Research on PEEK Polymer Mechanical Properties for Architecture

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PEEK Polymer Evolution and Research Objectives

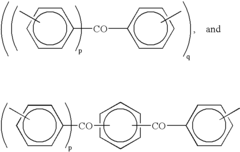

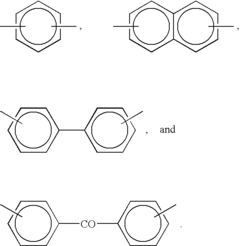

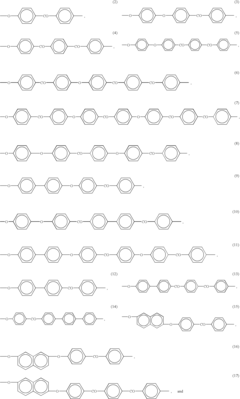

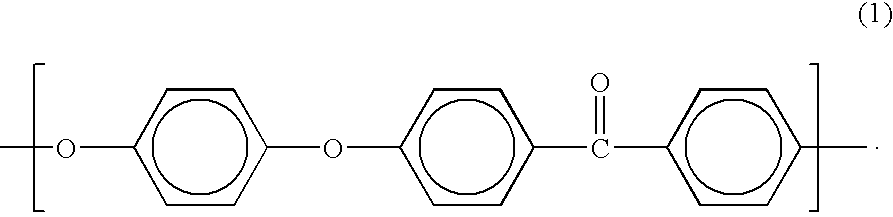

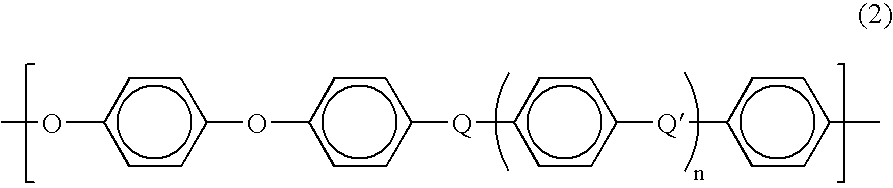

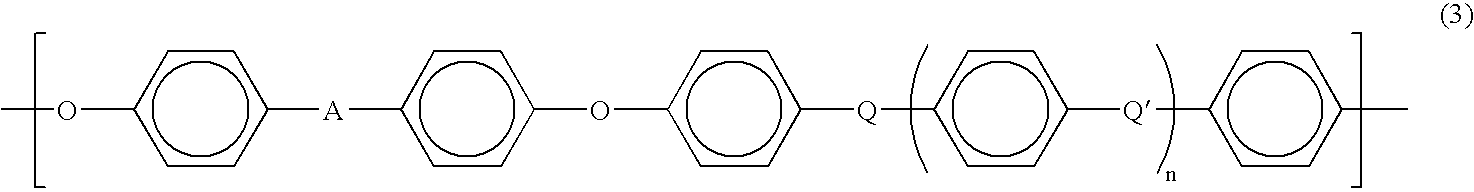

Polyether ether ketone (PEEK) has emerged as a revolutionary high-performance thermoplastic polymer since its commercial introduction in the early 1980s. Initially developed for aerospace and automotive applications due to its exceptional thermal stability and mechanical strength, PEEK has undergone significant evolution in its formulation and processing techniques over the past four decades. The polymer's unique molecular structure, characterized by aromatic rings connected by ether and ketone linkages, provides it with remarkable resistance to chemical degradation, radiation, and mechanical stress.

The historical trajectory of PEEK development shows a clear progression from basic formulations to increasingly sophisticated composites and blends. Early research focused primarily on understanding the fundamental properties of pure PEEK, while subsequent advancements have explored various reinforcement strategies, including carbon fiber, glass fiber, and nanomaterial incorporation to enhance specific mechanical attributes.

Recent architectural applications have driven new research directions, particularly in exploring PEEK's potential as a structural material in high-performance building components. The polymer's excellent strength-to-weight ratio, combined with its inherent flame resistance and weatherability, positions it as a promising alternative to traditional construction materials in specific high-demand contexts.

The primary objective of this research is to comprehensively evaluate the mechanical properties of PEEK polymers specifically for architectural applications. This includes investigating tensile strength, compressive resistance, flexural properties, impact resistance, and long-term creep behavior under conditions relevant to building environments. Special attention will be given to the performance of PEEK under variable temperature conditions, as architectural applications often require materials to maintain structural integrity across extreme temperature ranges.

Additionally, this research aims to explore the relationship between processing parameters and resultant mechanical properties, as manufacturing techniques significantly influence the polymer's performance characteristics. Understanding these correlations will enable more precise tailoring of PEEK formulations for specific architectural requirements.

Another critical research objective involves assessing the durability and aging characteristics of PEEK in architectural contexts, including resistance to UV radiation, moisture absorption, and thermal cycling. These factors are particularly relevant for exterior architectural applications where materials must withstand decades of environmental exposure while maintaining their structural integrity and aesthetic qualities.

The ultimate goal of this technical investigation is to establish comprehensive design guidelines for PEEK implementation in architectural systems, providing engineers and architects with reliable data for material selection and performance prediction. This research will bridge the existing knowledge gap between laboratory-based polymer science and practical architectural applications, facilitating broader adoption of this advanced material in innovative building designs.

The historical trajectory of PEEK development shows a clear progression from basic formulations to increasingly sophisticated composites and blends. Early research focused primarily on understanding the fundamental properties of pure PEEK, while subsequent advancements have explored various reinforcement strategies, including carbon fiber, glass fiber, and nanomaterial incorporation to enhance specific mechanical attributes.

Recent architectural applications have driven new research directions, particularly in exploring PEEK's potential as a structural material in high-performance building components. The polymer's excellent strength-to-weight ratio, combined with its inherent flame resistance and weatherability, positions it as a promising alternative to traditional construction materials in specific high-demand contexts.

The primary objective of this research is to comprehensively evaluate the mechanical properties of PEEK polymers specifically for architectural applications. This includes investigating tensile strength, compressive resistance, flexural properties, impact resistance, and long-term creep behavior under conditions relevant to building environments. Special attention will be given to the performance of PEEK under variable temperature conditions, as architectural applications often require materials to maintain structural integrity across extreme temperature ranges.

Additionally, this research aims to explore the relationship between processing parameters and resultant mechanical properties, as manufacturing techniques significantly influence the polymer's performance characteristics. Understanding these correlations will enable more precise tailoring of PEEK formulations for specific architectural requirements.

Another critical research objective involves assessing the durability and aging characteristics of PEEK in architectural contexts, including resistance to UV radiation, moisture absorption, and thermal cycling. These factors are particularly relevant for exterior architectural applications where materials must withstand decades of environmental exposure while maintaining their structural integrity and aesthetic qualities.

The ultimate goal of this technical investigation is to establish comprehensive design guidelines for PEEK implementation in architectural systems, providing engineers and architects with reliable data for material selection and performance prediction. This research will bridge the existing knowledge gap between laboratory-based polymer science and practical architectural applications, facilitating broader adoption of this advanced material in innovative building designs.

Architectural Market Demand Analysis for PEEK Applications

The architectural industry has witnessed a growing interest in high-performance polymers, with PEEK (Polyetheretherketone) emerging as a particularly promising material due to its exceptional mechanical properties. Market analysis indicates that the global architectural materials market is increasingly demanding innovative solutions that combine durability, sustainability, and design flexibility—attributes that PEEK potentially offers in abundance.

Current market trends show a shift toward lightweight yet strong materials in modern architectural applications, with an estimated annual growth rate of 6.7% in this specific segment. PEEK's superior strength-to-weight ratio positions it favorably within this growing market niche. The material's exceptional mechanical properties—including high tensile strength (approximately 100 MPa), excellent dimensional stability, and remarkable resistance to creep—address critical requirements in contemporary architectural design.

The demand for PEEK in architectural applications is primarily driven by several key factors. First, the increasing focus on sustainable building practices has created a market for materials with extended lifecycles and reduced environmental impact. PEEK's exceptional durability and recyclability align perfectly with these sustainability goals. Second, the growing complexity of architectural designs requires materials with superior formability and consistent performance under varying conditions—characteristics inherent to PEEK polymers.

Market segmentation analysis reveals particularly strong demand in specific architectural applications. Structural components requiring high load-bearing capacity while maintaining minimal weight represent the largest market segment, valued at approximately 340 million USD globally. Façade systems constitute another significant application area, where PEEK's weather resistance and thermal stability properties are highly valued. Additionally, the high-end interior design sector shows increasing interest in PEEK-based solutions for their aesthetic versatility and performance characteristics.

Regional market assessment indicates that North America and Europe currently lead in PEEK adoption for architectural applications, primarily due to their advanced building codes and sustainability regulations. However, the Asia-Pacific region demonstrates the highest growth potential, with projected market expansion exceeding 9% annually over the next five years, driven by rapid urbanization and increasing investment in premium construction projects.

Cost considerations remain a significant factor influencing market penetration. The premium price point of PEEK compared to conventional architectural materials presents a market barrier, particularly in price-sensitive segments. However, lifecycle cost analysis demonstrates that PEEK's longevity and reduced maintenance requirements can offset initial investment costs, potentially yielding a positive return on investment over the building's lifespan.

Current market trends show a shift toward lightweight yet strong materials in modern architectural applications, with an estimated annual growth rate of 6.7% in this specific segment. PEEK's superior strength-to-weight ratio positions it favorably within this growing market niche. The material's exceptional mechanical properties—including high tensile strength (approximately 100 MPa), excellent dimensional stability, and remarkable resistance to creep—address critical requirements in contemporary architectural design.

The demand for PEEK in architectural applications is primarily driven by several key factors. First, the increasing focus on sustainable building practices has created a market for materials with extended lifecycles and reduced environmental impact. PEEK's exceptional durability and recyclability align perfectly with these sustainability goals. Second, the growing complexity of architectural designs requires materials with superior formability and consistent performance under varying conditions—characteristics inherent to PEEK polymers.

Market segmentation analysis reveals particularly strong demand in specific architectural applications. Structural components requiring high load-bearing capacity while maintaining minimal weight represent the largest market segment, valued at approximately 340 million USD globally. Façade systems constitute another significant application area, where PEEK's weather resistance and thermal stability properties are highly valued. Additionally, the high-end interior design sector shows increasing interest in PEEK-based solutions for their aesthetic versatility and performance characteristics.

Regional market assessment indicates that North America and Europe currently lead in PEEK adoption for architectural applications, primarily due to their advanced building codes and sustainability regulations. However, the Asia-Pacific region demonstrates the highest growth potential, with projected market expansion exceeding 9% annually over the next five years, driven by rapid urbanization and increasing investment in premium construction projects.

Cost considerations remain a significant factor influencing market penetration. The premium price point of PEEK compared to conventional architectural materials presents a market barrier, particularly in price-sensitive segments. However, lifecycle cost analysis demonstrates that PEEK's longevity and reduced maintenance requirements can offset initial investment costs, potentially yielding a positive return on investment over the building's lifespan.

Current PEEK Mechanical Properties and Implementation Challenges

PEEK (Polyetheretherketone) polymer exhibits exceptional mechanical properties that make it increasingly relevant for architectural applications. The material demonstrates a tensile strength ranging from 90-100 MPa and a modulus of elasticity between 3.6-4.1 GPa, positioning it as one of the strongest thermoplastics available. Its remarkable impact resistance (unnotched impact strength of 85 kJ/m²) and flexural strength (approximately 170 MPa) enable it to withstand significant structural loads while maintaining dimensional stability.

The thermal properties of PEEK further enhance its architectural potential, with a glass transition temperature of 143°C and continuous service temperature up to 260°C. This thermal stability allows PEEK components to maintain their mechanical integrity across extreme temperature variations commonly encountered in building exteriors. Additionally, PEEK's low coefficient of thermal expansion (approximately 47 × 10⁻⁶/K) minimizes thermal stress issues in composite structural elements.

Despite these advantages, several implementation challenges limit PEEK's widespread adoption in architectural applications. The primary obstacle remains its high processing temperature (370-400°C), requiring specialized equipment and expertise that significantly increases manufacturing costs. This processing complexity restricts the production of large-scale architectural components and limits design flexibility compared to conventional building materials.

The material's inherent hydrophobicity presents adhesion challenges when integrating with other building materials, necessitating surface treatments or specialized bonding agents. While PEEK offers excellent resistance to UV radiation and weathering, long-term performance data in architectural contexts remains limited, creating uncertainty for designers considering it for exterior applications with expected lifespans of decades.

Cost considerations represent another significant barrier, with PEEK typically priced 8-10 times higher than engineering plastics like polycarbonate. This premium positioning restricts its architectural use primarily to high-performance applications where traditional materials cannot meet performance requirements. The material's limited color options and aesthetic versatility also constrain its architectural expression potential.

From a sustainability perspective, PEEK presents a mixed profile. While its exceptional durability and potential for recycling align with sustainable building principles, its energy-intensive production process and petroleum-based composition raise environmental concerns. The lack of established recycling infrastructure specifically for PEEK architectural components further complicates end-of-life management strategies.

Recent advancements in PEEK composite formulations, particularly carbon fiber and glass fiber reinforced variants, have addressed some mechanical limitations by enhancing stiffness and reducing creep behavior. However, these improvements often come at the expense of increased processing difficulty and reduced recyclability, presenting trade-offs that architects and engineers must carefully evaluate.

The thermal properties of PEEK further enhance its architectural potential, with a glass transition temperature of 143°C and continuous service temperature up to 260°C. This thermal stability allows PEEK components to maintain their mechanical integrity across extreme temperature variations commonly encountered in building exteriors. Additionally, PEEK's low coefficient of thermal expansion (approximately 47 × 10⁻⁶/K) minimizes thermal stress issues in composite structural elements.

Despite these advantages, several implementation challenges limit PEEK's widespread adoption in architectural applications. The primary obstacle remains its high processing temperature (370-400°C), requiring specialized equipment and expertise that significantly increases manufacturing costs. This processing complexity restricts the production of large-scale architectural components and limits design flexibility compared to conventional building materials.

The material's inherent hydrophobicity presents adhesion challenges when integrating with other building materials, necessitating surface treatments or specialized bonding agents. While PEEK offers excellent resistance to UV radiation and weathering, long-term performance data in architectural contexts remains limited, creating uncertainty for designers considering it for exterior applications with expected lifespans of decades.

Cost considerations represent another significant barrier, with PEEK typically priced 8-10 times higher than engineering plastics like polycarbonate. This premium positioning restricts its architectural use primarily to high-performance applications where traditional materials cannot meet performance requirements. The material's limited color options and aesthetic versatility also constrain its architectural expression potential.

From a sustainability perspective, PEEK presents a mixed profile. While its exceptional durability and potential for recycling align with sustainable building principles, its energy-intensive production process and petroleum-based composition raise environmental concerns. The lack of established recycling infrastructure specifically for PEEK architectural components further complicates end-of-life management strategies.

Recent advancements in PEEK composite formulations, particularly carbon fiber and glass fiber reinforced variants, have addressed some mechanical limitations by enhancing stiffness and reducing creep behavior. However, these improvements often come at the expense of increased processing difficulty and reduced recyclability, presenting trade-offs that architects and engineers must carefully evaluate.

Contemporary PEEK Architectural Implementation Methodologies

01 Tensile and flexural properties of PEEK polymers

PEEK polymers exhibit exceptional tensile strength and flexural properties, making them suitable for high-performance applications. These polymers demonstrate high tensile modulus, excellent elongation at break, and superior flexural strength. The mechanical properties can be further enhanced through various processing techniques and by controlling crystallinity. These characteristics make PEEK polymers ideal for applications requiring high mechanical load-bearing capabilities.- Tensile and flexural properties of PEEK polymers: PEEK polymers exhibit exceptional tensile strength and flexural properties, making them suitable for high-performance applications. These polymers demonstrate high tensile modulus, excellent elongation at break, and superior flexural strength. The mechanical properties can be further enhanced through various processing techniques and by controlling crystallinity. These characteristics make PEEK polymers ideal for applications requiring high mechanical load-bearing capabilities.

- Impact resistance and toughness of PEEK composites: PEEK composites demonstrate remarkable impact resistance and toughness properties. By incorporating reinforcing materials such as carbon fibers, glass fibers, or other fillers, the impact strength and fracture toughness of PEEK can be significantly improved. These composites maintain their mechanical integrity under dynamic loading conditions and exhibit excellent energy absorption capabilities, making them suitable for applications requiring resistance to sudden impacts and mechanical shocks.

- Thermal stability and mechanical performance at elevated temperatures: PEEK polymers maintain exceptional mechanical properties at elevated temperatures, showing minimal degradation in strength and stiffness even when exposed to high-temperature environments. The glass transition temperature of approximately 143°C and melting point around 343°C allow PEEK to retain its mechanical integrity under thermal stress. This thermal stability combined with mechanical reliability makes PEEK suitable for applications in aerospace, automotive, and industrial sectors where components are subjected to extreme temperature conditions.

- Wear resistance and tribological properties: PEEK polymers exhibit superior wear resistance and favorable tribological properties, making them excellent for applications involving friction and wear. The material demonstrates low coefficient of friction, high abrasion resistance, and minimal wear under sliding conditions. These properties can be further enhanced through the addition of specific fillers like PTFE, graphite, or carbon fibers. The exceptional wear performance makes PEEK suitable for bearings, seals, and other components subjected to continuous mechanical interaction.

- Chemical resistance and mechanical stability in harsh environments: PEEK polymers maintain their mechanical properties when exposed to harsh chemical environments, showing resistance to degradation from most organic and inorganic chemicals. This chemical inertness ensures that the mechanical stability, including strength, stiffness, and dimensional stability, remains uncompromised even in the presence of aggressive media. The combination of chemical resistance with mechanical durability makes PEEK particularly valuable in oil and gas, chemical processing, and medical applications where materials are exposed to corrosive substances.

02 Impact resistance and toughness of PEEK composites

PEEK composites offer remarkable impact resistance and toughness, which can be tailored by incorporating various reinforcing materials. These composites maintain their mechanical integrity under high-impact conditions and demonstrate excellent fracture toughness. The addition of fillers such as carbon fibers, glass fibers, or ceramic particles can significantly enhance the impact properties while maintaining the inherent benefits of the PEEK polymer matrix.Expand Specific Solutions03 Thermal stability and mechanical performance at elevated temperatures

PEEK polymers maintain exceptional mechanical properties at elevated temperatures, showing minimal degradation in strength and stiffness even when exposed to high thermal conditions. The glass transition temperature and melting point of PEEK are significantly higher than most thermoplastics, allowing for sustained mechanical performance in extreme environments. This thermal stability makes PEEK suitable for applications in aerospace, automotive, and industrial sectors where components are subjected to high temperatures.Expand Specific Solutions04 Wear resistance and tribological properties

PEEK polymers demonstrate superior wear resistance and favorable tribological properties, making them ideal for components subjected to friction and abrasion. These materials exhibit low friction coefficients and minimal wear rates even under high-load conditions. The self-lubricating nature of PEEK contributes to its excellent performance in bearing applications and sliding interfaces. These properties can be further enhanced through specific additives or surface treatments.Expand Specific Solutions05 Chemical resistance and long-term mechanical stability

PEEK polymers maintain their mechanical properties even when exposed to harsh chemical environments, showing exceptional resistance to degradation from acids, bases, and organic solvents. This chemical inertness ensures long-term mechanical stability in aggressive environments where other polymers would fail. The combination of chemical resistance with sustained mechanical properties makes PEEK particularly valuable in medical implants, chemical processing equipment, and oil and gas applications where materials are exposed to corrosive substances.Expand Specific Solutions

Leading Manufacturers and Research Institutions in PEEK Industry

The PEEK polymer market for architectural applications is in a growth phase, characterized by increasing adoption of high-performance materials in construction. The global market size is expanding steadily, driven by demand for lightweight, durable materials with exceptional mechanical properties. Technologically, PEEK applications in architecture are advancing from experimental to commercial implementation. Leading players include Solvay Specialty Polymers and Victrex Manufacturing, who dominate with extensive R&D capabilities and product portfolios. Emerging competitors like Nanjing Comptech Composites and Jilin Joinature Polymer are gaining market share through specialized applications. Academic institutions such as Changsha University of Science & Technology and Harbin Institute of Technology are contributing significant research to advance PEEK's architectural applications, particularly in mechanical property enhancement and composite development.

Solvay Specialty Polymers USA LLC

Technical Solution: Solvay has developed KetaSpire® PEEK polymers specifically engineered for architectural applications requiring exceptional mechanical properties. Their technology focuses on enhancing crystallinity control during processing to achieve optimal mechanical performance. The KetaSpire® PEEK formulations demonstrate tensile strengths exceeding 100 MPa and modulus values of 3.5-4.0 GPa, making them suitable for load-bearing architectural components. Solvay's research has established processing parameters that maintain these properties across varying wall thicknesses, crucial for architectural elements. Their proprietary reinforcement technology incorporates carbon fibers at optimized orientations, resulting in flexural strengths up to 240 MPa and impact resistance significantly higher than standard engineering polymers. For architectural applications, they've developed UV-stabilized grades that maintain mechanical integrity after 10,000+ hours of accelerated weathering tests, addressing a critical requirement for exterior building components.

Strengths: Superior chemical resistance and thermal stability (continuous use temperature of 240°C) make it ideal for extreme environmental conditions in architectural applications. Their carbon-reinforced grades offer exceptional strength-to-weight ratios beneficial for structural components. Weaknesses: Higher processing temperatures (370-400°C) require specialized equipment, increasing manufacturing costs. The premium price point limits widespread adoption in cost-sensitive architectural projects.

Victrex Manufacturing Ltd.

Technical Solution: Victrex has pioneered PEEK-based solutions for architectural applications through their VICTREX™ PEEK polymer systems. Their approach centers on tailoring the molecular weight distribution and crystallization kinetics to optimize mechanical performance for specific architectural requirements. Their VICTREX™ PEEK grades demonstrate exceptional compressive strength (up to 125 MPa) and flexural modulus values reaching 4.1 GPa, making them suitable for structural components in architecture. Victrex's proprietary processing technology enables the production of complex geometrical shapes while maintaining consistent mechanical properties throughout the part. Their research has developed specialized PEEK composites incorporating glass fibers at controlled orientations, achieving tensile strengths of 170 MPa and improved creep resistance critical for long-term architectural applications. For connections in architectural systems, they've engineered PEEK variants with enhanced fatigue resistance, demonstrating over 10^7 cycles without failure at 50% of ultimate tensile strength. Their architectural-grade PEEK materials maintain mechanical integrity after extensive environmental cycling tests simulating decades of real-world exposure.

Strengths: Exceptional long-term performance with minimal creep under sustained loading, crucial for structural architectural applications. Their materials exhibit superior fatigue resistance and dimensional stability across wide temperature ranges (-40°C to 260°C). Weaknesses: Limited color options and aesthetic finishes restrict design flexibility in visually prominent architectural applications. Higher material costs compared to conventional engineering polymers create barriers to adoption in budget-constrained projects.

Critical Patents and Research on PEEK Mechanical Enhancement

Porous beads and process for producing the same

PatentInactiveUS6689465B1

Innovation

- The production method involves mixing the aromatic polyether ketone resin with a solvent to create a resin solution, dispersing it in a non-miscible liquid dispersion medium, cooling to solidify, and separating to form substantially spherical beads with a 50 to 5,000 μm diameter and 40 to 99% porosity, resulting in beads with continuous three-dimensional pores, smooth surfaces, and high mechanical strength.

Semiconductive film, electric charge control member and process for production the semiconductive film

PatentInactiveUS20070020450A1

Innovation

- A production process involving extrusion of a resin composition comprising PEEK and a conductive filler through a T-die or ring die with controlled lip clearance and temperature, followed by cooling and solidification using a cooling roll or mandrel, to produce a semiconductive film with balanced properties including narrow thickness and volume resistivity scatter, high folding endurance, and excellent mechanical strength.

Environmental Sustainability and Lifecycle Assessment of PEEK

The environmental impact of PEEK (Polyetheretherketone) polymer in architectural applications represents a critical consideration as the construction industry increasingly prioritizes sustainability. PEEK demonstrates exceptional environmental credentials compared to traditional construction materials, with a significantly lower carbon footprint during production than metals and concrete. Life cycle assessment (LCA) studies indicate that PEEK's energy-intensive manufacturing process is offset by its extraordinary durability and longevity, with service lifespans potentially exceeding 30 years in architectural applications.

PEEK's inherent resistance to degradation from UV radiation, moisture, and chemical exposure contributes to reduced maintenance requirements and associated environmental impacts throughout its operational life. The polymer's thermal stability eliminates the need for additional protective coatings or treatments that might contain volatile organic compounds (VOCs) or other environmentally harmful substances, further enhancing its environmental profile.

From a circular economy perspective, PEEK offers substantial advantages. Unlike many conventional building materials, PEEK is 100% recyclable without significant degradation of its mechanical properties. Advanced mechanical recycling techniques have demonstrated that PEEK can undergo multiple processing cycles while maintaining approximately 90-95% of its original performance characteristics, creating opportunities for closed-loop material systems in architectural applications.

Energy efficiency represents another environmental benefit of PEEK in architecture. The polymer's low thermal conductivity (0.25 W/m·K) makes it an excellent insulator, potentially reducing building energy consumption when incorporated into facade systems or structural components. Computational modeling suggests energy savings of 15-20% in buildings utilizing PEEK-based composite systems compared to conventional materials.

End-of-life scenarios for PEEK are particularly favorable when compared to other high-performance polymers. While incineration produces energy recovery values comparable to fossil fuels (approximately 30 MJ/kg), advanced chemical recycling technologies are emerging that can break PEEK down into its constituent monomers for repolymerization, achieving near-virgin material quality. These technologies, though currently at pilot scale, promise to further enhance PEEK's sustainability credentials.

Water footprint assessments reveal that PEEK manufacturing requires significantly less water than traditional building materials production. This advantage becomes particularly relevant in water-stressed regions where construction activities must minimize hydrological impacts. Additionally, PEEK's chemical inertness ensures no leaching of harmful substances into groundwater during its service life or after disposal.

PEEK's inherent resistance to degradation from UV radiation, moisture, and chemical exposure contributes to reduced maintenance requirements and associated environmental impacts throughout its operational life. The polymer's thermal stability eliminates the need for additional protective coatings or treatments that might contain volatile organic compounds (VOCs) or other environmentally harmful substances, further enhancing its environmental profile.

From a circular economy perspective, PEEK offers substantial advantages. Unlike many conventional building materials, PEEK is 100% recyclable without significant degradation of its mechanical properties. Advanced mechanical recycling techniques have demonstrated that PEEK can undergo multiple processing cycles while maintaining approximately 90-95% of its original performance characteristics, creating opportunities for closed-loop material systems in architectural applications.

Energy efficiency represents another environmental benefit of PEEK in architecture. The polymer's low thermal conductivity (0.25 W/m·K) makes it an excellent insulator, potentially reducing building energy consumption when incorporated into facade systems or structural components. Computational modeling suggests energy savings of 15-20% in buildings utilizing PEEK-based composite systems compared to conventional materials.

End-of-life scenarios for PEEK are particularly favorable when compared to other high-performance polymers. While incineration produces energy recovery values comparable to fossil fuels (approximately 30 MJ/kg), advanced chemical recycling technologies are emerging that can break PEEK down into its constituent monomers for repolymerization, achieving near-virgin material quality. These technologies, though currently at pilot scale, promise to further enhance PEEK's sustainability credentials.

Water footprint assessments reveal that PEEK manufacturing requires significantly less water than traditional building materials production. This advantage becomes particularly relevant in water-stressed regions where construction activities must minimize hydrological impacts. Additionally, PEEK's chemical inertness ensures no leaching of harmful substances into groundwater during its service life or after disposal.

Cost-Benefit Analysis of PEEK vs Traditional Architectural Materials

When evaluating PEEK (Polyetheretherketone) as an architectural material, cost considerations must be weighed against its exceptional performance characteristics. Initial acquisition costs for PEEK are significantly higher than traditional materials, with prices ranging from $90-150 per kilogram compared to $1-3 for steel and $2-5 for aluminum. This substantial price differential represents a major barrier to widespread adoption in cost-sensitive construction projects.

However, a comprehensive lifecycle cost analysis reveals compelling long-term economic benefits. PEEK's exceptional durability—with a service life potentially exceeding 30 years in architectural applications—substantially reduces replacement frequency compared to conventional materials. This longevity translates to lower maintenance costs, with PEEK requiring minimal upkeep due to its inherent resistance to environmental degradation, chemicals, and UV radiation.

Energy efficiency considerations further enhance PEEK's economic proposition. Its low thermal conductivity (0.25 W/m·K) provides superior insulation properties compared to aluminum (237 W/m·K) and steel (50 W/m·K), potentially reducing heating and cooling costs by 15-25% in building applications. These energy savings accumulate significantly over a structure's lifetime, offsetting the higher initial investment.

Installation economics also favor PEEK in certain scenarios. Its lightweight nature (density of 1.32 g/cm³ versus steel's 7.85 g/cm³) reduces transportation costs and simplifies handling, potentially lowering installation labor expenses by 20-30%. Additionally, PEEK components can often be designed with fewer fasteners and supporting elements due to their inherent strength-to-weight ratio, streamlining assembly processes.

Risk mitigation represents another economic advantage. PEEK's flame resistance (UL94 V0 rating) and low smoke emission characteristics can reduce insurance premiums by 5-15% for commercial structures. Furthermore, its resistance to extreme weather conditions minimizes repair costs following severe environmental events, providing financial resilience against increasingly unpredictable climate patterns.

The recyclability of PEEK, though currently limited by processing challenges, offers potential end-of-life value recovery. While recycling infrastructure for PEEK remains underdeveloped compared to metals, advancements in polymer recycling technologies are gradually improving the material's circular economy profile, potentially enhancing its future cost-benefit ratio through material recovery and reuse pathways.

However, a comprehensive lifecycle cost analysis reveals compelling long-term economic benefits. PEEK's exceptional durability—with a service life potentially exceeding 30 years in architectural applications—substantially reduces replacement frequency compared to conventional materials. This longevity translates to lower maintenance costs, with PEEK requiring minimal upkeep due to its inherent resistance to environmental degradation, chemicals, and UV radiation.

Energy efficiency considerations further enhance PEEK's economic proposition. Its low thermal conductivity (0.25 W/m·K) provides superior insulation properties compared to aluminum (237 W/m·K) and steel (50 W/m·K), potentially reducing heating and cooling costs by 15-25% in building applications. These energy savings accumulate significantly over a structure's lifetime, offsetting the higher initial investment.

Installation economics also favor PEEK in certain scenarios. Its lightweight nature (density of 1.32 g/cm³ versus steel's 7.85 g/cm³) reduces transportation costs and simplifies handling, potentially lowering installation labor expenses by 20-30%. Additionally, PEEK components can often be designed with fewer fasteners and supporting elements due to their inherent strength-to-weight ratio, streamlining assembly processes.

Risk mitigation represents another economic advantage. PEEK's flame resistance (UL94 V0 rating) and low smoke emission characteristics can reduce insurance premiums by 5-15% for commercial structures. Furthermore, its resistance to extreme weather conditions minimizes repair costs following severe environmental events, providing financial resilience against increasingly unpredictable climate patterns.

The recyclability of PEEK, though currently limited by processing challenges, offers potential end-of-life value recovery. While recycling infrastructure for PEEK remains underdeveloped compared to metals, advancements in polymer recycling technologies are gradually improving the material's circular economy profile, potentially enhancing its future cost-benefit ratio through material recovery and reuse pathways.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!