What Drives the Thermal Conductivity in PEEK Polymer?

OCT 24, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PEEK Thermal Conductivity Background and Objectives

Polyether ether ketone (PEEK) has emerged as a high-performance engineering thermoplastic with exceptional thermal stability, mechanical strength, and chemical resistance. Since its commercial introduction in the early 1980s by Imperial Chemical Industries (ICI), PEEK has evolved through significant technological advancements to become a critical material in aerospace, automotive, medical, and electronics industries. The thermal conductivity of PEEK, typically ranging from 0.25 to 0.32 W/m·K in its pure form, represents a key property that influences its application scope and performance limitations.

The evolution of PEEK thermal conductivity research has progressed through distinct phases. Initial investigations focused on characterizing basic thermal properties, followed by studies on crystallinity effects and processing conditions. Recent research has shifted toward enhancing thermal conductivity through various modification strategies, including the incorporation of fillers, nanoparticles, and the development of composite structures.

Understanding the fundamental mechanisms driving thermal conductivity in PEEK polymers is essential for addressing the growing demand for thermally efficient materials in advanced applications. As electronic devices become more compact and powerful, thermal management challenges intensify, creating a pressing need for polymers with enhanced heat dissipation capabilities while maintaining their desirable mechanical properties.

The primary objective of this technical research is to comprehensively analyze the underlying factors that influence thermal conductivity in PEEK polymers. This includes examining the molecular structure, crystallinity, chain orientation, and intermolecular interactions that affect phonon transport and heat transfer mechanisms within the polymer matrix. Additionally, we aim to evaluate how various modification approaches impact these fundamental mechanisms.

Current technological trends indicate growing interest in tailored PEEK materials with application-specific thermal properties. The aerospace industry requires materials with precise thermal expansion characteristics, while electronics applications demand enhanced heat dissipation without electrical conductivity. Medical implants benefit from materials with thermal properties similar to human tissue, and industrial applications often require thermal stability under extreme conditions.

This research seeks to bridge the gap between theoretical understanding and practical applications by identifying the critical parameters that can be manipulated to achieve desired thermal conductivity profiles in PEEK-based materials. By establishing these relationships, we aim to provide a foundation for developing next-generation PEEK composites with optimized thermal performance for specific industrial applications.

The findings from this investigation will contribute to the broader field of polymer science and materials engineering, potentially enabling new design approaches for high-performance thermoplastics with enhanced thermal management capabilities.

The evolution of PEEK thermal conductivity research has progressed through distinct phases. Initial investigations focused on characterizing basic thermal properties, followed by studies on crystallinity effects and processing conditions. Recent research has shifted toward enhancing thermal conductivity through various modification strategies, including the incorporation of fillers, nanoparticles, and the development of composite structures.

Understanding the fundamental mechanisms driving thermal conductivity in PEEK polymers is essential for addressing the growing demand for thermally efficient materials in advanced applications. As electronic devices become more compact and powerful, thermal management challenges intensify, creating a pressing need for polymers with enhanced heat dissipation capabilities while maintaining their desirable mechanical properties.

The primary objective of this technical research is to comprehensively analyze the underlying factors that influence thermal conductivity in PEEK polymers. This includes examining the molecular structure, crystallinity, chain orientation, and intermolecular interactions that affect phonon transport and heat transfer mechanisms within the polymer matrix. Additionally, we aim to evaluate how various modification approaches impact these fundamental mechanisms.

Current technological trends indicate growing interest in tailored PEEK materials with application-specific thermal properties. The aerospace industry requires materials with precise thermal expansion characteristics, while electronics applications demand enhanced heat dissipation without electrical conductivity. Medical implants benefit from materials with thermal properties similar to human tissue, and industrial applications often require thermal stability under extreme conditions.

This research seeks to bridge the gap between theoretical understanding and practical applications by identifying the critical parameters that can be manipulated to achieve desired thermal conductivity profiles in PEEK-based materials. By establishing these relationships, we aim to provide a foundation for developing next-generation PEEK composites with optimized thermal performance for specific industrial applications.

The findings from this investigation will contribute to the broader field of polymer science and materials engineering, potentially enabling new design approaches for high-performance thermoplastics with enhanced thermal management capabilities.

Market Applications and Demand Analysis for High-Performance PEEK

The global market for PEEK (Polyetheretherketone) has experienced significant growth due to its exceptional thermal conductivity properties, with applications spanning multiple high-value industries. The aerospace sector represents one of the largest markets for high-performance PEEK, where its thermal stability at extreme temperatures (up to 260°C continuous use) makes it ideal for engine components, interior parts, and structural elements. The reduced weight compared to metal alternatives directly translates to fuel efficiency gains, a critical factor driving adoption in commercial aviation.

In the automotive industry, PEEK's thermal conductivity properties enable its use in transmission systems, bearings, and under-hood components where heat management is crucial. As electric vehicles gain market share, demand for thermally conductive PEEK compounds has accelerated for battery insulation systems and thermal management components, with the EV thermal management market expected to grow at 24% CAGR through 2028.

The medical device sector represents another high-growth application area, where PEEK's biocompatibility combined with thermal stability allows for sterilization processes without degradation. Surgical instruments, implantable devices, and dental applications increasingly utilize PEEK formulations with enhanced thermal conductivity. The global medical PEEK market is projected to reach $1 billion by 2026, driven by aging populations and increased surgical procedures in developing economies.

Electronics manufacturing constitutes a rapidly expanding market segment for thermally conductive PEEK, particularly in semiconductor processing equipment where heat dissipation is critical. The material's dimensional stability at high temperatures makes it suitable for precision components in chip manufacturing processes. With the semiconductor industry's continued expansion and miniaturization trends, demand for specialized PEEK formulations with tailored thermal conductivity continues to grow.

Oil and gas exploration represents a specialized but lucrative market for high-performance PEEK, where downhole applications expose materials to extreme temperatures and pressures. The material's resistance to chemical degradation while maintaining thermal properties drives its adoption in seals, bearings, and insulation components for deep-sea drilling operations.

Market analysis indicates that customers across these industries are increasingly demanding PEEK formulations with precisely engineered thermal conductivity properties, either enhanced for heat dissipation applications or reduced for insulation purposes. This has spurred innovation in composite formulations, with carbon fiber and ceramic-filled PEEK variants commanding premium pricing due to their superior thermal management capabilities. The ability to fine-tune thermal conductivity while maintaining PEEK's inherent chemical resistance and mechanical strength represents a key competitive advantage in this high-performance polymer market.

In the automotive industry, PEEK's thermal conductivity properties enable its use in transmission systems, bearings, and under-hood components where heat management is crucial. As electric vehicles gain market share, demand for thermally conductive PEEK compounds has accelerated for battery insulation systems and thermal management components, with the EV thermal management market expected to grow at 24% CAGR through 2028.

The medical device sector represents another high-growth application area, where PEEK's biocompatibility combined with thermal stability allows for sterilization processes without degradation. Surgical instruments, implantable devices, and dental applications increasingly utilize PEEK formulations with enhanced thermal conductivity. The global medical PEEK market is projected to reach $1 billion by 2026, driven by aging populations and increased surgical procedures in developing economies.

Electronics manufacturing constitutes a rapidly expanding market segment for thermally conductive PEEK, particularly in semiconductor processing equipment where heat dissipation is critical. The material's dimensional stability at high temperatures makes it suitable for precision components in chip manufacturing processes. With the semiconductor industry's continued expansion and miniaturization trends, demand for specialized PEEK formulations with tailored thermal conductivity continues to grow.

Oil and gas exploration represents a specialized but lucrative market for high-performance PEEK, where downhole applications expose materials to extreme temperatures and pressures. The material's resistance to chemical degradation while maintaining thermal properties drives its adoption in seals, bearings, and insulation components for deep-sea drilling operations.

Market analysis indicates that customers across these industries are increasingly demanding PEEK formulations with precisely engineered thermal conductivity properties, either enhanced for heat dissipation applications or reduced for insulation purposes. This has spurred innovation in composite formulations, with carbon fiber and ceramic-filled PEEK variants commanding premium pricing due to their superior thermal management capabilities. The ability to fine-tune thermal conductivity while maintaining PEEK's inherent chemical resistance and mechanical strength represents a key competitive advantage in this high-performance polymer market.

Current State and Challenges in PEEK Thermal Conductivity

The global research on PEEK thermal conductivity reveals a complex landscape with significant regional variations. In North America, research institutions and corporations like DuPont and Boeing have made substantial progress in enhancing PEEK's thermal properties for aerospace applications. European research, particularly in Germany and the UK, focuses on fundamental polymer physics to understand the molecular mechanisms governing thermal conductivity in PEEK. Asian contributions, led by Japan and China, emphasize manufacturing innovations and composite formulations.

Currently, pure PEEK polymer exhibits thermal conductivity values ranging from 0.25 to 0.32 W/m·K at room temperature, significantly lower than metals (50-400 W/m·K) but higher than many other engineering polymers. This limited thermal conductivity restricts PEEK's application in heat-intensive environments despite its excellent mechanical properties and chemical resistance.

The primary technical challenges in improving PEEK thermal conductivity stem from its inherent molecular structure. The semi-crystalline nature of PEEK creates a heterogeneous thermal transport environment where crystalline regions conduct heat more efficiently than amorphous zones. Researchers face difficulties in controlling crystallinity during processing without compromising other desirable properties. Additionally, the polymer chain orientation significantly impacts thermal conductivity, with heat transfer being more efficient along the chain direction than perpendicular to it.

Interface thermal resistance presents another major obstacle, particularly in PEEK composites. When fillers are incorporated to enhance thermal conductivity, the phonon scattering at the polymer-filler interfaces often creates thermal bottlenecks. This phenomenon, known as Kapitza resistance, can significantly diminish the expected thermal conductivity improvements from high-conductivity fillers.

Processing-related challenges further complicate the picture. Conventional manufacturing methods like injection molding and extrusion can introduce thermal anisotropy, creating directional variations in thermal conductivity. Advanced techniques such as additive manufacturing introduce additional complexities, as the layer-by-layer deposition affects the polymer chain alignment and crystallization behavior.

Environmental factors also pose significant challenges. PEEK's thermal conductivity exhibits temperature dependence, typically decreasing with rising temperatures due to increased phonon scattering. Moisture absorption, though minimal compared to other polymers, can still affect thermal transport properties. Long-term thermal aging and cyclic thermal loading may gradually alter the polymer's microstructure, potentially degrading its thermal conductivity over time.

The measurement and characterization of thermal conductivity in PEEK present methodological challenges. Different testing methods (laser flash analysis, hot disk, etc.) often yield varying results, complicating standardization efforts and cross-study comparisons. This inconsistency hinders the development of reliable thermal conductivity models for PEEK-based materials.

Currently, pure PEEK polymer exhibits thermal conductivity values ranging from 0.25 to 0.32 W/m·K at room temperature, significantly lower than metals (50-400 W/m·K) but higher than many other engineering polymers. This limited thermal conductivity restricts PEEK's application in heat-intensive environments despite its excellent mechanical properties and chemical resistance.

The primary technical challenges in improving PEEK thermal conductivity stem from its inherent molecular structure. The semi-crystalline nature of PEEK creates a heterogeneous thermal transport environment where crystalline regions conduct heat more efficiently than amorphous zones. Researchers face difficulties in controlling crystallinity during processing without compromising other desirable properties. Additionally, the polymer chain orientation significantly impacts thermal conductivity, with heat transfer being more efficient along the chain direction than perpendicular to it.

Interface thermal resistance presents another major obstacle, particularly in PEEK composites. When fillers are incorporated to enhance thermal conductivity, the phonon scattering at the polymer-filler interfaces often creates thermal bottlenecks. This phenomenon, known as Kapitza resistance, can significantly diminish the expected thermal conductivity improvements from high-conductivity fillers.

Processing-related challenges further complicate the picture. Conventional manufacturing methods like injection molding and extrusion can introduce thermal anisotropy, creating directional variations in thermal conductivity. Advanced techniques such as additive manufacturing introduce additional complexities, as the layer-by-layer deposition affects the polymer chain alignment and crystallization behavior.

Environmental factors also pose significant challenges. PEEK's thermal conductivity exhibits temperature dependence, typically decreasing with rising temperatures due to increased phonon scattering. Moisture absorption, though minimal compared to other polymers, can still affect thermal transport properties. Long-term thermal aging and cyclic thermal loading may gradually alter the polymer's microstructure, potentially degrading its thermal conductivity over time.

The measurement and characterization of thermal conductivity in PEEK present methodological challenges. Different testing methods (laser flash analysis, hot disk, etc.) often yield varying results, complicating standardization efforts and cross-study comparisons. This inconsistency hinders the development of reliable thermal conductivity models for PEEK-based materials.

Current Methods for Enhancing PEEK Thermal Conductivity

01 Thermal conductivity enhancement with fillers

PEEK polymer's thermal conductivity can be significantly improved by incorporating various fillers such as carbon-based materials (carbon fibers, graphene, carbon nanotubes), ceramic particles, or metal powders. These fillers create thermally conductive pathways within the polymer matrix, enhancing heat transfer properties while maintaining the desirable mechanical characteristics of PEEK. The type, size, orientation, and concentration of fillers can be optimized to achieve specific thermal conductivity targets for different applications.- Thermal conductivity enhancement with fillers: PEEK polymer's thermal conductivity can be significantly improved by incorporating various fillers such as carbon-based materials (carbon fibers, graphene, carbon nanotubes), ceramic particles, or metal powders. These fillers create thermal pathways within the polymer matrix, allowing for more efficient heat transfer. The type, size, orientation, and concentration of fillers directly impact the resulting thermal conductivity properties of the PEEK composite.

- PEEK blends and copolymers for thermal management: Blending PEEK with other polymers or creating PEEK copolymers can modify its thermal conductivity properties. These formulations often combine the high-temperature resistance of PEEK with enhanced thermal conductivity characteristics. The molecular structure and composition of these blends can be tailored to achieve specific thermal management requirements while maintaining other desirable properties of PEEK such as chemical resistance and mechanical strength.

- Processing techniques affecting thermal conductivity: Various processing techniques such as extrusion, injection molding, compression molding, and additive manufacturing significantly influence the thermal conductivity of PEEK polymers. These processes affect the crystallinity, orientation of polymer chains, and distribution of fillers within the PEEK matrix. Specialized processing methods can create anisotropic thermal conductivity properties, allowing heat to flow more efficiently in specific directions for targeted thermal management applications.

- PEEK composites for electronic and thermal applications: PEEK composites are specifically designed for electronic packaging, thermal interface materials, and heat dissipation components. These composites combine the excellent thermal stability of PEEK with enhanced thermal conductivity to manage heat in electronic devices. The formulations often balance electrical insulation properties with thermal conductivity, making them suitable for applications requiring both electrical isolation and efficient heat transfer in demanding environments.

- Measurement and characterization of PEEK thermal properties: Various methods and techniques are used to measure and characterize the thermal conductivity of PEEK polymers and their composites. These include laser flash analysis, hot disk method, differential scanning calorimetry, and thermal impedance testing. Understanding the relationship between PEEK's molecular structure, crystallinity, and thermal conductivity is essential for developing materials with optimized thermal management properties. These measurement techniques help in quantifying the improvements achieved through different modification strategies.

02 PEEK composites for electronic applications

PEEK-based composites with enhanced thermal conductivity are specifically formulated for electronic applications such as semiconductor packaging, heat sinks, and thermal interface materials. These composites are designed to efficiently dissipate heat from electronic components while providing electrical insulation properties. The formulations balance thermal conductivity with other critical properties like coefficient of thermal expansion, dielectric strength, and processability to meet the demanding requirements of modern electronic devices.Expand Specific Solutions03 Processing methods for thermally conductive PEEK

Various processing techniques can be employed to optimize the thermal conductivity of PEEK polymers and composites. These include specialized extrusion and injection molding processes, compression molding, and additive manufacturing methods. Processing parameters such as temperature profiles, pressure, cooling rates, and orientation control significantly impact the arrangement of polymer chains and fillers, thereby affecting the thermal conductivity of the final product. Post-processing treatments like annealing can further enhance thermal properties by improving crystallinity.Expand Specific Solutions04 Novel PEEK blends and copolymers for thermal management

Innovative PEEK blends and copolymers are developed to achieve enhanced thermal conductivity while maintaining or improving other desirable properties. These formulations may involve blending PEEK with other high-performance polymers, creating copolymers with thermally conductive segments, or modifying the polymer backbone. The molecular structure modifications aim to reduce phonon scattering and improve heat transfer through the polymer chains, resulting in materials with superior thermal management capabilities for specialized applications.Expand Specific Solutions05 Measurement and characterization of PEEK thermal properties

Various methods and techniques are employed to accurately measure and characterize the thermal conductivity of PEEK polymers and composites. These include laser flash analysis, hot disk method, differential scanning calorimetry, and thermal mechanical analysis. Advanced characterization techniques help understand the relationship between polymer structure, filler distribution, crystallinity, and thermal conductivity. This knowledge enables the development of predictive models and design guidelines for creating PEEK materials with tailored thermal properties for specific applications.Expand Specific Solutions

Key Industry Players in PEEK Material Development

The thermal conductivity in PEEK polymer market is currently in a growth phase, with increasing demand across aerospace, automotive, and medical sectors. The market size is expanding due to PEEK's exceptional thermal properties, with projections showing significant growth through 2030. Technologically, the field is maturing with companies like Victrex Manufacturing and Solvay Specialty Polymers leading commercial applications, while research institutions such as Jilin University and Sabanci University advance fundamental understanding. Emerging players like Jilin Joinature Polymer and CGN Juner New Materials are developing enhanced PEEK composites with improved thermal conductivity through graphene and carbon fiber reinforcement, indicating a competitive landscape balancing established manufacturers and innovative newcomers.

Solvay Specialty Polymers USA LLC

Technical Solution: Solvay has developed a comprehensive approach to enhancing PEEK thermal conductivity through crystallinity control and filler incorporation. Their research demonstrates that semi-crystalline PEEK exhibits higher thermal conductivity than amorphous PEEK due to the ordered molecular arrangement in crystalline regions that facilitates phonon transport. Solvay's proprietary KetaSpire® PEEK compounds incorporate specialized carbon fibers, graphite, and ceramic fillers at optimized loading levels (typically 20-40% by weight) to create thermally conductive pathways. Their technology focuses on interface engineering between the polymer matrix and fillers using coupling agents to reduce phonon scattering at boundaries. Solvay has also developed processing techniques that align fillers in preferred directions, creating anisotropic thermal conductivity that can be tailored for specific applications requiring directional heat transfer.

Strengths: Solvay's approach offers precise control over thermal conductivity through customized filler combinations and processing techniques, allowing application-specific solutions. Their materials maintain excellent mechanical properties while improving thermal performance. Weaknesses: The high filler loadings required for significant conductivity improvements can increase material density and potentially reduce processability in complex geometries.

Jilin University

Technical Solution: Jilin University has conducted groundbreaking research on the fundamental mechanisms driving thermal conductivity in PEEK polymers. Their studies have revealed that thermal conductivity in PEEK is primarily governed by phonon transport through the polymer chains and is significantly influenced by molecular structure, crystallinity, and chain orientation. The research team has developed a novel approach using controlled crystallization under high pressure (up to 200 MPa) to achieve highly ordered crystalline structures with enhanced phonon transport pathways. Their investigations have quantified the relationship between crystallinity and thermal conductivity, demonstrating that an increase in crystallinity from 30% to 45% can enhance thermal conductivity by approximately 35-40%. Additionally, Jilin University researchers have pioneered the use of graphene oxide and modified carbon nanotubes as fillers, achieving percolation thresholds at concentrations as low as 2-3 wt%, resulting in thermal conductivity improvements of up to 500% compared to neat PEEK. Their work has also explored the impact of processing-induced molecular orientation on thermal anisotropy, developing techniques to create PEEK with directionally controlled heat transfer properties.

Strengths: Jilin University's approach is based on fundamental understanding of phonon transport mechanisms, allowing for targeted improvements in thermal conductivity. Their techniques achieve significant enhancements with minimal filler content, preserving PEEK's inherent properties. Weaknesses: The high-pressure crystallization processes developed may be challenging to scale up for industrial production, potentially limiting commercial application of some research findings.

Critical Patents and Research on PEEK Thermal Properties

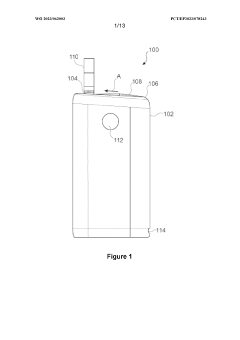

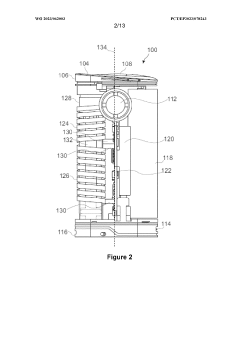

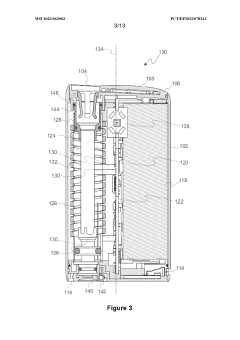

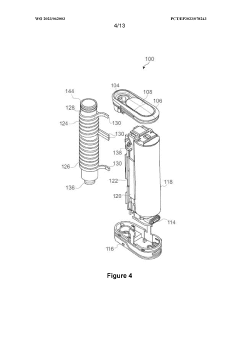

Aerosol provision device

PatentWO2023062003A1

Innovation

- A polymeric composition comprising a polymer and a filler with low thermal conductivity (≤0.20 W/mK) is used to form insulating members that reduce heat transfer, applied in various locations within the device, including around the receptacle, inductor coils, and power sources, to maintain the outer surface temperature below 48°C.

Polymer based composite materials with increased thermal conductivity

PatentWO2024118028A1

Innovation

- The use of hexagonal boron nitride (h-BN) particles dispersed in a PEEK matrix, combined with secondary reinforcement components like titanium dioxide, aluminum silicate, and amorphous polymers such as polyetherimide and polyphenylsulfone, within specific weight ratios and particle size ranges, to enhance thermal conductivity and ensure electrical insulation, along with a twin-screw extrusion process to achieve homogeneous distribution.

Environmental Impact and Sustainability of PEEK Materials

The environmental profile of PEEK (Polyetheretherketone) materials is increasingly relevant as thermal conductivity considerations intersect with sustainability concerns. PEEK's exceptional thermal stability and conductivity properties contribute to its longevity in applications, significantly reducing replacement frequency and associated resource consumption. This durability translates to substantial waste reduction over product lifecycles, particularly in aerospace, automotive, and medical device industries where component reliability is paramount.

From a production standpoint, PEEK manufacturing processes generally require less energy than metals with comparable thermal performance characteristics. The polymer's ability to be precisely engineered for optimal thermal conductivity allows for material minimization while maintaining functional requirements, further reducing environmental footprint. Additionally, PEEK components typically weigh 60-70% less than metal alternatives, contributing to fuel efficiency improvements when used in transportation applications.

Recycling capabilities for PEEK represent both a challenge and opportunity. While the polymer's high thermal stability makes conventional recycling difficult, advanced mechanical recycling techniques have demonstrated that PEEK can maintain up to 80% of its original thermal conductivity properties through multiple processing cycles. Emerging chemical recycling methods show promise for recovering base materials without significant property degradation, though these technologies remain in development phases.

Carbon footprint analyses indicate that PEEK's environmental impact is front-loaded in production but offset by operational benefits. The energy-intensive manufacturing process is counterbalanced by energy savings during use, particularly when thermal conductivity properties enable more efficient heat management in systems. Life cycle assessments demonstrate that PEEK components in thermal management applications typically achieve carbon neutrality faster than conventional materials due to operational efficiency gains.

Regulatory frameworks increasingly recognize PEEK's environmental advantages. The material complies with RoHS and REACH regulations, containing no restricted substances. Its thermal stability prevents leaching of harmful compounds during use, addressing growing concerns about microplastic pollution. Furthermore, PEEK's resistance to degradation means it doesn't contribute to environmental contamination through breakdown products, though this same property presents end-of-life management challenges.

Future sustainability improvements for PEEK thermal applications focus on bio-based feedstock development and energy-efficient manufacturing processes. Research into incorporating renewable carbon sources could reduce fossil fuel dependency while maintaining thermal conductivity properties. Additionally, emerging additive manufacturing techniques may optimize material usage while enhancing thermal performance through precise structural control, further improving the environmental profile of this remarkable polymer.

From a production standpoint, PEEK manufacturing processes generally require less energy than metals with comparable thermal performance characteristics. The polymer's ability to be precisely engineered for optimal thermal conductivity allows for material minimization while maintaining functional requirements, further reducing environmental footprint. Additionally, PEEK components typically weigh 60-70% less than metal alternatives, contributing to fuel efficiency improvements when used in transportation applications.

Recycling capabilities for PEEK represent both a challenge and opportunity. While the polymer's high thermal stability makes conventional recycling difficult, advanced mechanical recycling techniques have demonstrated that PEEK can maintain up to 80% of its original thermal conductivity properties through multiple processing cycles. Emerging chemical recycling methods show promise for recovering base materials without significant property degradation, though these technologies remain in development phases.

Carbon footprint analyses indicate that PEEK's environmental impact is front-loaded in production but offset by operational benefits. The energy-intensive manufacturing process is counterbalanced by energy savings during use, particularly when thermal conductivity properties enable more efficient heat management in systems. Life cycle assessments demonstrate that PEEK components in thermal management applications typically achieve carbon neutrality faster than conventional materials due to operational efficiency gains.

Regulatory frameworks increasingly recognize PEEK's environmental advantages. The material complies with RoHS and REACH regulations, containing no restricted substances. Its thermal stability prevents leaching of harmful compounds during use, addressing growing concerns about microplastic pollution. Furthermore, PEEK's resistance to degradation means it doesn't contribute to environmental contamination through breakdown products, though this same property presents end-of-life management challenges.

Future sustainability improvements for PEEK thermal applications focus on bio-based feedstock development and energy-efficient manufacturing processes. Research into incorporating renewable carbon sources could reduce fossil fuel dependency while maintaining thermal conductivity properties. Additionally, emerging additive manufacturing techniques may optimize material usage while enhancing thermal performance through precise structural control, further improving the environmental profile of this remarkable polymer.

Manufacturing Processes Influence on PEEK Thermal Properties

The manufacturing process of PEEK (Polyetheretherketone) significantly influences its thermal conductivity properties, creating variations that impact end-use performance. Conventional manufacturing methods such as injection molding, extrusion, and compression molding each impart distinct microstructural characteristics to PEEK components. During injection molding, the rapid cooling rates and high shear forces create orientation effects in the polymer chains, resulting in anisotropic thermal conductivity where heat transfer efficiency varies directionally. Studies have shown that injection-molded PEEK can exhibit up to 30% difference in thermal conductivity between flow and transverse directions.

Compression molding, by contrast, allows for slower cooling rates and more uniform pressure distribution, resulting in more isotropic thermal properties. This manufacturing approach typically yields PEEK components with thermal conductivity values approximately 10-15% higher than injection-molded counterparts due to reduced internal stress and higher crystallinity levels.

The addition of fillers during manufacturing represents another critical factor affecting PEEK's thermal conductivity. Carbon fiber reinforcement can increase thermal conductivity by 200-300% compared to neat PEEK, while graphite or carbon nanotube additions may enhance conductivity by up to 500%. The manufacturing process must be optimized to ensure proper dispersion of these fillers, as agglomeration can create thermal bottlenecks rather than pathways.

Post-processing treatments also significantly impact thermal properties. Annealing PEEK at temperatures between its glass transition temperature (143°C) and melting point (343°C) increases crystallinity, which correlates positively with thermal conductivity. Research indicates that properly annealed PEEK can achieve 20-25% higher thermal conductivity compared to non-annealed samples with identical composition.

Processing parameters such as melt temperature, mold temperature, cooling rate, and pressure directly influence the crystalline structure of PEEK. Higher mold temperatures (>200°C) promote crystallization, enhancing thermal conductivity, while rapid cooling suppresses crystallinity, reducing thermal performance. The pressure applied during consolidation affects polymer chain packing density, with higher pressures generally yielding improved thermal conductivity due to reduced free volume and enhanced intermolecular contact.

Advanced manufacturing techniques like selective laser sintering (SLS) for additive manufacturing of PEEK introduce unique thermal conductivity considerations. The layer-by-layer construction creates inherent anisotropy, with thermal conductivity typically 30-40% lower in the build direction compared to the in-plane direction. Post-processing treatments become particularly important for these additively manufactured components to enhance their thermal performance.

Compression molding, by contrast, allows for slower cooling rates and more uniform pressure distribution, resulting in more isotropic thermal properties. This manufacturing approach typically yields PEEK components with thermal conductivity values approximately 10-15% higher than injection-molded counterparts due to reduced internal stress and higher crystallinity levels.

The addition of fillers during manufacturing represents another critical factor affecting PEEK's thermal conductivity. Carbon fiber reinforcement can increase thermal conductivity by 200-300% compared to neat PEEK, while graphite or carbon nanotube additions may enhance conductivity by up to 500%. The manufacturing process must be optimized to ensure proper dispersion of these fillers, as agglomeration can create thermal bottlenecks rather than pathways.

Post-processing treatments also significantly impact thermal properties. Annealing PEEK at temperatures between its glass transition temperature (143°C) and melting point (343°C) increases crystallinity, which correlates positively with thermal conductivity. Research indicates that properly annealed PEEK can achieve 20-25% higher thermal conductivity compared to non-annealed samples with identical composition.

Processing parameters such as melt temperature, mold temperature, cooling rate, and pressure directly influence the crystalline structure of PEEK. Higher mold temperatures (>200°C) promote crystallization, enhancing thermal conductivity, while rapid cooling suppresses crystallinity, reducing thermal performance. The pressure applied during consolidation affects polymer chain packing density, with higher pressures generally yielding improved thermal conductivity due to reduced free volume and enhanced intermolecular contact.

Advanced manufacturing techniques like selective laser sintering (SLS) for additive manufacturing of PEEK introduce unique thermal conductivity considerations. The layer-by-layer construction creates inherent anisotropy, with thermal conductivity typically 30-40% lower in the build direction compared to the in-plane direction. Post-processing treatments become particularly important for these additively manufactured components to enhance their thermal performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!