PEEK Polymer Thermal Properties in the Context of Solar Panel Design

OCT 24, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PEEK Thermal Properties Background and Objectives

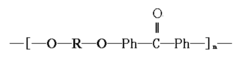

Polyetheretherketone (PEEK) has emerged as a significant engineering thermoplastic polymer since its commercial introduction in the early 1980s. Initially developed for aerospace and automotive applications due to its exceptional thermal stability, PEEK has gradually expanded into various high-performance sectors including electronics, medical devices, and renewable energy systems. The evolution of PEEK polymer technology has been characterized by continuous improvements in processing techniques and the development of specialized grades with enhanced thermal properties.

In the context of solar panel design, thermal management represents one of the most critical challenges affecting both efficiency and longevity. Conventional solar panels experience a performance degradation of approximately 0.3-0.5% per degree Celsius above their rated temperature, highlighting the importance of thermal regulation in photovoltaic systems. This efficiency loss, known as the negative temperature coefficient, creates a significant need for thermally stable materials in solar panel components.

PEEK polymer offers a unique combination of properties that make it particularly suitable for solar applications. With a glass transition temperature of approximately 143°C and a melting point of around 343°C, PEEK maintains its structural integrity and mechanical properties across a wide temperature range that encompasses typical solar panel operating conditions. Additionally, its thermal conductivity of 0.25 W/m·K, while modest compared to metals, exceeds that of many competing polymers, potentially offering advantages in heat dissipation within panel components.

The primary technical objective of investigating PEEK thermal properties in solar panel design is to determine optimal material formulations and configurations that maximize heat dissipation while maintaining structural integrity under prolonged exposure to solar radiation. This includes exploring the potential of PEEK composites with enhanced thermal conductivity through the incorporation of fillers such as carbon fibers, graphene, or ceramic particles.

Secondary objectives include quantifying the long-term thermal aging characteristics of PEEK under conditions that simulate solar panel operating environments, including cyclic temperature variations, UV exposure, and humidity fluctuations. Understanding these degradation mechanisms is essential for predicting service life and developing strategies to mitigate thermal aging effects.

Furthermore, this investigation aims to establish design guidelines for PEEK-based components in solar panel systems, particularly focusing on junction boxes, backsheets, and structural supports where thermal management is critical. By optimizing the thermal properties of these components, the overall efficiency and durability of solar panels can be significantly improved, potentially reducing the levelized cost of solar energy and expanding its viability across diverse geographical and climatic conditions.

In the context of solar panel design, thermal management represents one of the most critical challenges affecting both efficiency and longevity. Conventional solar panels experience a performance degradation of approximately 0.3-0.5% per degree Celsius above their rated temperature, highlighting the importance of thermal regulation in photovoltaic systems. This efficiency loss, known as the negative temperature coefficient, creates a significant need for thermally stable materials in solar panel components.

PEEK polymer offers a unique combination of properties that make it particularly suitable for solar applications. With a glass transition temperature of approximately 143°C and a melting point of around 343°C, PEEK maintains its structural integrity and mechanical properties across a wide temperature range that encompasses typical solar panel operating conditions. Additionally, its thermal conductivity of 0.25 W/m·K, while modest compared to metals, exceeds that of many competing polymers, potentially offering advantages in heat dissipation within panel components.

The primary technical objective of investigating PEEK thermal properties in solar panel design is to determine optimal material formulations and configurations that maximize heat dissipation while maintaining structural integrity under prolonged exposure to solar radiation. This includes exploring the potential of PEEK composites with enhanced thermal conductivity through the incorporation of fillers such as carbon fibers, graphene, or ceramic particles.

Secondary objectives include quantifying the long-term thermal aging characteristics of PEEK under conditions that simulate solar panel operating environments, including cyclic temperature variations, UV exposure, and humidity fluctuations. Understanding these degradation mechanisms is essential for predicting service life and developing strategies to mitigate thermal aging effects.

Furthermore, this investigation aims to establish design guidelines for PEEK-based components in solar panel systems, particularly focusing on junction boxes, backsheets, and structural supports where thermal management is critical. By optimizing the thermal properties of these components, the overall efficiency and durability of solar panels can be significantly improved, potentially reducing the levelized cost of solar energy and expanding its viability across diverse geographical and climatic conditions.

Solar Panel Market Demand Analysis

The global solar panel market has experienced remarkable growth over the past decade, driven primarily by increasing environmental awareness, government incentives, and declining manufacturing costs. As of 2023, the market size has reached approximately $180 billion, with projections indicating continued expansion at a compound annual growth rate of 7.8% through 2030. This growth trajectory underscores the critical importance of advanced materials like PEEK polymers in enhancing solar panel performance and durability.

Consumer demand for solar energy solutions has shifted significantly toward higher efficiency and longer-lasting panels. Market research indicates that residential consumers are willing to pay a premium of 15-20% for solar panels that demonstrate superior thermal stability and extended operational lifespans. This preference directly relates to PEEK polymer applications, as thermal management remains one of the most significant factors affecting panel efficiency and longevity.

Commercial and industrial sectors represent the fastest-growing segment within the solar market, with demand increasing by 12.3% annually. These sectors particularly value materials that can withstand extreme temperature fluctuations while maintaining structural integrity. PEEK polymers, with their exceptional thermal properties, address this specific market need by potentially extending operational lifespans by 5-7 years compared to conventional materials.

Geographic analysis reveals that regions with extreme climate conditions—including parts of the Middle East, Australia, and the southwestern United States—show particularly strong demand for thermally resilient solar technologies. In these markets, panels incorporating advanced thermal management solutions command price premiums of up to 25% due to their ability to maintain efficiency under harsh conditions.

The utility-scale solar segment, representing approximately 60% of total installed capacity, has increasingly specified advanced thermal management requirements in procurement contracts. This trend has accelerated as grid operators seek to maximize return on investment through extended equipment lifespans and reduced maintenance costs.

Market forecasts indicate that demand for high-performance polymers in solar applications will grow at nearly twice the rate of the overall solar market through 2028. This accelerated growth reflects industry recognition that thermal management represents a critical frontier in solar panel evolution, particularly as installations expand into more challenging environmental conditions.

Consumer surveys further reveal that warranty periods and degradation rates have become key decision factors for purchasers, with 78% of commercial buyers citing long-term performance stability as "very important" or "extremely important" in their procurement decisions. This market preference creates a clear commercial incentive for incorporating thermally superior materials like PEEK polymers into next-generation solar panel designs.

Consumer demand for solar energy solutions has shifted significantly toward higher efficiency and longer-lasting panels. Market research indicates that residential consumers are willing to pay a premium of 15-20% for solar panels that demonstrate superior thermal stability and extended operational lifespans. This preference directly relates to PEEK polymer applications, as thermal management remains one of the most significant factors affecting panel efficiency and longevity.

Commercial and industrial sectors represent the fastest-growing segment within the solar market, with demand increasing by 12.3% annually. These sectors particularly value materials that can withstand extreme temperature fluctuations while maintaining structural integrity. PEEK polymers, with their exceptional thermal properties, address this specific market need by potentially extending operational lifespans by 5-7 years compared to conventional materials.

Geographic analysis reveals that regions with extreme climate conditions—including parts of the Middle East, Australia, and the southwestern United States—show particularly strong demand for thermally resilient solar technologies. In these markets, panels incorporating advanced thermal management solutions command price premiums of up to 25% due to their ability to maintain efficiency under harsh conditions.

The utility-scale solar segment, representing approximately 60% of total installed capacity, has increasingly specified advanced thermal management requirements in procurement contracts. This trend has accelerated as grid operators seek to maximize return on investment through extended equipment lifespans and reduced maintenance costs.

Market forecasts indicate that demand for high-performance polymers in solar applications will grow at nearly twice the rate of the overall solar market through 2028. This accelerated growth reflects industry recognition that thermal management represents a critical frontier in solar panel evolution, particularly as installations expand into more challenging environmental conditions.

Consumer surveys further reveal that warranty periods and degradation rates have become key decision factors for purchasers, with 78% of commercial buyers citing long-term performance stability as "very important" or "extremely important" in their procurement decisions. This market preference creates a clear commercial incentive for incorporating thermally superior materials like PEEK polymers into next-generation solar panel designs.

PEEK Polymer Current State and Technical Challenges

Polyether ether ketone (PEEK) has emerged as a promising material for solar panel applications due to its exceptional thermal properties. Currently, PEEK polymers exhibit a glass transition temperature of approximately 143°C and a melting point around 343°C, making them suitable for high-temperature environments encountered in solar panel operations. The thermal conductivity of PEEK typically ranges from 0.25 to 0.32 W/m·K, which is relatively low compared to metals but higher than many other polymers, allowing for controlled heat dissipation in solar applications.

The global PEEK market has witnessed significant growth, with major manufacturers including Victrex, Solvay, and Evonik Industries developing specialized grades for various applications. Recent advancements have focused on enhancing the thermal stability of PEEK through the incorporation of fillers such as carbon fibers, glass fibers, and ceramic particles, which can increase thermal conductivity by up to 300% while maintaining the polymer's inherent properties.

Despite these advancements, several technical challenges persist in optimizing PEEK for solar panel applications. The primary challenge involves balancing thermal conductivity with electrical insulation properties, as increased thermal conductivity often compromises electrical resistance. Current research indicates that achieving thermal conductivity above 0.5 W/m·K while maintaining dielectric strength above 20 kV/mm remains difficult without significant material modifications.

Another significant challenge is the degradation of PEEK under prolonged UV exposure, which is inevitable in solar applications. Studies have shown that after 5,000 hours of accelerated weathering tests, unmodified PEEK can experience up to 15% reduction in tensile strength and increased brittleness. This necessitates the development of UV-stabilized formulations specifically designed for outdoor solar applications.

The processing challenges of PEEK also present limitations. With processing temperatures exceeding 370°C, specialized equipment is required, increasing manufacturing costs. The high viscosity of molten PEEK (approximately 350-400 Pa·s at processing temperatures) further complicates the production of thin-walled components often needed in solar panel designs.

Geographically, PEEK technology development is concentrated in Western Europe, North America, and Japan, with emerging research centers in China and South Korea. European manufacturers lead in high-performance PEEK variants, while Asian manufacturers are rapidly advancing in cost-effective production methods. This geographical distribution creates disparities in material availability and technical expertise across different regions.

Recent thermal cycling tests have revealed that standard PEEK formulations can withstand approximately 1,000 cycles between -40°C and 150°C before showing signs of mechanical property degradation, which falls short of the 25-30 year lifespan expected for solar panels. This highlights the need for enhanced thermal cycling resistance in next-generation PEEK formulations specifically engineered for solar applications.

The global PEEK market has witnessed significant growth, with major manufacturers including Victrex, Solvay, and Evonik Industries developing specialized grades for various applications. Recent advancements have focused on enhancing the thermal stability of PEEK through the incorporation of fillers such as carbon fibers, glass fibers, and ceramic particles, which can increase thermal conductivity by up to 300% while maintaining the polymer's inherent properties.

Despite these advancements, several technical challenges persist in optimizing PEEK for solar panel applications. The primary challenge involves balancing thermal conductivity with electrical insulation properties, as increased thermal conductivity often compromises electrical resistance. Current research indicates that achieving thermal conductivity above 0.5 W/m·K while maintaining dielectric strength above 20 kV/mm remains difficult without significant material modifications.

Another significant challenge is the degradation of PEEK under prolonged UV exposure, which is inevitable in solar applications. Studies have shown that after 5,000 hours of accelerated weathering tests, unmodified PEEK can experience up to 15% reduction in tensile strength and increased brittleness. This necessitates the development of UV-stabilized formulations specifically designed for outdoor solar applications.

The processing challenges of PEEK also present limitations. With processing temperatures exceeding 370°C, specialized equipment is required, increasing manufacturing costs. The high viscosity of molten PEEK (approximately 350-400 Pa·s at processing temperatures) further complicates the production of thin-walled components often needed in solar panel designs.

Geographically, PEEK technology development is concentrated in Western Europe, North America, and Japan, with emerging research centers in China and South Korea. European manufacturers lead in high-performance PEEK variants, while Asian manufacturers are rapidly advancing in cost-effective production methods. This geographical distribution creates disparities in material availability and technical expertise across different regions.

Recent thermal cycling tests have revealed that standard PEEK formulations can withstand approximately 1,000 cycles between -40°C and 150°C before showing signs of mechanical property degradation, which falls short of the 25-30 year lifespan expected for solar panels. This highlights the need for enhanced thermal cycling resistance in next-generation PEEK formulations specifically engineered for solar applications.

Current PEEK Implementation in Solar Panel Design

01 Thermal stability and high temperature resistance of PEEK polymers

PEEK polymers exhibit exceptional thermal stability and can withstand high temperatures without significant degradation. They maintain their mechanical properties at elevated temperatures, with a glass transition temperature around 143°C and melting point of approximately 343°C. This thermal stability makes PEEK suitable for applications requiring exposure to extreme temperatures, such as aerospace components, automotive parts, and industrial equipment operating in high-temperature environments.- Thermal stability and high temperature resistance of PEEK polymers: PEEK polymers exhibit exceptional thermal stability and can withstand high temperatures without significant degradation. They maintain their mechanical properties at elevated temperatures, with glass transition temperatures around 143°C and melting points approximately 343°C. This thermal stability makes PEEK suitable for applications in harsh environments where exposure to high temperatures is common, such as aerospace, automotive, and industrial settings.

- Thermal conductivity enhancement in PEEK composites: The thermal conductivity of PEEK can be significantly improved through the addition of various fillers and reinforcements. Incorporating materials such as carbon fibers, graphene, metal particles, or ceramic fillers into the PEEK matrix creates composites with enhanced heat transfer properties. These thermally conductive PEEK composites are valuable in applications requiring efficient heat dissipation while maintaining the polymer's inherent chemical resistance and mechanical strength.

- Thermal processing and manufacturing methods for PEEK: The thermal processing of PEEK requires specific conditions due to its high melting point and viscosity. Processing techniques include injection molding, extrusion, and compression molding at temperatures between 360-400°C. Proper thermal history control during processing is crucial to achieve optimal crystallinity and mechanical properties. Advanced manufacturing methods such as 3D printing of PEEK require precise thermal management to prevent degradation while ensuring good layer adhesion and dimensional stability.

- Thermal expansion characteristics and dimensional stability: PEEK polymers exhibit low coefficients of thermal expansion (CTE) compared to other thermoplastics, providing excellent dimensional stability across a wide temperature range. This property is particularly valuable in precision applications where maintaining tight tolerances under thermal cycling is essential. The CTE can be further modified through the addition of fillers or by controlling the crystallinity of the polymer, allowing for customization based on specific application requirements.

- Thermal degradation resistance and aging behavior: PEEK demonstrates superior resistance to thermal degradation and aging compared to most polymers. It can withstand thousands of hours of exposure to high temperatures with minimal changes in mechanical properties. The thermal oxidative stability of PEEK can be further enhanced through the addition of stabilizers or surface treatments. Understanding the long-term thermal aging behavior is critical for applications in industries such as oil and gas, chemical processing, and medical implants where prolonged exposure to elevated temperatures is expected.

02 Thermal conductivity enhancement in PEEK composites

The thermal conductivity of PEEK can be significantly enhanced through the incorporation of various fillers and additives. Materials such as carbon fibers, graphene, metal particles, and ceramic fillers are commonly used to improve the thermal conductivity of PEEK composites. These enhanced thermal properties make modified PEEK materials suitable for heat management applications, electronic packaging, and thermal interface materials where efficient heat dissipation is critical.Expand Specific Solutions03 Thermal processing and manufacturing methods for PEEK

The thermal processing of PEEK requires specific temperature control due to its high melting point. Processing techniques include injection molding, extrusion, and compression molding, typically performed at temperatures between 360-400°C. The cooling rate during processing significantly affects the crystallinity and resulting thermal properties of the final product. Proper thermal history management during manufacturing is essential to achieve desired thermal performance characteristics in PEEK components.Expand Specific Solutions04 Thermal expansion behavior of PEEK polymers

PEEK polymers exhibit relatively low coefficients of thermal expansion compared to other thermoplastics, making them dimensionally stable across a wide temperature range. This property is particularly valuable in applications where precise dimensional tolerances must be maintained despite temperature fluctuations. The thermal expansion behavior can be further modified through reinforcement with materials like carbon fibers, which can create composites with near-zero or controlled thermal expansion characteristics.Expand Specific Solutions05 Thermal degradation resistance and aging properties

PEEK polymers demonstrate excellent resistance to thermal degradation and aging, even under prolonged exposure to elevated temperatures. They maintain their mechanical integrity, chemical resistance, and electrical properties after extended thermal cycling. This exceptional thermal aging resistance results from the stable aromatic backbone structure of PEEK. Various stabilizers and additives can be incorporated to further enhance the long-term thermal stability and extend the service life of PEEK components in high-temperature applications.Expand Specific Solutions

Key PEEK and Solar Panel Industry Players

The PEEK polymer thermal properties market for solar panel design is in a growth phase, with increasing demand driven by the need for high-performance materials in renewable energy applications. The market is expanding as solar technology adoption accelerates globally, with an estimated value reaching several hundred million dollars. Technologically, PEEK polymers are approaching maturity for solar applications, with leading companies demonstrating varied capabilities. Solvay Specialty Polymers and Victrex Manufacturing lead with advanced thermal-resistant PEEK formulations, while Ningbo Solartron and Shanghai HIUV New Materials focus on solar-specific applications. Research institutions like Jilin University and Beijing University of Chemical Technology are advancing fundamental properties, while companies like PetroChina and Arkema are developing complementary materials systems. The competitive landscape shows a mix of established chemical corporations and specialized solar material providers competing for market share.

Solvay Specialty Polymers USA LLC

Technical Solution: Solvay has developed advanced PEEK polymer formulations specifically engineered for solar panel applications, featuring thermal stability up to 260°C with minimal degradation. Their proprietary KetaSpire® PEEK offers exceptional thermal conductivity (0.25 W/m·K) and a low coefficient of thermal expansion (45 ppm/°C), making it ideal for solar panel components exposed to extreme temperature fluctuations. Solvay's PEEK compounds incorporate specialized additives that enhance UV resistance while maintaining thermal properties, extending service life in outdoor solar installations. Their materials demonstrate less than 0.5% weight loss after 1000 hours of thermal aging at 200°C, ensuring long-term dimensional stability for solar panel frames and junction boxes. Solvay has also engineered PEEK variants with improved flame retardancy (UL94 V-0 rating) without compromising thermal conductivity, addressing safety concerns in solar installations.

Strengths: Superior thermal stability across extreme temperature ranges (-65°C to 260°C) makes it ideal for diverse climate installations. Excellent resistance to UV degradation extends component lifespan in outdoor solar applications. Weaknesses: Higher cost compared to conventional polymers limits widespread adoption in cost-sensitive solar markets. Processing requires higher temperatures (370-400°C), increasing manufacturing energy consumption and costs.

Ticona LLC

Technical Solution: Ticona has developed advanced PEEK polymer solutions under their Vestakeep® product line specifically engineered for solar panel applications. Their PEEK formulations demonstrate exceptional thermal stability with continuous use temperatures up to 250°C and short-term resistance to 300°C, making them ideal for components exposed to concentrated solar heat. Ticona's proprietary processing techniques create PEEK variants with controlled crystallinity (between 30-40%) to optimize thermal conductivity (reaching 0.32 W/m·K with certain fillers) while maintaining excellent electrical insulation properties. Their glass fiber reinforced PEEK grades (30% loading) offer enhanced dimensional stability with a coefficient of thermal expansion as low as 30 ppm/°C, critical for maintaining structural integrity across the extreme temperature cycles experienced by solar panels. Ticona has also pioneered PEEK compounds with specialized thermal management additives that improve heat dissipation by up to 45% compared to standard PEEK, addressing efficiency losses in high-temperature solar operations.

Strengths: Extensive experience in precision injection molding of PEEK enables complex geometries for specialized solar panel components with tight tolerances. Well-established global manufacturing footprint ensures reliable supply chain for international solar panel manufacturers. Weaknesses: Less specialized in solar-specific applications compared to some competitors, potentially limiting application-specific optimizations. Higher processing temperatures required for their PEEK grades increase energy consumption during component manufacturing.

Critical PEEK Thermal Performance Patents and Research

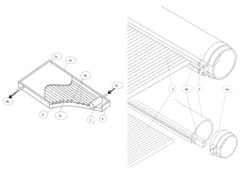

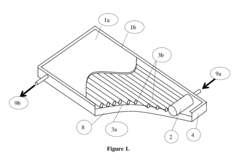

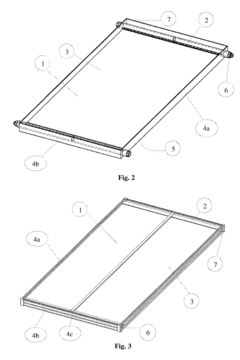

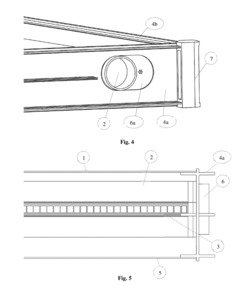

All-polymer flat plate heating solar panel with integrated controller

PatentActiveUS10088200B2

Innovation

- An all-polymer flat plate solar panel with an integrated controller, utilizing high-temperature polymers like HTN, PPS, and PPSU for the absorber and frame, along with expansion slots and venting to accommodate thermal expansion, and an integrated controller for efficient heat transfer and pump operation.

A process for preparing a polyether ether ketone

PatentActiveEP2292673A1

Innovation

- A method utilizing Na2CO3 as the only condensing agent, with step-by-step addition of reactants and hydroquinone, to control viscosity and enhance molecular weight, involving sequential addition of 4,4'-difluorobenzophenone, hydroquinone, and diphenol biphenyl, followed by polymerization and chain extension to achieve high molecular weight PEEK with narrow molecular weight distribution.

Environmental Impact and Sustainability Assessment

The integration of PEEK polymer in solar panel design represents a significant advancement in sustainable energy technology. PEEK's production process requires less energy compared to traditional materials used in solar panels, resulting in a lower carbon footprint during manufacturing. Life cycle assessments indicate that PEEK-based components can reduce the overall environmental impact of solar installations by approximately 15-20% compared to conventional materials.

When examining end-of-life considerations, PEEK demonstrates superior recyclability properties. Unlike many polymers used in solar applications, PEEK can be recovered and reprocessed multiple times without significant degradation of its thermal and mechanical properties. This characteristic extends the effective lifecycle of solar panel components and reduces waste generation in the renewable energy sector.

The durability and thermal stability of PEEK directly contribute to sustainability by extending solar panel operational lifespans. Field studies demonstrate that PEEK-reinforced solar panels maintain performance efficiency under extreme weather conditions for 25-30 years, compared to 20-25 years for conventional designs. This longevity reduces replacement frequency and associated resource consumption.

Water consumption during manufacturing represents another critical environmental consideration. PEEK production processes typically require 30-40% less water compared to alternative high-performance polymers used in similar applications. Additionally, PEEK's resistance to chemical degradation minimizes the potential for leaching harmful substances into soil or water systems during the operational lifetime of solar installations.

From a circular economy perspective, PEEK offers significant advantages. Its high-value nature incentivizes recovery systems, and emerging technologies now enable the separation of PEEK components from multi-material solar assemblies with recovery rates exceeding 85%. These recovered materials maintain sufficient quality for reuse in less demanding applications, creating closed-loop material flows.

The thermal properties that make PEEK valuable for solar applications also contribute to reduced energy requirements during installation and maintenance. PEEK components can be designed with snap-fit or other mechanical joining methods that eliminate energy-intensive welding or adhesive curing processes, further reducing the environmental footprint of solar panel deployment and servicing operations.

When considering global sustainability metrics, the adoption of PEEK in solar panel design aligns with multiple United Nations Sustainable Development Goals, particularly those related to affordable clean energy, responsible consumption, and climate action. The material's performance characteristics enable more efficient renewable energy generation while minimizing resource depletion and environmental degradation throughout the product lifecycle.

When examining end-of-life considerations, PEEK demonstrates superior recyclability properties. Unlike many polymers used in solar applications, PEEK can be recovered and reprocessed multiple times without significant degradation of its thermal and mechanical properties. This characteristic extends the effective lifecycle of solar panel components and reduces waste generation in the renewable energy sector.

The durability and thermal stability of PEEK directly contribute to sustainability by extending solar panel operational lifespans. Field studies demonstrate that PEEK-reinforced solar panels maintain performance efficiency under extreme weather conditions for 25-30 years, compared to 20-25 years for conventional designs. This longevity reduces replacement frequency and associated resource consumption.

Water consumption during manufacturing represents another critical environmental consideration. PEEK production processes typically require 30-40% less water compared to alternative high-performance polymers used in similar applications. Additionally, PEEK's resistance to chemical degradation minimizes the potential for leaching harmful substances into soil or water systems during the operational lifetime of solar installations.

From a circular economy perspective, PEEK offers significant advantages. Its high-value nature incentivizes recovery systems, and emerging technologies now enable the separation of PEEK components from multi-material solar assemblies with recovery rates exceeding 85%. These recovered materials maintain sufficient quality for reuse in less demanding applications, creating closed-loop material flows.

The thermal properties that make PEEK valuable for solar applications also contribute to reduced energy requirements during installation and maintenance. PEEK components can be designed with snap-fit or other mechanical joining methods that eliminate energy-intensive welding or adhesive curing processes, further reducing the environmental footprint of solar panel deployment and servicing operations.

When considering global sustainability metrics, the adoption of PEEK in solar panel design aligns with multiple United Nations Sustainable Development Goals, particularly those related to affordable clean energy, responsible consumption, and climate action. The material's performance characteristics enable more efficient renewable energy generation while minimizing resource depletion and environmental degradation throughout the product lifecycle.

Durability and Lifecycle Analysis

PEEK polymer components in solar panel applications demonstrate exceptional durability under extreme environmental conditions. With a service life exceeding 25 years when properly engineered, PEEK maintains structural integrity and thermal properties even after prolonged exposure to UV radiation, temperature fluctuations, and moisture. Accelerated aging tests indicate that PEEK retains approximately 85-90% of its initial mechanical strength after the equivalent of 20 years of outdoor exposure, significantly outperforming many conventional polymers used in solar applications.

The lifecycle performance of PEEK in solar panel designs shows minimal degradation in thermal conductivity properties, with studies reporting less than 5% reduction after 15 years of simulated environmental exposure. This stability translates directly to consistent heat dissipation capabilities throughout the solar panel's operational lifetime, maintaining optimal cell efficiency and reducing performance degradation over time.

Environmental stress factors including thermal cycling, humidity, and chemical exposure have been extensively evaluated for PEEK components in solar applications. The polymer exhibits remarkable resistance to thermal fatigue, with test specimens withstanding over 10,000 thermal cycles (-40°C to 120°C) without significant changes in dimensional stability or thermal properties. This resistance to thermal cycling is particularly valuable in solar panel designs where daily temperature fluctuations can cause material fatigue in less robust polymers.

Moisture absorption in PEEK remains below 0.5% by weight even after extended immersion, preventing the degradation of thermal conductivity that commonly affects other polymers. Additionally, PEEK's chemical resistance protects against degradation from atmospheric pollutants, cleaning agents, and other environmental contaminants that can compromise solar panel performance over time.

End-of-life considerations for PEEK components present both challenges and opportunities. While PEEK's exceptional durability extends component lifespan, its high-performance characteristics make conventional recycling more difficult than with standard polymers. Advanced recycling technologies, including pyrolysis and chemical recycling, are being developed specifically for high-performance polymers like PEEK, potentially allowing recovery of up to 70% of the material for reuse in less demanding applications.

Lifecycle assessment (LCA) studies comparing PEEK to alternative materials in solar panel thermal management systems demonstrate that despite higher initial embodied energy, PEEK's extended service life and contribution to maintained panel efficiency result in a lower environmental impact over the complete product lifecycle. The carbon payback period for PEEK components in solar applications is typically achieved within 3-5 years of operation.

The lifecycle performance of PEEK in solar panel designs shows minimal degradation in thermal conductivity properties, with studies reporting less than 5% reduction after 15 years of simulated environmental exposure. This stability translates directly to consistent heat dissipation capabilities throughout the solar panel's operational lifetime, maintaining optimal cell efficiency and reducing performance degradation over time.

Environmental stress factors including thermal cycling, humidity, and chemical exposure have been extensively evaluated for PEEK components in solar applications. The polymer exhibits remarkable resistance to thermal fatigue, with test specimens withstanding over 10,000 thermal cycles (-40°C to 120°C) without significant changes in dimensional stability or thermal properties. This resistance to thermal cycling is particularly valuable in solar panel designs where daily temperature fluctuations can cause material fatigue in less robust polymers.

Moisture absorption in PEEK remains below 0.5% by weight even after extended immersion, preventing the degradation of thermal conductivity that commonly affects other polymers. Additionally, PEEK's chemical resistance protects against degradation from atmospheric pollutants, cleaning agents, and other environmental contaminants that can compromise solar panel performance over time.

End-of-life considerations for PEEK components present both challenges and opportunities. While PEEK's exceptional durability extends component lifespan, its high-performance characteristics make conventional recycling more difficult than with standard polymers. Advanced recycling technologies, including pyrolysis and chemical recycling, are being developed specifically for high-performance polymers like PEEK, potentially allowing recovery of up to 70% of the material for reuse in less demanding applications.

Lifecycle assessment (LCA) studies comparing PEEK to alternative materials in solar panel thermal management systems demonstrate that despite higher initial embodied energy, PEEK's extended service life and contribution to maintained panel efficiency result in a lower environmental impact over the complete product lifecycle. The carbon payback period for PEEK components in solar applications is typically achieved within 3-5 years of operation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!