Analysis of PEEK Polymer Properties for Electronic Component Durability

OCT 24, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PEEK Polymer Evolution and Performance Objectives

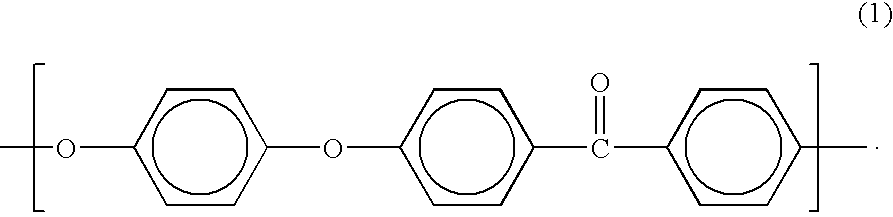

Polyether ether ketone (PEEK) has emerged as a revolutionary high-performance thermoplastic polymer since its commercial introduction in the early 1980s by Imperial Chemical Industries. The evolution of PEEK has been characterized by continuous improvements in synthesis methods, processing techniques, and property enhancements, transforming it from a specialty material to a critical component in high-demand electronic applications.

The historical development of PEEK began with nucleophilic aromatic substitution polymerization methods, which have since evolved to include more efficient catalytic systems and reaction conditions. This evolution has enabled manufacturers to produce PEEK with higher molecular weights, improved purity, and more consistent property profiles, all critical factors for electronic component applications.

In the electronic component sector, PEEK's evolution has been driven by increasingly stringent performance requirements. The miniaturization trend in electronics has demanded materials capable of withstanding higher temperatures in smaller spaces, with PEEK's exceptional thermal stability (glass transition temperature of 143°C and melting point of 343°C) positioning it as an ideal candidate for these applications.

The primary performance objectives for PEEK in electronic component applications center around durability under extreme conditions. These include maintaining dimensional stability and mechanical integrity at elevated temperatures, resisting degradation from exposure to harsh chemicals commonly used in electronic manufacturing processes, and providing consistent electrical insulation properties throughout the component lifecycle.

Another critical performance objective is PEEK's ability to withstand repeated thermal cycling without property degradation. Electronic components frequently experience temperature fluctuations during operation, and PEEK's excellent thermal fatigue resistance ensures long-term reliability in these dynamic environments.

Radiation resistance represents an emerging performance objective for PEEK polymers, particularly in aerospace and medical electronic applications. The development of radiation-hardened PEEK variants aims to maintain structural and electrical properties even after exposure to ionizing radiation, extending the material's utility in specialized electronic systems.

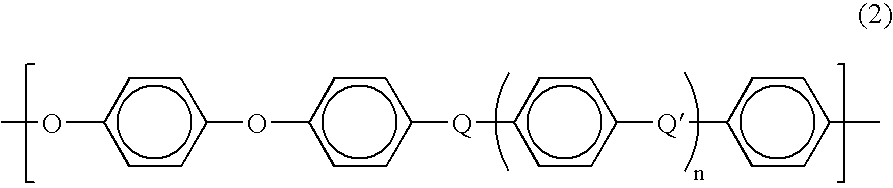

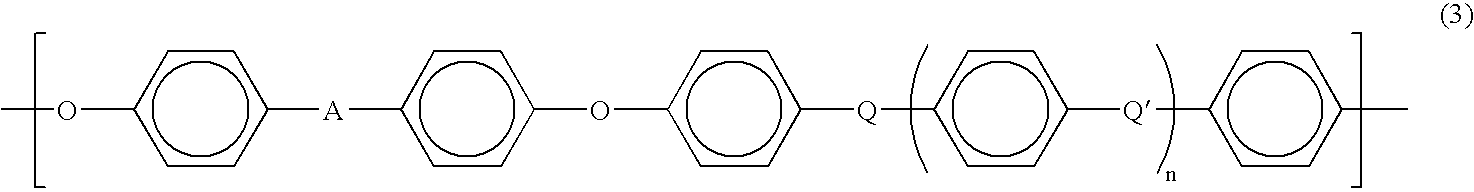

The evolution of PEEK composites, particularly those reinforced with carbon fibers or glass fibers, has expanded the performance envelope of these materials. These composites offer enhanced mechanical properties, improved dimensional stability, and in some cases, tailored electrical conductivity, addressing specific requirements in advanced electronic applications.

Looking forward, performance objectives for PEEK in electronic components are increasingly focused on sustainability and processing efficiency. Research efforts are directed toward developing bio-based precursors for PEEK synthesis, reducing energy consumption during processing, and enhancing end-of-life recyclability while maintaining the exceptional durability that defines this polymer class.

The historical development of PEEK began with nucleophilic aromatic substitution polymerization methods, which have since evolved to include more efficient catalytic systems and reaction conditions. This evolution has enabled manufacturers to produce PEEK with higher molecular weights, improved purity, and more consistent property profiles, all critical factors for electronic component applications.

In the electronic component sector, PEEK's evolution has been driven by increasingly stringent performance requirements. The miniaturization trend in electronics has demanded materials capable of withstanding higher temperatures in smaller spaces, with PEEK's exceptional thermal stability (glass transition temperature of 143°C and melting point of 343°C) positioning it as an ideal candidate for these applications.

The primary performance objectives for PEEK in electronic component applications center around durability under extreme conditions. These include maintaining dimensional stability and mechanical integrity at elevated temperatures, resisting degradation from exposure to harsh chemicals commonly used in electronic manufacturing processes, and providing consistent electrical insulation properties throughout the component lifecycle.

Another critical performance objective is PEEK's ability to withstand repeated thermal cycling without property degradation. Electronic components frequently experience temperature fluctuations during operation, and PEEK's excellent thermal fatigue resistance ensures long-term reliability in these dynamic environments.

Radiation resistance represents an emerging performance objective for PEEK polymers, particularly in aerospace and medical electronic applications. The development of radiation-hardened PEEK variants aims to maintain structural and electrical properties even after exposure to ionizing radiation, extending the material's utility in specialized electronic systems.

The evolution of PEEK composites, particularly those reinforced with carbon fibers or glass fibers, has expanded the performance envelope of these materials. These composites offer enhanced mechanical properties, improved dimensional stability, and in some cases, tailored electrical conductivity, addressing specific requirements in advanced electronic applications.

Looking forward, performance objectives for PEEK in electronic components are increasingly focused on sustainability and processing efficiency. Research efforts are directed toward developing bio-based precursors for PEEK synthesis, reducing energy consumption during processing, and enhancing end-of-life recyclability while maintaining the exceptional durability that defines this polymer class.

Electronic Component Market Requirements Analysis

The electronic component market is experiencing unprecedented growth driven by the expansion of industries such as telecommunications, automotive electronics, aerospace, and consumer electronics. This growth has created stringent requirements for component materials, particularly in harsh operating environments. PEEK (Polyetheretherketone) polymers have emerged as critical materials due to their exceptional thermal stability, chemical resistance, and mechanical strength.

Market research indicates that the global electronic components market is projected to reach $455.6 billion by 2027, with a compound annual growth rate of 4.8%. Within this market, high-performance polymers like PEEK are gaining significant traction, especially in applications requiring durability under extreme conditions. The demand for PEEK in electronic components is primarily driven by the miniaturization trend, which necessitates materials capable of withstanding higher temperatures in smaller spaces.

Reliability requirements have become increasingly stringent across various sectors. In automotive electronics, components must function flawlessly in temperature ranges from -40°C to 150°C, with some under-hood applications requiring even higher temperature resistance. PEEK's glass transition temperature of approximately 143°C and melting point of around 343°C make it particularly suitable for these demanding environments.

Chemical resistance is another critical market requirement. Electronic components in industrial settings are frequently exposed to aggressive chemicals, oils, and solvents. Market data shows that maintenance costs due to chemical degradation of components amount to billions annually across industries. PEEK's exceptional resistance to a wide range of chemicals positions it as a preferred material for such applications.

Mechanical durability requirements have also evolved significantly. Modern electronic assemblies undergo numerous thermal cycles and mechanical stresses during operation. Market analysis reveals that approximately 65% of electronic component failures are attributed to mechanical issues, including fractures and connection failures. PEEK's high tensile strength (approximately 100 MPa) and excellent fatigue resistance address these concerns effectively.

The market increasingly demands materials with low outgassing properties for sensitive electronic applications, particularly in aerospace and medical electronics. PEEK's stability under vacuum conditions makes it suitable for these specialized markets, which are growing at rates exceeding the overall electronic component market average.

Electrical insulation properties represent another crucial market requirement. With increasing power densities in modern electronics, materials must maintain their insulative properties at elevated temperatures. PEEK's volume resistivity remains stable even at high temperatures, meeting the market's need for reliable electrical insulation in compact, high-power designs.

Market research indicates that the global electronic components market is projected to reach $455.6 billion by 2027, with a compound annual growth rate of 4.8%. Within this market, high-performance polymers like PEEK are gaining significant traction, especially in applications requiring durability under extreme conditions. The demand for PEEK in electronic components is primarily driven by the miniaturization trend, which necessitates materials capable of withstanding higher temperatures in smaller spaces.

Reliability requirements have become increasingly stringent across various sectors. In automotive electronics, components must function flawlessly in temperature ranges from -40°C to 150°C, with some under-hood applications requiring even higher temperature resistance. PEEK's glass transition temperature of approximately 143°C and melting point of around 343°C make it particularly suitable for these demanding environments.

Chemical resistance is another critical market requirement. Electronic components in industrial settings are frequently exposed to aggressive chemicals, oils, and solvents. Market data shows that maintenance costs due to chemical degradation of components amount to billions annually across industries. PEEK's exceptional resistance to a wide range of chemicals positions it as a preferred material for such applications.

Mechanical durability requirements have also evolved significantly. Modern electronic assemblies undergo numerous thermal cycles and mechanical stresses during operation. Market analysis reveals that approximately 65% of electronic component failures are attributed to mechanical issues, including fractures and connection failures. PEEK's high tensile strength (approximately 100 MPa) and excellent fatigue resistance address these concerns effectively.

The market increasingly demands materials with low outgassing properties for sensitive electronic applications, particularly in aerospace and medical electronics. PEEK's stability under vacuum conditions makes it suitable for these specialized markets, which are growing at rates exceeding the overall electronic component market average.

Electrical insulation properties represent another crucial market requirement. With increasing power densities in modern electronics, materials must maintain their insulative properties at elevated temperatures. PEEK's volume resistivity remains stable even at high temperatures, meeting the market's need for reliable electrical insulation in compact, high-power designs.

PEEK Technology Assessment and Implementation Barriers

Despite PEEK's exceptional properties for electronic applications, several significant barriers impede its widespread implementation. The primary challenge remains its high processing temperature, typically requiring 370-400°C for injection molding and extrusion. This necessitates specialized equipment with capabilities exceeding standard polymer processing machinery, substantially increasing manufacturing costs and limiting production facilities capable of PEEK processing.

Cost factors present another major barrier, with PEEK commanding prices 10-15 times higher than conventional engineering polymers. This premium pricing stems from complex synthesis processes, high-purity requirements, and relatively limited production volumes. For electronic component manufacturers operating in competitive markets with tight margins, this cost differential often proves prohibitive despite PEEK's superior long-term performance benefits.

Technical processing challenges further complicate PEEK implementation. The polymer exhibits a narrow processing window, requiring precise temperature control to prevent degradation while ensuring proper melt flow. Additionally, PEEK's semi-crystalline nature demands careful cooling rate management to achieve optimal crystallinity levels that directly impact mechanical and electrical properties. Improper processing can result in warpage, dimensional instability, and compromised performance characteristics.

Integration with existing electronic manufacturing processes presents compatibility issues. PEEK's high melting point complicates bonding with other materials and components, often requiring specialized adhesives or surface treatments. Furthermore, its inherent chemical resistance, while beneficial for end-use applications, creates challenges for surface modification and metallization processes essential in electronic component manufacturing.

Knowledge barriers also exist within the industry. Many electronic design engineers lack familiarity with PEEK's unique properties and processing requirements, leading to suboptimal designs that fail to leverage the material's full potential. This knowledge gap extends to processing technicians who require specialized training to work effectively with this high-performance polymer.

Regulatory and certification hurdles present additional implementation barriers. While PEEK generally exhibits excellent compliance with electronics industry standards, the qualification process for new materials in critical electronic applications is time-consuming and expensive, particularly in highly regulated sectors like aerospace, medical devices, and automotive electronics.

Market acceptance represents the final significant barrier. Conservative approaches in electronics manufacturing create resistance to material substitution, especially when existing solutions meet minimum requirements. Overcoming this inertia requires compelling demonstration of PEEK's value proposition through comprehensive case studies, field trials, and long-term reliability data that many potential adopters are reluctant to pioneer.

Cost factors present another major barrier, with PEEK commanding prices 10-15 times higher than conventional engineering polymers. This premium pricing stems from complex synthesis processes, high-purity requirements, and relatively limited production volumes. For electronic component manufacturers operating in competitive markets with tight margins, this cost differential often proves prohibitive despite PEEK's superior long-term performance benefits.

Technical processing challenges further complicate PEEK implementation. The polymer exhibits a narrow processing window, requiring precise temperature control to prevent degradation while ensuring proper melt flow. Additionally, PEEK's semi-crystalline nature demands careful cooling rate management to achieve optimal crystallinity levels that directly impact mechanical and electrical properties. Improper processing can result in warpage, dimensional instability, and compromised performance characteristics.

Integration with existing electronic manufacturing processes presents compatibility issues. PEEK's high melting point complicates bonding with other materials and components, often requiring specialized adhesives or surface treatments. Furthermore, its inherent chemical resistance, while beneficial for end-use applications, creates challenges for surface modification and metallization processes essential in electronic component manufacturing.

Knowledge barriers also exist within the industry. Many electronic design engineers lack familiarity with PEEK's unique properties and processing requirements, leading to suboptimal designs that fail to leverage the material's full potential. This knowledge gap extends to processing technicians who require specialized training to work effectively with this high-performance polymer.

Regulatory and certification hurdles present additional implementation barriers. While PEEK generally exhibits excellent compliance with electronics industry standards, the qualification process for new materials in critical electronic applications is time-consuming and expensive, particularly in highly regulated sectors like aerospace, medical devices, and automotive electronics.

Market acceptance represents the final significant barrier. Conservative approaches in electronics manufacturing create resistance to material substitution, especially when existing solutions meet minimum requirements. Overcoming this inertia requires compelling demonstration of PEEK's value proposition through comprehensive case studies, field trials, and long-term reliability data that many potential adopters are reluctant to pioneer.

Current PEEK Solutions for Electronic Component Protection

01 Chemical resistance and thermal stability of PEEK polymers

PEEK polymers demonstrate exceptional chemical resistance and thermal stability, making them suitable for harsh environments. These polymers can withstand exposure to various chemicals, high temperatures, and thermal cycling without significant degradation. The inherent stability of the polymer backbone contributes to its long-term durability in applications requiring resistance to chemical attack and thermal stress.- Chemical resistance and thermal stability of PEEK polymers: PEEK polymers demonstrate exceptional chemical resistance and thermal stability, making them suitable for harsh environments. These properties allow PEEK to maintain structural integrity and performance characteristics under extreme conditions including exposure to chemicals, high temperatures, and thermal cycling. The inherent stability of the polymer backbone contributes to its long-term durability in industrial applications where conventional polymers would degrade.

- PEEK composite formulations for enhanced mechanical properties: Incorporating reinforcing materials such as carbon fibers, glass fibers, or mineral fillers into PEEK matrices creates composites with superior mechanical properties. These composites exhibit improved tensile strength, flexural modulus, and impact resistance compared to neat PEEK. The reinforcement mechanisms provide enhanced load-bearing capacity and structural durability, extending the service life of components in high-stress applications while maintaining the inherent chemical resistance of the base polymer.

- Surface modification techniques for PEEK durability enhancement: Various surface treatment methods can be applied to PEEK polymers to enhance their durability characteristics. These include plasma treatment, chemical etching, and coating applications that modify surface properties without compromising the bulk material integrity. Such modifications can improve wear resistance, reduce friction coefficients, enhance bonding capabilities with other materials, and provide additional protection against environmental factors that might otherwise accelerate degradation.

- Weathering and UV resistance of PEEK materials: PEEK polymers exhibit excellent resistance to weathering and UV radiation, contributing to their long-term durability in outdoor applications. The aromatic structure of PEEK provides inherent stability against photodegradation mechanisms that typically affect other engineering plastics. This resistance can be further enhanced through the incorporation of stabilizers and additives that absorb or block harmful radiation, preventing chain scission and maintaining mechanical properties over extended exposure periods.

- Wear resistance and tribological properties of PEEK: PEEK polymers demonstrate exceptional wear resistance and favorable tribological properties, making them suitable for applications involving friction and mechanical abrasion. The self-lubricating characteristics of PEEK reduce wear rates in sliding contact applications. These properties can be further enhanced through the incorporation of solid lubricants or through specific processing techniques that optimize the surface morphology for reduced friction coefficients and improved durability under dynamic loading conditions.

02 Mechanical properties enhancement in PEEK composites

PEEK polymer durability can be significantly enhanced through the development of composite materials. By incorporating reinforcing agents such as carbon fibers, glass fibers, or mineral fillers, the mechanical properties including tensile strength, impact resistance, and wear resistance can be improved. These composites maintain the base polymer's chemical resistance while offering superior mechanical performance for demanding applications.Expand Specific Solutions03 Surface modification techniques for PEEK durability

Various surface modification techniques can be applied to PEEK polymers to enhance their durability characteristics. These include plasma treatment, chemical etching, coating applications, and surface functionalization. Such modifications can improve adhesion properties, wear resistance, and biocompatibility while maintaining the core mechanical and thermal properties of the base polymer.Expand Specific Solutions04 PEEK polymer applications in extreme environments

PEEK polymers are specifically formulated for use in extreme environments where durability is critical. These applications include aerospace components, oil and gas extraction equipment, automotive parts, and medical implants. The polymer's ability to maintain structural integrity under high pressure, temperature fluctuations, and mechanical stress makes it ideal for these demanding applications where material failure is not an option.Expand Specific Solutions05 Long-term aging and weathering resistance of PEEK

PEEK polymers exhibit exceptional resistance to long-term aging and weathering effects. Studies on the polymer's performance under UV exposure, moisture, oxidation, and radiation demonstrate minimal degradation of mechanical and thermal properties over extended periods. This inherent stability makes PEEK suitable for outdoor applications and environments where materials are exposed to multiple degradation factors simultaneously.Expand Specific Solutions

Leading PEEK Manufacturers and Industry Landscape

The PEEK polymer market for electronic component durability is in a growth phase, with increasing demand driven by electronics miniaturization and harsh operating environments. The global market is expanding rapidly as PEEK's exceptional thermal stability, chemical resistance, and mechanical strength become essential for next-generation electronics. Leading players include established Western manufacturers like Victrex Manufacturing and Solvay Specialty Polymers, who possess advanced R&D capabilities, alongside emerging Asian competitors such as Jilin Joinature Polymer and Jiangsu Junhua, who are rapidly developing technical expertise. The technology maturity varies across applications, with aerospace and medical implementations being highly developed, while consumer electronics applications continue to evolve as manufacturers optimize PEEK formulations for specific performance requirements.

Solvay Specialty Polymers USA LLC

Technical Solution: Solvay has developed advanced PEEK polymer formulations specifically engineered for electronic component applications requiring exceptional durability. Their KetaSpire® PEEK products feature a unique molecular structure with optimized crystallinity levels (typically 35-45%) that enhance mechanical stability at elevated temperatures up to 240°C. Solvay's proprietary processing techniques create PEEK variants with dielectric strength exceeding 20 kV/mm and volume resistivity above 10^16 Ω·cm, making them ideal for high-performance electronic insulation applications. Their PEEK compounds incorporate specialized additives that improve resistance to hydrolysis and chemical degradation while maintaining dimensional stability under thermal cycling conditions. Solvay has also pioneered carbon fiber reinforced PEEK grades that offer enhanced thermal conductivity (up to 0.95 W/m·K) to dissipate heat in densely packed electronic assemblies while maintaining electrical isolation properties.

Strengths: Superior chemical resistance against aggressive fluids and solvents used in electronics manufacturing; excellent thermal stability with continuous use temperature up to 240°C; inherent flame retardancy (UL94 V-0 rating) without additives. Weaknesses: Higher processing temperatures (370-400°C) require specialized equipment; relatively high cost compared to conventional engineering polymers; limited transparency restricts optical applications.

Jilin Joinature Polymer Co., Ltd.

Technical Solution: Jilin Joinature has developed a proprietary PEEK polymer manufacturing process that yields materials with exceptional thermal stability for electronic component applications. Their JoinPEEK® product line features carefully controlled molecular weight (typically 80,000-100,000 g/mol) and narrow polydispersity indices (1.5-2.0) that enhance crystallization behavior and mechanical properties. Their PEEK formulations incorporate specialized nucleating agents that promote uniform crystallization, resulting in improved dimensional stability during thermal cycling between -40°C and 200°C. For electronic applications, Jilin Joinature has engineered PEEK compounds with volume resistivity exceeding 10^15 Ω·cm and dielectric strength above 22 kV/mm. Their manufacturing process includes rigorous purification steps that reduce ionic contaminants to below 10 ppm, preventing electrical migration issues in high-humidity environments. The company has also developed carbon-filled PEEK grades with controlled electrical conductivity (10^2-10^6 Ω·cm) for ESD protection applications in sensitive electronic components.

Strengths: Competitive pricing compared to Western PEEK suppliers; customizable formulations for specific electronic applications; excellent batch-to-batch consistency; good balance of mechanical properties and processability. Weaknesses: More limited track record in high-end electronic applications compared to industry leaders; smaller portfolio of specialized grades; less extensive third-party testing and certification documentation; more limited global technical support infrastructure.

Critical Patents and Research in PEEK Polymer Technology

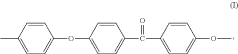

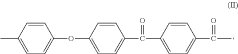

Semiconductive film, electric charge control member and process for production the semiconductive film

PatentInactiveUS20070020450A1

Innovation

- A production process involving extrusion of a resin composition comprising PEEK and a conductive filler through a T-die or ring die with controlled lip clearance and temperature, followed by cooling and solidification using a cooling roll or mandrel, to produce a semiconductive film with balanced properties including narrow thickness and volume resistivity scatter, high folding endurance, and excellent mechanical strength.

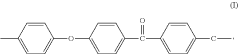

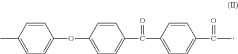

Polymer composition

PatentInactiveUS20190169430A1

Innovation

- A polymer composition comprising a poly(aryl ether ketone), a polyphenylsulfone, and a reinforcing fiber, with specific weight ratios that balance cost and performance, providing high chemical resistance and environmental stress rupture resistance similar to reinforced poly(aryl ether ketone)s.

Thermal and Chemical Resistance Properties of PEEK

PEEK (Polyetheretherketone) exhibits exceptional thermal resistance properties, maintaining structural integrity at continuous operating temperatures up to 250°C and short-term exposure capabilities reaching 300°C. This remarkable thermal stability stems from its semi-crystalline structure and aromatic backbone, which provide dimensional stability across wide temperature ranges critical for electronic components operating in extreme environments.

The glass transition temperature (Tg) of PEEK typically ranges between 143°C and 150°C, while its melting point reaches approximately 343°C. These properties enable PEEK components to withstand thermal cycling without significant degradation, making them ideal for applications requiring repeated heating and cooling cycles in electronic assemblies.

PEEK demonstrates outstanding chemical resistance against most organic and inorganic chemicals, including acids, bases, hydrocarbons, and organic solvents. Notably, it resists degradation from automotive fluids, hydraulic fluids, and cleaning agents commonly encountered in industrial electronic applications. This chemical inertness prevents material breakdown that could compromise electronic component functionality over time.

The polymer's resistance to hydrolysis is particularly valuable for electronic components exposed to humid environments. PEEK maintains its mechanical and electrical properties even after prolonged exposure to moisture and steam, with water absorption rates typically below 0.5% after 24 hours of immersion. This characteristic significantly reduces the risk of electrical shorts or performance degradation in high-humidity conditions.

Radiation resistance represents another critical advantage of PEEK for electronic applications in specialized environments. The material can withstand gamma radiation exposure up to 1000 kGy with minimal property changes, making it suitable for electronic components in nuclear, aerospace, and medical equipment where radiation exposure is a concern.

When exposed to UV radiation, PEEK exhibits better stability than many alternative polymers, though surface yellowing may occur after extended exposure. This property is particularly relevant for outdoor electronic enclosures or components with potential UV exposure during their service life.

The combination of these resistance properties contributes to PEEK's exceptional long-term durability. Accelerated aging tests demonstrate that PEEK components can maintain their essential properties for 10+ years under continuous high-temperature operation, significantly outperforming conventional engineering plastics like polyamides or polycarbonates in harsh environmental conditions.

For electronic component applications specifically, these resistance properties translate to enhanced reliability in challenging operating environments, reduced maintenance requirements, and extended service life, ultimately justifying the higher initial material cost through improved total cost of ownership metrics.

The glass transition temperature (Tg) of PEEK typically ranges between 143°C and 150°C, while its melting point reaches approximately 343°C. These properties enable PEEK components to withstand thermal cycling without significant degradation, making them ideal for applications requiring repeated heating and cooling cycles in electronic assemblies.

PEEK demonstrates outstanding chemical resistance against most organic and inorganic chemicals, including acids, bases, hydrocarbons, and organic solvents. Notably, it resists degradation from automotive fluids, hydraulic fluids, and cleaning agents commonly encountered in industrial electronic applications. This chemical inertness prevents material breakdown that could compromise electronic component functionality over time.

The polymer's resistance to hydrolysis is particularly valuable for electronic components exposed to humid environments. PEEK maintains its mechanical and electrical properties even after prolonged exposure to moisture and steam, with water absorption rates typically below 0.5% after 24 hours of immersion. This characteristic significantly reduces the risk of electrical shorts or performance degradation in high-humidity conditions.

Radiation resistance represents another critical advantage of PEEK for electronic applications in specialized environments. The material can withstand gamma radiation exposure up to 1000 kGy with minimal property changes, making it suitable for electronic components in nuclear, aerospace, and medical equipment where radiation exposure is a concern.

When exposed to UV radiation, PEEK exhibits better stability than many alternative polymers, though surface yellowing may occur after extended exposure. This property is particularly relevant for outdoor electronic enclosures or components with potential UV exposure during their service life.

The combination of these resistance properties contributes to PEEK's exceptional long-term durability. Accelerated aging tests demonstrate that PEEK components can maintain their essential properties for 10+ years under continuous high-temperature operation, significantly outperforming conventional engineering plastics like polyamides or polycarbonates in harsh environmental conditions.

For electronic component applications specifically, these resistance properties translate to enhanced reliability in challenging operating environments, reduced maintenance requirements, and extended service life, ultimately justifying the higher initial material cost through improved total cost of ownership metrics.

Environmental Impact and Sustainability Considerations

The environmental impact of PEEK (Polyetheretherketone) polymer in electronic applications represents a critical consideration as industries increasingly prioritize sustainability. PEEK demonstrates remarkable environmental advantages compared to traditional polymers used in electronic components. Its exceptional durability and resistance to degradation significantly extend product lifecycles, reducing the frequency of replacement and consequently minimizing electronic waste generation. Studies indicate that PEEK-based components can maintain structural integrity for 15-20 years in demanding applications, compared to 3-5 years for conventional polymers.

PEEK's high recyclability further enhances its environmental profile. Unlike many engineering plastics, PEEK can be reprocessed multiple times without significant degradation of its mechanical properties. Research demonstrates that recycled PEEK retains approximately 90% of its original performance characteristics after five reprocessing cycles, making it an excellent candidate for closed-loop manufacturing systems in electronics production.

The energy-intensive manufacturing process of PEEK presents a notable environmental challenge. Production requires temperatures exceeding 400°C, resulting in a carbon footprint approximately 2.5 times higher than conventional polymers during manufacturing. However, lifecycle assessments reveal that this initial environmental cost is offset by PEEK's extended service life and reduced replacement frequency when applied in electronic components exposed to harsh environments.

PEEK's resistance to hazardous chemicals and minimal leaching characteristics contribute significantly to its environmental advantages. Unlike many polymers that may release harmful substances during use or disposal, PEEK remains chemically stable across its lifecycle. This stability prevents contamination of soil and water systems when electronic components reach end-of-life, addressing growing concerns about electronic waste toxicity in landfills.

The polymer's compliance with RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations positions it favorably as global environmental standards become increasingly stringent. PEEK contains no halogenated compounds or other substances of very high concern, making it suitable for environmentally conscious electronic applications where regulatory compliance is paramount.

Recent innovations in PEEK manufacturing, including bio-based precursors and energy-efficient processing techniques, are further improving its sustainability profile. Research indicates that next-generation production methods could reduce the carbon footprint of PEEK manufacturing by up to 35%, enhancing its position as an environmentally responsible choice for durable electronic components.

PEEK's high recyclability further enhances its environmental profile. Unlike many engineering plastics, PEEK can be reprocessed multiple times without significant degradation of its mechanical properties. Research demonstrates that recycled PEEK retains approximately 90% of its original performance characteristics after five reprocessing cycles, making it an excellent candidate for closed-loop manufacturing systems in electronics production.

The energy-intensive manufacturing process of PEEK presents a notable environmental challenge. Production requires temperatures exceeding 400°C, resulting in a carbon footprint approximately 2.5 times higher than conventional polymers during manufacturing. However, lifecycle assessments reveal that this initial environmental cost is offset by PEEK's extended service life and reduced replacement frequency when applied in electronic components exposed to harsh environments.

PEEK's resistance to hazardous chemicals and minimal leaching characteristics contribute significantly to its environmental advantages. Unlike many polymers that may release harmful substances during use or disposal, PEEK remains chemically stable across its lifecycle. This stability prevents contamination of soil and water systems when electronic components reach end-of-life, addressing growing concerns about electronic waste toxicity in landfills.

The polymer's compliance with RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulations positions it favorably as global environmental standards become increasingly stringent. PEEK contains no halogenated compounds or other substances of very high concern, making it suitable for environmentally conscious electronic applications where regulatory compliance is paramount.

Recent innovations in PEEK manufacturing, including bio-based precursors and energy-efficient processing techniques, are further improving its sustainability profile. Research indicates that next-generation production methods could reduce the carbon footprint of PEEK manufacturing by up to 35%, enhancing its position as an environmentally responsible choice for durable electronic components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!