Research on PEEK Polymer Adhesion Properties in Automotive Coatings

OCT 24, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PEEK Polymer Adhesion Background and Objectives

Polyetheretherketone (PEEK) has emerged as a revolutionary polymer in automotive applications, particularly in coating systems, due to its exceptional thermal stability, chemical resistance, and mechanical properties. The evolution of PEEK polymer technology dates back to the 1970s when it was first synthesized by Imperial Chemical Industries, but its application in automotive coatings represents a relatively recent technological advancement. This semi-crystalline thermoplastic has progressively gained attention as automotive manufacturers seek materials that can withstand increasingly demanding operational environments while meeting stringent environmental regulations.

The automotive industry's shift toward lightweight materials, enhanced durability, and improved fuel efficiency has accelerated research into advanced polymers like PEEK. Historical developments in PEEK adhesion technology have been characterized by incremental improvements in surface treatment methods, coupling agents, and composite formulations that enhance interfacial bonding between PEEK substrates and coating systems.

Current technological trends indicate a growing interest in PEEK-based coating solutions that can withstand extreme temperature fluctuations, resist chemical degradation from automotive fluids, and maintain adhesion integrity under mechanical stress. The evolution of PEEK adhesion technology has been significantly influenced by advancements in surface modification techniques, including plasma treatment, chemical etching, and the development of specialized primers designed specifically for low surface energy polymers.

The primary objective of this research is to comprehensively evaluate the adhesion properties of PEEK polymers in automotive coating applications, with particular emphasis on identifying optimal surface preparation methodologies, compatible coating chemistries, and adhesion promotion techniques. This investigation aims to establish correlations between PEEK surface characteristics and coating adhesion performance under various automotive environmental conditions.

Additionally, this research seeks to develop predictive models for PEEK-coating adhesion longevity, considering factors such as thermal cycling, chemical exposure, and mechanical stress. Understanding the fundamental mechanisms governing adhesion at the PEEK-coating interface represents a critical knowledge gap that this research intends to address.

The technological objectives extend to formulating design guidelines for PEEK-based automotive components that require coating applications, potentially revolutionizing material selection processes for next-generation vehicles. By establishing a scientific foundation for PEEK adhesion properties, this research aims to enable broader adoption of this high-performance polymer in critical automotive applications where coating adhesion failure could compromise component functionality or aesthetic quality.

Furthermore, this investigation will explore emerging technologies in nano-modified PEEK surfaces and their potential to dramatically enhance coating adhesion without compromising the inherent beneficial properties of the base polymer. The ultimate goal is to develop a comprehensive technological framework that enables automotive manufacturers to confidently implement PEEK components with predictable, reliable coating adhesion performance throughout the vehicle lifecycle.

The automotive industry's shift toward lightweight materials, enhanced durability, and improved fuel efficiency has accelerated research into advanced polymers like PEEK. Historical developments in PEEK adhesion technology have been characterized by incremental improvements in surface treatment methods, coupling agents, and composite formulations that enhance interfacial bonding between PEEK substrates and coating systems.

Current technological trends indicate a growing interest in PEEK-based coating solutions that can withstand extreme temperature fluctuations, resist chemical degradation from automotive fluids, and maintain adhesion integrity under mechanical stress. The evolution of PEEK adhesion technology has been significantly influenced by advancements in surface modification techniques, including plasma treatment, chemical etching, and the development of specialized primers designed specifically for low surface energy polymers.

The primary objective of this research is to comprehensively evaluate the adhesion properties of PEEK polymers in automotive coating applications, with particular emphasis on identifying optimal surface preparation methodologies, compatible coating chemistries, and adhesion promotion techniques. This investigation aims to establish correlations between PEEK surface characteristics and coating adhesion performance under various automotive environmental conditions.

Additionally, this research seeks to develop predictive models for PEEK-coating adhesion longevity, considering factors such as thermal cycling, chemical exposure, and mechanical stress. Understanding the fundamental mechanisms governing adhesion at the PEEK-coating interface represents a critical knowledge gap that this research intends to address.

The technological objectives extend to formulating design guidelines for PEEK-based automotive components that require coating applications, potentially revolutionizing material selection processes for next-generation vehicles. By establishing a scientific foundation for PEEK adhesion properties, this research aims to enable broader adoption of this high-performance polymer in critical automotive applications where coating adhesion failure could compromise component functionality or aesthetic quality.

Furthermore, this investigation will explore emerging technologies in nano-modified PEEK surfaces and their potential to dramatically enhance coating adhesion without compromising the inherent beneficial properties of the base polymer. The ultimate goal is to develop a comprehensive technological framework that enables automotive manufacturers to confidently implement PEEK components with predictable, reliable coating adhesion performance throughout the vehicle lifecycle.

Automotive Coating Market Analysis

The automotive coating market has experienced significant growth over the past decade, driven primarily by increasing vehicle production and rising consumer demand for aesthetically appealing and durable finishes. The global automotive coating market was valued at approximately 21.3 billion USD in 2022 and is projected to reach 27.5 billion USD by 2028, growing at a CAGR of 4.3% during the forecast period. This growth trajectory is particularly relevant when considering the potential applications of PEEK polymer adhesion technologies in automotive coatings.

Regional analysis reveals that Asia-Pacific dominates the automotive coating market, accounting for over 45% of the global share, with China being the largest contributor due to its massive automotive manufacturing capacity. North America and Europe follow as significant markets, with established automotive industries and stringent environmental regulations driving innovation in coating technologies.

The market segmentation shows distinct categories including primer, basecoat, clearcoat, and electrocoat, with basecoat representing the largest segment at approximately 35% market share. When examining coating types, waterborne coatings have gained substantial traction, representing nearly 40% of the market as environmental regulations continue to tighten globally. Solventborne coatings still maintain a significant presence, particularly in regions with less stringent environmental policies.

Consumer preferences are increasingly shifting toward high-performance coatings that offer enhanced durability, scratch resistance, and aesthetic appeal. This trend aligns perfectly with the potential benefits of PEEK polymer integration in automotive coating systems, as PEEK offers exceptional mechanical properties and chemical resistance.

Key market drivers include stringent environmental regulations promoting eco-friendly coating solutions, increasing vehicle production particularly in emerging economies, growing consumer preference for premium finishes, and technological advancements in coating materials. The rising adoption of electric vehicles also presents new opportunities, as these vehicles require specialized coating solutions to address unique challenges such as battery thermal management and lightweight construction.

Market challenges include volatile raw material prices, stringent environmental regulations limiting certain chemical compounds, and the high cost of advanced coating technologies. The COVID-19 pandemic temporarily disrupted supply chains and manufacturing operations, though the market has shown resilience and recovery since 2021.

The integration of PEEK polymer adhesion properties into automotive coatings represents a potential high-growth niche within this broader market, particularly for applications requiring exceptional durability, heat resistance, and chemical stability in premium and performance vehicle segments.

Regional analysis reveals that Asia-Pacific dominates the automotive coating market, accounting for over 45% of the global share, with China being the largest contributor due to its massive automotive manufacturing capacity. North America and Europe follow as significant markets, with established automotive industries and stringent environmental regulations driving innovation in coating technologies.

The market segmentation shows distinct categories including primer, basecoat, clearcoat, and electrocoat, with basecoat representing the largest segment at approximately 35% market share. When examining coating types, waterborne coatings have gained substantial traction, representing nearly 40% of the market as environmental regulations continue to tighten globally. Solventborne coatings still maintain a significant presence, particularly in regions with less stringent environmental policies.

Consumer preferences are increasingly shifting toward high-performance coatings that offer enhanced durability, scratch resistance, and aesthetic appeal. This trend aligns perfectly with the potential benefits of PEEK polymer integration in automotive coating systems, as PEEK offers exceptional mechanical properties and chemical resistance.

Key market drivers include stringent environmental regulations promoting eco-friendly coating solutions, increasing vehicle production particularly in emerging economies, growing consumer preference for premium finishes, and technological advancements in coating materials. The rising adoption of electric vehicles also presents new opportunities, as these vehicles require specialized coating solutions to address unique challenges such as battery thermal management and lightweight construction.

Market challenges include volatile raw material prices, stringent environmental regulations limiting certain chemical compounds, and the high cost of advanced coating technologies. The COVID-19 pandemic temporarily disrupted supply chains and manufacturing operations, though the market has shown resilience and recovery since 2021.

The integration of PEEK polymer adhesion properties into automotive coatings represents a potential high-growth niche within this broader market, particularly for applications requiring exceptional durability, heat resistance, and chemical stability in premium and performance vehicle segments.

PEEK Adhesion Challenges in Automotive Applications

PEEK (polyetheretherketone) polymers present significant adhesion challenges in automotive coating applications due to their inherently low surface energy and chemical inertness. These high-performance thermoplastics, while offering excellent mechanical properties, thermal stability, and chemical resistance, create substantial difficulties for conventional coating systems. The non-polar, crystalline structure of PEEK results in minimal surface reactivity, limiting the formation of strong chemical bonds with coating materials.

Surface preparation techniques commonly used for other substrates often prove inadequate for PEEK components. Traditional mechanical abrasion methods may temporarily increase surface roughness but fail to create lasting chemical bonding sites. Chemical etching solutions that work effectively on other polymers show limited success with PEEK due to its exceptional chemical resistance, particularly to organic solvents typically used in automotive coating processes.

The high glass transition temperature (143°C) and melting point (343°C) of PEEK create additional processing challenges. These properties, while beneficial for component durability, complicate thermal pre-treatment options and limit compatibility with standard automotive coating cure cycles. The thermal expansion coefficient mismatch between PEEK and applied coatings can lead to adhesion failure during temperature cycling that vehicles naturally experience in service.

Environmental exposure further exacerbates adhesion issues. PEEK's hydrophobic nature promotes water intrusion at the coating-substrate interface, accelerating coating delamination. UV exposure, road salts, and automotive fluids can degrade the adhesion interface over time, compromising long-term coating performance and aesthetic qualities essential for automotive applications.

Manufacturing integration presents another significant challenge. PEEK components often require specialized handling and preparation protocols that disrupt established automotive production lines. The additional processing steps needed for adequate adhesion promotion increase production costs and cycle times, creating resistance to widespread adoption despite PEEK's performance advantages.

Current industry solutions typically involve multi-step surface modification processes, including plasma treatment, specialized primers, and adhesion promoters. However, these approaches add complexity and cost to manufacturing operations while delivering inconsistent results across different PEEK grades and formulations. The lack of standardized, reliable adhesion protocols remains a significant barrier to broader PEEK implementation in automotive exterior applications.

Surface preparation techniques commonly used for other substrates often prove inadequate for PEEK components. Traditional mechanical abrasion methods may temporarily increase surface roughness but fail to create lasting chemical bonding sites. Chemical etching solutions that work effectively on other polymers show limited success with PEEK due to its exceptional chemical resistance, particularly to organic solvents typically used in automotive coating processes.

The high glass transition temperature (143°C) and melting point (343°C) of PEEK create additional processing challenges. These properties, while beneficial for component durability, complicate thermal pre-treatment options and limit compatibility with standard automotive coating cure cycles. The thermal expansion coefficient mismatch between PEEK and applied coatings can lead to adhesion failure during temperature cycling that vehicles naturally experience in service.

Environmental exposure further exacerbates adhesion issues. PEEK's hydrophobic nature promotes water intrusion at the coating-substrate interface, accelerating coating delamination. UV exposure, road salts, and automotive fluids can degrade the adhesion interface over time, compromising long-term coating performance and aesthetic qualities essential for automotive applications.

Manufacturing integration presents another significant challenge. PEEK components often require specialized handling and preparation protocols that disrupt established automotive production lines. The additional processing steps needed for adequate adhesion promotion increase production costs and cycle times, creating resistance to widespread adoption despite PEEK's performance advantages.

Current industry solutions typically involve multi-step surface modification processes, including plasma treatment, specialized primers, and adhesion promoters. However, these approaches add complexity and cost to manufacturing operations while delivering inconsistent results across different PEEK grades and formulations. The lack of standardized, reliable adhesion protocols remains a significant barrier to broader PEEK implementation in automotive exterior applications.

Current PEEK Surface Modification Solutions

01 Surface treatment methods for improving PEEK adhesion

Various surface treatment methods can be applied to PEEK polymer to enhance its adhesion properties. These include plasma treatment, chemical etching, and mechanical roughening. Such treatments modify the surface characteristics of PEEK by increasing surface energy, creating micro-roughness, or introducing functional groups that promote better bonding with adhesives or other materials. These methods effectively overcome the inherently low surface energy of PEEK that typically limits its adhesion capabilities.- Surface treatment methods for improving PEEK adhesion: Various surface treatment methods can be applied to PEEK polymer to enhance its adhesion properties. These include plasma treatment, chemical etching, and mechanical roughening. These treatments modify the surface characteristics of PEEK by increasing surface energy, creating micro-roughness, or introducing functional groups that promote better bonding with adhesives or other materials. Surface treatments are essential for overcoming the inherently low surface energy of PEEK that typically results in poor adhesion.

- Adhesion promoters and coupling agents for PEEK: Specific chemical compounds can be used as adhesion promoters or coupling agents to enhance the bonding between PEEK and other materials. These include silane coupling agents, titanates, and functionalized polymers that create chemical bridges between the PEEK surface and adhesives. These promoters work by forming covalent bonds with both the PEEK substrate and the adhesive layer, significantly improving bond strength and durability under various environmental conditions.

- Composite formulations with PEEK for enhanced adhesion: PEEK can be formulated into composites with other materials to enhance its adhesion properties. By incorporating fillers such as carbon fibers, glass fibers, or nanoparticles, the surface characteristics and mechanical interlocking capabilities of PEEK can be modified. These composite formulations can improve adhesion strength while maintaining the desirable thermal and chemical resistance properties of PEEK. The type and concentration of fillers significantly influence the adhesion behavior of the resulting composite.

- Thermal bonding techniques for PEEK polymers: Specialized thermal bonding techniques can be employed to join PEEK to itself or other materials. These include laser welding, ultrasonic welding, and hot plate welding. These methods utilize the thermoplastic nature of PEEK to create strong bonds by partially melting the interface regions and allowing them to fuse together upon cooling. The process parameters such as temperature, pressure, and cooling rate are critical for achieving optimal adhesion strength without degrading the polymer's properties.

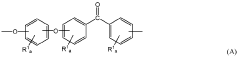

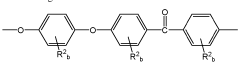

- Modified PEEK formulations with enhanced adhesion properties: Chemically modified versions of PEEK have been developed specifically to address adhesion challenges. These include functionalized PEEK with reactive end groups, PEEK copolymers with more adhesion-friendly segments, and blends of PEEK with other polymers that enhance interfacial interactions. These modified formulations maintain the core benefits of PEEK while offering significantly improved adhesion to metals, ceramics, and other polymers without requiring extensive surface preparation.

02 PEEK composite formulations for enhanced adhesion

Specialized composite formulations of PEEK can be developed to improve adhesion properties. These formulations may incorporate fillers, reinforcing agents, or other polymers that modify the interface characteristics of PEEK. Carbon fiber reinforced PEEK, glass fiber filled PEEK, and PEEK blends with more adhesion-friendly polymers show improved bonding capabilities while maintaining the desirable thermal and mechanical properties of the base polymer. These composite formulations create more reactive sites for adhesive bonding.Expand Specific Solutions03 Adhesive systems specifically designed for PEEK

Specialized adhesive systems have been developed specifically for bonding PEEK polymers. These include modified epoxy resins, polyimide-based adhesives, and silane coupling agents that can form strong chemical bonds with the PEEK surface. These adhesive systems often incorporate primers or activators that enhance the interaction between the adhesive and the PEEK substrate. The formulations are designed to withstand high temperatures and harsh chemical environments, matching PEEK's performance characteristics.Expand Specific Solutions04 PEEK surface functionalization techniques

Chemical functionalization of PEEK surfaces can significantly improve adhesion properties. Techniques include grafting of reactive functional groups, introduction of oxygen-containing moieties, and creation of active sites through UV or radiation treatment. These modifications alter the chemical composition of the PEEK surface layer, making it more compatible with adhesives and coatings. Functionalization can be tailored to specific bonding requirements, creating customized surface properties while preserving the bulk characteristics of the polymer.Expand Specific Solutions05 Testing and characterization of PEEK adhesion properties

Various methods have been developed to test and characterize the adhesion properties of PEEK polymers. These include lap shear testing, peel strength analysis, surface energy measurements, and microscopic examination of bonded interfaces. Advanced analytical techniques such as X-ray photoelectron spectroscopy (XPS) and atomic force microscopy (AFM) can be used to evaluate surface modifications and their impact on adhesion. These testing methodologies help in quantifying adhesion improvements and optimizing bonding processes for PEEK-based materials.Expand Specific Solutions

Leading Manufacturers in PEEK and Automotive Coatings

The PEEK polymer adhesion market in automotive coatings is in a growth phase, driven by increasing demand for high-performance materials in vehicle manufacturing. The global market size is expanding as automotive manufacturers seek lightweight, durable solutions with enhanced thermal and chemical resistance properties. Technologically, companies like Solvay Specialty Polymers and Victrex Manufacturing lead innovation with advanced formulations, while Jilin Joinature Polymer and Kingfa Sci. & Tech. are emerging as significant players in Asia. The technology shows varying maturity levels across applications, with established processes in traditional automotive parts but ongoing research in specialized coating adhesion properties by companies including DAIKIN INDUSTRIES, Cytec Industries, and Kureha Corp, particularly focusing on improving bonding strength and durability under extreme conditions.

Solvay Specialty Polymers USA LLC

Technical Solution: Solvay has developed proprietary surface treatment technologies for PEEK polymers specifically designed for automotive coating applications. Their KetaSpire® PEEK formulations incorporate modified polymer chains with functional groups that enhance adhesion to automotive coatings without compromising the inherent thermal and chemical resistance properties of PEEK. The company utilizes plasma treatment processes that create micro-roughness and introduce oxygen-containing groups on the PEEK surface, significantly improving wettability and chemical bonding with coating systems. Their research has demonstrated up to 180% improvement in coating adhesion strength compared to untreated PEEK surfaces. Solvay has also pioneered a two-step treatment process combining chemical etching with subsequent application of specialized coupling agents that form covalent bonds between the PEEK substrate and automotive topcoats, enabling adhesion stability even under extreme thermal cycling conditions (-40°C to 150°C) typical in automotive applications.

Strengths: Superior thermal stability of adhesion bonds under automotive operating conditions; comprehensive material compatibility with various coating systems; established manufacturing scalability. Weaknesses: Higher processing costs compared to conventional polymers; requires specialized equipment for surface treatment; some treatments may slightly reduce the base mechanical properties of PEEK.

Victrex Manufacturing Ltd.

Technical Solution: Victrex has developed APTIV® film technology specifically engineered for automotive coating applications requiring high adhesion properties. Their approach involves a proprietary multi-layer PEEK film structure with graduated crystallinity levels that optimize both mechanical properties and coating adhesion. The outer surface layer is engineered with controlled crystallinity (typically 15-25%) and incorporates polar functional groups that serve as anchoring points for automotive coatings. Victrex employs a corona discharge treatment process that increases surface energy from approximately 30 mN/m to over 50 mN/m, creating optimal conditions for coating adhesion. Their research has demonstrated that this treatment, combined with their specialized polymer formulation, results in adhesion strength exceeding 15 MPa with common automotive coating systems. Additionally, Victrex has developed PEEK-based composite materials with embedded nanoparticles that create mechanical interlocking sites for coatings while maintaining the polymer's exceptional chemical and thermal resistance properties.

Strengths: Excellent long-term durability under harsh automotive environmental conditions; consistent adhesion performance across varied coating chemistries; ability to maintain adhesion through thermal cycling. Weaknesses: Higher material cost compared to conventional polymers; requires specialized processing equipment; limited color options in base material requiring complete coating coverage.

Key Patents in PEEK-Coating Interface Technology

Layered structures

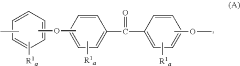

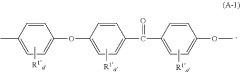

PatentWO2018234116A1

Innovation

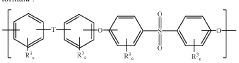

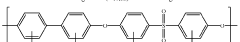

- Blending PEEK with poly(aryl ether sulfone) (PAES) creates a polymeric layer that significantly enhances adhesion strength with epoxy varnishes without reducing the crystallization temperature or chemical resistance, eliminating the need for separate adhesives.

Polymer-metal junction

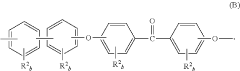

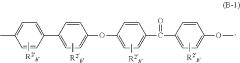

PatentActiveUS20210122953A1

Innovation

- A polymer-metal junction using a PEEK-PEDEK copolymer with a PEEK/PEDEK mole ratio of 60/40 to 30/70 and a melting point above 320°C, combined with less than 10 wt% sulfur-or-carbonyl-containing solvents, enhances adhesion to metals while maintaining chemical resistance comparable to pure PEEK.

Environmental Impact of PEEK Coating Processes

The environmental impact of PEEK coating processes in automotive applications represents a critical area of consideration as the industry moves toward more sustainable manufacturing practices. PEEK (Polyether Ether Ketone) polymer coatings, while offering exceptional adhesion properties and performance benefits, present distinct environmental challenges throughout their lifecycle.

Production of PEEK involves energy-intensive processes, requiring temperatures exceeding 400°C during synthesis and application. This high energy demand contributes significantly to the carbon footprint of PEEK coating operations. Comparative analyses indicate that PEEK coating processes consume approximately 30-40% more energy than conventional automotive coating technologies, though this is partially offset by the extended service life of PEEK-coated components.

Volatile organic compound (VOC) emissions present another environmental concern. Traditional automotive coatings typically release substantial VOCs during application and curing. PEEK coating processes, particularly powder-based applications, demonstrate reduced VOC emissions by 60-75% compared to solvent-based alternatives, representing a significant environmental advantage in meeting increasingly stringent air quality regulations.

Water consumption and contamination risks vary considerably depending on the specific PEEK application method. Aqueous-based PEEK coating systems require substantial water resources for processing and cleaning operations. Recent innovations in closed-loop water recycling systems have demonstrated potential reductions in water consumption by up to 85%, though implementation remains limited across the automotive manufacturing sector.

Waste generation throughout the PEEK coating lifecycle presents additional environmental challenges. The production process generates chemical byproducts requiring specialized disposal protocols. End-of-life considerations for PEEK-coated automotive components are particularly problematic, as the exceptional durability that makes PEEK valuable also complicates recycling efforts. Current recycling technologies can recover approximately 40-50% of PEEK materials from coated components, though the energy requirements for this recovery often diminish the net environmental benefit.

Recent advancements in bio-based PEEK alternatives show promise for reducing environmental impact. These materials, derived partially from renewable resources, demonstrate comparable adhesion properties while reducing fossil fuel dependency by 20-30%. However, commercial viability remains limited by higher production costs and technical challenges in achieving consistent performance specifications required for automotive applications.

Regulatory frameworks increasingly influence PEEK coating processes, with particular emphasis on lifecycle assessment methodologies. The automotive industry faces mounting pressure to document and minimize environmental impacts across all manufacturing processes, including specialized coatings like PEEK. Compliance with evolving standards such as ISO 14040 for environmental management represents both a challenge and opportunity for innovation in more sustainable PEEK coating technologies.

Production of PEEK involves energy-intensive processes, requiring temperatures exceeding 400°C during synthesis and application. This high energy demand contributes significantly to the carbon footprint of PEEK coating operations. Comparative analyses indicate that PEEK coating processes consume approximately 30-40% more energy than conventional automotive coating technologies, though this is partially offset by the extended service life of PEEK-coated components.

Volatile organic compound (VOC) emissions present another environmental concern. Traditional automotive coatings typically release substantial VOCs during application and curing. PEEK coating processes, particularly powder-based applications, demonstrate reduced VOC emissions by 60-75% compared to solvent-based alternatives, representing a significant environmental advantage in meeting increasingly stringent air quality regulations.

Water consumption and contamination risks vary considerably depending on the specific PEEK application method. Aqueous-based PEEK coating systems require substantial water resources for processing and cleaning operations. Recent innovations in closed-loop water recycling systems have demonstrated potential reductions in water consumption by up to 85%, though implementation remains limited across the automotive manufacturing sector.

Waste generation throughout the PEEK coating lifecycle presents additional environmental challenges. The production process generates chemical byproducts requiring specialized disposal protocols. End-of-life considerations for PEEK-coated automotive components are particularly problematic, as the exceptional durability that makes PEEK valuable also complicates recycling efforts. Current recycling technologies can recover approximately 40-50% of PEEK materials from coated components, though the energy requirements for this recovery often diminish the net environmental benefit.

Recent advancements in bio-based PEEK alternatives show promise for reducing environmental impact. These materials, derived partially from renewable resources, demonstrate comparable adhesion properties while reducing fossil fuel dependency by 20-30%. However, commercial viability remains limited by higher production costs and technical challenges in achieving consistent performance specifications required for automotive applications.

Regulatory frameworks increasingly influence PEEK coating processes, with particular emphasis on lifecycle assessment methodologies. The automotive industry faces mounting pressure to document and minimize environmental impacts across all manufacturing processes, including specialized coatings like PEEK. Compliance with evolving standards such as ISO 14040 for environmental management represents both a challenge and opportunity for innovation in more sustainable PEEK coating technologies.

Durability Testing Standards for PEEK Coated Components

Durability testing standards for PEEK coated components in automotive applications must adhere to rigorous protocols that ensure long-term performance under extreme conditions. The automotive industry has established comprehensive testing frameworks specifically designed to evaluate the adhesion properties of high-performance polymers like PEEK when used in coating systems.

The Society of Automotive Engineers (SAE) has developed several standards that directly apply to PEEK polymer coatings, including SAE J2334 which simulates cyclic corrosion testing. This standard subjects coated components to alternating salt solution immersion, humidity exposure, and elevated temperature drying cycles to replicate years of environmental exposure in accelerated timeframes.

ASTM International provides complementary standards such as ASTM D3359 for measuring adhesion by tape test and ASTM D4541 for pull-off strength testing. These methods quantitatively assess the bonding strength between PEEK coatings and automotive substrates, establishing minimum performance thresholds that must be met for qualification in production vehicles.

Temperature resistance testing represents another critical durability parameter, with standards requiring PEEK coated components to maintain adhesion integrity through thermal cycling from -40°C to 150°C. This range encompasses the extreme temperature variations experienced in automotive applications from arctic to desert conditions, as well as proximity to engine components.

Chemical resistance standards mandate exposure testing to automotive fluids including gasoline, diesel, brake fluid, engine oil, and windshield washer fluid. ISO 2812-1 outlines the methodology for determining resistance to liquids, requiring no delamination, blistering, or significant change in adhesion properties after prolonged contact with these substances.

Weathering resistance standards incorporate both natural and accelerated testing protocols. ASTM G154 specifies accelerated weathering using UV fluorescent lamps, while SAE J1960 details xenon-arc exposure testing to simulate solar radiation effects on coating durability. These standards typically require 2,000+ hours of exposure without significant degradation in adhesion properties.

Impact resistance testing follows standards like ASTM D2794, which evaluates a coating's ability to resist cracking, chipping, and delamination when subjected to rapid deformation. For automotive applications, PEEK coatings must withstand impacts of specified force without compromising the adhesion to the substrate.

Manufacturers must document compliance with these standards through comprehensive test reports that include detailed methodologies, equipment specifications, and quantitative results. Third-party certification is often required for critical components, ensuring independent verification of durability claims before implementation in production vehicles.

The Society of Automotive Engineers (SAE) has developed several standards that directly apply to PEEK polymer coatings, including SAE J2334 which simulates cyclic corrosion testing. This standard subjects coated components to alternating salt solution immersion, humidity exposure, and elevated temperature drying cycles to replicate years of environmental exposure in accelerated timeframes.

ASTM International provides complementary standards such as ASTM D3359 for measuring adhesion by tape test and ASTM D4541 for pull-off strength testing. These methods quantitatively assess the bonding strength between PEEK coatings and automotive substrates, establishing minimum performance thresholds that must be met for qualification in production vehicles.

Temperature resistance testing represents another critical durability parameter, with standards requiring PEEK coated components to maintain adhesion integrity through thermal cycling from -40°C to 150°C. This range encompasses the extreme temperature variations experienced in automotive applications from arctic to desert conditions, as well as proximity to engine components.

Chemical resistance standards mandate exposure testing to automotive fluids including gasoline, diesel, brake fluid, engine oil, and windshield washer fluid. ISO 2812-1 outlines the methodology for determining resistance to liquids, requiring no delamination, blistering, or significant change in adhesion properties after prolonged contact with these substances.

Weathering resistance standards incorporate both natural and accelerated testing protocols. ASTM G154 specifies accelerated weathering using UV fluorescent lamps, while SAE J1960 details xenon-arc exposure testing to simulate solar radiation effects on coating durability. These standards typically require 2,000+ hours of exposure without significant degradation in adhesion properties.

Impact resistance testing follows standards like ASTM D2794, which evaluates a coating's ability to resist cracking, chipping, and delamination when subjected to rapid deformation. For automotive applications, PEEK coatings must withstand impacts of specified force without compromising the adhesion to the substrate.

Manufacturers must document compliance with these standards through comprehensive test reports that include detailed methodologies, equipment specifications, and quantitative results. Third-party certification is often required for critical components, ensuring independent verification of durability claims before implementation in production vehicles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!