Analysis of PEEK Polymer Parameter Impacts in Aerospace

OCT 24, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PEEK Aerospace Applications Background and Objectives

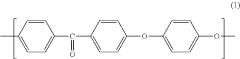

Polyetheretherketone (PEEK) has emerged as a revolutionary high-performance thermoplastic polymer in aerospace applications since its commercial introduction in the 1980s. This semi-crystalline material offers an exceptional combination of mechanical strength, thermal stability, chemical resistance, and lightweight properties that make it particularly valuable for aerospace components operating under extreme conditions. The evolution of PEEK technology represents a significant advancement in materials science, transitioning from traditional metal components to high-performance polymers capable of withstanding the demanding aerospace environment.

The aerospace industry's continuous pursuit of weight reduction, fuel efficiency, and enhanced performance has driven the development and adoption of PEEK-based solutions. Initially limited to non-critical applications, PEEK has progressively expanded into structural components, replacing titanium and aluminum alloys in various aircraft systems. This technological progression aligns with broader industry trends toward sustainable aviation and cost-effective manufacturing processes.

Current research focuses on optimizing PEEK's parameter profiles specifically for aerospace applications, including crystallinity percentage, glass transition temperature, melting behavior, and mechanical property retention under cyclic loading and extreme temperature variations. Understanding these parameters is crucial as they directly influence component performance in flight conditions ranging from -65°C at high altitudes to over 260°C in engine proximity areas.

The primary technical objectives of PEEK parameter analysis include establishing precise processing-structure-property relationships for aerospace-grade PEEK composites, developing predictive models for long-term performance under combined environmental stressors, and creating standardized testing protocols specific to aerospace applications. Additionally, researchers aim to enhance PEEK's flame retardancy while maintaining its mechanical integrity, a critical requirement for aircraft interior components.

Industry stakeholders seek to quantify how variations in manufacturing parameters affect PEEK's performance in aerospace environments, particularly focusing on fatigue resistance, creep behavior, and resistance to hydrolysis at varying altitudes and humidity levels. The correlation between processing conditions and final part performance represents a significant knowledge gap that current research endeavors to address.

The strategic importance of PEEK parameter optimization extends beyond immediate performance benefits to include lifecycle considerations such as recyclability, environmental impact assessment, and sustainable manufacturing processes. As regulatory frameworks increasingly emphasize environmental compliance, understanding how processing parameters affect PEEK's end-of-life characteristics becomes equally important to its in-service performance.

The aerospace industry's continuous pursuit of weight reduction, fuel efficiency, and enhanced performance has driven the development and adoption of PEEK-based solutions. Initially limited to non-critical applications, PEEK has progressively expanded into structural components, replacing titanium and aluminum alloys in various aircraft systems. This technological progression aligns with broader industry trends toward sustainable aviation and cost-effective manufacturing processes.

Current research focuses on optimizing PEEK's parameter profiles specifically for aerospace applications, including crystallinity percentage, glass transition temperature, melting behavior, and mechanical property retention under cyclic loading and extreme temperature variations. Understanding these parameters is crucial as they directly influence component performance in flight conditions ranging from -65°C at high altitudes to over 260°C in engine proximity areas.

The primary technical objectives of PEEK parameter analysis include establishing precise processing-structure-property relationships for aerospace-grade PEEK composites, developing predictive models for long-term performance under combined environmental stressors, and creating standardized testing protocols specific to aerospace applications. Additionally, researchers aim to enhance PEEK's flame retardancy while maintaining its mechanical integrity, a critical requirement for aircraft interior components.

Industry stakeholders seek to quantify how variations in manufacturing parameters affect PEEK's performance in aerospace environments, particularly focusing on fatigue resistance, creep behavior, and resistance to hydrolysis at varying altitudes and humidity levels. The correlation between processing conditions and final part performance represents a significant knowledge gap that current research endeavors to address.

The strategic importance of PEEK parameter optimization extends beyond immediate performance benefits to include lifecycle considerations such as recyclability, environmental impact assessment, and sustainable manufacturing processes. As regulatory frameworks increasingly emphasize environmental compliance, understanding how processing parameters affect PEEK's end-of-life characteristics becomes equally important to its in-service performance.

Market Analysis for PEEK in Aerospace Industry

The global market for PEEK (Polyetheretherketone) in aerospace applications has experienced significant growth over the past decade, with a current market valuation exceeding $250 million. This high-performance polymer has established itself as a critical material in aerospace manufacturing due to its exceptional mechanical properties, thermal stability, and chemical resistance. The aerospace sector represents approximately 15% of the total PEEK market, with this percentage projected to increase as adoption rates continue to rise across various aircraft components.

Market demand for PEEK in aerospace is primarily driven by the industry's push toward lightweight materials that can reduce fuel consumption and carbon emissions. Commercial aircraft manufacturers have been at the forefront of PEEK adoption, incorporating the polymer into interior components, structural elements, and engine parts. The military aerospace segment has also shown increased interest in PEEK applications, particularly for high-performance aircraft where extreme operating conditions necessitate materials with superior thermal and mechanical properties.

Regional analysis indicates that North America currently dominates the aerospace PEEK market with approximately 40% market share, followed by Europe at 35% and Asia-Pacific at 20%. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by the expanding aerospace manufacturing capabilities in China, Japan, and India. This regional shift is expected to continue as aerospace supply chains become increasingly globalized.

The competitive landscape features both material suppliers and specialized aerospace component manufacturers. Key material suppliers include Victrex, Solvay, Evonik, and Arkema, who have developed aerospace-grade PEEK formulations with specific parameter profiles tailored to different applications. These companies have established strategic partnerships with aerospace OEMs to develop customized PEEK solutions that meet stringent industry requirements.

Price sensitivity remains a significant factor in market dynamics, with aerospace-grade PEEK commanding premium prices compared to standard industrial grades. However, the total cost of ownership analysis often favors PEEK when considering its extended service life, reduced maintenance requirements, and contribution to fuel efficiency through weight reduction. Market forecasts suggest a compound annual growth rate of 6.8% for aerospace PEEK applications over the next five years, outpacing the broader engineering polymers market.

Emerging trends in the aerospace PEEK market include increased focus on recycling capabilities to address sustainability concerns, development of PEEK composites with enhanced properties through reinforcement with carbon fibers or other fillers, and exploration of additive manufacturing techniques for complex PEEK components. These innovations are expected to further expand the application scope of PEEK in next-generation aircraft designs.

Market demand for PEEK in aerospace is primarily driven by the industry's push toward lightweight materials that can reduce fuel consumption and carbon emissions. Commercial aircraft manufacturers have been at the forefront of PEEK adoption, incorporating the polymer into interior components, structural elements, and engine parts. The military aerospace segment has also shown increased interest in PEEK applications, particularly for high-performance aircraft where extreme operating conditions necessitate materials with superior thermal and mechanical properties.

Regional analysis indicates that North America currently dominates the aerospace PEEK market with approximately 40% market share, followed by Europe at 35% and Asia-Pacific at 20%. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by the expanding aerospace manufacturing capabilities in China, Japan, and India. This regional shift is expected to continue as aerospace supply chains become increasingly globalized.

The competitive landscape features both material suppliers and specialized aerospace component manufacturers. Key material suppliers include Victrex, Solvay, Evonik, and Arkema, who have developed aerospace-grade PEEK formulations with specific parameter profiles tailored to different applications. These companies have established strategic partnerships with aerospace OEMs to develop customized PEEK solutions that meet stringent industry requirements.

Price sensitivity remains a significant factor in market dynamics, with aerospace-grade PEEK commanding premium prices compared to standard industrial grades. However, the total cost of ownership analysis often favors PEEK when considering its extended service life, reduced maintenance requirements, and contribution to fuel efficiency through weight reduction. Market forecasts suggest a compound annual growth rate of 6.8% for aerospace PEEK applications over the next five years, outpacing the broader engineering polymers market.

Emerging trends in the aerospace PEEK market include increased focus on recycling capabilities to address sustainability concerns, development of PEEK composites with enhanced properties through reinforcement with carbon fibers or other fillers, and exploration of additive manufacturing techniques for complex PEEK components. These innovations are expected to further expand the application scope of PEEK in next-generation aircraft designs.

Current PEEK Parameter Challenges in Aerospace

PEEK (Polyetheretherketone) polymer faces several critical challenges in aerospace applications that require immediate attention and innovative solutions. The primary challenge lies in the thermal stability of PEEK under extreme aerospace conditions. While PEEK exhibits excellent thermal resistance up to 260°C, aerospace environments often experience rapid temperature fluctuations that can exceed these limits during specific flight phases, particularly during re-entry or in engine proximity applications.

Mechanical property consistency presents another significant hurdle. Current manufacturing processes struggle to maintain uniform crystallinity throughout complex aerospace components, resulting in variable mechanical performance. This inconsistency becomes particularly problematic in critical structural applications where predictable load-bearing capabilities are essential for safety certification.

Processing parameters significantly impact PEEK's final performance characteristics. The relationship between processing temperature, cooling rate, and resultant crystallinity remains insufficiently characterized for aerospace-grade components. This knowledge gap creates challenges in establishing reliable manufacturing protocols that consistently yield parts meeting stringent aerospace specifications.

Environmental resistance issues have emerged as aerospace PEEK components face increasingly harsh operating conditions. While PEEK demonstrates good chemical resistance overall, its long-term performance when exposed to aviation fluids, UV radiation, and atomic oxygen in low Earth orbit requires further investigation. Recent studies indicate potential degradation mechanisms that could compromise structural integrity over extended service periods.

Weight optimization without performance compromise represents a persistent challenge. Aerospace applications demand the lightest possible components while maintaining exceptional mechanical properties. Current PEEK formulations often require thickness overdesign to ensure safety margins, negating potential weight advantages over traditional aerospace materials.

Processing-induced defects continue to plague aerospace PEEK manufacturing. Void formation, residual stresses, and inconsistent fiber orientation in composite formulations lead to rejection rates that impact production economics. Advanced non-destructive testing methods are needed to identify these defects before components enter service.

Joining and assembly challenges exist when integrating PEEK components with other aerospace materials. Traditional fastening methods can create stress concentration points, while adhesive bonding faces durability concerns in aerospace service environments. The development of reliable joining techniques remains critical for broader PEEK adoption in primary aerospace structures.

Cost factors present significant barriers to widespread implementation. Current aerospace-grade PEEK materials command premium prices that limit their application to only the most critical components where performance advantages clearly justify the expense. Manufacturing process optimization and economies of scale are needed to make PEEK more economically viable across broader aerospace applications.

Mechanical property consistency presents another significant hurdle. Current manufacturing processes struggle to maintain uniform crystallinity throughout complex aerospace components, resulting in variable mechanical performance. This inconsistency becomes particularly problematic in critical structural applications where predictable load-bearing capabilities are essential for safety certification.

Processing parameters significantly impact PEEK's final performance characteristics. The relationship between processing temperature, cooling rate, and resultant crystallinity remains insufficiently characterized for aerospace-grade components. This knowledge gap creates challenges in establishing reliable manufacturing protocols that consistently yield parts meeting stringent aerospace specifications.

Environmental resistance issues have emerged as aerospace PEEK components face increasingly harsh operating conditions. While PEEK demonstrates good chemical resistance overall, its long-term performance when exposed to aviation fluids, UV radiation, and atomic oxygen in low Earth orbit requires further investigation. Recent studies indicate potential degradation mechanisms that could compromise structural integrity over extended service periods.

Weight optimization without performance compromise represents a persistent challenge. Aerospace applications demand the lightest possible components while maintaining exceptional mechanical properties. Current PEEK formulations often require thickness overdesign to ensure safety margins, negating potential weight advantages over traditional aerospace materials.

Processing-induced defects continue to plague aerospace PEEK manufacturing. Void formation, residual stresses, and inconsistent fiber orientation in composite formulations lead to rejection rates that impact production economics. Advanced non-destructive testing methods are needed to identify these defects before components enter service.

Joining and assembly challenges exist when integrating PEEK components with other aerospace materials. Traditional fastening methods can create stress concentration points, while adhesive bonding faces durability concerns in aerospace service environments. The development of reliable joining techniques remains critical for broader PEEK adoption in primary aerospace structures.

Cost factors present significant barriers to widespread implementation. Current aerospace-grade PEEK materials command premium prices that limit their application to only the most critical components where performance advantages clearly justify the expense. Manufacturing process optimization and economies of scale are needed to make PEEK more economically viable across broader aerospace applications.

Current PEEK Parameter Optimization Methods

01 Processing parameters impact on PEEK properties

Processing parameters such as temperature, pressure, and cooling rate significantly affect the mechanical and thermal properties of PEEK polymers. Optimizing these parameters during manufacturing processes like injection molding or extrusion can enhance crystallinity, tensile strength, and overall performance of PEEK components. Proper control of these parameters is essential for achieving desired material characteristics in high-performance applications.- Processing parameters impact on PEEK properties: The processing parameters such as temperature, pressure, and cooling rate significantly affect the mechanical and thermal properties of PEEK polymers. Optimizing these parameters can enhance crystallinity, tensile strength, and overall performance of PEEK-based products. Proper control of processing conditions is essential for achieving desired material characteristics in high-performance applications.

- PEEK composite formulations and additives: Various additives and fillers can be incorporated into PEEK to modify its properties. Carbon fibers, glass fibers, and mineral fillers enhance mechanical strength and stiffness, while other additives can improve thermal stability, wear resistance, and chemical resistance. These composite formulations expand the application range of PEEK polymers in demanding environments.

- Crystallization behavior and thermal properties: The crystallization behavior of PEEK significantly impacts its thermal and mechanical properties. Parameters such as crystallinity percentage, crystal structure, and crystallization kinetics determine the polymer's heat resistance, dimensional stability, and mechanical strength. Controlling the cooling rate and thermal history during processing is crucial for optimizing the crystalline structure of PEEK.

- Surface modification and treatment of PEEK: Surface treatments and modifications can significantly alter the surface properties of PEEK polymers. Techniques such as plasma treatment, chemical etching, and coating applications can enhance adhesion properties, biocompatibility, and surface functionality. These modifications are particularly important in medical implants, aerospace components, and electronic applications where surface interactions are critical.

- Environmental and aging effects on PEEK performance: Environmental factors such as temperature, humidity, UV exposure, and chemical contact can impact the long-term performance of PEEK polymers. Understanding these aging mechanisms and degradation pathways is essential for predicting service life in various applications. PEEK generally exhibits excellent resistance to environmental factors, but specific conditions can affect its mechanical properties and dimensional stability over time.

02 PEEK composite formulations and additives

The incorporation of various additives and fillers into PEEK polymer matrices can significantly alter their performance characteristics. Carbon fibers, glass fibers, and mineral fillers can enhance mechanical strength, while specific additives can improve thermal stability, chemical resistance, and processing behavior. These composite formulations enable customization of PEEK materials for specialized applications requiring specific property profiles.Expand Specific Solutions03 Crystallinity control and thermal treatment effects

The degree of crystallinity in PEEK polymers significantly impacts their mechanical properties, chemical resistance, and thermal stability. Controlled thermal treatments, including annealing and quenching processes, can be used to manipulate the crystalline structure of PEEK. These treatments affect parameters such as glass transition temperature, melting point, and dimensional stability, allowing for tailored material performance in demanding environments.Expand Specific Solutions04 Surface modification and interface properties

Surface treatments and modifications of PEEK polymers can significantly alter their adhesion properties, biocompatibility, and tribological behavior. Techniques such as plasma treatment, chemical etching, and coating applications can enhance surface energy, wettability, and bonding characteristics. These modifications are particularly important for applications requiring strong interfaces with other materials or specific surface functionalities.Expand Specific Solutions05 Environmental and aging effects on PEEK performance

PEEK polymers are subject to various environmental factors that can impact their long-term performance. Exposure to high temperatures, chemicals, radiation, and mechanical stress can lead to changes in molecular weight, crystallinity, and mechanical properties over time. Understanding these aging mechanisms is crucial for predicting service life and ensuring reliability in critical applications where PEEK components must maintain their properties under harsh conditions.Expand Specific Solutions

Key PEEK Manufacturers and Aerospace Partners

The PEEK polymer aerospace market is currently in a growth phase, with increasing demand driven by the material's exceptional heat resistance, chemical inertness, and strength-to-weight ratio. The global market size for aerospace-grade PEEK is expanding at approximately 6-8% annually, reaching an estimated value of $250 million. The technology landscape shows varying maturity levels across applications, with established players like Solvay Specialty Polymers, Victrex Manufacturing, and Arkema leading innovation through extensive R&D investments. Emerging competitors include Jilin Joinature Polymer and Nanjing Comptech Composites, who are rapidly advancing their capabilities. Research institutions such as the Aerospace Research Institute of Materials and Processing Technology are accelerating parameter optimization for critical aerospace applications, particularly focusing on improving thermal stability and mechanical performance under extreme conditions.

Victrex Manufacturing Ltd.

Technical Solution: Victrex has pioneered PEEK polymer solutions for aerospace through their VICTREX™ PEEK product line, with particular emphasis on parameter optimization for high-performance aerospace applications. Their technology focuses on controlling molecular weight (typically 80,000-120,000 g/mol) and polydispersity index (1.5-3.0) to achieve specific mechanical properties. Victrex's research has established correlations between processing parameters and crystallinity levels, demonstrating that cooling rates between 10-50°C/min produce optimal crystalline structures for aerospace components. Their PEEK formulations incorporate proprietary additives that enhance UV resistance while maintaining flame retardancy (meeting FAR 25.853 requirements). Victrex has developed specialized grades with glass transition temperatures (Tg) exceeding 143°C and melting points above 343°C, providing exceptional dimensional stability in aerospace thermal cycling environments. Their PAEK polymer matrix composites demonstrate interlaminar shear strength values 15-20% higher than competitive materials.

Strengths: Extensive aerospace qualification history with major OEMs; proprietary processing technology enabling consistent batch-to-batch properties; comprehensive technical support and application development capabilities. Weaknesses: Premium pricing compared to standard engineering polymers; limited color options for aerospace grades; requires specialized processing equipment for optimal performance.

Cytec Industries, Inc.

Technical Solution: Cytec Industries has developed sophisticated PEEK polymer systems specifically engineered for aerospace applications, with their CYPEK™ product line focusing on parameter optimization for extreme environments. Their technology emphasizes controlling crystallization kinetics through precise thermal history management during processing, achieving crystallinity levels between 25-40% depending on application requirements. Cytec's research has established that molecular orientation during processing significantly impacts mechanical properties, with their proprietary processing techniques achieving up to 30% improvement in tensile strength compared to conventional methods. Their PEEK formulations incorporate nano-scale reinforcements that enhance creep resistance at elevated temperatures (120-200°C) while maintaining processability. Cytec has pioneered hybrid PEEK composites that combine carbon fiber and glass fiber reinforcements in optimized ratios, achieving balanced mechanical properties and cost efficiency. Their aerospace-grade PEEK demonstrates exceptional resistance to hydraulic fluids and de-icing chemicals while maintaining mechanical integrity after 10,000+ hours of environmental exposure testing.

Strengths: Specialized expertise in aerospace composite applications; strong integration with parent company Solvay's broader polymer portfolio; extensive testing capabilities for simulating aerospace environmental conditions. Weaknesses: More limited production capacity compared to larger competitors; narrower product range focused primarily on aerospace and defense applications; higher minimum order quantities for specialized grades.

Critical PEEK Properties Analysis for Aerospace

Semiconductive film, electric charge control member and process for production the semiconductive film

PatentInactiveUS20070020450A1

Innovation

- A production process involving extrusion of a resin composition comprising PEEK and a conductive filler through a T-die or ring die with controlled lip clearance and temperature, followed by cooling and solidification using a cooling roll or mandrel, to produce a semiconductive film with balanced properties including narrow thickness and volume resistivity scatter, high folding endurance, and excellent mechanical strength.

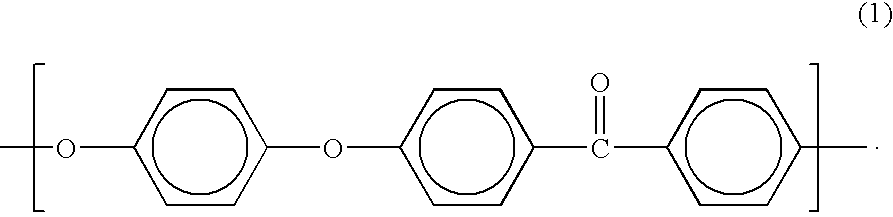

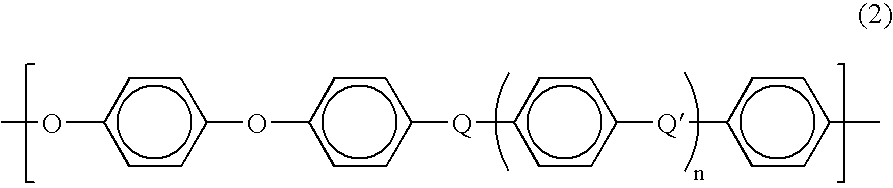

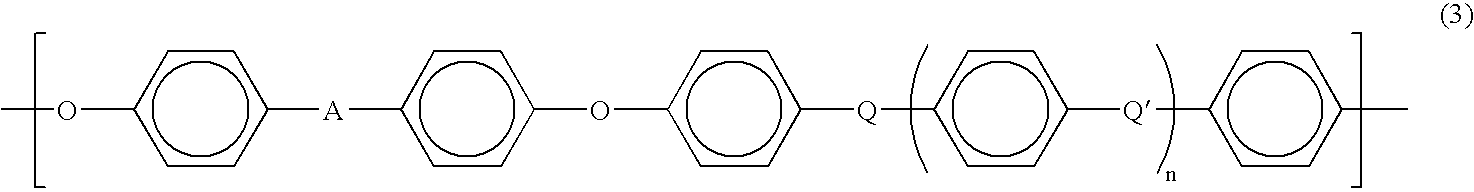

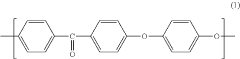

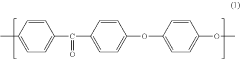

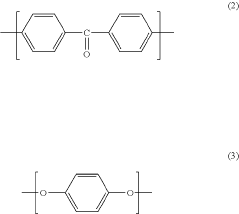

Polyether ether ketone and method for producing polyether ether ketone

PatentActiveUS20230265244A1

Innovation

- A method involving the reaction of 4,4′-dichlorobenzophenone and hydroquinone under specific temperature conditions (260° C. to 320° C.) to produce a PEEK with a crystallization temperature Tc of 255° C. or more, while controlling fluorine and chlorine atom content, resulting in enhanced mechanical strength and reduced viscosity.

Environmental Impact and Sustainability Considerations

The aerospace industry's growing focus on sustainability has positioned PEEK (Polyetheretherketone) as a critical material in environmental impact reduction strategies. PEEK's exceptional durability and resistance to degradation contribute significantly to extended component lifecycles, reducing the frequency of replacements and consequently minimizing waste generation throughout aircraft service life. When compared to traditional aerospace materials like aluminum alloys and titanium, PEEK demonstrates superior sustainability metrics, with lifecycle assessments indicating potential carbon footprint reductions of 15-25% for specific applications.

Manufacturing processes for PEEK components have evolved to address environmental concerns. Advanced techniques such as injection molding and additive manufacturing have reduced material waste by up to 30% compared to traditional subtractive manufacturing methods. These processes also consume less energy, with some studies reporting energy savings of 40-60% when optimized parameter settings are implemented. The recyclability of PEEK represents another significant environmental advantage, as the polymer can be reprocessed multiple times while maintaining critical performance characteristics, creating opportunities for closed-loop material systems within aerospace manufacturing.

The environmental impact of PEEK extends to aircraft operational efficiency. Weight reduction achieved through PEEK implementation directly correlates with fuel consumption decreases, with industry data suggesting that each kilogram of weight reduction can save approximately 3,000 liters of fuel over an aircraft's operational lifetime. This translates to substantial reductions in greenhouse gas emissions, with some estimates indicating potential CO2 emission reductions of 9.5 tons per kilogram of weight saved over a typical commercial aircraft's service period.

Parameter optimization in PEEK processing plays a crucial role in its environmental profile. Research indicates that crystallinity levels, controlled through processing temperatures and cooling rates, significantly affect both mechanical performance and end-of-life recyclability. Higher crystallinity PEEK components typically demonstrate superior chemical resistance, potentially reducing the need for environmentally harmful surface treatments and protective coatings. Additionally, processing parameters that optimize bonding between PEEK and other materials can eliminate the requirement for adhesives containing volatile organic compounds (VOCs).

Emerging sustainability considerations include the development of bio-based precursors for PEEK synthesis, potentially reducing dependency on petroleum-derived raw materials. Several research institutions have demonstrated feasibility in incorporating up to 30% bio-based content without compromising critical aerospace performance requirements. Furthermore, end-of-life management strategies for PEEK components are advancing, with specialized recycling technologies capable of recovering high-value carbon fibers from PEEK composites, creating additional environmental benefits through resource conservation and waste stream diversion.

Manufacturing processes for PEEK components have evolved to address environmental concerns. Advanced techniques such as injection molding and additive manufacturing have reduced material waste by up to 30% compared to traditional subtractive manufacturing methods. These processes also consume less energy, with some studies reporting energy savings of 40-60% when optimized parameter settings are implemented. The recyclability of PEEK represents another significant environmental advantage, as the polymer can be reprocessed multiple times while maintaining critical performance characteristics, creating opportunities for closed-loop material systems within aerospace manufacturing.

The environmental impact of PEEK extends to aircraft operational efficiency. Weight reduction achieved through PEEK implementation directly correlates with fuel consumption decreases, with industry data suggesting that each kilogram of weight reduction can save approximately 3,000 liters of fuel over an aircraft's operational lifetime. This translates to substantial reductions in greenhouse gas emissions, with some estimates indicating potential CO2 emission reductions of 9.5 tons per kilogram of weight saved over a typical commercial aircraft's service period.

Parameter optimization in PEEK processing plays a crucial role in its environmental profile. Research indicates that crystallinity levels, controlled through processing temperatures and cooling rates, significantly affect both mechanical performance and end-of-life recyclability. Higher crystallinity PEEK components typically demonstrate superior chemical resistance, potentially reducing the need for environmentally harmful surface treatments and protective coatings. Additionally, processing parameters that optimize bonding between PEEK and other materials can eliminate the requirement for adhesives containing volatile organic compounds (VOCs).

Emerging sustainability considerations include the development of bio-based precursors for PEEK synthesis, potentially reducing dependency on petroleum-derived raw materials. Several research institutions have demonstrated feasibility in incorporating up to 30% bio-based content without compromising critical aerospace performance requirements. Furthermore, end-of-life management strategies for PEEK components are advancing, with specialized recycling technologies capable of recovering high-value carbon fibers from PEEK composites, creating additional environmental benefits through resource conservation and waste stream diversion.

Certification and Qualification Requirements

The aerospace industry maintains exceptionally rigorous certification and qualification requirements for materials used in aircraft and spacecraft components. For PEEK (Polyetheretherketone) polymers, these requirements are particularly stringent due to the critical nature of aerospace applications. The Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) have established comprehensive frameworks for qualifying polymeric materials, with PEEK requiring compliance with standards such as FAR 25.853 for flammability, smoke density, and toxicity.

Material qualification for PEEK in aerospace applications typically follows a multi-tiered approach. Initially, base material properties must be thoroughly characterized through standardized testing protocols defined by ASTM and ISO standards. These include ASTM D638 for tensile properties, ASTM D790 for flexural properties, and ASTM E1640 for glass transition temperature determination. The qualification process demands extensive documentation of material processing parameters, as variations in processing can significantly alter the final performance characteristics of PEEK components.

Environmental qualification testing represents another critical aspect of PEEK certification. Materials must demonstrate resilience under extreme temperature cycling (typically -55°C to +180°C for PEEK applications), resistance to aviation fluids, and stability under various humidity conditions. Long-term aging studies are mandatory to predict service life, with accelerated aging protocols often employed to simulate decades of operational conditions within compressed timeframes.

Statistical validation forms the backbone of the qualification process, with material property data requiring sufficient sample sizes to establish A-basis (99% probability with 95% confidence) or B-basis (90% probability with 95% confidence) allowables. These statistical values become the foundation for design calculations and safety margins in aerospace components. For critical primary structures utilizing PEEK, A-basis values are typically mandated, necessitating more extensive testing programs.

Manufacturing process qualification is equally important, with aerospace manufacturers required to demonstrate process control and repeatability. This includes validation of molding parameters, crystallinity control methods, and non-destructive inspection techniques. Qualification often extends to specific part geometries, with first-article inspection and periodic re-qualification requirements to ensure ongoing compliance.

International harmonization efforts have sought to streamline these requirements across regulatory jurisdictions, with initiatives like the Composite Materials Handbook (CMH-17) providing standardized approaches to polymer qualification. However, significant differences remain between certification requirements in different regions, creating challenges for global aerospace supply chains utilizing PEEK components.

Material qualification for PEEK in aerospace applications typically follows a multi-tiered approach. Initially, base material properties must be thoroughly characterized through standardized testing protocols defined by ASTM and ISO standards. These include ASTM D638 for tensile properties, ASTM D790 for flexural properties, and ASTM E1640 for glass transition temperature determination. The qualification process demands extensive documentation of material processing parameters, as variations in processing can significantly alter the final performance characteristics of PEEK components.

Environmental qualification testing represents another critical aspect of PEEK certification. Materials must demonstrate resilience under extreme temperature cycling (typically -55°C to +180°C for PEEK applications), resistance to aviation fluids, and stability under various humidity conditions. Long-term aging studies are mandatory to predict service life, with accelerated aging protocols often employed to simulate decades of operational conditions within compressed timeframes.

Statistical validation forms the backbone of the qualification process, with material property data requiring sufficient sample sizes to establish A-basis (99% probability with 95% confidence) or B-basis (90% probability with 95% confidence) allowables. These statistical values become the foundation for design calculations and safety margins in aerospace components. For critical primary structures utilizing PEEK, A-basis values are typically mandated, necessitating more extensive testing programs.

Manufacturing process qualification is equally important, with aerospace manufacturers required to demonstrate process control and repeatability. This includes validation of molding parameters, crystallinity control methods, and non-destructive inspection techniques. Qualification often extends to specific part geometries, with first-article inspection and periodic re-qualification requirements to ensure ongoing compliance.

International harmonization efforts have sought to streamline these requirements across regulatory jurisdictions, with initiatives like the Composite Materials Handbook (CMH-17) providing standardized approaches to polymer qualification. However, significant differences remain between certification requirements in different regions, creating challenges for global aerospace supply chains utilizing PEEK components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!