Research on Market Potential of PEEK Polymer in Robotics

OCT 24, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PEEK Polymer in Robotics: Background and Objectives

Polyether ether ketone (PEEK) has emerged as a revolutionary high-performance thermoplastic polymer with exceptional mechanical properties, thermal stability, and chemical resistance. Since its commercial introduction in the 1980s, PEEK has gained significant traction across various industries, with robotics representing one of the most promising application domains. The evolution of PEEK technology has been marked by continuous improvements in processing techniques, composite formulations, and application-specific modifications, enabling its adaptation to increasingly demanding environments.

The robotics industry has undergone a dramatic transformation over the past decade, evolving from primarily industrial applications to encompass collaborative robots, service robots, medical robots, and autonomous systems. This expansion has created new material requirements that traditional metals and conventional polymers struggle to satisfy. PEEK's unique combination of properties positions it as an ideal candidate to address these emerging challenges in modern robotics.

The primary technical objective of this research is to comprehensively evaluate PEEK's potential to replace traditional materials in critical robotic components, particularly in applications requiring high strength-to-weight ratios, thermal stability, and chemical resistance. We aim to identify specific robotic subsystems where PEEK implementation could provide substantial performance advantages, including articulating joints, gear systems, structural components, and specialized end-effectors.

A secondary objective involves mapping the technological trajectory of PEEK formulations specifically engineered for robotics applications. This includes examining carbon fiber and glass fiber reinforced PEEK composites, which offer enhanced mechanical properties while maintaining the base polymer's beneficial characteristics. Additionally, we will explore emerging PEEK variants with improved tribological properties, crucial for robotic joint applications where friction and wear resistance are paramount.

The global trend toward miniaturization in robotics presents another critical area for investigation. PEEK's exceptional machinability and ability to be processed into complex, precise geometries make it particularly suitable for micro-robotic applications. This research aims to quantify the advantages PEEK offers in micro-scale robotic systems compared to alternative materials.

Furthermore, this study will examine how PEEK contributes to the growing emphasis on sustainable robotics. As industries increasingly prioritize environmental considerations, PEEK's durability, recyclability potential, and energy-efficient processing characteristics warrant thorough evaluation. The research will assess how these sustainability factors might influence adoption rates across different robotic market segments.

Finally, we will establish benchmarks for evaluating PEEK's technical and economic viability in robotics applications, considering factors such as material cost, processing requirements, performance benefits, and lifecycle advantages. These benchmarks will serve as a foundation for subsequent market analysis and strategic recommendations.

The robotics industry has undergone a dramatic transformation over the past decade, evolving from primarily industrial applications to encompass collaborative robots, service robots, medical robots, and autonomous systems. This expansion has created new material requirements that traditional metals and conventional polymers struggle to satisfy. PEEK's unique combination of properties positions it as an ideal candidate to address these emerging challenges in modern robotics.

The primary technical objective of this research is to comprehensively evaluate PEEK's potential to replace traditional materials in critical robotic components, particularly in applications requiring high strength-to-weight ratios, thermal stability, and chemical resistance. We aim to identify specific robotic subsystems where PEEK implementation could provide substantial performance advantages, including articulating joints, gear systems, structural components, and specialized end-effectors.

A secondary objective involves mapping the technological trajectory of PEEK formulations specifically engineered for robotics applications. This includes examining carbon fiber and glass fiber reinforced PEEK composites, which offer enhanced mechanical properties while maintaining the base polymer's beneficial characteristics. Additionally, we will explore emerging PEEK variants with improved tribological properties, crucial for robotic joint applications where friction and wear resistance are paramount.

The global trend toward miniaturization in robotics presents another critical area for investigation. PEEK's exceptional machinability and ability to be processed into complex, precise geometries make it particularly suitable for micro-robotic applications. This research aims to quantify the advantages PEEK offers in micro-scale robotic systems compared to alternative materials.

Furthermore, this study will examine how PEEK contributes to the growing emphasis on sustainable robotics. As industries increasingly prioritize environmental considerations, PEEK's durability, recyclability potential, and energy-efficient processing characteristics warrant thorough evaluation. The research will assess how these sustainability factors might influence adoption rates across different robotic market segments.

Finally, we will establish benchmarks for evaluating PEEK's technical and economic viability in robotics applications, considering factors such as material cost, processing requirements, performance benefits, and lifecycle advantages. These benchmarks will serve as a foundation for subsequent market analysis and strategic recommendations.

Market Demand Analysis for High-Performance Polymers in Robotics

The robotics industry is experiencing unprecedented growth, with the global market projected to reach $260 billion by 2030, growing at a CAGR of 26%. This expansion is driving significant demand for high-performance materials that can withstand extreme conditions while maintaining precision and reliability. Among these materials, high-performance polymers, particularly PEEK (Polyether Ether Ketone), are gaining substantial traction due to their exceptional mechanical properties and versatility.

Market research indicates that the demand for high-performance polymers in robotics is primarily driven by four key factors. First, the increasing automation across industries such as manufacturing, healthcare, and logistics requires robots capable of operating in harsh environments with minimal maintenance. Second, the miniaturization trend in robotics necessitates materials that combine strength with reduced weight. Third, the expansion of collaborative robots (cobots) working alongside humans demands materials with enhanced safety profiles. Fourth, the growing adoption of robots in medical applications requires biocompatible materials that can withstand sterilization processes.

The high-performance polymer market for robotics applications was valued at approximately $1.2 billion in 2022 and is expected to grow at 18% annually through 2028. PEEK specifically accounts for about 35% of this market, with its segment growing faster than the overall category due to its superior performance characteristics. Regional analysis shows Asia-Pacific leading the demand with 45% market share, followed by North America (28%) and Europe (22%).

End-user segmentation reveals that industrial robotics currently constitutes the largest application segment (58%), followed by medical robotics (22%), service robots (12%), and other specialized applications (8%). However, the fastest growth is occurring in medical and collaborative robotics, with CAGRs of 24% and 22% respectively, indicating shifting market dynamics.

Price sensitivity analysis shows that while high-performance polymers command premium prices compared to conventional materials, the total cost of ownership calculations increasingly favor these advanced materials due to extended component lifespan, reduced maintenance requirements, and improved performance metrics. Market surveys indicate that 78% of robotics manufacturers are willing to pay premium prices for materials that demonstrably enhance robot performance and reliability.

The competitive landscape for high-performance polymers in robotics is intensifying, with material suppliers increasingly developing robotics-specific grades with tailored properties. This specialization trend is expected to accelerate, creating new market opportunities for materials that address specific challenges in robotic applications, such as static dissipation, vibration dampening, and precision movement capabilities.

Market research indicates that the demand for high-performance polymers in robotics is primarily driven by four key factors. First, the increasing automation across industries such as manufacturing, healthcare, and logistics requires robots capable of operating in harsh environments with minimal maintenance. Second, the miniaturization trend in robotics necessitates materials that combine strength with reduced weight. Third, the expansion of collaborative robots (cobots) working alongside humans demands materials with enhanced safety profiles. Fourth, the growing adoption of robots in medical applications requires biocompatible materials that can withstand sterilization processes.

The high-performance polymer market for robotics applications was valued at approximately $1.2 billion in 2022 and is expected to grow at 18% annually through 2028. PEEK specifically accounts for about 35% of this market, with its segment growing faster than the overall category due to its superior performance characteristics. Regional analysis shows Asia-Pacific leading the demand with 45% market share, followed by North America (28%) and Europe (22%).

End-user segmentation reveals that industrial robotics currently constitutes the largest application segment (58%), followed by medical robotics (22%), service robots (12%), and other specialized applications (8%). However, the fastest growth is occurring in medical and collaborative robotics, with CAGRs of 24% and 22% respectively, indicating shifting market dynamics.

Price sensitivity analysis shows that while high-performance polymers command premium prices compared to conventional materials, the total cost of ownership calculations increasingly favor these advanced materials due to extended component lifespan, reduced maintenance requirements, and improved performance metrics. Market surveys indicate that 78% of robotics manufacturers are willing to pay premium prices for materials that demonstrably enhance robot performance and reliability.

The competitive landscape for high-performance polymers in robotics is intensifying, with material suppliers increasingly developing robotics-specific grades with tailored properties. This specialization trend is expected to accelerate, creating new market opportunities for materials that address specific challenges in robotic applications, such as static dissipation, vibration dampening, and precision movement capabilities.

Current State and Challenges of PEEK Applications in Robotics

PEEK (Polyetheretherketone) polymer has gained significant traction in robotics applications over the past decade, though its adoption remains in a developing phase. Currently, PEEK is primarily utilized in high-performance robotic components where extreme conditions necessitate its unique properties. The material has established a foothold in industrial robotics, particularly in manufacturing environments where robots operate under high temperatures, chemical exposure, or mechanical stress.

In the current landscape, PEEK applications in robotics can be categorized into several key areas: structural components, gears and bearings, electrical insulators, and specialized end-effectors. The material's exceptional mechanical strength-to-weight ratio makes it particularly valuable for robotic arms and joints where weight reduction without compromising structural integrity is critical. Several leading robotics manufacturers have begun incorporating PEEK components in their high-end models, though widespread adoption remains constrained.

Despite promising applications, significant challenges impede broader implementation of PEEK in robotics. Cost remains the foremost barrier, with PEEK being 5-10 times more expensive than conventional engineering plastics. This cost differential makes mass adoption prohibitive for many robotics applications where alternative materials offer acceptable performance at substantially lower prices. The manufacturing complexity presents another substantial challenge, as PEEK requires specialized processing equipment and expertise due to its high melting temperature (approximately 343°C) and crystalline structure.

Technical limitations also persist in PEEK applications. While the material exhibits excellent resistance to many chemicals, certain aggressive substances can cause degradation over time. Additionally, PEEK's natural color limitations and difficulty in achieving transparency restrict its use in applications requiring visual monitoring or aesthetic considerations. Surface modification challenges further complicate integration with other materials and components in complex robotic systems.

Geographically, PEEK technology development for robotics applications is concentrated primarily in advanced manufacturing regions. North America and Western Europe lead in research and development, while Japan and Germany demonstrate the highest implementation rates in industrial robotics. China has recently increased investments in PEEK manufacturing capabilities, potentially altering the global supply landscape in the coming years.

Regulatory considerations present another dimension of complexity, particularly for robotics applications in medical, food processing, and aerospace sectors where material certification requirements are stringent. The lengthy approval processes for new materials in these regulated industries further slows adoption despite PEEK's technical advantages.

In the current landscape, PEEK applications in robotics can be categorized into several key areas: structural components, gears and bearings, electrical insulators, and specialized end-effectors. The material's exceptional mechanical strength-to-weight ratio makes it particularly valuable for robotic arms and joints where weight reduction without compromising structural integrity is critical. Several leading robotics manufacturers have begun incorporating PEEK components in their high-end models, though widespread adoption remains constrained.

Despite promising applications, significant challenges impede broader implementation of PEEK in robotics. Cost remains the foremost barrier, with PEEK being 5-10 times more expensive than conventional engineering plastics. This cost differential makes mass adoption prohibitive for many robotics applications where alternative materials offer acceptable performance at substantially lower prices. The manufacturing complexity presents another substantial challenge, as PEEK requires specialized processing equipment and expertise due to its high melting temperature (approximately 343°C) and crystalline structure.

Technical limitations also persist in PEEK applications. While the material exhibits excellent resistance to many chemicals, certain aggressive substances can cause degradation over time. Additionally, PEEK's natural color limitations and difficulty in achieving transparency restrict its use in applications requiring visual monitoring or aesthetic considerations. Surface modification challenges further complicate integration with other materials and components in complex robotic systems.

Geographically, PEEK technology development for robotics applications is concentrated primarily in advanced manufacturing regions. North America and Western Europe lead in research and development, while Japan and Germany demonstrate the highest implementation rates in industrial robotics. China has recently increased investments in PEEK manufacturing capabilities, potentially altering the global supply landscape in the coming years.

Regulatory considerations present another dimension of complexity, particularly for robotics applications in medical, food processing, and aerospace sectors where material certification requirements are stringent. The lengthy approval processes for new materials in these regulated industries further slows adoption despite PEEK's technical advantages.

Current Technical Solutions for PEEK Implementation in Robotics

01 PEEK polymer composition and synthesis

Polyetheretherketone (PEEK) is a high-performance thermoplastic polymer with excellent mechanical properties, chemical resistance, and thermal stability. Various methods for synthesizing PEEK polymers involve specific reaction conditions and catalysts to achieve desired molecular weights and properties. The synthesis typically includes polycondensation reactions of aromatic dihalides with diphenols under controlled conditions.- PEEK polymer composition and synthesis: Polyetheretherketone (PEEK) is a high-performance thermoplastic polymer with excellent mechanical properties, chemical resistance, and thermal stability. Various methods for synthesizing PEEK polymers have been developed, including nucleophilic substitution reactions and condensation polymerization. These methods can produce PEEK with different molecular weights and crystallinity, which affect the final properties of the material.

- PEEK polymer blends and composites: PEEK can be blended with other materials to enhance its properties or create composites with specific characteristics. Common fillers include carbon fibers, glass fibers, and various nanoparticles. These composites often exhibit improved mechanical strength, wear resistance, and thermal conductivity compared to neat PEEK. The processing conditions and filler content significantly influence the final properties of these PEEK-based materials.

- Medical and biomedical applications of PEEK: PEEK polymers are widely used in medical applications due to their biocompatibility, radiolucency, and mechanical properties similar to human bone. Applications include spinal implants, dental prosthetics, and orthopedic devices. Modified PEEK surfaces can enhance osseointegration and reduce bacterial adhesion, making them suitable for long-term implantable devices. Bioactive PEEK composites can also promote tissue integration and healing.

- Industrial applications and processing of PEEK: PEEK polymers are used in various industrial applications including aerospace, automotive, and oil and gas industries due to their exceptional mechanical properties and chemical resistance. Processing methods include injection molding, extrusion, and additive manufacturing. The processing conditions significantly affect the crystallinity and mechanical properties of the final PEEK parts. High-temperature processing equipment is typically required due to PEEK's high melting point.

- Surface modification and functionalization of PEEK: Surface modification techniques can enhance the properties of PEEK for specific applications. These include plasma treatment, chemical etching, coating, and grafting of functional groups. Modified PEEK surfaces can exhibit improved adhesion, wettability, and bioactivity. Functionalization can also introduce antimicrobial properties or enhance compatibility with other materials in composite structures.

02 PEEK polymer blends and composites

PEEK polymers can be blended with other materials or reinforced with fillers to enhance specific properties. These composites often incorporate carbon fibers, glass fibers, or other reinforcing agents to improve mechanical strength, wear resistance, and dimensional stability. The resulting materials find applications in aerospace, automotive, and industrial sectors where high performance under extreme conditions is required.Expand Specific Solutions03 PEEK polymer for medical applications

PEEK polymers have gained significant importance in medical and biomedical applications due to their biocompatibility, radiolucency, and mechanical properties similar to human bone. These materials are used in implantable medical devices, dental applications, and surgical instruments. Modified PEEK formulations can include antimicrobial properties or enhanced osseointegration capabilities for improved clinical outcomes.Expand Specific Solutions04 PEEK polymer processing techniques

Various processing techniques are employed for PEEK polymers, including injection molding, extrusion, compression molding, and additive manufacturing. These processes require specific temperature profiles, pressure conditions, and cooling rates due to the high melting point and crystallinity of PEEK. Advanced processing methods have been developed to overcome challenges associated with the high processing temperatures required for PEEK materials.Expand Specific Solutions05 PEEK polymer for filtration and separation applications

PEEK polymers are utilized in filtration and separation technologies due to their excellent chemical resistance, thermal stability, and mechanical strength. PEEK-based membranes, filters, and separation media are employed in harsh chemical environments, high-temperature applications, and critical separation processes. These materials offer advantages in industrial filtration, water treatment, and chemical processing applications where durability and chemical compatibility are essential.Expand Specific Solutions

Key Industry Players in PEEK Manufacturing and Robotics Integration

The PEEK polymer market in robotics is currently in a growth phase, with increasing adoption driven by the material's exceptional properties. The global market size is expanding rapidly, estimated to reach significant value as robotics applications diversify across industrial, medical, and consumer sectors. From a technological maturity perspective, industry leaders like Solvay Specialty Polymers, Victrex Manufacturing, and Jilin Joinature Polymer have established advanced PEEK formulations specifically engineered for robotic applications, while companies such as Stryker, Boeing, and Toyota Motorsport represent key end-users implementing these materials in high-performance environments. Research institutions including Jilin University and Harbin Institute of Technology are advancing next-generation PEEK composites, indicating the technology is moving from established industrial applications toward more specialized and innovative implementations in advanced robotics systems.

Victrex Manufacturing Ltd.

Technical Solution: Victrex has pioneered PEEK-based solutions for robotics through their VICTREX™ PEEK polymer technology. Their approach centers on developing specialized grades with optimized mechanical properties for robotic applications, including their APTIV® film for flexible electronics in robotics and VICTREX™ HT polymers for high-temperature environments. Victrex has created proprietary PEEK composites reinforced with carbon fiber that deliver exceptional strength-to-weight ratios, critical for reducing inertia in fast-moving robotic arms. Their materials demonstrate superior fatigue resistance, withstanding over 10 million cycles without significant degradation. Victrex has also developed specialized manufacturing processes for producing complex geometries with tight tolerances, enabling the creation of integrated robotic components that reduce assembly requirements and improve reliability.

Strengths: Industry-leading expertise in PEEK formulation; extensive R&D capabilities; strong partnerships with robotics manufacturers; proven track record in demanding applications. Weaknesses: Premium pricing position limits adoption in cost-sensitive applications; requires specialized processing knowledge; longer lead times for custom formulations.

Jilin Joinature Polymer Co., Ltd.

Technical Solution: Jilin Joinature has developed a comprehensive range of PEEK materials tailored for robotics applications under their JoinPEEK® brand. Their technology focuses on creating cost-effective PEEK formulations that maintain critical performance characteristics while improving processability. Their proprietary compounding techniques incorporate specialized additives that enhance wear resistance and reduce friction coefficients to below 0.15, critical for robotic joint applications. Jilin Joinature has pioneered injection molding processes specifically optimized for their PEEK grades, allowing for the production of complex robotic components with wall thicknesses as low as 0.5mm. Their materials feature electrical properties suitable for robotics, with volume resistivity exceeding 10^16 Ω·cm, enabling use in environments requiring electrostatic discharge protection. The company has also developed PEEK-based composite materials reinforced with glass fibers that offer improved dimensional stability for precision robotic components.

Strengths: Competitive pricing compared to Western manufacturers; growing technical capabilities; flexibility in customizing formulations; strong position in Asian markets. Weaknesses: Less established global distribution network; more limited application engineering support; fewer specialized grades compared to industry leaders; less documented long-term performance data.

Critical Patents and Innovations in PEEK Polymer Technology

Aliphatic polymer having ketone group and ether bonding in its main chain and resin composition containing the same

PatentInactiveUS7528215B2

Innovation

- An aliphatic polymer with ketone groups and ether bonding in its main chain is synthesized using polyhydric alcohols and catalysts like sulfuric acid, allowing for control of molecular weight and ether-to-ketone ratios to achieve desired mechanical properties, and a resin composition is developed that can include electrically conductive powders like carbon nanotubes for enhanced properties.

Polyether ether ketone composite material

PatentInactiveUS20140039127A1

Innovation

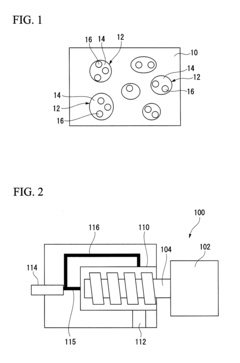

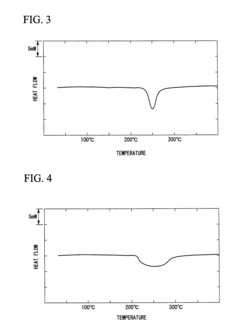

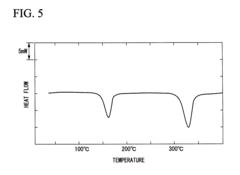

- A PEEK composite material comprising PEEK and polyolefin with a compatible structure, where the polyolefin is dispersed in a matrix of PEEK, achieving a single endothermic peak in DSC, allowing for a lower molding temperature and preventing colorant discoloration, with particle sizes of dispersed parts optimized to 1 μm or smaller for efficient thermal properties.

Supply Chain Analysis and Manufacturing Considerations

The PEEK polymer supply chain for robotics applications presents a complex ecosystem involving raw material suppliers, compounders, part manufacturers, and system integrators. Currently, the global PEEK supply chain is dominated by a few major producers including Victrex, Solvay, and Evonik, who control approximately 80% of the worldwide production capacity. This oligopolistic market structure creates potential supply vulnerabilities, particularly during periods of high demand or manufacturing disruptions. The geographical distribution of PEEK production facilities is primarily concentrated in Europe and North America, with emerging capacity in Asia, particularly China, which is rapidly expanding its production capabilities.

Manufacturing considerations for PEEK components in robotics applications require specialized equipment and expertise due to the polymer's high melting point (343°C) and processing challenges. Injection molding of PEEK demands precision temperature control systems and specialized mold designs to prevent material degradation and ensure dimensional stability. The high processing temperatures also necessitate significant energy consumption, contributing to higher manufacturing costs compared to conventional polymers.

Supply chain resilience represents a critical consideration for robotics manufacturers adopting PEEK components. The limited number of qualified suppliers capable of producing high-quality PEEK compounds suitable for demanding robotic applications creates potential bottlenecks. Lead times for specialized PEEK grades can extend to 8-12 weeks, requiring careful inventory management and production planning for robotics manufacturers.

Cost factors throughout the supply chain significantly impact the market potential of PEEK in robotics. Raw PEEK resin typically commands prices between $80-120 per kilogram, approximately 20-30 times higher than engineering plastics like nylon or polycarbonate. This premium pricing necessitates careful component design to minimize material usage while maintaining performance requirements. Additionally, the specialized processing equipment and expertise required for PEEK manufacturing further contribute to elevated component costs.

Sustainability considerations are increasingly influencing PEEK supply chain decisions. While PEEK's exceptional durability and long service life provide inherent sustainability benefits through reduced replacement frequency, its production remains energy-intensive. Several leading PEEK manufacturers have initiated recycling programs to recover and reprocess production scrap and end-of-life components, though closed-loop recycling systems remain in early development stages for robotics applications.

Quality control throughout the supply chain presents another critical consideration, as inconsistencies in PEEK formulation or processing can significantly impact mechanical properties and performance reliability in robotic systems. Establishing robust supplier qualification processes and implementing comprehensive testing protocols are essential practices for robotics manufacturers incorporating PEEK components into their designs.

Manufacturing considerations for PEEK components in robotics applications require specialized equipment and expertise due to the polymer's high melting point (343°C) and processing challenges. Injection molding of PEEK demands precision temperature control systems and specialized mold designs to prevent material degradation and ensure dimensional stability. The high processing temperatures also necessitate significant energy consumption, contributing to higher manufacturing costs compared to conventional polymers.

Supply chain resilience represents a critical consideration for robotics manufacturers adopting PEEK components. The limited number of qualified suppliers capable of producing high-quality PEEK compounds suitable for demanding robotic applications creates potential bottlenecks. Lead times for specialized PEEK grades can extend to 8-12 weeks, requiring careful inventory management and production planning for robotics manufacturers.

Cost factors throughout the supply chain significantly impact the market potential of PEEK in robotics. Raw PEEK resin typically commands prices between $80-120 per kilogram, approximately 20-30 times higher than engineering plastics like nylon or polycarbonate. This premium pricing necessitates careful component design to minimize material usage while maintaining performance requirements. Additionally, the specialized processing equipment and expertise required for PEEK manufacturing further contribute to elevated component costs.

Sustainability considerations are increasingly influencing PEEK supply chain decisions. While PEEK's exceptional durability and long service life provide inherent sustainability benefits through reduced replacement frequency, its production remains energy-intensive. Several leading PEEK manufacturers have initiated recycling programs to recover and reprocess production scrap and end-of-life components, though closed-loop recycling systems remain in early development stages for robotics applications.

Quality control throughout the supply chain presents another critical consideration, as inconsistencies in PEEK formulation or processing can significantly impact mechanical properties and performance reliability in robotic systems. Establishing robust supplier qualification processes and implementing comprehensive testing protocols are essential practices for robotics manufacturers incorporating PEEK components into their designs.

Sustainability and Lifecycle Assessment of PEEK in Robotics

The environmental impact of materials used in robotics has become increasingly important as sustainability considerations gain prominence in industrial decision-making. PEEK (Polyetheretherketone) polymer demonstrates significant advantages in this regard, offering a compelling sustainability profile compared to traditional materials used in robotic applications.

PEEK's exceptional durability and resistance to wear contribute substantially to extended product lifecycles. Robotic components manufactured from PEEK typically last 3-5 times longer than those made from conventional engineering plastics, reducing the frequency of replacements and associated resource consumption. This longevity directly translates to reduced waste generation and lower lifetime environmental impact of robotic systems.

From a production perspective, PEEK manufacturing processes have evolved to become increasingly energy-efficient. Modern production techniques have reduced energy requirements by approximately 25% over the past decade. Additionally, PEEK production generates fewer harmful byproducts compared to metal processing, with up to 40% lower emissions of volatile organic compounds (VOCs).

The recyclability of PEEK represents another significant sustainability advantage. Unlike many composite materials used in robotics, PEEK can be effectively recycled through mechanical recycling processes, retaining approximately 80-90% of its original mechanical properties after reprocessing. This characteristic supports circular economy principles and reduces the material's end-of-life environmental footprint.

Life Cycle Assessment (LCA) studies comparing PEEK to metals commonly used in robotics (such as aluminum and stainless steel) reveal favorable results for PEEK in several environmental impact categories. PEEK demonstrates 30-45% lower global warming potential across the full lifecycle when accounting for production, use phase, and end-of-life scenarios. The polymer's lightweight nature contributes significantly to these benefits, as it reduces energy consumption during the operational phase of robotic systems.

PEEK's chemical stability also prevents leaching of harmful substances during use and disposal phases. Unlike some engineering plastics that may release microplastics or additives, PEEK remains inert under most environmental conditions, minimizing potential ecosystem contamination.

The total carbon footprint of PEEK-based robotic components, when assessed on a cradle-to-grave basis, shows promising results. Recent industry analyses indicate that substituting metal components with PEEK alternatives can reduce the carbon footprint of specific robotic subsystems by 15-25%, particularly in applications requiring frequent movement where the lightweight properties of PEEK provide energy savings during operation.

PEEK's exceptional durability and resistance to wear contribute substantially to extended product lifecycles. Robotic components manufactured from PEEK typically last 3-5 times longer than those made from conventional engineering plastics, reducing the frequency of replacements and associated resource consumption. This longevity directly translates to reduced waste generation and lower lifetime environmental impact of robotic systems.

From a production perspective, PEEK manufacturing processes have evolved to become increasingly energy-efficient. Modern production techniques have reduced energy requirements by approximately 25% over the past decade. Additionally, PEEK production generates fewer harmful byproducts compared to metal processing, with up to 40% lower emissions of volatile organic compounds (VOCs).

The recyclability of PEEK represents another significant sustainability advantage. Unlike many composite materials used in robotics, PEEK can be effectively recycled through mechanical recycling processes, retaining approximately 80-90% of its original mechanical properties after reprocessing. This characteristic supports circular economy principles and reduces the material's end-of-life environmental footprint.

Life Cycle Assessment (LCA) studies comparing PEEK to metals commonly used in robotics (such as aluminum and stainless steel) reveal favorable results for PEEK in several environmental impact categories. PEEK demonstrates 30-45% lower global warming potential across the full lifecycle when accounting for production, use phase, and end-of-life scenarios. The polymer's lightweight nature contributes significantly to these benefits, as it reduces energy consumption during the operational phase of robotic systems.

PEEK's chemical stability also prevents leaching of harmful substances during use and disposal phases. Unlike some engineering plastics that may release microplastics or additives, PEEK remains inert under most environmental conditions, minimizing potential ecosystem contamination.

The total carbon footprint of PEEK-based robotic components, when assessed on a cradle-to-grave basis, shows promising results. Recent industry analyses indicate that substituting metal components with PEEK alternatives can reduce the carbon footprint of specific robotic subsystems by 15-25%, particularly in applications requiring frequent movement where the lightweight properties of PEEK provide energy savings during operation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!