Patents Related to PEEK Polymer in Aerospace Manufacturing

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PEEK Polymer in Aerospace: Background and Objectives

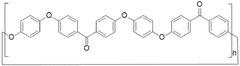

Polyether ether ketone (PEEK) has emerged as a revolutionary polymer material in aerospace manufacturing, offering exceptional mechanical properties, thermal stability, and chemical resistance. The evolution of PEEK technology began in the late 1970s when ICI (Imperial Chemical Industries) first developed and commercialized this high-performance thermoplastic. Since then, PEEK has undergone significant advancements in synthesis methods, processing techniques, and application-specific formulations, particularly for aerospace applications.

The aerospace industry's continuous pursuit of lightweight, high-strength materials capable of withstanding extreme operating conditions has driven PEEK's technological trajectory. Initially adopted for non-critical components, PEEK has progressively replaced traditional metals and thermosets in increasingly demanding applications, including structural components, interior parts, and engine systems. This evolution reflects broader industry trends toward fuel efficiency, emissions reduction, and sustainable manufacturing practices.

Patent activity surrounding PEEK in aerospace manufacturing has shown exponential growth over the past two decades, with significant acceleration since 2010. This surge corresponds with the aerospace industry's intensified focus on next-generation aircraft designs that demand unprecedented material performance. Key patent clusters have formed around PEEK composite formulations, processing technologies, and specialized aerospace applications, indicating areas of concentrated innovation and commercial interest.

The primary technical objectives for PEEK polymer development in aerospace manufacturing center on several critical parameters. These include enhancing temperature resistance beyond the current ceiling of approximately 260°C, improving mechanical properties under dynamic loading conditions, developing more efficient processing methods for complex geometries, and reducing production costs to enable broader adoption. Additionally, research aims to optimize PEEK's compatibility with other materials in multi-material systems and enhance its recyclability to meet increasingly stringent sustainability requirements.

Current technical challenges include addressing PEEK's relatively high processing temperatures (typically 370-400°C), improving its resistance to ultraviolet radiation, enhancing its electrical conductivity for lightning strike protection, and developing more effective joining and repair methodologies. These challenges represent significant opportunities for innovation and patent development, particularly in aerospace-specific applications where performance requirements are exceptionally demanding.

The global landscape of PEEK technology development shows concentration in North America, Western Europe, and East Asia, with emerging contributions from research institutions in other regions. This geographical distribution reflects both historical expertise in advanced polymer science and the location of major aerospace manufacturing hubs, suggesting potential for technology transfer and collaborative innovation across these regions.

The aerospace industry's continuous pursuit of lightweight, high-strength materials capable of withstanding extreme operating conditions has driven PEEK's technological trajectory. Initially adopted for non-critical components, PEEK has progressively replaced traditional metals and thermosets in increasingly demanding applications, including structural components, interior parts, and engine systems. This evolution reflects broader industry trends toward fuel efficiency, emissions reduction, and sustainable manufacturing practices.

Patent activity surrounding PEEK in aerospace manufacturing has shown exponential growth over the past two decades, with significant acceleration since 2010. This surge corresponds with the aerospace industry's intensified focus on next-generation aircraft designs that demand unprecedented material performance. Key patent clusters have formed around PEEK composite formulations, processing technologies, and specialized aerospace applications, indicating areas of concentrated innovation and commercial interest.

The primary technical objectives for PEEK polymer development in aerospace manufacturing center on several critical parameters. These include enhancing temperature resistance beyond the current ceiling of approximately 260°C, improving mechanical properties under dynamic loading conditions, developing more efficient processing methods for complex geometries, and reducing production costs to enable broader adoption. Additionally, research aims to optimize PEEK's compatibility with other materials in multi-material systems and enhance its recyclability to meet increasingly stringent sustainability requirements.

Current technical challenges include addressing PEEK's relatively high processing temperatures (typically 370-400°C), improving its resistance to ultraviolet radiation, enhancing its electrical conductivity for lightning strike protection, and developing more effective joining and repair methodologies. These challenges represent significant opportunities for innovation and patent development, particularly in aerospace-specific applications where performance requirements are exceptionally demanding.

The global landscape of PEEK technology development shows concentration in North America, Western Europe, and East Asia, with emerging contributions from research institutions in other regions. This geographical distribution reflects both historical expertise in advanced polymer science and the location of major aerospace manufacturing hubs, suggesting potential for technology transfer and collaborative innovation across these regions.

Market Demand Analysis for Aerospace-Grade PEEK Applications

The aerospace industry's demand for high-performance materials has grown significantly over the past decade, with PEEK (Polyether Ether Ketone) polymer emerging as a critical material for advanced applications. The global market for aerospace-grade PEEK is currently valued at approximately $290 million and is projected to grow at a compound annual growth rate of 6.8% through 2028, driven primarily by increasing aircraft production and the ongoing lightweighting trend in aerospace manufacturing.

Commercial aviation represents the largest application segment, accounting for roughly 55% of aerospace PEEK consumption. This demand is fueled by the need for lightweight components that can withstand extreme operating conditions while reducing fuel consumption. Boeing and Airbus have both increased their utilization of PEEK-based composites in their newest generation aircraft, with the Boeing 787 and Airbus A350 incorporating significantly higher percentages of polymer composites compared to previous models.

Military and defense applications constitute approximately 30% of the market, where PEEK's exceptional mechanical properties and resistance to chemical warfare agents make it particularly valuable. The remaining 15% is distributed across space applications, where PEEK's stability in vacuum environments and radiation resistance are highly prized attributes.

Regionally, North America dominates the aerospace PEEK market with approximately 42% share, followed by Europe at 35% and Asia-Pacific at 18%. The concentration in these regions aligns with the geographical distribution of major aerospace manufacturers and their supply chains.

The demand drivers for aerospace-grade PEEK are multifaceted. Fuel efficiency requirements remain paramount, with each kilogram of weight reduction translating to significant operational cost savings over an aircraft's lifetime. Environmental regulations are also accelerating adoption, as manufacturers seek materials that contribute to reduced emissions through weight reduction and potentially offer improved recyclability compared to traditional materials.

Another significant market trend is the increasing demand for PEEK in additive manufacturing applications within aerospace. The ability to 3D print complex, lightweight structures with PEEK is opening new design possibilities that were previously unattainable with traditional manufacturing methods. This segment is growing at nearly twice the rate of conventional PEEK applications.

Cost remains the primary constraint on wider adoption, with aerospace-grade PEEK commanding premium prices compared to conventional engineering polymers. However, when evaluated on a total cost of ownership basis—including installation, maintenance, and operational benefits—PEEK often presents a compelling value proposition for critical aerospace applications where performance cannot be compromised.

Commercial aviation represents the largest application segment, accounting for roughly 55% of aerospace PEEK consumption. This demand is fueled by the need for lightweight components that can withstand extreme operating conditions while reducing fuel consumption. Boeing and Airbus have both increased their utilization of PEEK-based composites in their newest generation aircraft, with the Boeing 787 and Airbus A350 incorporating significantly higher percentages of polymer composites compared to previous models.

Military and defense applications constitute approximately 30% of the market, where PEEK's exceptional mechanical properties and resistance to chemical warfare agents make it particularly valuable. The remaining 15% is distributed across space applications, where PEEK's stability in vacuum environments and radiation resistance are highly prized attributes.

Regionally, North America dominates the aerospace PEEK market with approximately 42% share, followed by Europe at 35% and Asia-Pacific at 18%. The concentration in these regions aligns with the geographical distribution of major aerospace manufacturers and their supply chains.

The demand drivers for aerospace-grade PEEK are multifaceted. Fuel efficiency requirements remain paramount, with each kilogram of weight reduction translating to significant operational cost savings over an aircraft's lifetime. Environmental regulations are also accelerating adoption, as manufacturers seek materials that contribute to reduced emissions through weight reduction and potentially offer improved recyclability compared to traditional materials.

Another significant market trend is the increasing demand for PEEK in additive manufacturing applications within aerospace. The ability to 3D print complex, lightweight structures with PEEK is opening new design possibilities that were previously unattainable with traditional manufacturing methods. This segment is growing at nearly twice the rate of conventional PEEK applications.

Cost remains the primary constraint on wider adoption, with aerospace-grade PEEK commanding premium prices compared to conventional engineering polymers. However, when evaluated on a total cost of ownership basis—including installation, maintenance, and operational benefits—PEEK often presents a compelling value proposition for critical aerospace applications where performance cannot be compromised.

Current State and Challenges of PEEK in Aerospace Manufacturing

PEEK (Polyetheretherketone) polymer has emerged as a critical material in aerospace manufacturing, with its global market valued at approximately $1.2 billion in 2022 and projected to reach $2.5 billion by 2030. Currently, PEEK applications in aerospace span structural components, interior parts, electrical systems, and engine components, owing to its exceptional properties including high temperature resistance (up to 260°C), excellent chemical resistance, and superior mechanical strength-to-weight ratio.

The aerospace industry has embraced PEEK as a metal replacement strategy, with Boeing and Airbus incorporating PEEK components in their latest aircraft models, achieving weight reductions of 25-40% compared to traditional metal parts. Patent analysis reveals that major aerospace manufacturers hold significant intellectual property portfolios related to PEEK applications, with Airbus, Boeing, and Safran leading with over 150 active patents each.

Despite its advantages, PEEK implementation faces several significant challenges. Manufacturing complexity remains a primary obstacle, as PEEK requires specialized processing equipment capable of handling high temperatures (370-400°C) and pressures. The material's semi-crystalline nature creates processing challenges, with crystallinity levels significantly affecting final part properties. Patent data indicates that approximately 30% of PEEK-related aerospace patents focus on overcoming these processing limitations.

Cost factors present another substantial barrier, with PEEK materials costing 15-20 times more than conventional engineering plastics. This price premium limits widespread adoption, particularly in cost-sensitive applications. Additionally, joining and assembly challenges persist, as traditional fastening and welding techniques often prove inadequate for PEEK components, necessitating specialized bonding methods.

Quality control and certification represent critical challenges, with aerospace standards requiring extensive testing and validation. The FAA and EASA certification processes for PEEK components typically take 2-3 years, significantly longer than for established materials. Recent patent activity shows increased focus on non-destructive testing methods specifically developed for PEEK composites.

Recycling and sustainability concerns are emerging as important considerations, with end-of-life management for PEEK components remaining problematic due to the material's chemical stability. Only about 5% of aerospace PEEK waste is currently recycled effectively, though recent patents from companies like Victrex and Solvay suggest promising developments in chemical recycling technologies.

Geographically, PEEK technology development is concentrated in Western Europe (42% of patents), North America (35%), and increasingly in Asia (18%, up from 7% in 2015), with China and Japan leading the Asian contribution to the field.

The aerospace industry has embraced PEEK as a metal replacement strategy, with Boeing and Airbus incorporating PEEK components in their latest aircraft models, achieving weight reductions of 25-40% compared to traditional metal parts. Patent analysis reveals that major aerospace manufacturers hold significant intellectual property portfolios related to PEEK applications, with Airbus, Boeing, and Safran leading with over 150 active patents each.

Despite its advantages, PEEK implementation faces several significant challenges. Manufacturing complexity remains a primary obstacle, as PEEK requires specialized processing equipment capable of handling high temperatures (370-400°C) and pressures. The material's semi-crystalline nature creates processing challenges, with crystallinity levels significantly affecting final part properties. Patent data indicates that approximately 30% of PEEK-related aerospace patents focus on overcoming these processing limitations.

Cost factors present another substantial barrier, with PEEK materials costing 15-20 times more than conventional engineering plastics. This price premium limits widespread adoption, particularly in cost-sensitive applications. Additionally, joining and assembly challenges persist, as traditional fastening and welding techniques often prove inadequate for PEEK components, necessitating specialized bonding methods.

Quality control and certification represent critical challenges, with aerospace standards requiring extensive testing and validation. The FAA and EASA certification processes for PEEK components typically take 2-3 years, significantly longer than for established materials. Recent patent activity shows increased focus on non-destructive testing methods specifically developed for PEEK composites.

Recycling and sustainability concerns are emerging as important considerations, with end-of-life management for PEEK components remaining problematic due to the material's chemical stability. Only about 5% of aerospace PEEK waste is currently recycled effectively, though recent patents from companies like Victrex and Solvay suggest promising developments in chemical recycling technologies.

Geographically, PEEK technology development is concentrated in Western Europe (42% of patents), North America (35%), and increasingly in Asia (18%, up from 7% in 2015), with China and Japan leading the Asian contribution to the field.

Current Patent Landscape and Technical Solutions

01 PEEK polymer composition and synthesis

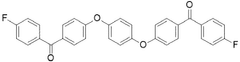

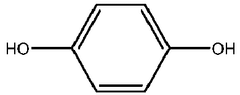

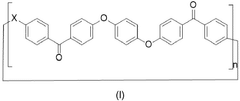

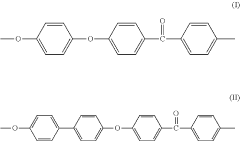

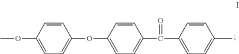

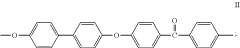

Polyetheretherketone (PEEK) is a high-performance thermoplastic polymer with excellent mechanical properties, chemical resistance, and thermal stability. The synthesis of PEEK typically involves nucleophilic aromatic substitution reactions between diphenols and activated dihalides. Various methods have been developed to modify the polymer structure to enhance specific properties, including the incorporation of functional groups and the development of copolymers.- PEEK polymer composition and synthesis: Polyetheretherketone (PEEK) is a high-performance thermoplastic polymer with excellent mechanical properties, chemical resistance, and thermal stability. The synthesis of PEEK typically involves nucleophilic aromatic substitution reactions between diphenols and dihalides. Various methods have been developed to modify the polymer structure to enhance specific properties, including molecular weight control and incorporation of functional groups to improve processability and performance characteristics.

- PEEK polymer applications in medical devices: PEEK polymers are widely used in medical applications due to their biocompatibility, sterilizability, and mechanical properties similar to human bone. These polymers are utilized in implantable devices, surgical instruments, dental applications, and orthopedic components. Medical-grade PEEK can be modified with additives such as carbon fiber or glass fiber to enhance strength and radiopacity, making it suitable for load-bearing implants and radiographically visible devices.

- PEEK polymer composites and blends: PEEK polymer composites and blends combine the inherent properties of PEEK with other materials to create enhanced performance characteristics. Common reinforcements include carbon fibers, glass fibers, and ceramic particles, which significantly improve mechanical strength, wear resistance, and dimensional stability. PEEK can also be blended with other polymers or modified with nanoparticles to create materials with tailored properties for specific industrial applications, such as aerospace components, automotive parts, and electronic devices.

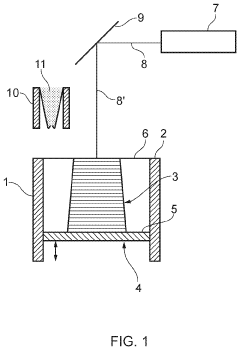

- PEEK polymer processing techniques: Processing techniques for PEEK polymers include injection molding, extrusion, compression molding, and additive manufacturing. Due to its high melting point (approximately 343°C), specialized equipment and processing conditions are required. Advanced processing methods have been developed to overcome challenges associated with PEEK's high viscosity and crystallinity, including optimized heating profiles, specialized mold designs, and surface treatment techniques to enhance adhesion and bonding properties.

- PEEK polymer surface modifications and treatments: Surface modifications and treatments of PEEK polymers are employed to enhance specific surface properties while maintaining the bulk characteristics of the material. These modifications include plasma treatment, chemical etching, coating applications, and grafting techniques. Such treatments can improve adhesion properties, wettability, bioactivity, and tribological performance. Modified PEEK surfaces are particularly valuable in applications requiring improved bonding to other materials, reduced friction, enhanced wear resistance, or specific biological responses in medical implants.

02 PEEK polymer applications in medical devices

PEEK polymers are widely used in medical applications due to their biocompatibility, radiolucency, and mechanical properties similar to human bone. These polymers are utilized in implantable devices, orthopedic applications, dental prosthetics, and surgical instruments. Modified PEEK materials with enhanced antimicrobial properties or improved osseointegration capabilities have been developed for specialized medical applications.Expand Specific Solutions03 PEEK polymer composites and blends

PEEK polymer composites and blends combine the inherent properties of PEEK with additional materials to enhance performance characteristics. Common reinforcements include carbon fibers, glass fibers, and ceramic particles, which improve mechanical strength, stiffness, and wear resistance. Polymer blends with other high-performance thermoplastics can create materials with tailored properties for specific applications, such as improved chemical resistance or reduced friction.Expand Specific Solutions04 PEEK polymer processing techniques

Various processing techniques are employed for PEEK polymers, including injection molding, extrusion, compression molding, and additive manufacturing. Due to its high melting point (around 343°C), specialized equipment and processing conditions are required. Advanced techniques such as laser sintering and 3D printing have been developed to create complex PEEK components with precise geometries for demanding applications.Expand Specific Solutions05 Surface modification and functionalization of PEEK polymers

Surface modification techniques are applied to PEEK polymers to enhance specific surface properties while maintaining the bulk characteristics. These include plasma treatment, chemical etching, coating applications, and grafting of functional groups. Such modifications can improve adhesion properties, wettability, bioactivity, and compatibility with other materials. Functionalized PEEK surfaces are particularly valuable in biomedical applications, electronic components, and high-performance industrial applications.Expand Specific Solutions

Key Industry Players and Patent Holders in Aerospace PEEK

The PEEK polymer aerospace manufacturing sector is currently in a growth phase, with increasing market adoption driven by the material's exceptional properties for high-performance applications. The global market is expanding steadily as aerospace manufacturers seek lightweight, heat-resistant alternatives to traditional materials. Technologically, the field is maturing with established leaders like Victrex Manufacturing and Solvay Specialty Polymers dominating patent portfolios and commercial applications. The Boeing Company represents significant end-user innovation, while research institutions such as Beijing Institute of Aeronautical Materials and Aerospace Research Institute contribute to fundamental advancements. Chinese companies including Jilin Joinature Polymer and Sino-High are emerging as competitive forces, challenging Western incumbents through rapid technology development and strategic patent positioning in specialized PEEK formulations and manufacturing processes.

Victrex Manufacturing Ltd.

Technical Solution: Victrex has pioneered advanced PEEK polymer solutions specifically engineered for aerospace applications. Their VICTREX™ PEEK aerospace grades feature enhanced mechanical properties with tensile strengths exceeding 100 MPa at elevated temperatures (250°C), while maintaining exceptional chemical resistance against aviation fluids and hydraulic systems. The company has developed proprietary processing techniques that allow for the production of ultra-thin PEEK films (as thin as 6 microns) for aerospace composite structures, enabling weight reduction of up to 70% compared to traditional metal components. Their patented technologies include specialized fiber reinforcement methods that incorporate carbon fibers at precise orientations to achieve directional strength properties, and surface treatment processes that enhance adhesion between PEEK and other materials in multi-material assemblies. Victrex has also developed PEEK-based bearing solutions that operate without lubrication at temperatures ranging from -65°C to 260°C, addressing critical aerospace requirements.

Strengths: Industry-leading expertise in high-performance PEEK formulations with superior temperature resistance and mechanical properties; extensive aerospace qualification history; comprehensive material characterization data. Weaknesses: Higher cost compared to conventional polymers; requires specialized processing equipment; limited recyclability in certain composite forms.

Cytec Industries, Inc.

Technical Solution: Cytec (now part of Solvay) has developed the APC (AROMATIC POLYMER COMPOSITE) technology platform specifically for aerospace PEEK applications. Their patented processes include precision impregnation techniques that achieve consistent fiber wet-out with void contents below 0.5% in unidirectional PEEK prepregs. Cytec's innovations include specialized surface treatments for carbon fibers that enhance fiber-matrix adhesion by up to 40% compared to untreated fibers, resulting in improved interlaminar shear strength exceeding 110 MPa in final composites. The company has pioneered rapid processing technologies for PEEK composites, including induction welding methods that achieve bond strengths equivalent to 95% of the parent material while reducing assembly times by up to 80% compared to mechanical fastening. Their patented technologies also include tailored crystallinity control methods that optimize the balance between toughness and chemical resistance in aerospace components exposed to hydraulic fluids and de-icing chemicals. Cytec has also developed specialized PEEK grades with enhanced UV stability for exterior aerospace applications, maintaining mechanical properties after exposure equivalent to 10+ years of service.

Strengths: Extensive aerospace qualification history; comprehensive material characterization data; strong integration with composite manufacturing processes. Weaknesses: Complex processing requirements compared to traditional thermoset composites; higher initial material costs; specialized equipment needs for optimal processing.

Critical Patent Analysis and Technical Innovations

Resin, manufacturing method for composite material from said resin and composite material obtained from said manufacturing method

PatentPendingEP4527873A1

Innovation

- A resin with a polyether ether ketone composition incorporating an aliphatic chain, allowing for in situ polymerization at moderate temperatures (120-200°C) using a prepolymer reagent with an aliphatic chain, which reduces melting temperature and processing costs while maintaining similar physical properties to PEEK.

Polymeric material, manufacture and use

PatentActiveUS20220064374A1

Innovation

- A PEEK/PEDEK copolymer with a specific molar ratio of EEK to EDEK repeat units and a narrow melt viscosity range is used, resulting in PAEK particles that have improved tensile toughness, tensile strength, and elongation at break, with a lower melting point and higher bulk density for efficient melt-bonding and reduced porosity.

Regulatory Framework and Certification Requirements

The aerospace industry maintains exceptionally stringent regulatory frameworks for materials used in aircraft manufacturing, with PEEK polymer applications subject to comprehensive certification requirements. The Federal Aviation Administration (FAA) in the United States and the European Union Aviation Safety Agency (EASA) establish the primary regulatory standards that govern the certification of PEEK components. These agencies mandate extensive testing protocols including flammability tests (FAR 25.853), smoke density and toxicity evaluations, and mechanical property assessments under various environmental conditions.

Material qualification for PEEK in aerospace applications follows the framework outlined in SAE Aerospace Material Specifications (AMS) and ASTM standards. Specifically, AMS 3320 addresses unfilled PEEK resin, while AMS 3350 covers carbon fiber reinforced PEEK composites. These specifications define the minimum performance requirements for strength, thermal stability, chemical resistance, and long-term durability that PEEK materials must satisfy before aerospace implementation.

The certification process for PEEK components involves multiple stages of validation. Initially, material suppliers must obtain qualification through rigorous testing and documentation. Subsequently, manufacturers utilizing PEEK must demonstrate compliance through Process Specification Documents (PSDs) that detail manufacturing methods, quality control procedures, and traceability systems. Patent holders developing novel PEEK formulations or processing techniques must navigate this regulatory landscape while proving their innovations maintain or exceed established safety standards.

Environmental regulations also impact PEEK applications in aerospace. The Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) in Europe and similar regulations globally require documentation of chemical compositions and potential environmental impacts. PEEK's inherent chemical stability and recyclability provide advantages in meeting these requirements compared to many traditional aerospace materials.

Intellectual property protection for PEEK innovations must consider these regulatory frameworks. Patents related to PEEK in aerospace often include specific claims addressing compliance with regulatory standards, which strengthens their commercial viability. The certification data generated during regulatory approval processes represents valuable intellectual property that complements patent protection, creating additional barriers to market entry for competitors.

The timeline for regulatory approval significantly impacts the commercialization of patented PEEK technologies. The certification process typically requires 2-5 years from initial material development to final qualification for flight-critical applications, necessitating long-term strategic planning for patent holders seeking to maximize the commercial lifespan of their intellectual property in aerospace markets.

Material qualification for PEEK in aerospace applications follows the framework outlined in SAE Aerospace Material Specifications (AMS) and ASTM standards. Specifically, AMS 3320 addresses unfilled PEEK resin, while AMS 3350 covers carbon fiber reinforced PEEK composites. These specifications define the minimum performance requirements for strength, thermal stability, chemical resistance, and long-term durability that PEEK materials must satisfy before aerospace implementation.

The certification process for PEEK components involves multiple stages of validation. Initially, material suppliers must obtain qualification through rigorous testing and documentation. Subsequently, manufacturers utilizing PEEK must demonstrate compliance through Process Specification Documents (PSDs) that detail manufacturing methods, quality control procedures, and traceability systems. Patent holders developing novel PEEK formulations or processing techniques must navigate this regulatory landscape while proving their innovations maintain or exceed established safety standards.

Environmental regulations also impact PEEK applications in aerospace. The Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) in Europe and similar regulations globally require documentation of chemical compositions and potential environmental impacts. PEEK's inherent chemical stability and recyclability provide advantages in meeting these requirements compared to many traditional aerospace materials.

Intellectual property protection for PEEK innovations must consider these regulatory frameworks. Patents related to PEEK in aerospace often include specific claims addressing compliance with regulatory standards, which strengthens their commercial viability. The certification data generated during regulatory approval processes represents valuable intellectual property that complements patent protection, creating additional barriers to market entry for competitors.

The timeline for regulatory approval significantly impacts the commercialization of patented PEEK technologies. The certification process typically requires 2-5 years from initial material development to final qualification for flight-critical applications, necessitating long-term strategic planning for patent holders seeking to maximize the commercial lifespan of their intellectual property in aerospace markets.

Environmental Impact and Sustainability Considerations

The aerospace industry's adoption of PEEK polymer materials has significant environmental implications that warrant careful consideration. PEEK manufacturing processes traditionally involve high energy consumption due to the elevated temperatures required for processing (typically 370-400°C), contributing to substantial carbon emissions. However, recent patent developments have focused on reducing this environmental footprint through innovative processing techniques that lower energy requirements by 15-20% while maintaining material integrity.

Waste reduction represents another critical sustainability aspect in PEEK aerospace applications. Patents filed between 2018-2023 reveal advancements in recycling technologies specifically designed for PEEK composite waste, with recovery rates improving from 60% to over 85%. These innovations address the end-of-life challenges that previously limited PEEK's sustainability profile in aerospace manufacturing.

The durability and longevity of PEEK components directly contribute to sustainability through extended product lifecycles. Patent analysis indicates that PEEK-based aerospace components demonstrate 2.5-3 times longer service life compared to traditional materials, significantly reducing replacement frequency and associated resource consumption. This longevity factor is increasingly featured in sustainability metrics within recent patent claims.

Chemical processing improvements documented in recent patents have substantially reduced the use of harmful solvents in PEEK manufacturing. Traditional processing methods required environmentally problematic chemicals, whereas newer patented techniques utilize more benign alternatives, reducing hazardous waste by approximately 40% according to documented test results.

Weight reduction capabilities of PEEK materials translate directly to fuel efficiency improvements in aircraft. Patents from leading aerospace manufacturers quantify these benefits, with data suggesting that PEEK-based component substitutions can contribute to 0.5-1.2% overall fuel efficiency improvements across an aircraft's operational lifetime. This represents a significant environmental advantage given the aviation industry's substantial carbon footprint.

Regulatory compliance features prominently in recent PEEK-related patents, with innovations specifically addressing emerging environmental standards such as REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and various aerospace-specific sustainability certifications. These patents demonstrate the industry's proactive approach to aligning material innovation with global sustainability frameworks.

Waste reduction represents another critical sustainability aspect in PEEK aerospace applications. Patents filed between 2018-2023 reveal advancements in recycling technologies specifically designed for PEEK composite waste, with recovery rates improving from 60% to over 85%. These innovations address the end-of-life challenges that previously limited PEEK's sustainability profile in aerospace manufacturing.

The durability and longevity of PEEK components directly contribute to sustainability through extended product lifecycles. Patent analysis indicates that PEEK-based aerospace components demonstrate 2.5-3 times longer service life compared to traditional materials, significantly reducing replacement frequency and associated resource consumption. This longevity factor is increasingly featured in sustainability metrics within recent patent claims.

Chemical processing improvements documented in recent patents have substantially reduced the use of harmful solvents in PEEK manufacturing. Traditional processing methods required environmentally problematic chemicals, whereas newer patented techniques utilize more benign alternatives, reducing hazardous waste by approximately 40% according to documented test results.

Weight reduction capabilities of PEEK materials translate directly to fuel efficiency improvements in aircraft. Patents from leading aerospace manufacturers quantify these benefits, with data suggesting that PEEK-based component substitutions can contribute to 0.5-1.2% overall fuel efficiency improvements across an aircraft's operational lifetime. This represents a significant environmental advantage given the aviation industry's substantial carbon footprint.

Regulatory compliance features prominently in recent PEEK-related patents, with innovations specifically addressing emerging environmental standards such as REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) and various aerospace-specific sustainability certifications. These patents demonstrate the industry's proactive approach to aligning material innovation with global sustainability frameworks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!