Assessment of PEEK Polymer Properties in Structural Integrity

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PEEK Polymer Development History and Objectives

Polyether ether ketone (PEEK) emerged in the late 1970s as a groundbreaking high-performance thermoplastic polymer, first commercialized by Imperial Chemical Industries (ICI) in 1978. The development of PEEK represented a significant milestone in polymer science, offering an unprecedented combination of mechanical strength, thermal stability, and chemical resistance. This semi-crystalline polymer with its aromatic backbone structure was initially designed to meet the demanding requirements of aerospace and automotive industries seeking lightweight alternatives to metals.

The evolution of PEEK technology has followed a trajectory of continuous refinement and expansion into new application domains. During the 1980s, researchers focused primarily on understanding the fundamental properties and processing techniques of this novel material. By the 1990s, PEEK had established itself as a premium engineering plastic, with manufacturers developing specialized grades with enhanced properties through various reinforcement strategies, particularly carbon fiber and glass fiber composites.

The early 2000s witnessed a significant shift in PEEK development objectives, with increased attention to its biocompatibility and potential applications in medical implants. This period marked the beginning of PEEK's penetration into the healthcare sector, where its radiolucency, biocompatibility, and mechanical properties similar to human bone made it an attractive alternative to traditional metallic implants.

In the context of structural integrity assessment, PEEK's development has been characterized by progressive improvements in understanding its long-term performance under various environmental conditions. Research objectives have increasingly focused on predicting and enhancing the polymer's resistance to creep, fatigue, and environmental stress cracking – critical factors for applications where structural reliability is paramount.

The past decade has seen a notable shift toward sustainability objectives in PEEK development. Manufacturers have invested in more energy-efficient production processes and explored recycling methodologies to address the environmental impact of this high-performance polymer. Simultaneously, research efforts have intensified around optimizing PEEK's processing parameters to enhance its crystallinity and consequently its mechanical properties for structural applications.

Current technological objectives in PEEK development center on expanding its temperature resistance envelope, improving its tribological properties, and enhancing its compatibility with advanced manufacturing techniques such as additive manufacturing. The growing demand for lightweight, high-strength materials in critical structural applications continues to drive innovation in PEEK formulations, with particular emphasis on improving its performance in extreme environments and extending its service life under dynamic loading conditions.

The evolution of PEEK technology has followed a trajectory of continuous refinement and expansion into new application domains. During the 1980s, researchers focused primarily on understanding the fundamental properties and processing techniques of this novel material. By the 1990s, PEEK had established itself as a premium engineering plastic, with manufacturers developing specialized grades with enhanced properties through various reinforcement strategies, particularly carbon fiber and glass fiber composites.

The early 2000s witnessed a significant shift in PEEK development objectives, with increased attention to its biocompatibility and potential applications in medical implants. This period marked the beginning of PEEK's penetration into the healthcare sector, where its radiolucency, biocompatibility, and mechanical properties similar to human bone made it an attractive alternative to traditional metallic implants.

In the context of structural integrity assessment, PEEK's development has been characterized by progressive improvements in understanding its long-term performance under various environmental conditions. Research objectives have increasingly focused on predicting and enhancing the polymer's resistance to creep, fatigue, and environmental stress cracking – critical factors for applications where structural reliability is paramount.

The past decade has seen a notable shift toward sustainability objectives in PEEK development. Manufacturers have invested in more energy-efficient production processes and explored recycling methodologies to address the environmental impact of this high-performance polymer. Simultaneously, research efforts have intensified around optimizing PEEK's processing parameters to enhance its crystallinity and consequently its mechanical properties for structural applications.

Current technological objectives in PEEK development center on expanding its temperature resistance envelope, improving its tribological properties, and enhancing its compatibility with advanced manufacturing techniques such as additive manufacturing. The growing demand for lightweight, high-strength materials in critical structural applications continues to drive innovation in PEEK formulations, with particular emphasis on improving its performance in extreme environments and extending its service life under dynamic loading conditions.

Market Analysis for High-Performance Structural Polymers

The high-performance polymer market has experienced substantial growth over the past decade, with PEEK (Polyether Ether Ketone) emerging as a frontrunner in structural applications. The global market for high-performance polymers reached approximately $14.5 billion in 2022 and is projected to grow at a CAGR of 7.2% through 2028. PEEK specifically commands a significant market share within this segment, valued at around $1.2 billion in 2022.

The aerospace and automotive industries represent the largest end-users of PEEK and similar high-performance polymers, collectively accounting for over 45% of market consumption. This demand is primarily driven by the increasing need for lightweight materials that can withstand extreme conditions while reducing overall vehicle weight and improving fuel efficiency. The aerospace sector particularly values PEEK for its exceptional strength-to-weight ratio and resistance to high temperatures up to 260°C.

Medical applications constitute another rapidly growing market segment, expanding at nearly 9% annually. PEEK's biocompatibility, sterilization resistance, and mechanical properties similar to human bone make it increasingly popular for implants, surgical instruments, and dental applications. The material's radiolucency (transparency to X-rays) provides additional advantages in medical imaging contexts.

Industrial applications, including oil and gas, electronics, and general manufacturing, represent approximately 30% of the current market. In these sectors, PEEK's chemical resistance, dimensional stability, and electrical insulation properties are particularly valued. The semiconductor industry specifically relies on PEEK components for their purity and resistance to aggressive chemicals used in processing.

Regional analysis indicates North America and Europe currently dominate the high-performance polymer market with combined market share exceeding 60%. However, the Asia-Pacific region, particularly China and India, is witnessing the fastest growth rates at approximately 8.5% annually, driven by rapid industrialization and increasing adoption of advanced materials in manufacturing.

Market challenges include the relatively high cost of PEEK compared to conventional polymers, with raw material prices approximately 8-10 times higher than engineering plastics like nylon or polycarbonate. This cost factor remains the primary barrier to wider adoption in price-sensitive applications. Additionally, processing complexities and the need for specialized equipment for manufacturing PEEK components contribute to higher overall production costs.

The aerospace and automotive industries represent the largest end-users of PEEK and similar high-performance polymers, collectively accounting for over 45% of market consumption. This demand is primarily driven by the increasing need for lightweight materials that can withstand extreme conditions while reducing overall vehicle weight and improving fuel efficiency. The aerospace sector particularly values PEEK for its exceptional strength-to-weight ratio and resistance to high temperatures up to 260°C.

Medical applications constitute another rapidly growing market segment, expanding at nearly 9% annually. PEEK's biocompatibility, sterilization resistance, and mechanical properties similar to human bone make it increasingly popular for implants, surgical instruments, and dental applications. The material's radiolucency (transparency to X-rays) provides additional advantages in medical imaging contexts.

Industrial applications, including oil and gas, electronics, and general manufacturing, represent approximately 30% of the current market. In these sectors, PEEK's chemical resistance, dimensional stability, and electrical insulation properties are particularly valued. The semiconductor industry specifically relies on PEEK components for their purity and resistance to aggressive chemicals used in processing.

Regional analysis indicates North America and Europe currently dominate the high-performance polymer market with combined market share exceeding 60%. However, the Asia-Pacific region, particularly China and India, is witnessing the fastest growth rates at approximately 8.5% annually, driven by rapid industrialization and increasing adoption of advanced materials in manufacturing.

Market challenges include the relatively high cost of PEEK compared to conventional polymers, with raw material prices approximately 8-10 times higher than engineering plastics like nylon or polycarbonate. This cost factor remains the primary barrier to wider adoption in price-sensitive applications. Additionally, processing complexities and the need for specialized equipment for manufacturing PEEK components contribute to higher overall production costs.

Current PEEK Technology Status and Limitations

PEEK (Polyetheretherketone) has established itself as a high-performance thermoplastic polymer with exceptional mechanical, thermal, and chemical properties. Currently, PEEK materials exhibit tensile strengths ranging from 90-100 MPa and continuous service temperatures up to 260°C, positioning them as superior alternatives to metals in various structural applications. The material's inherent flame resistance without additives (UL94 V0 rating) and excellent resistance to hydrolysis and chemical degradation have made it particularly valuable in aerospace, automotive, and medical industries.

Despite these impressive properties, PEEK faces several significant limitations that constrain its broader adoption. The primary challenge remains its high processing temperature (typically 370-400°C), which necessitates specialized equipment and increases manufacturing costs substantially compared to conventional thermoplastics. This high processing temperature also creates difficulties in achieving consistent part quality, particularly for complex geometries where thermal management becomes critical.

The semi-crystalline nature of PEEK presents another technical hurdle, as crystallinity significantly influences mechanical properties. Current manufacturing processes struggle to control crystallization rates uniformly throughout parts, leading to inconsistent mechanical performance. This variability becomes particularly problematic in structural applications where predictable performance is essential.

From a global perspective, PEEK technology development shows geographical concentration, with major advancements primarily occurring in Western Europe, North America, and increasingly in East Asia. The technology transfer to emerging markets remains limited due to intellectual property restrictions and the specialized knowledge required for processing.

Cost remains a substantial barrier to wider PEEK adoption, with raw material prices approximately 20-30 times higher than engineering plastics like polyamide. This cost differential has restricted PEEK applications primarily to high-value sectors where performance requirements justify the premium.

Recent research has identified limitations in PEEK's long-term performance under combined mechanical stress and aggressive environmental conditions. Studies indicate potential degradation mechanisms that can compromise structural integrity over extended service periods, particularly in applications involving cyclic loading combined with chemical exposure.

The reinforcement of PEEK with carbon or glass fibers, while enhancing mechanical properties, introduces new challenges in processing and recycling. Current fiber reinforcement technologies often result in anisotropic properties that must be carefully managed in design applications. Additionally, the recyclability of fiber-reinforced PEEK remains limited, presenting sustainability challenges as environmental regulations become more stringent globally.

Despite these impressive properties, PEEK faces several significant limitations that constrain its broader adoption. The primary challenge remains its high processing temperature (typically 370-400°C), which necessitates specialized equipment and increases manufacturing costs substantially compared to conventional thermoplastics. This high processing temperature also creates difficulties in achieving consistent part quality, particularly for complex geometries where thermal management becomes critical.

The semi-crystalline nature of PEEK presents another technical hurdle, as crystallinity significantly influences mechanical properties. Current manufacturing processes struggle to control crystallization rates uniformly throughout parts, leading to inconsistent mechanical performance. This variability becomes particularly problematic in structural applications where predictable performance is essential.

From a global perspective, PEEK technology development shows geographical concentration, with major advancements primarily occurring in Western Europe, North America, and increasingly in East Asia. The technology transfer to emerging markets remains limited due to intellectual property restrictions and the specialized knowledge required for processing.

Cost remains a substantial barrier to wider PEEK adoption, with raw material prices approximately 20-30 times higher than engineering plastics like polyamide. This cost differential has restricted PEEK applications primarily to high-value sectors where performance requirements justify the premium.

Recent research has identified limitations in PEEK's long-term performance under combined mechanical stress and aggressive environmental conditions. Studies indicate potential degradation mechanisms that can compromise structural integrity over extended service periods, particularly in applications involving cyclic loading combined with chemical exposure.

The reinforcement of PEEK with carbon or glass fibers, while enhancing mechanical properties, introduces new challenges in processing and recycling. Current fiber reinforcement technologies often result in anisotropic properties that must be carefully managed in design applications. Additionally, the recyclability of fiber-reinforced PEEK remains limited, presenting sustainability challenges as environmental regulations become more stringent globally.

Current Methodologies for PEEK Structural Integrity Assessment

01 PEEK polymer mechanical properties and testing methods

PEEK (Polyetheretherketone) polymers exhibit exceptional mechanical properties that contribute to their structural integrity. Various testing methods are employed to evaluate these properties, including tensile strength, compression resistance, and impact resistance. These tests help determine the polymer's durability under different stress conditions and its suitability for high-performance applications. The mechanical properties of PEEK make it an ideal material for applications requiring high strength-to-weight ratios and resistance to mechanical deformation.- PEEK polymer mechanical properties and testing methods: PEEK (Polyetheretherketone) polymers exhibit exceptional mechanical properties that contribute to their structural integrity. Various testing methods are employed to evaluate these properties, including tensile strength, compression resistance, and fatigue testing. These tests help determine the polymer's durability under different stress conditions and its suitability for high-performance applications. The mechanical properties of PEEK make it ideal for applications requiring high strength-to-weight ratios and resistance to mechanical deformation.

- Thermal stability and degradation resistance of PEEK: PEEK polymers demonstrate exceptional thermal stability and resistance to degradation, which are crucial aspects of their structural integrity. These polymers can withstand high temperatures without significant loss of mechanical properties, making them suitable for applications in extreme thermal environments. The thermal stability of PEEK is attributed to its aromatic backbone structure, which provides resistance to thermal oxidation and decomposition. This characteristic ensures the maintenance of structural integrity even under prolonged exposure to elevated temperatures.

- PEEK composites and reinforcement techniques: The structural integrity of PEEK polymers can be enhanced through various reinforcement techniques and the development of composites. Carbon fiber reinforced PEEK composites demonstrate significantly improved mechanical properties compared to neat PEEK. Other reinforcement materials include glass fibers, ceramic particles, and nanomaterials. These reinforcements can be incorporated through methods such as melt blending, in-situ polymerization, or surface modification techniques. The resulting composites exhibit superior strength, stiffness, and dimensional stability while maintaining the inherent chemical resistance of PEEK.

- Environmental resistance and chemical stability: PEEK polymers exhibit exceptional resistance to environmental factors and chemical exposure, which contributes significantly to their long-term structural integrity. They demonstrate resistance to hydrolysis, radiation, and a wide range of chemicals including acids, bases, and organic solvents. This chemical stability ensures that PEEK components maintain their mechanical properties even when exposed to harsh operating environments. The environmental resistance of PEEK makes it particularly valuable in applications where exposure to aggressive chemicals or extreme conditions is expected.

- Structural integrity monitoring and prediction methods: Various methods have been developed to monitor and predict the structural integrity of PEEK polymer components during service. These include non-destructive testing techniques, computational modeling approaches, and accelerated aging tests. Advanced analytical methods such as finite element analysis can predict the long-term performance of PEEK components under various loading conditions. Real-time monitoring systems can detect early signs of structural degradation, allowing for preventive maintenance. These methods are crucial for ensuring the reliability and safety of PEEK components in critical applications.

02 Thermal stability and degradation resistance of PEEK

PEEK polymers demonstrate exceptional thermal stability and resistance to degradation, which are crucial aspects of their structural integrity. They can maintain their mechanical properties at elevated temperatures and show minimal degradation when exposed to harsh environmental conditions. This thermal stability makes PEEK suitable for applications in extreme environments where other polymers would fail. The polymer's ability to withstand high temperatures without significant loss of mechanical properties contributes to its long-term structural integrity and reliability.Expand Specific Solutions03 PEEK composites and reinforcement techniques

The structural integrity of PEEK polymers can be enhanced through various reinforcement techniques and the creation of composites. By incorporating materials such as carbon fibers, glass fibers, or other fillers, the mechanical properties of PEEK can be significantly improved. These reinforced PEEK composites offer superior strength, stiffness, and dimensional stability compared to the base polymer. The type and amount of reinforcement can be tailored to meet specific application requirements, providing customized solutions for demanding structural applications.Expand Specific Solutions04 PEEK in high-stress applications and environments

PEEK polymers are widely used in high-stress applications and harsh environments due to their exceptional structural integrity. These applications include aerospace components, oil and gas equipment, and medical implants. The polymer's ability to maintain its properties under extreme conditions, such as high pressure, temperature fluctuations, and exposure to chemicals, makes it an ideal material for these demanding applications. The long-term performance and reliability of PEEK in such environments demonstrate its superior structural integrity compared to other engineering plastics.Expand Specific Solutions05 Analytical methods for evaluating PEEK structural integrity

Various analytical methods are employed to evaluate and predict the structural integrity of PEEK polymers. These include non-destructive testing techniques, computational modeling, and accelerated aging tests. Such methods help in understanding the behavior of PEEK under different conditions and predicting its long-term performance. Advanced analytical techniques, such as spectroscopy and thermal analysis, provide insights into the molecular structure and potential degradation mechanisms of PEEK, which are crucial for ensuring its structural integrity in critical applications.Expand Specific Solutions

Leading PEEK Manufacturers and Industry Landscape

The PEEK polymer structural integrity market is currently in a growth phase, with increasing adoption across aerospace, medical, and industrial sectors. The global market size for high-performance polymers like PEEK is expanding at approximately 7-8% annually, driven by demand for lightweight, high-strength materials. Leading players include established chemical companies such as Solvay Specialty Polymers and Victrex Manufacturing, who have developed mature PEEK formulations with proven structural integrity properties. Medical device manufacturers like Stryker Corp. and Arthrex are advancing PEEK applications in implantable devices, while companies such as EOS GmbH are exploring additive manufacturing techniques. Technical maturity varies by application, with aerospace and medical implementations being most advanced. Research institutions like Jiangsu University and Changsha University of Science & Technology are actively developing next-generation PEEK composites with enhanced structural properties.

Solvay Specialty Polymers USA LLC

Technical Solution: Solvay has developed KetaSpire® PEEK polymers with advanced structural integrity properties through proprietary manufacturing techniques. Their technology incorporates precise control of molecular weight distribution and crystallinity to achieve tensile strengths of 90-100 MPa and flexural modulus values of 3.8-4.1 GPa[1]. Solvay's approach includes specialized nucleation technology that enhances crystallization kinetics, resulting in improved dimensional stability and reduced internal stress. Their PEEK formulations undergo comprehensive mechanical testing including dynamic mechanical analysis (DMA) across temperature ranges from -50°C to 300°C to characterize viscoelastic behavior[2]. Solvay has also pioneered wear-resistant PEEK compounds with proprietary fillers that demonstrate up to 65% reduction in wear rate while maintaining core mechanical properties, particularly beneficial for tribological applications in harsh environments[3]. Their assessment methodology includes accelerated aging studies simulating 10+ years of service conditions.

Strengths: Exceptional chemical resistance against aggressive fluids and excellent retention of mechanical properties at elevated temperatures (>200°C). Their materials show superior fatigue resistance and creep performance compared to conventional engineering polymers. Weaknesses: Higher processing temperatures (380-400°C) require specialized equipment, and some grades exhibit anisotropic shrinkage that can complicate dimensional control in precision components.

Victrex Manufacturing Ltd.

Technical Solution: Victrex has developed advanced PEEK polymer solutions with enhanced structural integrity through their proprietary manufacturing processes. Their PEEK-OPTIMA™ technology demonstrates exceptional mechanical properties with tensile strengths exceeding 100 MPa and modulus values of 3-4 GPa[1]. The company employs a unique polymerization process that ensures higher molecular weight and crystallinity control, resulting in superior mechanical performance. Their VICTREX™ PEEK grades undergo rigorous testing protocols including long-term creep resistance assessment, fatigue testing (>10^7 cycles), and environmental stress cracking resistance evaluations[2]. Victrex has pioneered composite PEEK formulations with carbon fiber reinforcement that achieves up to 3x the strength of standard PEEK while maintaining excellent chemical resistance and dimensional stability at elevated temperatures up to 260°C[3].

Strengths: Industry-leading expertise in high-performance PEEK formulations with superior mechanical properties and extensive testing protocols. Their carbon fiber reinforced grades offer exceptional strength-to-weight ratios ideal for aerospace and medical applications. Weaknesses: Premium pricing structure limits adoption in cost-sensitive applications, and their specialized grades often require specific processing parameters that may require equipment modifications.

Critical Patents and Research in PEEK Polymer Enhancement

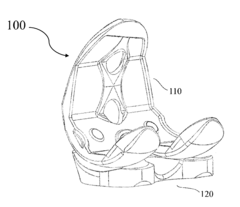

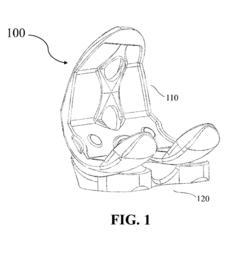

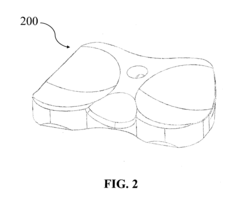

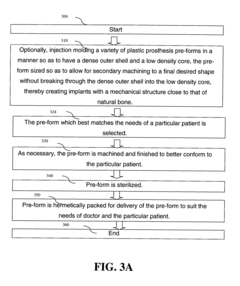

Polymer based joint implants and method of manufacture

PatentActiveUS20160317310A9

Innovation

- A method involving injection molding to create custom implants with a dense outer shell and low-density core, mimicking the structure of natural bone, using polymers like PEEK or VESTAKEEP, which allows for minimal machining and sterilization, and optionally incorporating a diamond-like carbon layer for improved wear resistance.

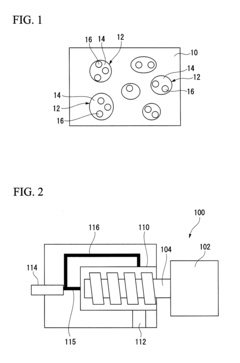

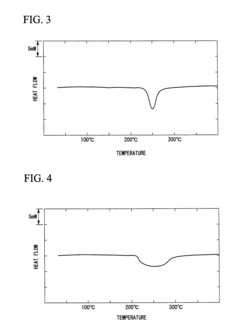

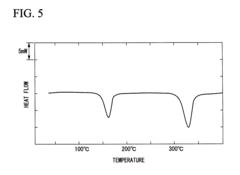

Polyether ether ketone composite material

PatentInactiveUS20140039127A1

Innovation

- A PEEK composite material comprising PEEK and polyolefin with a compatible structure, where the polyolefin is dispersed in a matrix of PEEK, achieving a single endothermic peak in DSC, allowing for a lower molding temperature and preventing colorant discoloration, with particle sizes of dispersed parts optimized to 1 μm or smaller for efficient thermal properties.

Environmental Impact and Sustainability of PEEK Materials

PEEK (Polyetheretherketone) materials demonstrate remarkable environmental sustainability characteristics compared to traditional engineering polymers and metals. The production of PEEK requires significantly less energy than metals like aluminum or titanium, resulting in a lower carbon footprint during the manufacturing phase. Life cycle assessments indicate that PEEK components can reduce CO2 emissions by up to 40% compared to metal alternatives when considering the entire product lifecycle.

The exceptional durability and chemical resistance of PEEK contribute substantially to its sustainability profile. With service lifespans often exceeding 20 years in demanding applications, PEEK components require less frequent replacement than conventional materials. This longevity translates directly to reduced resource consumption and waste generation over time. Additionally, PEEK's resistance to degradation means fewer chemical treatments and protective coatings are needed during its service life, further minimizing environmental impact.

Recyclability represents another critical aspect of PEEK's environmental profile. While thermoplastic in nature, PEEK can be mechanically recycled through grinding and reprocessing methods. Research indicates that recycled PEEK can retain up to 80-90% of its original mechanical properties after multiple processing cycles, making it suitable for cascading applications. Advanced chemical recycling technologies are also emerging, potentially enabling the recovery of virgin-quality PEEK monomers from end-of-life products.

The lightweight nature of PEEK delivers significant environmental benefits in transportation applications. When replacing metals in aerospace or automotive components, PEEK's lower density (approximately 1.32 g/cm³) contributes to weight reduction, improving fuel efficiency and reducing emissions. Studies in the aerospace sector demonstrate that each kilogram of weight reduction can save approximately 2,900 liters of fuel over an aircraft's lifetime.

Despite these advantages, challenges remain in PEEK's sustainability profile. The high processing temperatures required (370-400°C) demand substantial energy inputs during manufacturing. Additionally, the complex polymer structure makes widespread recycling infrastructure limited compared to commodity plastics. End-of-life management remains problematic in certain applications where PEEK is used in composite structures or permanently bonded to dissimilar materials.

Future sustainability improvements for PEEK materials focus on bio-based precursors, energy-efficient processing technologies, and enhanced recycling methodologies. Research into catalytic depolymerization shows promise for closed-loop recycling systems, potentially transforming PEEK's environmental footprint across industries where structural integrity requirements have traditionally demanded less sustainable material choices.

The exceptional durability and chemical resistance of PEEK contribute substantially to its sustainability profile. With service lifespans often exceeding 20 years in demanding applications, PEEK components require less frequent replacement than conventional materials. This longevity translates directly to reduced resource consumption and waste generation over time. Additionally, PEEK's resistance to degradation means fewer chemical treatments and protective coatings are needed during its service life, further minimizing environmental impact.

Recyclability represents another critical aspect of PEEK's environmental profile. While thermoplastic in nature, PEEK can be mechanically recycled through grinding and reprocessing methods. Research indicates that recycled PEEK can retain up to 80-90% of its original mechanical properties after multiple processing cycles, making it suitable for cascading applications. Advanced chemical recycling technologies are also emerging, potentially enabling the recovery of virgin-quality PEEK monomers from end-of-life products.

The lightweight nature of PEEK delivers significant environmental benefits in transportation applications. When replacing metals in aerospace or automotive components, PEEK's lower density (approximately 1.32 g/cm³) contributes to weight reduction, improving fuel efficiency and reducing emissions. Studies in the aerospace sector demonstrate that each kilogram of weight reduction can save approximately 2,900 liters of fuel over an aircraft's lifetime.

Despite these advantages, challenges remain in PEEK's sustainability profile. The high processing temperatures required (370-400°C) demand substantial energy inputs during manufacturing. Additionally, the complex polymer structure makes widespread recycling infrastructure limited compared to commodity plastics. End-of-life management remains problematic in certain applications where PEEK is used in composite structures or permanently bonded to dissimilar materials.

Future sustainability improvements for PEEK materials focus on bio-based precursors, energy-efficient processing technologies, and enhanced recycling methodologies. Research into catalytic depolymerization shows promise for closed-loop recycling systems, potentially transforming PEEK's environmental footprint across industries where structural integrity requirements have traditionally demanded less sustainable material choices.

Comparative Analysis with Alternative High-Performance Polymers

When comparing PEEK (Polyetheretherketone) with other high-performance polymers, several key materials emerge as significant alternatives in structural applications. PEEK's primary competitors include Polyimide (PI), Polyphenylene Sulfide (PPS), Polyetherimide (PEI), and Polysulfone (PSU). Each offers distinct advantages and limitations that must be evaluated against PEEK's performance profile.

Polyimide demonstrates superior thermal stability with continuous service temperatures reaching 260°C, exceeding PEEK's 250°C threshold. However, PI exhibits higher moisture absorption (2-3%) compared to PEEK's minimal 0.5%, potentially compromising dimensional stability in humid environments. Additionally, PI processing requires more specialized equipment due to its higher melting temperature, increasing manufacturing complexity and costs.

Polyphenylene Sulfide presents a cost-effective alternative at approximately 60-70% of PEEK's price point while maintaining excellent chemical resistance. PPS offers comparable flame retardancy but falls short in impact resistance (30-50 J/m versus PEEK's 85-100 J/m) and demonstrates lower fatigue resistance, limiting its application in high-cycle mechanical systems.

Polyetherimide (PEI) provides superior transparency and radiation resistance compared to PEEK, making it preferable for medical and aerospace applications requiring these properties. However, PEI's tensile strength (105 MPa) remains below PEEK's (140 MPa), and its chemical resistance against aggressive solvents is less robust, particularly against ketones and chlorinated hydrocarbons.

Polysulfone offers enhanced hydrolysis resistance and maintains better mechanical properties when exposed to hot water or steam environments. This advantage is particularly valuable in medical sterilization applications. Nevertheless, PSU's lower continuous service temperature (180°C) and reduced wear resistance restrict its use in high-temperature tribological applications where PEEK excels.

Recent market analysis indicates PEEK maintains approximately 45% of the high-performance polymer market share in structural applications, with PEI at 25%, PPS at 15%, and others comprising the remainder. This distribution reflects PEEK's balanced property profile, though specialized applications increasingly favor tailored material selection based on specific performance requirements rather than defaulting to PEEK.

Cost-benefit analysis reveals that while PEEK commands a premium price (approximately $85-100/kg), its extended service life and reduced maintenance requirements often justify the initial investment in critical applications. Alternative polymers may present lower acquisition costs but frequently require more frequent replacement or additional engineering accommodations to achieve comparable performance.

Polyimide demonstrates superior thermal stability with continuous service temperatures reaching 260°C, exceeding PEEK's 250°C threshold. However, PI exhibits higher moisture absorption (2-3%) compared to PEEK's minimal 0.5%, potentially compromising dimensional stability in humid environments. Additionally, PI processing requires more specialized equipment due to its higher melting temperature, increasing manufacturing complexity and costs.

Polyphenylene Sulfide presents a cost-effective alternative at approximately 60-70% of PEEK's price point while maintaining excellent chemical resistance. PPS offers comparable flame retardancy but falls short in impact resistance (30-50 J/m versus PEEK's 85-100 J/m) and demonstrates lower fatigue resistance, limiting its application in high-cycle mechanical systems.

Polyetherimide (PEI) provides superior transparency and radiation resistance compared to PEEK, making it preferable for medical and aerospace applications requiring these properties. However, PEI's tensile strength (105 MPa) remains below PEEK's (140 MPa), and its chemical resistance against aggressive solvents is less robust, particularly against ketones and chlorinated hydrocarbons.

Polysulfone offers enhanced hydrolysis resistance and maintains better mechanical properties when exposed to hot water or steam environments. This advantage is particularly valuable in medical sterilization applications. Nevertheless, PSU's lower continuous service temperature (180°C) and reduced wear resistance restrict its use in high-temperature tribological applications where PEEK excels.

Recent market analysis indicates PEEK maintains approximately 45% of the high-performance polymer market share in structural applications, with PEI at 25%, PPS at 15%, and others comprising the remainder. This distribution reflects PEEK's balanced property profile, though specialized applications increasingly favor tailored material selection based on specific performance requirements rather than defaulting to PEEK.

Cost-benefit analysis reveals that while PEEK commands a premium price (approximately $85-100/kg), its extended service life and reduced maintenance requirements often justify the initial investment in critical applications. Alternative polymers may present lower acquisition costs but frequently require more frequent replacement or additional engineering accommodations to achieve comparable performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!