PEEK Polymer Properties in High-Demand Electronic Applications

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PEEK Evolution and Application Objectives

Polyetheretherketone (PEEK) has emerged as a revolutionary high-performance thermoplastic polymer since its commercial introduction in the early 1980s by ICI (now Victrex). The evolution of PEEK technology represents a significant milestone in materials science, particularly for applications requiring exceptional thermal stability, mechanical strength, and chemical resistance. Initially developed for aerospace and automotive industries, PEEK's unique property profile has driven its expansion into electronic applications over the past four decades.

The historical development of PEEK polymers shows a clear trajectory from basic formulations to increasingly specialized grades tailored for specific electronic applications. Early PEEK materials offered thermal stability up to 260°C and good mechanical properties, but lacked the refined characteristics needed for precision electronic components. By the 1990s, research focused on enhancing PEEK's electrical insulation properties and dimensional stability, leading to the development of carbon-filled and glass-reinforced PEEK composites with improved performance profiles.

The 2000s witnessed significant advancements in PEEK processing technologies, enabling more complex geometries and finer tolerances essential for miniaturized electronic components. Concurrently, modifications to the polymer backbone and crystallinity control techniques allowed manufacturers to fine-tune properties such as dielectric strength, volume resistivity, and thermal conductivity to meet increasingly demanding electronic application requirements.

Recent technological evolution has centered on PEEK's integration with other materials and technologies. This includes the development of PEEK-based 3D printing filaments for rapid prototyping of electronic housings, PEEK-metal hybrid structures for thermal management applications, and nano-modified PEEK composites with enhanced electrical properties. These innovations have expanded PEEK's utility in semiconductor manufacturing equipment, high-frequency communication devices, and next-generation battery technologies.

The primary objectives for PEEK in modern electronic applications focus on several critical areas. First, enhancing thermal management capabilities to address the increasing power densities in electronic devices while maintaining dimensional stability under thermal cycling. Second, improving PEEK's compatibility with emerging manufacturing processes, particularly additive manufacturing and micro-molding techniques. Third, developing PEEK formulations with tailored electrical properties for specific applications ranging from insulation to controlled conductivity.

Additionally, research aims to extend PEEK's service life in harsh electronic environments, particularly those involving exposure to aggressive chemicals, radiation, or extreme temperatures. This includes developing more hydrolysis-resistant grades for humid environments and formulations with improved resistance to plasma etching processes used in semiconductor manufacturing.

The historical development of PEEK polymers shows a clear trajectory from basic formulations to increasingly specialized grades tailored for specific electronic applications. Early PEEK materials offered thermal stability up to 260°C and good mechanical properties, but lacked the refined characteristics needed for precision electronic components. By the 1990s, research focused on enhancing PEEK's electrical insulation properties and dimensional stability, leading to the development of carbon-filled and glass-reinforced PEEK composites with improved performance profiles.

The 2000s witnessed significant advancements in PEEK processing technologies, enabling more complex geometries and finer tolerances essential for miniaturized electronic components. Concurrently, modifications to the polymer backbone and crystallinity control techniques allowed manufacturers to fine-tune properties such as dielectric strength, volume resistivity, and thermal conductivity to meet increasingly demanding electronic application requirements.

Recent technological evolution has centered on PEEK's integration with other materials and technologies. This includes the development of PEEK-based 3D printing filaments for rapid prototyping of electronic housings, PEEK-metal hybrid structures for thermal management applications, and nano-modified PEEK composites with enhanced electrical properties. These innovations have expanded PEEK's utility in semiconductor manufacturing equipment, high-frequency communication devices, and next-generation battery technologies.

The primary objectives for PEEK in modern electronic applications focus on several critical areas. First, enhancing thermal management capabilities to address the increasing power densities in electronic devices while maintaining dimensional stability under thermal cycling. Second, improving PEEK's compatibility with emerging manufacturing processes, particularly additive manufacturing and micro-molding techniques. Third, developing PEEK formulations with tailored electrical properties for specific applications ranging from insulation to controlled conductivity.

Additionally, research aims to extend PEEK's service life in harsh electronic environments, particularly those involving exposure to aggressive chemicals, radiation, or extreme temperatures. This includes developing more hydrolysis-resistant grades for humid environments and formulations with improved resistance to plasma etching processes used in semiconductor manufacturing.

Electronic Industry Demand Analysis for High-Performance Polymers

The electronic industry's demand for high-performance polymers has experienced significant growth over the past decade, driven primarily by the miniaturization of components, increased operating temperatures, and the need for materials that can withstand harsh chemical environments. PEEK (Polyetheretherketone) has emerged as a frontrunner among high-performance polymers due to its exceptional thermal stability, mechanical strength, and chemical resistance properties.

Market research indicates that the global high-performance polymers market for electronic applications reached approximately $2.7 billion in 2022, with PEEK and its composites accounting for roughly 18% of this market. The compound annual growth rate (CAGR) for PEEK in electronics is projected at 6.8% through 2028, outpacing many competing materials.

The primary demand drivers for PEEK in electronic applications include semiconductor manufacturing equipment, where its high temperature resistance (up to 260°C continuous use) and excellent dimensional stability are critical. The material's inherent flame retardancy (UL94 V-0 rating without additives) has positioned it as an ideal choice for connectors, circuit boards, and insulation components in high-reliability electronics.

5G infrastructure deployment has created another significant demand vector, with PEEK being utilized in antenna components, waveguides, and base station equipment due to its excellent dielectric properties and minimal signal interference characteristics. The material's dielectric constant of 3.2-3.4 remains stable across a wide frequency range, making it suitable for high-frequency applications.

Consumer electronics manufacturers have increasingly adopted PEEK for premium device components, particularly in areas requiring high wear resistance and structural integrity. The automotive electronics sector represents another growth area, with PEEK components being used in advanced driver assistance systems (ADAS), battery management systems, and other high-temperature electronic applications.

Regional analysis shows Asia-Pacific dominating the demand landscape, accounting for approximately 58% of global consumption, followed by North America (22%) and Europe (17%). This distribution closely follows electronic manufacturing hubs, with particular concentration in China, Taiwan, South Korea, and Japan.

The price premium of PEEK (typically 5-8 times higher than engineering plastics like polycarbonate) remains a limiting factor for broader adoption. However, its total cost of ownership advantages—including longer component lifespan, reduced maintenance requirements, and elimination of costly failures in critical applications—continue to justify its specification in high-value electronic systems.

Market research indicates that the global high-performance polymers market for electronic applications reached approximately $2.7 billion in 2022, with PEEK and its composites accounting for roughly 18% of this market. The compound annual growth rate (CAGR) for PEEK in electronics is projected at 6.8% through 2028, outpacing many competing materials.

The primary demand drivers for PEEK in electronic applications include semiconductor manufacturing equipment, where its high temperature resistance (up to 260°C continuous use) and excellent dimensional stability are critical. The material's inherent flame retardancy (UL94 V-0 rating without additives) has positioned it as an ideal choice for connectors, circuit boards, and insulation components in high-reliability electronics.

5G infrastructure deployment has created another significant demand vector, with PEEK being utilized in antenna components, waveguides, and base station equipment due to its excellent dielectric properties and minimal signal interference characteristics. The material's dielectric constant of 3.2-3.4 remains stable across a wide frequency range, making it suitable for high-frequency applications.

Consumer electronics manufacturers have increasingly adopted PEEK for premium device components, particularly in areas requiring high wear resistance and structural integrity. The automotive electronics sector represents another growth area, with PEEK components being used in advanced driver assistance systems (ADAS), battery management systems, and other high-temperature electronic applications.

Regional analysis shows Asia-Pacific dominating the demand landscape, accounting for approximately 58% of global consumption, followed by North America (22%) and Europe (17%). This distribution closely follows electronic manufacturing hubs, with particular concentration in China, Taiwan, South Korea, and Japan.

The price premium of PEEK (typically 5-8 times higher than engineering plastics like polycarbonate) remains a limiting factor for broader adoption. However, its total cost of ownership advantages—including longer component lifespan, reduced maintenance requirements, and elimination of costly failures in critical applications—continue to justify its specification in high-value electronic systems.

PEEK Technical Limitations and Development Challenges

Despite PEEK's exceptional properties making it ideal for electronic applications, several technical limitations and development challenges persist. The high processing temperature of PEEK (370-400°C) presents significant manufacturing difficulties, requiring specialized equipment and precise temperature control. This thermal processing challenge increases production costs and limits widespread adoption in cost-sensitive electronic applications.

Crystallinity control remains problematic for PEEK in electronic contexts. The polymer's semi-crystalline nature affects its electrical and mechanical properties, with inconsistent crystallization potentially leading to performance variations across batches. This unpredictability poses serious reliability concerns for high-precision electronic components where consistent performance is paramount.

Adhesion issues represent another major challenge. PEEK's chemical inertness, while beneficial for durability, creates difficulties in forming strong bonds with metals, ceramics, and other polymers commonly used in electronic assemblies. This limitation complicates the integration of PEEK components into complex electronic systems, often requiring specialized surface treatments or adhesion promoters that add processing steps and costs.

The electrical properties of standard PEEK formulations present limitations for certain electronic applications. While PEEK offers good electrical insulation, its native form lacks the conductivity needed for applications requiring electrostatic discharge protection or electromagnetic interference shielding. Modification with conductive fillers can address this limitation but often compromises other desirable properties like mechanical strength or processability.

Moisture absorption, though minimal compared to other polymers, remains problematic in ultra-sensitive electronic applications. Even PEEK's low 0.1-0.5% moisture uptake can affect dimensional stability and electrical performance in precision components, particularly in environments with fluctuating humidity levels.

Cost factors continue to restrict PEEK's broader adoption in electronics. The high raw material cost (typically 10-15 times that of engineering plastics like polycarbonate) limits its use to high-value applications where performance justifies the expense. This economic barrier prevents PEEK from penetrating mass-market electronic applications despite its technical advantages.

Recyclability presents growing challenges as sustainability becomes increasingly important in electronics manufacturing. PEEK's high thermal stability makes conventional recycling difficult, and its cross-linked structure after prolonged high-temperature exposure further complicates reprocessing efforts, creating end-of-life management issues for electronic components.

Crystallinity control remains problematic for PEEK in electronic contexts. The polymer's semi-crystalline nature affects its electrical and mechanical properties, with inconsistent crystallization potentially leading to performance variations across batches. This unpredictability poses serious reliability concerns for high-precision electronic components where consistent performance is paramount.

Adhesion issues represent another major challenge. PEEK's chemical inertness, while beneficial for durability, creates difficulties in forming strong bonds with metals, ceramics, and other polymers commonly used in electronic assemblies. This limitation complicates the integration of PEEK components into complex electronic systems, often requiring specialized surface treatments or adhesion promoters that add processing steps and costs.

The electrical properties of standard PEEK formulations present limitations for certain electronic applications. While PEEK offers good electrical insulation, its native form lacks the conductivity needed for applications requiring electrostatic discharge protection or electromagnetic interference shielding. Modification with conductive fillers can address this limitation but often compromises other desirable properties like mechanical strength or processability.

Moisture absorption, though minimal compared to other polymers, remains problematic in ultra-sensitive electronic applications. Even PEEK's low 0.1-0.5% moisture uptake can affect dimensional stability and electrical performance in precision components, particularly in environments with fluctuating humidity levels.

Cost factors continue to restrict PEEK's broader adoption in electronics. The high raw material cost (typically 10-15 times that of engineering plastics like polycarbonate) limits its use to high-value applications where performance justifies the expense. This economic barrier prevents PEEK from penetrating mass-market electronic applications despite its technical advantages.

Recyclability presents growing challenges as sustainability becomes increasingly important in electronics manufacturing. PEEK's high thermal stability makes conventional recycling difficult, and its cross-linked structure after prolonged high-temperature exposure further complicates reprocessing efforts, creating end-of-life management issues for electronic components.

Current PEEK Formulations for Electronic Applications

01 Thermal and mechanical properties of PEEK polymers

PEEK (Polyetheretherketone) polymers exhibit exceptional thermal stability and mechanical strength. They maintain their structural integrity at high temperatures, with a glass transition temperature of approximately 143°C and melting point around 343°C. These polymers demonstrate excellent mechanical properties including high tensile strength, stiffness, and impact resistance, making them suitable for demanding applications in aerospace, automotive, and industrial sectors where high performance under extreme conditions is required.- Thermal properties of PEEK polymers: PEEK polymers exhibit exceptional thermal stability and resistance to high temperatures. They maintain their mechanical properties at elevated temperatures, with a glass transition temperature around 143°C and melting point of approximately 343°C. This thermal stability makes PEEK suitable for applications in extreme temperature environments, allowing it to function effectively in both high and low temperature conditions without significant degradation.

- Mechanical properties and strength characteristics: PEEK polymers demonstrate outstanding mechanical properties including high tensile strength, excellent fatigue resistance, and remarkable impact resistance. They maintain dimensional stability under load and exhibit low creep even at elevated temperatures. The inherent stiffness and durability of PEEK make it an ideal material for structural components in demanding applications where mechanical reliability is crucial.

- Chemical resistance and stability: PEEK polymers possess exceptional resistance to a wide range of chemicals including acids, bases, hydrocarbons, and organic solvents. This chemical inertness prevents degradation in harsh chemical environments, making PEEK suitable for applications in chemical processing equipment, oil and gas industries, and medical implants. The material maintains its structural integrity and properties even after prolonged exposure to aggressive chemicals.

- Biocompatibility and medical applications: PEEK polymers exhibit excellent biocompatibility properties, making them suitable for medical implants and devices. They are non-toxic, non-allergenic, and resistant to degradation in biological environments. PEEK's mechanical properties closely match those of human bone, reducing stress shielding effects in orthopedic applications. Additionally, PEEK can be sterilized using conventional methods without significant degradation of its properties.

- Processing and modification techniques: PEEK polymers can be processed using various techniques including injection molding, extrusion, and compression molding. The material can be modified through the addition of fillers such as carbon fibers, glass fibers, or nanoparticles to enhance specific properties. These modifications can improve mechanical strength, wear resistance, or electrical conductivity while maintaining the inherent benefits of the base PEEK polymer. Advanced processing techniques allow for the creation of complex geometries and specialized PEEK composites for specific applications.

02 Chemical resistance and biocompatibility of PEEK

PEEK polymers possess outstanding chemical resistance to a wide range of solvents, acids, bases, and hydrocarbons. They are highly resistant to hydrolysis, oxidation, and radiation damage. Additionally, PEEK demonstrates excellent biocompatibility, making it suitable for medical implants and devices. The material is inert, non-toxic, and does not cause adverse reactions in biological environments, which has led to its increased use in orthopedic, spinal, and dental applications.Expand Specific Solutions03 PEEK composite formulations and enhancements

PEEK polymers can be enhanced through the incorporation of various fillers and reinforcements to improve specific properties. Carbon fiber reinforced PEEK offers increased stiffness and strength while maintaining low weight. Glass fiber reinforced variants provide improved dimensional stability and electrical insulation properties. Other additives such as graphene, carbon nanotubes, and ceramic particles can be incorporated to enhance thermal conductivity, wear resistance, and other specialized properties for specific applications.Expand Specific Solutions04 Processing techniques for PEEK polymers

PEEK polymers can be processed using various techniques including injection molding, extrusion, compression molding, and additive manufacturing. Due to their high melting temperatures, specialized equipment and processing conditions are required. The crystallinity of PEEK can be controlled through processing parameters such as cooling rate and annealing treatments, which significantly affects the final properties of the material. Advanced processing techniques have been developed to overcome challenges associated with the high processing temperatures required for PEEK.Expand Specific Solutions05 Applications and functional properties of PEEK

PEEK polymers find applications across various industries due to their unique combination of properties. In aerospace and automotive sectors, they serve as lightweight alternatives to metals. In electronics, they function as high-performance insulators. Their tribological properties make them excellent for bearings and wear components. In the oil and gas industry, they withstand harsh environments. Medical applications leverage their biocompatibility for implants and surgical instruments. The functional properties of PEEK can be tailored through modifications to meet specific application requirements.Expand Specific Solutions

Leading PEEK Manufacturers and Market Competition

The PEEK polymer market for high-demand electronic applications is currently in a growth phase, with increasing adoption across multiple industries. The competitive landscape is dominated by established global players like Solvay Specialty Polymers and Victrex Manufacturing, who possess advanced R&D capabilities and extensive manufacturing infrastructure. Market size is expanding rapidly due to PEEK's exceptional thermal stability, chemical resistance, and mechanical strength properties critical for electronic applications. From a technological maturity perspective, companies like Ticona LLC and Jilin Joinature Polymer are advancing PEEK formulations for specialized electronic requirements, while academic institutions such as Jilin University and Shanghai University are contributing fundamental research. Asian manufacturers, particularly Chinese firms, are increasingly challenging Western incumbents by developing cost-effective production methods and application-specific PEEK variants for the electronics sector.

Solvay Specialty Polymers USA LLC

Technical Solution: Solvay has developed advanced PEEK formulations specifically engineered for high-demand electronic applications. Their KetaSpire® PEEK offers exceptional thermal stability (glass transition temperature of 143°C and melting point of 343°C) and maintains mechanical properties at continuous use temperatures up to 240°C. Solvay has implemented proprietary processing techniques to enhance crystallinity control, resulting in improved dimensional stability critical for precision electronic components. Their PEEK compounds incorporate specialized additives for ESD (electrostatic discharge) protection while maintaining excellent electrical insulation properties. Solvay's technology includes carbon fiber and glass fiber reinforced PEEK grades that provide enhanced mechanical strength and reduced coefficient of thermal expansion, making them suitable for miniaturized electronic components requiring dimensional precision. Recent innovations include laser-markable PEEK formulations for permanent component identification in harsh environments.

Strengths: Superior chemical resistance against aggressive fluids used in electronics manufacturing; excellent dielectric properties maintained across wide frequency and temperature ranges; UL94 V0 flame retardancy without additives. Weaknesses: Higher processing temperatures (370-400°C) require specialized equipment; premium pricing compared to standard engineering polymers; limited transparency options for visual inspection applications.

Victrex Manufacturing Ltd.

Technical Solution: Victrex has pioneered PEEK polymer solutions specifically designed for electronic applications through their APTIV® film and VICTREX® PEEK product lines. Their technology focuses on ultra-thin PEEK films (as thin as 6 microns) with exceptional dimensional stability and dielectric properties. Victrex has developed proprietary extrusion and orientation processes that create biaxially oriented PEEK films with enhanced mechanical properties and reduced thickness variability. Their PEEK formulations incorporate precisely controlled molecular weight distributions to optimize flow characteristics during processing while maintaining thermal performance (continuous use temperature of 260°C). For high-frequency electronic applications, Victrex has engineered PEEK variants with tailored dielectric constants and dissipation factors that remain stable across broad frequency ranges (up to 10 GHz). Their technology includes specialized surface treatment methods that enhance adhesion properties for metallization processes in flexible circuit applications.

Strengths: Industry-leading thin film capabilities enabling miniaturization of electronic components; exceptional mechanical properties retention after multiple reflow soldering cycles; comprehensive technical support and application development resources. Weaknesses: Higher cost compared to conventional polymers limits adoption in cost-sensitive applications; requires specialized processing equipment; limited natural transparency restricts optical applications.

Key Patents and Breakthroughs in PEEK Technology

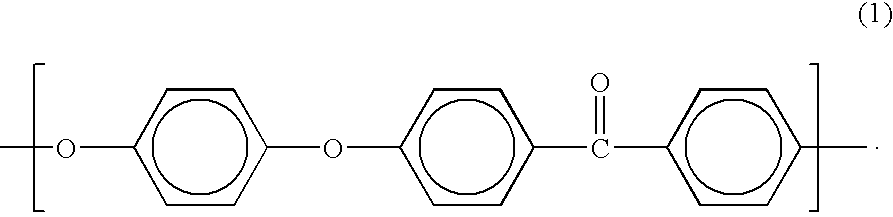

Semiconductive film, electric charge control member and process for production the semiconductive film

PatentInactiveUS20070020450A1

Innovation

- A production process involving extrusion of a resin composition comprising PEEK and a conductive filler through a T-die or ring die with controlled lip clearance and temperature, followed by cooling and solidification using a cooling roll or mandrel, to produce a semiconductive film with balanced properties including narrow thickness and volume resistivity scatter, high folding endurance, and excellent mechanical strength.

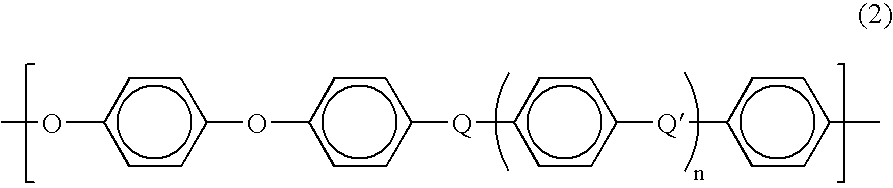

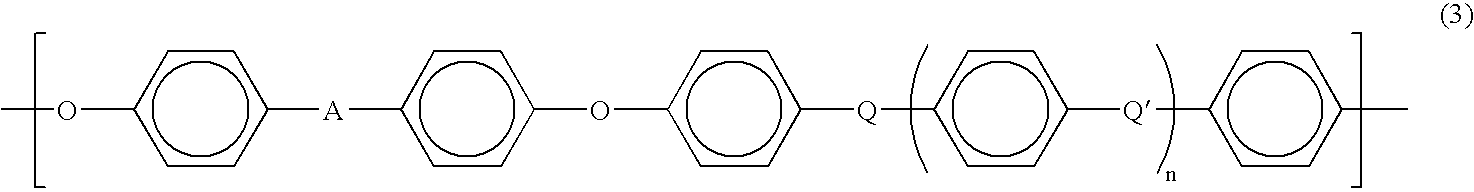

High-strength and low-chroma polyetheretherketone and preparation method therefor

PatentPendingUS20240360279A1

Innovation

- A nucleophilic polycondensation reaction process under controlled pressure (0.15 MPa to 1.0 MPa) and temperature (140° C. to 260° C.) using specific monomers and alkali carbonates in an inert atmosphere to produce PEEK with improved impact strength and whiter color.

Thermal and Electrical Performance Benchmarking

Comprehensive thermal and electrical performance benchmarking reveals PEEK polymer's exceptional capabilities in high-demand electronic applications. When compared to conventional polymers like PPS, PEI, and LCP, PEEK demonstrates superior thermal stability with a glass transition temperature of 143°C and melting point of 343°C, enabling continuous operation at temperatures up to 260°C without significant property degradation.

Thermal conductivity measurements position PEEK (0.25-0.32 W/m·K) favorably against most engineering thermoplastics, though slightly below specialized thermal management polymers. This property becomes particularly valuable in heat-generating electronic components where efficient thermal dissipation prevents performance degradation and extends device lifespan.

Electrical insulation properties of PEEK remain remarkably stable across varying environmental conditions. With dielectric strength exceeding 20 kV/mm and volume resistivity of 10^16 ohm·cm, PEEK maintains reliable electrical isolation even in harsh operating environments. Comparative testing shows PEEK retains over 90% of its insulative properties after 10,000 hours of thermal aging at 200°C, outperforming PEI which exhibits 15-20% degradation under identical conditions.

Frequency-dependent testing demonstrates PEEK's stable dielectric constant (approximately 3.2-3.4) across a wide frequency range (100 Hz to 10 MHz), making it suitable for high-frequency applications. This contrasts with several competing polymers that show significant dielectric property fluctuations at higher frequencies.

Accelerated aging tests simulating real-world electronic application environments reveal PEEK's exceptional performance retention. After 2,000 hours of exposure to 85°C/85% relative humidity conditions, PEEK samples maintained 95% of original electrical properties and 97% of mechanical strength, significantly outperforming most alternative materials.

Thermal cycling resistance testing (-65°C to +200°C for 1,000 cycles) demonstrates PEEK's dimensional stability with less than 0.1% permanent deformation, compared to 0.3-0.5% for PPS and LCP alternatives. This characteristic proves critical for applications requiring precise component alignment and connection integrity over repeated thermal expansion/contraction cycles.

Combined thermal-electrical performance metrics position PEEK as an optimal material for demanding electronic applications including high-temperature connectors, semiconductor test sockets, and next-generation power electronics where the convergence of thermal stability and electrical insulation properties is essential for reliable long-term performance.

Thermal conductivity measurements position PEEK (0.25-0.32 W/m·K) favorably against most engineering thermoplastics, though slightly below specialized thermal management polymers. This property becomes particularly valuable in heat-generating electronic components where efficient thermal dissipation prevents performance degradation and extends device lifespan.

Electrical insulation properties of PEEK remain remarkably stable across varying environmental conditions. With dielectric strength exceeding 20 kV/mm and volume resistivity of 10^16 ohm·cm, PEEK maintains reliable electrical isolation even in harsh operating environments. Comparative testing shows PEEK retains over 90% of its insulative properties after 10,000 hours of thermal aging at 200°C, outperforming PEI which exhibits 15-20% degradation under identical conditions.

Frequency-dependent testing demonstrates PEEK's stable dielectric constant (approximately 3.2-3.4) across a wide frequency range (100 Hz to 10 MHz), making it suitable for high-frequency applications. This contrasts with several competing polymers that show significant dielectric property fluctuations at higher frequencies.

Accelerated aging tests simulating real-world electronic application environments reveal PEEK's exceptional performance retention. After 2,000 hours of exposure to 85°C/85% relative humidity conditions, PEEK samples maintained 95% of original electrical properties and 97% of mechanical strength, significantly outperforming most alternative materials.

Thermal cycling resistance testing (-65°C to +200°C for 1,000 cycles) demonstrates PEEK's dimensional stability with less than 0.1% permanent deformation, compared to 0.3-0.5% for PPS and LCP alternatives. This characteristic proves critical for applications requiring precise component alignment and connection integrity over repeated thermal expansion/contraction cycles.

Combined thermal-electrical performance metrics position PEEK as an optimal material for demanding electronic applications including high-temperature connectors, semiconductor test sockets, and next-generation power electronics where the convergence of thermal stability and electrical insulation properties is essential for reliable long-term performance.

Environmental Impact and Recyclability Assessment

The environmental impact of PEEK (Polyetheretherketone) in electronic applications presents a complex sustainability profile that warrants thorough assessment. PEEK demonstrates exceptional durability with a lifespan significantly longer than conventional polymers, reducing replacement frequency and associated waste generation. This longevity contributes to decreased resource consumption and manufacturing emissions over product lifecycles in electronic components.

When examining PEEK's production footprint, the polymer requires high-temperature processing (approximately 400°C), resulting in considerable energy consumption compared to standard thermoplastics. However, this initial environmental cost is often offset by PEEK's extended service life and superior performance characteristics in demanding electronic applications. The material's resistance to thermal degradation also minimizes harmful emissions during operation in high-temperature electronic environments.

PEEK demonstrates remarkable recyclability potential, maintaining up to 90% of its mechanical properties after multiple reprocessing cycles. This characteristic is particularly valuable for electronic applications where material integrity is critical. Mechanical recycling methods have proven effective for PEEK recovery, though the presence of additives and fillers in specialized electronic-grade formulations can complicate separation processes.

Chemical recycling techniques for PEEK are advancing, with solvolysis and pyrolysis showing promise for recovering base materials from complex electronic components. These methods can potentially close the material loop in electronic manufacturing, though commercial-scale implementation remains limited. The high value of virgin PEEK creates economic incentives for recovery systems, with reclaimed material commanding 60-70% of virgin material prices.

End-of-life management for PEEK-containing electronics presents both challenges and opportunities. While PEEK's chemical stability prevents leaching of harmful substances into the environment, this same property means the polymer persists for extended periods if improperly disposed of. Advanced sorting technologies utilizing near-infrared spectroscopy have improved identification and separation of PEEK from mixed waste streams, enhancing recovery rates.

The carbon footprint analysis of PEEK in electronic applications reveals that despite energy-intensive production, the total lifecycle emissions are often lower than alternatives when accounting for extended service life and reduced replacement needs. Life Cycle Assessment (LCA) studies indicate that PEEK components can reduce overall environmental impact by 30-40% compared to conventional materials in high-temperature electronic applications, primarily through extended operational lifespans and reduced failure rates.

When examining PEEK's production footprint, the polymer requires high-temperature processing (approximately 400°C), resulting in considerable energy consumption compared to standard thermoplastics. However, this initial environmental cost is often offset by PEEK's extended service life and superior performance characteristics in demanding electronic applications. The material's resistance to thermal degradation also minimizes harmful emissions during operation in high-temperature electronic environments.

PEEK demonstrates remarkable recyclability potential, maintaining up to 90% of its mechanical properties after multiple reprocessing cycles. This characteristic is particularly valuable for electronic applications where material integrity is critical. Mechanical recycling methods have proven effective for PEEK recovery, though the presence of additives and fillers in specialized electronic-grade formulations can complicate separation processes.

Chemical recycling techniques for PEEK are advancing, with solvolysis and pyrolysis showing promise for recovering base materials from complex electronic components. These methods can potentially close the material loop in electronic manufacturing, though commercial-scale implementation remains limited. The high value of virgin PEEK creates economic incentives for recovery systems, with reclaimed material commanding 60-70% of virgin material prices.

End-of-life management for PEEK-containing electronics presents both challenges and opportunities. While PEEK's chemical stability prevents leaching of harmful substances into the environment, this same property means the polymer persists for extended periods if improperly disposed of. Advanced sorting technologies utilizing near-infrared spectroscopy have improved identification and separation of PEEK from mixed waste streams, enhancing recovery rates.

The carbon footprint analysis of PEEK in electronic applications reveals that despite energy-intensive production, the total lifecycle emissions are often lower than alternatives when accounting for extended service life and reduced replacement needs. Life Cycle Assessment (LCA) studies indicate that PEEK components can reduce overall environmental impact by 30-40% compared to conventional materials in high-temperature electronic applications, primarily through extended operational lifespans and reduced failure rates.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!