-dimensional object

PatentPendingUS20240002597A1

Innovation

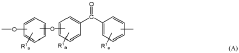

- The use of PEEK-PEoEK copolymers with a composition comprising at least 50 mol% of PEEK and PEoEK repeat units, which exhibit slower crystallization rates and lower melting temperatures, enabling reliable printing of complex objects with reduced warpage and maintaining crystallinity.

High flow polymer compositions

PatentWO2019025121A1

Innovation

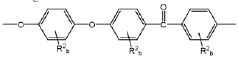

- A polymer composition combining PEEK with a poly(aryl ether sulfone) (PAES) having a number average molecular weight less than 10,000 g/mol, along with optional reinforcing fillers and additives, which maintains or enhances mechanical properties while reducing melt viscosity.

Sustainability and Recyclability of PEEK Materials

In the realm of sustainable manufacturing, PEEK (Polyether Ether Ketone) materials demonstrate exceptional potential for environmentally responsible applications in 3D printing industries. The inherent thermal stability of PEEK allows for multiple melting and solidification cycles without significant degradation of its mechanical properties, making it highly suitable for recycling processes. This characteristic stands in stark contrast to many conventional thermoplastics that experience substantial property deterioration after repeated thermal processing.

PEEK's recyclability is further enhanced by its resistance to chemical degradation, which preserves material integrity throughout multiple use cycles. Research indicates that recycled PEEK can retain up to 90% of its original mechanical properties after several reprocessing iterations, significantly reducing the need for virgin material production and associated environmental impacts. This high retention rate of properties positions PEEK as a premium material for circular economy models within additive manufacturing ecosystems.

From a lifecycle assessment perspective, PEEK demonstrates favorable environmental credentials despite its energy-intensive initial production. The extended service life of PEEK components, often exceeding 10-15 years in demanding applications, distributes the environmental production costs over a longer operational period. Additionally, the high-performance characteristics of PEEK enable the production of lightweight components that contribute to energy efficiency in end-use applications, particularly in aerospace and automotive sectors.

The biocompatibility of medical-grade PEEK variants introduces another dimension to its sustainability profile. Unlike many high-performance polymers that require potentially harmful additives, PEEK can achieve its exceptional properties without environmentally problematic compounds. This characteristic not only enhances its recyclability but also minimizes ecological risks associated with disposal or potential material leaching during use.

Recent innovations in PEEK recycling technologies have focused on maintaining the high purity levels required for critical applications. Advanced sorting techniques, including spectroscopic methods and artificial intelligence-driven separation systems, have improved the quality of recycled PEEK feedstock. These technological advancements are gradually reducing the cost differential between virgin and recycled PEEK materials, enhancing the economic viability of sustainable PEEK utilization in 3D printing applications.

The development of PEEK composites incorporating sustainable reinforcements, such as recycled carbon fibers or bio-based additives, represents an emerging frontier in enhancing both performance and environmental credentials. These hybrid materials potentially offer improved mechanical properties while maintaining the recyclability advantages of the base PEEK polymer, creating new opportunities for sustainable high-performance applications in additive manufacturing.

PEEK's recyclability is further enhanced by its resistance to chemical degradation, which preserves material integrity throughout multiple use cycles. Research indicates that recycled PEEK can retain up to 90% of its original mechanical properties after several reprocessing iterations, significantly reducing the need for virgin material production and associated environmental impacts. This high retention rate of properties positions PEEK as a premium material for circular economy models within additive manufacturing ecosystems.

From a lifecycle assessment perspective, PEEK demonstrates favorable environmental credentials despite its energy-intensive initial production. The extended service life of PEEK components, often exceeding 10-15 years in demanding applications, distributes the environmental production costs over a longer operational period. Additionally, the high-performance characteristics of PEEK enable the production of lightweight components that contribute to energy efficiency in end-use applications, particularly in aerospace and automotive sectors.

The biocompatibility of medical-grade PEEK variants introduces another dimension to its sustainability profile. Unlike many high-performance polymers that require potentially harmful additives, PEEK can achieve its exceptional properties without environmentally problematic compounds. This characteristic not only enhances its recyclability but also minimizes ecological risks associated with disposal or potential material leaching during use.

Recent innovations in PEEK recycling technologies have focused on maintaining the high purity levels required for critical applications. Advanced sorting techniques, including spectroscopic methods and artificial intelligence-driven separation systems, have improved the quality of recycled PEEK feedstock. These technological advancements are gradually reducing the cost differential between virgin and recycled PEEK materials, enhancing the economic viability of sustainable PEEK utilization in 3D printing applications.

The development of PEEK composites incorporating sustainable reinforcements, such as recycled carbon fibers or bio-based additives, represents an emerging frontier in enhancing both performance and environmental credentials. These hybrid materials potentially offer improved mechanical properties while maintaining the recyclability advantages of the base PEEK polymer, creating new opportunities for sustainable high-performance applications in additive manufacturing.

Regulatory Compliance for Medical-Grade PEEK Applications

The regulatory landscape for medical-grade PEEK applications is complex and multifaceted, requiring manufacturers to navigate various international standards and approval processes. In the United States, the Food and Drug Administration (FDA) classifies PEEK medical devices based on risk levels, with most PEEK implants falling under Class II or III, necessitating either 510(k) clearance or Premarket Approval (PMA). The FDA specifically evaluates biocompatibility, mechanical properties, and manufacturing consistency of 3D-printed PEEK components.

In Europe, medical-grade PEEK applications must comply with the Medical Device Regulation (MDR), which replaced the Medical Device Directive (MDD) with more stringent requirements for clinical evidence and post-market surveillance. The CE marking process demands comprehensive technical documentation and quality management systems that specifically address the unique characteristics of 3D-printed PEEK materials.

ISO 13485 serves as the foundational quality management standard for medical device manufacturers, with specific provisions relevant to additive manufacturing processes using PEEK. Additionally, ISO 10993 series standards govern biocompatibility testing, which is particularly critical for PEEK implants due to their direct contact with human tissues and long-term implantation scenarios.

ASTM F2026 specifically addresses PEEK polymers for surgical implant applications, establishing requirements for raw material composition, processing methods, and final product testing. For 3D-printed PEEK, ASTM F3335 provides guidelines for powder bed fusion processes, while the newer ISO/ASTM 52900 series standards address various aspects of additive manufacturing technologies.

Regulatory bodies increasingly require validation of the entire manufacturing process for 3D-printed PEEK medical devices, including material handling, printing parameters, post-processing treatments, and sterilization methods. This process validation must demonstrate that the unique thermal history experienced during 3D printing does not compromise PEEK's essential properties or introduce unexpected contaminants.

Traceability requirements present particular challenges for 3D-printed PEEK applications, as manufacturers must maintain comprehensive records linking raw material batches to specific printing parameters and post-processing conditions for each produced component. The FDA's guidance on "Technical Considerations for Additive Manufactured Medical Devices" specifically addresses these concerns, requiring detailed documentation of design-to-production workflows.

Regulatory compliance strategies must also account for international harmonization efforts, as manufacturers increasingly seek simultaneous approvals across multiple markets to maximize commercial potential for innovative PEEK medical applications.

In Europe, medical-grade PEEK applications must comply with the Medical Device Regulation (MDR), which replaced the Medical Device Directive (MDD) with more stringent requirements for clinical evidence and post-market surveillance. The CE marking process demands comprehensive technical documentation and quality management systems that specifically address the unique characteristics of 3D-printed PEEK materials.

ISO 13485 serves as the foundational quality management standard for medical device manufacturers, with specific provisions relevant to additive manufacturing processes using PEEK. Additionally, ISO 10993 series standards govern biocompatibility testing, which is particularly critical for PEEK implants due to their direct contact with human tissues and long-term implantation scenarios.

ASTM F2026 specifically addresses PEEK polymers for surgical implant applications, establishing requirements for raw material composition, processing methods, and final product testing. For 3D-printed PEEK, ASTM F3335 provides guidelines for powder bed fusion processes, while the newer ISO/ASTM 52900 series standards address various aspects of additive manufacturing technologies.

Regulatory bodies increasingly require validation of the entire manufacturing process for 3D-printed PEEK medical devices, including material handling, printing parameters, post-processing treatments, and sterilization methods. This process validation must demonstrate that the unique thermal history experienced during 3D printing does not compromise PEEK's essential properties or introduce unexpected contaminants.

Traceability requirements present particular challenges for 3D-printed PEEK applications, as manufacturers must maintain comprehensive records linking raw material batches to specific printing parameters and post-processing conditions for each produced component. The FDA's guidance on "Technical Considerations for Additive Manufactured Medical Devices" specifically addresses these concerns, requiring detailed documentation of design-to-production workflows.

Regulatory compliance strategies must also account for international harmonization efforts, as manufacturers increasingly seek simultaneous approvals across multiple markets to maximize commercial potential for innovative PEEK medical applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!