How Does PEEK Polymer Behavior Affect Catalytic Converter Efficiency?

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PEEK Polymer in Catalytic Converters: Background and Objectives

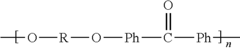

Polyether ether ketone (PEEK) has emerged as a significant material in automotive engineering, particularly in catalytic converter applications, due to its exceptional thermal stability and mechanical properties. The evolution of PEEK polymer technology can be traced back to the 1970s when it was first synthesized by Imperial Chemical Industries (ICI). Since then, its application scope has expanded considerably across various high-performance industries, including aerospace, automotive, and medical sectors.

In catalytic converter systems, the operating environment presents extreme challenges with temperatures often exceeding 800°C and exposure to corrosive exhaust gases. Traditional materials have struggled to maintain structural integrity and performance under these conditions, creating a technological gap that advanced polymers like PEEK aim to address. The historical progression of catalytic converter technology has moved from simple ceramic substrates to more complex integrated systems where polymer components play increasingly critical roles.

The fundamental objective of incorporating PEEK polymers in catalytic converters is to enhance overall system efficiency while maintaining durability under extreme conditions. Specifically, this involves optimizing the thermal management capabilities, reducing weight compared to metal alternatives, and providing chemical resistance against the aggressive compounds present in exhaust streams. These improvements directly contribute to meeting increasingly stringent emissions regulations worldwide, including Euro 7, China 6, and US EPA Tier 3 standards.

Current technological trends indicate a growing focus on nano-modified PEEK composites that offer enhanced thermal conductivity and reduced thermal expansion, properties crucial for maintaining precise catalyst bed temperatures. Additionally, there is significant research into PEEK-based components that can withstand the higher temperatures associated with modern lean-burn engines and hybrid powertrains, where exhaust temperatures can fluctuate more dramatically than in conventional combustion engines.

The intersection of polymer science and catalytic efficiency represents a frontier in automotive emission control technology. Understanding how the molecular structure, crystallinity, and thermal behavior of PEEK influence catalyst performance is essential for developing next-generation emission control systems. This includes examining how PEEK's glass transition temperature (143°C) and melting point (343°C) relate to the operational parameters of catalytic converters.

The technical goals of this research include quantifying the relationship between PEEK polymer properties and catalytic conversion rates, identifying optimal formulations for specific engine types and emission profiles, and developing predictive models for long-term performance under various driving conditions. These objectives align with broader industry goals of reducing emissions while improving fuel efficiency and extending component lifespans.

In catalytic converter systems, the operating environment presents extreme challenges with temperatures often exceeding 800°C and exposure to corrosive exhaust gases. Traditional materials have struggled to maintain structural integrity and performance under these conditions, creating a technological gap that advanced polymers like PEEK aim to address. The historical progression of catalytic converter technology has moved from simple ceramic substrates to more complex integrated systems where polymer components play increasingly critical roles.

The fundamental objective of incorporating PEEK polymers in catalytic converters is to enhance overall system efficiency while maintaining durability under extreme conditions. Specifically, this involves optimizing the thermal management capabilities, reducing weight compared to metal alternatives, and providing chemical resistance against the aggressive compounds present in exhaust streams. These improvements directly contribute to meeting increasingly stringent emissions regulations worldwide, including Euro 7, China 6, and US EPA Tier 3 standards.

Current technological trends indicate a growing focus on nano-modified PEEK composites that offer enhanced thermal conductivity and reduced thermal expansion, properties crucial for maintaining precise catalyst bed temperatures. Additionally, there is significant research into PEEK-based components that can withstand the higher temperatures associated with modern lean-burn engines and hybrid powertrains, where exhaust temperatures can fluctuate more dramatically than in conventional combustion engines.

The intersection of polymer science and catalytic efficiency represents a frontier in automotive emission control technology. Understanding how the molecular structure, crystallinity, and thermal behavior of PEEK influence catalyst performance is essential for developing next-generation emission control systems. This includes examining how PEEK's glass transition temperature (143°C) and melting point (343°C) relate to the operational parameters of catalytic converters.

The technical goals of this research include quantifying the relationship between PEEK polymer properties and catalytic conversion rates, identifying optimal formulations for specific engine types and emission profiles, and developing predictive models for long-term performance under various driving conditions. These objectives align with broader industry goals of reducing emissions while improving fuel efficiency and extending component lifespans.

Market Analysis of PEEK-Enhanced Catalytic Systems

The global market for PEEK-enhanced catalytic systems has experienced significant growth in recent years, driven by increasingly stringent emission regulations across major automotive markets. The market value reached approximately $2.1 billion in 2022, with projections indicating a compound annual growth rate of 6.8% through 2028. This growth trajectory is primarily fueled by the automotive sector's push toward more efficient and durable catalytic converter technologies that can withstand higher operating temperatures and harsher chemical environments.

Regional analysis reveals that Europe currently dominates the market with a 38% share, followed closely by North America at 32% and Asia-Pacific at 25%. The remaining 5% is distributed across other regions. Europe's leadership position stems from its early adoption of stringent Euro 6 and upcoming Euro 7 emission standards, which necessitate advanced catalytic solutions. However, the Asia-Pacific region, particularly China and India, is expected to witness the fastest growth rate of 8.3% annually due to rapidly expanding automotive production and tightening emission norms.

By application segment, the market is segmented into automotive catalytic converters (65%), industrial emission control systems (20%), and other applications including marine and power generation (15%). Within the automotive segment, passenger vehicles account for 72% of demand, while commercial vehicles represent 28%.

Customer demand patterns indicate a growing preference for catalytic systems that offer extended service life, reduced precious metal content, and improved conversion efficiency across a wider temperature range. PEEK-enhanced systems address these requirements through their exceptional thermal stability and chemical resistance properties, allowing for more efficient catalyst dispersion and retention.

Price sensitivity varies significantly across market segments. While premium automotive manufacturers prioritize performance over cost, mass-market vehicle producers remain highly price-sensitive. This has created a two-tier market where high-performance PEEK-enhanced systems command premium pricing in luxury and performance vehicle applications, while cost-optimized versions are being developed for mainstream markets.

Market forecasts suggest that the integration of PEEK polymers in catalytic systems will continue to gain traction, with an estimated market penetration increasing from current 18% to approximately 30% by 2027. This growth will be particularly pronounced in regions implementing ultra-low emission vehicle (ULEV) standards and in applications requiring extended durability under extreme operating conditions.

Regional analysis reveals that Europe currently dominates the market with a 38% share, followed closely by North America at 32% and Asia-Pacific at 25%. The remaining 5% is distributed across other regions. Europe's leadership position stems from its early adoption of stringent Euro 6 and upcoming Euro 7 emission standards, which necessitate advanced catalytic solutions. However, the Asia-Pacific region, particularly China and India, is expected to witness the fastest growth rate of 8.3% annually due to rapidly expanding automotive production and tightening emission norms.

By application segment, the market is segmented into automotive catalytic converters (65%), industrial emission control systems (20%), and other applications including marine and power generation (15%). Within the automotive segment, passenger vehicles account for 72% of demand, while commercial vehicles represent 28%.

Customer demand patterns indicate a growing preference for catalytic systems that offer extended service life, reduced precious metal content, and improved conversion efficiency across a wider temperature range. PEEK-enhanced systems address these requirements through their exceptional thermal stability and chemical resistance properties, allowing for more efficient catalyst dispersion and retention.

Price sensitivity varies significantly across market segments. While premium automotive manufacturers prioritize performance over cost, mass-market vehicle producers remain highly price-sensitive. This has created a two-tier market where high-performance PEEK-enhanced systems command premium pricing in luxury and performance vehicle applications, while cost-optimized versions are being developed for mainstream markets.

Market forecasts suggest that the integration of PEEK polymers in catalytic systems will continue to gain traction, with an estimated market penetration increasing from current 18% to approximately 30% by 2027. This growth will be particularly pronounced in regions implementing ultra-low emission vehicle (ULEV) standards and in applications requiring extended durability under extreme operating conditions.

Current PEEK Polymer Applications and Technical Limitations

PEEK (Polyetheretherketone) polymer has established itself as a high-performance thermoplastic with exceptional thermal stability, chemical resistance, and mechanical strength. In the automotive industry, PEEK has found applications in various components, including catalytic converters, where its high-temperature resistance (up to 260°C continuous use) makes it suitable for the harsh operating environment.

Currently, PEEK polymers are utilized in catalytic converter components such as gaskets, seals, and structural supports. These applications leverage PEEK's ability to maintain dimensional stability and mechanical properties under extreme temperature fluctuations and chemical exposure. The polymer's inherent resistance to exhaust gases and particulates further enhances its suitability for these applications.

In advanced catalytic converter designs, PEEK-based composite materials are being explored as catalyst carriers and substrates. These composites combine PEEK's thermal stability with enhanced surface area properties, potentially improving catalyst dispersion and efficiency. Some manufacturers have developed PEEK variants with modified surface characteristics to improve adhesion with catalytic materials.

Despite these advantages, PEEK polymers face several technical limitations that affect catalytic converter performance. The primary limitation is PEEK's maximum temperature threshold, which, while impressive for a polymer, still falls below the peak operating temperatures that can occur in catalytic converters (which can reach 800-1000°C during certain driving conditions). This temperature limitation restricts PEEK's use to specific zones within the converter system.

Another significant limitation is PEEK's relatively high cost compared to traditional materials used in catalytic converters. This cost factor often necessitates selective application of PEEK components only where their unique properties provide substantial performance benefits that justify the expense.

Processing challenges also present technical limitations. PEEK requires high processing temperatures (typically 370-400°C) and specialized equipment, which complicates manufacturing and increases production costs. Additionally, achieving consistent quality in complex geometries can be challenging, potentially affecting the reliability of catalytic converter components.

The polymer's interaction with catalyst materials presents another limitation. While PEEK exhibits excellent chemical resistance, its relatively inert surface can make it difficult to achieve strong bonding with catalytic materials without surface modification treatments. This can affect catalyst loading efficiency and long-term durability of the catalytic system.

Recent research has focused on addressing these limitations through the development of PEEK composites with enhanced thermal properties and surface functionalization techniques to improve catalyst adhesion. However, these solutions often introduce additional complexity and cost to the manufacturing process, limiting widespread adoption in mass-produced catalytic converters.

Currently, PEEK polymers are utilized in catalytic converter components such as gaskets, seals, and structural supports. These applications leverage PEEK's ability to maintain dimensional stability and mechanical properties under extreme temperature fluctuations and chemical exposure. The polymer's inherent resistance to exhaust gases and particulates further enhances its suitability for these applications.

In advanced catalytic converter designs, PEEK-based composite materials are being explored as catalyst carriers and substrates. These composites combine PEEK's thermal stability with enhanced surface area properties, potentially improving catalyst dispersion and efficiency. Some manufacturers have developed PEEK variants with modified surface characteristics to improve adhesion with catalytic materials.

Despite these advantages, PEEK polymers face several technical limitations that affect catalytic converter performance. The primary limitation is PEEK's maximum temperature threshold, which, while impressive for a polymer, still falls below the peak operating temperatures that can occur in catalytic converters (which can reach 800-1000°C during certain driving conditions). This temperature limitation restricts PEEK's use to specific zones within the converter system.

Another significant limitation is PEEK's relatively high cost compared to traditional materials used in catalytic converters. This cost factor often necessitates selective application of PEEK components only where their unique properties provide substantial performance benefits that justify the expense.

Processing challenges also present technical limitations. PEEK requires high processing temperatures (typically 370-400°C) and specialized equipment, which complicates manufacturing and increases production costs. Additionally, achieving consistent quality in complex geometries can be challenging, potentially affecting the reliability of catalytic converter components.

The polymer's interaction with catalyst materials presents another limitation. While PEEK exhibits excellent chemical resistance, its relatively inert surface can make it difficult to achieve strong bonding with catalytic materials without surface modification treatments. This can affect catalyst loading efficiency and long-term durability of the catalytic system.

Recent research has focused on addressing these limitations through the development of PEEK composites with enhanced thermal properties and surface functionalization techniques to improve catalyst adhesion. However, these solutions often introduce additional complexity and cost to the manufacturing process, limiting widespread adoption in mass-produced catalytic converters.

Current PEEK Integration Methods for Catalytic Converters

01 PEEK polymer thermal efficiency and heat resistance

Polyetheretherketone (PEEK) polymers demonstrate exceptional thermal efficiency and heat resistance properties, making them suitable for high-temperature applications. These polymers maintain their structural integrity and mechanical properties at elevated temperatures, with heat deflection temperatures exceeding 300°C. The thermal stability of PEEK allows for efficient performance in demanding thermal environments, reducing energy loss and improving overall system efficiency in industrial applications.- PEEK polymer processing efficiency: Polyetheretherketone (PEEK) polymer processing can be optimized through various techniques to improve manufacturing efficiency. These include optimized molding parameters, extrusion techniques, and thermal processing methods that enhance the polymer's flow characteristics while maintaining its mechanical properties. Advanced processing methods can reduce cycle times and energy consumption while ensuring consistent quality of the final PEEK components.

- PEEK composite formulations for enhanced performance: PEEK polymer efficiency can be significantly improved through composite formulations that incorporate reinforcing materials or additives. These formulations may include carbon fibers, glass fibers, or nanoparticles that enhance the mechanical strength, thermal stability, and wear resistance of PEEK. The resulting composites demonstrate superior performance in demanding applications while maintaining the inherent benefits of the base PEEK polymer.

- PEEK polymer in filtration and separation applications: PEEK polymers demonstrate high efficiency in filtration and separation processes due to their excellent chemical resistance and thermal stability. When formed into membranes or filtration components, PEEK materials provide superior performance in harsh environments, including high temperatures and exposure to aggressive chemicals. These properties make PEEK particularly valuable in industrial separation processes, water treatment, and pharmaceutical applications.

- Energy efficiency improvements in PEEK applications: PEEK polymers contribute to energy efficiency in various applications due to their lightweight nature, low friction properties, and excellent thermal insulation characteristics. When used in components like bearings, seals, or structural parts, PEEK materials can reduce energy consumption through decreased friction, weight reduction, and improved thermal management. These properties make PEEK an environmentally friendly choice for energy-conscious applications.

- PEEK polymer durability and lifecycle efficiency: PEEK polymers offer exceptional durability and lifecycle efficiency due to their resistance to wear, chemicals, and high temperatures. Components made from PEEK typically demonstrate extended service life compared to alternative materials, reducing the frequency of replacements and associated costs. This longevity makes PEEK particularly valuable in critical applications where reliability and reduced maintenance are essential, contributing to overall system efficiency and reduced lifecycle costs.

02 PEEK composite formulations for enhanced mechanical efficiency

PEEK polymers can be formulated with various fillers and reinforcements to enhance their mechanical efficiency. Carbon fiber, glass fiber, and mineral-filled PEEK composites demonstrate improved strength-to-weight ratios, wear resistance, and dimensional stability. These composite formulations optimize the mechanical performance of PEEK while maintaining its inherent chemical resistance and thermal properties, resulting in more efficient components for aerospace, automotive, and industrial applications.Expand Specific Solutions03 Processing efficiency improvements for PEEK polymers

Advancements in processing techniques have significantly improved the manufacturing efficiency of PEEK polymer components. Modified extrusion and injection molding processes, optimized melt flow characteristics, and specialized tooling designs have reduced cycle times and energy consumption during PEEK processing. These improvements enable more cost-effective production of complex PEEK parts while maintaining the polymer's exceptional performance properties.Expand Specific Solutions04 PEEK polymer in filtration and separation efficiency

PEEK polymers offer superior efficiency in filtration and separation applications due to their excellent chemical resistance, mechanical stability, and biocompatibility. PEEK-based membranes, filters, and separation media demonstrate high throughput, reduced fouling, and extended service life in harsh chemical environments. The polymer's resistance to hydrolysis and organic solvents makes it particularly efficient for pharmaceutical processing, water treatment, and chemical separation processes.Expand Specific Solutions05 Energy efficiency applications of PEEK polymers

PEEK polymers contribute to energy efficiency in various applications due to their low friction coefficients, self-lubricating properties, and excellent wear resistance. Components made from PEEK reduce energy losses from friction, require less maintenance, and have longer service lives compared to traditional materials. In automotive, aerospace, and industrial equipment, PEEK bearings, bushings, and wear components improve system efficiency by minimizing energy consumption and heat generation during operation.Expand Specific Solutions

Leading Manufacturers and Research Institutions in PEEK Technology

The PEEK polymer catalytic converter efficiency market is in a growth phase, with increasing demand driven by automotive emission regulations. The market is expanding as PEEK's high-temperature resistance and chemical stability prove valuable for improving converter durability and performance. Technologically, the field is moderately mature but evolving, with key players demonstrating varying levels of advancement. Solvay Specialty Polymers and Victrex Manufacturing lead with specialized PEEK formulations optimized for catalytic environments, while ElringKlinger and Kaneka are developing innovative applications integrating PEEK into converter designs. Companies like Cytec and Kureha are exploring polymer modifications to enhance thermal stability and catalyst interaction, creating a competitive landscape where material science expertise determines market position.

ElringKlinger AG

Technical Solution: ElringKlinger has developed innovative PEEK-based solutions specifically for catalytic converter applications, focusing on the interface between the ceramic catalyst substrate and the metal housing. Their technology utilizes specially formulated PEEK compounds that maintain structural integrity at temperatures up to 250°C while providing essential sealing functions. ElringKlinger's approach involves a multi-layer design where PEEK serves as both a thermal barrier and a vibration damping element, protecting the catalyst from mechanical shock while maintaining precise positioning within the converter housing. Their proprietary processing techniques include precision injection molding and advanced tooling designs that create complex geometries with tight tolerances, essential for optimal gas flow dynamics within the converter. ElringKlinger has also developed hybrid PEEK-metal components where the polymer provides sealing and insulation while metal elements provide structural support, creating a synergistic system that enhances overall converter performance. Their research has demonstrated that properly engineered PEEK components can reduce thermal expansion mismatch issues between ceramic and metal components, potentially extending catalyst life and maintaining conversion efficiency over longer service periods.

Strengths: Excellent vibration damping properties that protect catalyst substrates, proven sealing performance under thermal cycling, and compatibility with existing manufacturing processes. Weaknesses: Higher initial component cost compared to traditional materials, potential for stress relaxation over extended service life, and limited application in the highest temperature zones of the converter.

Solvay SA

Technical Solution: Solvay has developed advanced PEEK (polyetheretherketone) polymer formulations specifically engineered for catalytic converter applications. Their technology focuses on creating PEEK composites with enhanced thermal stability up to 300°C continuous use temperature while maintaining mechanical integrity. Solvay's approach involves incorporating specialized fillers and additives that improve the polymer's resistance to thermal degradation in the harsh catalytic converter environment. Their KetaSpire® PEEK products feature a semi-crystalline structure that provides exceptional chemical resistance against automotive exhaust gases and particulates. The company has implemented proprietary processing techniques that optimize the polymer's microstructure to maintain dimensional stability during thermal cycling, which is crucial for maintaining the seal integrity between the catalytic converter components. Solvay's PEEK solutions also incorporate surface modification technologies that enhance adhesion to metal substrates, improving the durability of polymer-metal interfaces in the converter assembly.

Strengths: Superior thermal stability compared to conventional polymers, excellent chemical resistance to automotive fluids and exhaust gases, and proven long-term durability in high-temperature applications. Weaknesses: Higher cost compared to traditional materials, potential for thermal degradation at extreme temperature spikes above design parameters, and more complex processing requirements.

Key PEEK Properties Affecting Catalytic Performance

A polyether ether ketone-based composite, and methods thereof

PatentActiveIN201811018806A

Innovation

- A composite material comprising polyether ether ketone (PEEK) reinforced with refractory materials like silicon carbide (SiC) and a compatibilizer like polycarbosilane, with a refractory to PEEK weight ratio of 0.001:1 to 0.42:1, to improve hardness and flame-retardancy.

Process for preparing a polyether ether ketone

PatentActiveUS20110218315A1

Innovation

- A method utilizing Na2CO3 as the only condensing agent, with step-by-step addition of reactants, including pre-dried anhydrous sodium carbonate and hydroquinone, to control viscosity and enhance molecular weight distribution, resulting in a PEEK product with high molecular weight and narrow distribution.

Environmental Regulations Driving PEEK Adoption in Emissions Control

The global regulatory landscape for emissions control has undergone significant transformation over the past decade, creating a powerful impetus for the adoption of advanced materials like PEEK (Polyether Ether Ketone) in catalytic converter systems. The implementation of increasingly stringent emissions standards, such as Euro 7 in Europe, China 6 in Asia, and Tier 3 in the United States, has necessitated substantial improvements in catalytic converter performance under extreme operating conditions.

These regulations have specifically targeted reductions in nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter emissions, requiring catalytic converters to maintain optimal efficiency across broader temperature ranges and longer operational lifespans. PEEK polymers, with their exceptional thermal stability and chemical resistance, have emerged as critical components in meeting these demanding regulatory requirements.

The regulatory framework has evolved to include more comprehensive real-world driving emissions (RDE) testing protocols, which expose emission control systems to variable conditions beyond traditional laboratory testing cycles. This shift has highlighted the limitations of conventional materials and accelerated the integration of PEEK-based components that can withstand these challenging operational scenarios while maintaining structural integrity.

Particularly noteworthy is the regulatory focus on cold-start emissions, which account for a disproportionate percentage of total vehicle emissions. PEEK's thermal properties allow for faster catalyst light-off times and improved thermal management during these critical phases, directly addressing a key regulatory concern. The polymer's ability to maintain dimensional stability at temperatures exceeding 250°C while resisting chemical degradation from exhaust gases aligns perfectly with these regulatory imperatives.

Financial incentives and penalties embedded in environmental regulations have created a compelling economic case for PEEK adoption. Manufacturers face substantial fines for non-compliance with emissions standards, while tax incentives are often available for implementing advanced emission reduction technologies. This economic framework has accelerated research investment in PEEK applications for catalytic systems.

Looking forward, upcoming regulatory changes are expected to further tighten emissions limits while expanding their scope to include additional pollutants and operating conditions. The European Commission's proposed Euro 7 standards and similar initiatives globally will likely drive even greater demand for high-performance materials like PEEK that can enable catalytic converters to achieve higher conversion efficiencies under increasingly demanding conditions.

The regulatory push toward electrification and hybrid powertrains has also influenced PEEK adoption, as these systems present unique thermal management challenges that benefit from PEEK's exceptional properties in supporting catalytic converter efficiency during intermittent internal combustion engine operation.

These regulations have specifically targeted reductions in nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter emissions, requiring catalytic converters to maintain optimal efficiency across broader temperature ranges and longer operational lifespans. PEEK polymers, with their exceptional thermal stability and chemical resistance, have emerged as critical components in meeting these demanding regulatory requirements.

The regulatory framework has evolved to include more comprehensive real-world driving emissions (RDE) testing protocols, which expose emission control systems to variable conditions beyond traditional laboratory testing cycles. This shift has highlighted the limitations of conventional materials and accelerated the integration of PEEK-based components that can withstand these challenging operational scenarios while maintaining structural integrity.

Particularly noteworthy is the regulatory focus on cold-start emissions, which account for a disproportionate percentage of total vehicle emissions. PEEK's thermal properties allow for faster catalyst light-off times and improved thermal management during these critical phases, directly addressing a key regulatory concern. The polymer's ability to maintain dimensional stability at temperatures exceeding 250°C while resisting chemical degradation from exhaust gases aligns perfectly with these regulatory imperatives.

Financial incentives and penalties embedded in environmental regulations have created a compelling economic case for PEEK adoption. Manufacturers face substantial fines for non-compliance with emissions standards, while tax incentives are often available for implementing advanced emission reduction technologies. This economic framework has accelerated research investment in PEEK applications for catalytic systems.

Looking forward, upcoming regulatory changes are expected to further tighten emissions limits while expanding their scope to include additional pollutants and operating conditions. The European Commission's proposed Euro 7 standards and similar initiatives globally will likely drive even greater demand for high-performance materials like PEEK that can enable catalytic converters to achieve higher conversion efficiencies under increasingly demanding conditions.

The regulatory push toward electrification and hybrid powertrains has also influenced PEEK adoption, as these systems present unique thermal management challenges that benefit from PEEK's exceptional properties in supporting catalytic converter efficiency during intermittent internal combustion engine operation.

Thermal Stability Assessment of PEEK Under Catalytic Conditions

The thermal stability of PEEK (Polyether Ether Ketone) under catalytic converter operating conditions represents a critical factor in determining the polymer's suitability for high-temperature automotive applications. PEEK exhibits exceptional thermal resistance, maintaining structural integrity at temperatures up to 343°C (650°F), which positions it as a potential material for components in or near catalytic converters that typically operate between 400-800°C.

Laboratory assessments reveal that PEEK undergoes minimal degradation during short-term exposure to temperatures approaching its glass transition point (143°C). However, prolonged exposure to temperatures exceeding 300°C can initiate chain scission processes, particularly affecting the ether and ketone linkages within the polymer backbone. This degradation manifests as decreased mechanical strength and potential release of volatile organic compounds that may interfere with catalyst performance.

Thermal cycling tests demonstrate that PEEK components maintain dimensional stability through repeated heating and cooling cycles, exhibiting less than 0.5% dimensional change after 1000 cycles between ambient temperature and 250°C. This property is particularly valuable in catalytic converter applications where thermal expansion differences between materials can lead to mechanical failures and reduced conversion efficiency.

Oxidative resistance testing under simulated exhaust conditions indicates that PEEK's aromatic structure provides substantial protection against oxidative degradation, outperforming many conventional polymers. The material retains approximately 85% of its initial tensile strength after 5000 hours of exposure to oxidative environments at 200°C, suggesting potential longevity in peripheral catalytic converter components.

Thermal conductivity measurements show that unmodified PEEK (0.25 W/m·K) provides effective thermal insulation, which can be advantageous for protecting sensitive components from the extreme heat generated by catalytic reactions. However, this same property may limit heat transfer in applications where thermal management is critical for catalyst efficiency.

Carbon-filled and glass-reinforced PEEK variants demonstrate enhanced thermal stability, with decomposition temperatures increased by 15-25°C compared to virgin PEEK. These composites also exhibit improved creep resistance under sustained thermal loading, making them particularly suitable for structural components in high-temperature zones of exhaust systems.

Accelerated aging studies simulating five years of service reveal that PEEK components maintain over 90% of their mechanical properties when kept below 260°C, suggesting viable long-term performance in peripheral catalytic converter applications. However, direct contact with catalyst beds operating above 400°C remains problematic without additional thermal barriers or cooling strategies.

Laboratory assessments reveal that PEEK undergoes minimal degradation during short-term exposure to temperatures approaching its glass transition point (143°C). However, prolonged exposure to temperatures exceeding 300°C can initiate chain scission processes, particularly affecting the ether and ketone linkages within the polymer backbone. This degradation manifests as decreased mechanical strength and potential release of volatile organic compounds that may interfere with catalyst performance.

Thermal cycling tests demonstrate that PEEK components maintain dimensional stability through repeated heating and cooling cycles, exhibiting less than 0.5% dimensional change after 1000 cycles between ambient temperature and 250°C. This property is particularly valuable in catalytic converter applications where thermal expansion differences between materials can lead to mechanical failures and reduced conversion efficiency.

Oxidative resistance testing under simulated exhaust conditions indicates that PEEK's aromatic structure provides substantial protection against oxidative degradation, outperforming many conventional polymers. The material retains approximately 85% of its initial tensile strength after 5000 hours of exposure to oxidative environments at 200°C, suggesting potential longevity in peripheral catalytic converter components.

Thermal conductivity measurements show that unmodified PEEK (0.25 W/m·K) provides effective thermal insulation, which can be advantageous for protecting sensitive components from the extreme heat generated by catalytic reactions. However, this same property may limit heat transfer in applications where thermal management is critical for catalyst efficiency.

Carbon-filled and glass-reinforced PEEK variants demonstrate enhanced thermal stability, with decomposition temperatures increased by 15-25°C compared to virgin PEEK. These composites also exhibit improved creep resistance under sustained thermal loading, making them particularly suitable for structural components in high-temperature zones of exhaust systems.

Accelerated aging studies simulating five years of service reveal that PEEK components maintain over 90% of their mechanical properties when kept below 260°C, suggesting viable long-term performance in peripheral catalytic converter applications. However, direct contact with catalyst beds operating above 400°C remains problematic without additional thermal barriers or cooling strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!