Analysis of Superhydrophobic Coating in Textile Industry Revolution

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Superhydrophobic Coating Technology Background and Objectives

Superhydrophobic coatings represent a revolutionary advancement in textile technology, drawing inspiration from nature's own water-repellent surfaces such as lotus leaves. The development of these coatings has evolved significantly over the past three decades, transitioning from academic curiosity to commercial application. Initially discovered through observations of the "lotus effect" in the 1970s, research intensified in the early 2000s when scientists began to understand the micro and nano-structural requirements for achieving superhydrophobicity.

The technical evolution of superhydrophobic coatings has followed a trajectory from simple hydrophobic treatments to sophisticated multi-layered systems that combine both chemical and physical modifications. Early approaches relied heavily on fluorinated compounds, while contemporary solutions increasingly emphasize environmentally sustainable alternatives that maintain performance while reducing ecological impact.

Current technological trends indicate a convergence of nanotechnology, polymer science, and surface engineering to create more durable and functional superhydrophobic textiles. The integration of additional properties such as oleophobicity, self-cleaning capabilities, and antimicrobial functions represents the frontier of development in this field. Research publications in this domain have grown exponentially, with particular acceleration noted in patent filings related to textile applications since 2010.

The primary technical objectives for superhydrophobic coatings in textiles include achieving water contact angles exceeding 150° with roll-off angles below 10°, ensuring durability against mechanical abrasion and washing cycles, maintaining breathability of the fabric, and developing scalable manufacturing processes suitable for industrial implementation. Additionally, there is a growing emphasis on creating coatings that maintain their functionality throughout the entire lifecycle of the textile product.

Global research efforts are increasingly focused on addressing the limitations of current superhydrophobic technologies, particularly regarding durability under real-world conditions. The challenge of maintaining superhydrophobicity after repeated mechanical stress or exposure to harsh environments remains a significant hurdle. Concurrently, regulatory pressures concerning perfluorinated compounds have accelerated research into bio-based alternatives and novel fabrication methods.

The anticipated trajectory for this technology suggests a move toward multi-functional coatings that combine superhydrophobicity with other desirable properties such as thermal regulation, UV protection, and electronic functionality. This evolution aligns with broader industry trends toward smart textiles and sustainable manufacturing practices, positioning superhydrophobic coatings as a key enabling technology for next-generation textile products across fashion, technical, and industrial applications.

The technical evolution of superhydrophobic coatings has followed a trajectory from simple hydrophobic treatments to sophisticated multi-layered systems that combine both chemical and physical modifications. Early approaches relied heavily on fluorinated compounds, while contemporary solutions increasingly emphasize environmentally sustainable alternatives that maintain performance while reducing ecological impact.

Current technological trends indicate a convergence of nanotechnology, polymer science, and surface engineering to create more durable and functional superhydrophobic textiles. The integration of additional properties such as oleophobicity, self-cleaning capabilities, and antimicrobial functions represents the frontier of development in this field. Research publications in this domain have grown exponentially, with particular acceleration noted in patent filings related to textile applications since 2010.

The primary technical objectives for superhydrophobic coatings in textiles include achieving water contact angles exceeding 150° with roll-off angles below 10°, ensuring durability against mechanical abrasion and washing cycles, maintaining breathability of the fabric, and developing scalable manufacturing processes suitable for industrial implementation. Additionally, there is a growing emphasis on creating coatings that maintain their functionality throughout the entire lifecycle of the textile product.

Global research efforts are increasingly focused on addressing the limitations of current superhydrophobic technologies, particularly regarding durability under real-world conditions. The challenge of maintaining superhydrophobicity after repeated mechanical stress or exposure to harsh environments remains a significant hurdle. Concurrently, regulatory pressures concerning perfluorinated compounds have accelerated research into bio-based alternatives and novel fabrication methods.

The anticipated trajectory for this technology suggests a move toward multi-functional coatings that combine superhydrophobicity with other desirable properties such as thermal regulation, UV protection, and electronic functionality. This evolution aligns with broader industry trends toward smart textiles and sustainable manufacturing practices, positioning superhydrophobic coatings as a key enabling technology for next-generation textile products across fashion, technical, and industrial applications.

Market Demand Analysis for Textile Waterproofing Solutions

The global market for textile waterproofing solutions has experienced significant growth in recent years, driven by increasing consumer demand for functional apparel and technical textiles. The superhydrophobic coating segment, in particular, has emerged as a revolutionary technology within this space, offering superior water repellency compared to traditional waterproofing methods. Current market valuations indicate that the technical textile sector, which includes waterproof fabrics, represents approximately 30% of the total textile industry, with annual growth rates consistently outpacing conventional textiles.

Consumer preferences have shifted dramatically toward multifunctional textiles that offer protection against environmental elements while maintaining comfort and breathability. This trend is particularly evident in outdoor recreation, sportswear, and high-performance workwear segments, where end-users are willing to pay premium prices for advanced waterproofing solutions. Market research indicates that consumers increasingly prioritize durability and sustainability alongside waterproofing performance, creating demand for solutions that maintain effectiveness through multiple wash cycles and minimize environmental impact.

The healthcare and medical textile sectors have emerged as significant growth areas for waterproof textiles, accelerated by recent global health concerns. Hospital textiles, surgical gowns, and patient bedding require robust waterproofing solutions that can withstand rigorous sterilization processes while providing protection against fluid penetration. This specialized segment is projected to grow substantially as healthcare facilities worldwide upgrade their textile infrastructure.

Industrial applications represent another expanding market for superhydrophobic coatings, particularly in geotextiles, agricultural coverings, and architectural fabrics. These applications demand waterproofing solutions that can withstand harsh environmental conditions while maintaining structural integrity over extended periods. The construction industry's increasing use of technical textiles for roofing, insulation, and moisture barriers has created substantial demand for advanced waterproofing technologies.

Regional market analysis reveals varying adoption rates for superhydrophobic textile solutions. North America and Europe currently lead in market value, driven by established outdoor recreation industries and stringent performance standards. However, the Asia-Pacific region demonstrates the highest growth potential, with rapidly expanding manufacturing capabilities and increasing consumer purchasing power creating favorable market conditions for premium waterproof textiles.

Supply chain considerations have become increasingly important in market development, with textile manufacturers seeking waterproofing solutions that can be integrated into existing production processes without significant capital investment. This has created demand for coating technologies that offer application flexibility while maintaining consistent performance across different fabric substrates and production environments.

Consumer preferences have shifted dramatically toward multifunctional textiles that offer protection against environmental elements while maintaining comfort and breathability. This trend is particularly evident in outdoor recreation, sportswear, and high-performance workwear segments, where end-users are willing to pay premium prices for advanced waterproofing solutions. Market research indicates that consumers increasingly prioritize durability and sustainability alongside waterproofing performance, creating demand for solutions that maintain effectiveness through multiple wash cycles and minimize environmental impact.

The healthcare and medical textile sectors have emerged as significant growth areas for waterproof textiles, accelerated by recent global health concerns. Hospital textiles, surgical gowns, and patient bedding require robust waterproofing solutions that can withstand rigorous sterilization processes while providing protection against fluid penetration. This specialized segment is projected to grow substantially as healthcare facilities worldwide upgrade their textile infrastructure.

Industrial applications represent another expanding market for superhydrophobic coatings, particularly in geotextiles, agricultural coverings, and architectural fabrics. These applications demand waterproofing solutions that can withstand harsh environmental conditions while maintaining structural integrity over extended periods. The construction industry's increasing use of technical textiles for roofing, insulation, and moisture barriers has created substantial demand for advanced waterproofing technologies.

Regional market analysis reveals varying adoption rates for superhydrophobic textile solutions. North America and Europe currently lead in market value, driven by established outdoor recreation industries and stringent performance standards. However, the Asia-Pacific region demonstrates the highest growth potential, with rapidly expanding manufacturing capabilities and increasing consumer purchasing power creating favorable market conditions for premium waterproof textiles.

Supply chain considerations have become increasingly important in market development, with textile manufacturers seeking waterproofing solutions that can be integrated into existing production processes without significant capital investment. This has created demand for coating technologies that offer application flexibility while maintaining consistent performance across different fabric substrates and production environments.

Current Status and Challenges in Superhydrophobic Textile Technology

The global landscape of superhydrophobic textile technology has witnessed significant advancements in recent years, yet remains confronted with substantial challenges that impede widespread commercial adoption. Currently, research institutions and industry leaders across North America, Europe, and East Asia dominate the development of superhydrophobic textile technologies, with China, the United States, and Germany emerging as key innovation hubs. Laboratory-scale achievements have demonstrated impressive water contact angles exceeding 150° and sliding angles below 10°, meeting theoretical requirements for superhydrophobicity.

Despite these achievements, durability remains the foremost challenge in superhydrophobic textile applications. Most current coatings suffer from mechanical abrasion vulnerability, with significant performance degradation observed after as few as 10-30 standard washing cycles. This limitation severely restricts application in everyday garments and industrial textiles where repeated cleaning is essential.

Cost-effectiveness presents another significant barrier, as current manufacturing processes for superhydrophobic textiles typically increase production costs by 30-200% compared to conventional treatments. The requirement for specialized equipment, controlled environments, and expensive chemical precursors contributes to this cost premium, making mass-market penetration difficult despite clear functional benefits.

Environmental and health concerns further complicate the technology's advancement. Many existing superhydrophobic formulations incorporate fluorinated compounds that pose potential environmental hazards and face increasing regulatory scrutiny worldwide. The EU's REACH regulations and similar frameworks in other regions are progressively restricting these substances, necessitating alternative approaches.

Scalability challenges persist in translating laboratory successes to industrial production. Current methods like plasma treatment and chemical vapor deposition deliver excellent performance but face significant hurdles in continuous, high-throughput manufacturing environments. Roll-to-roll compatibility remains limited, with processing speeds typically below commercially viable rates.

Standardization gaps compound these challenges, as the industry lacks universally accepted testing protocols for superhydrophobic performance, particularly regarding durability assessment. This inconsistency complicates comparative analysis and technology validation across different research groups and commercial entities.

Recent technological breakthroughs offer promising directions, including hierarchical micro/nano-structured surfaces that enhance durability, bio-inspired approaches mimicking natural superhydrophobic surfaces like lotus leaves, and self-healing coatings that can restore functionality after damage. However, these innovations remain predominantly at the research stage, requiring further development before commercial implementation.

Despite these achievements, durability remains the foremost challenge in superhydrophobic textile applications. Most current coatings suffer from mechanical abrasion vulnerability, with significant performance degradation observed after as few as 10-30 standard washing cycles. This limitation severely restricts application in everyday garments and industrial textiles where repeated cleaning is essential.

Cost-effectiveness presents another significant barrier, as current manufacturing processes for superhydrophobic textiles typically increase production costs by 30-200% compared to conventional treatments. The requirement for specialized equipment, controlled environments, and expensive chemical precursors contributes to this cost premium, making mass-market penetration difficult despite clear functional benefits.

Environmental and health concerns further complicate the technology's advancement. Many existing superhydrophobic formulations incorporate fluorinated compounds that pose potential environmental hazards and face increasing regulatory scrutiny worldwide. The EU's REACH regulations and similar frameworks in other regions are progressively restricting these substances, necessitating alternative approaches.

Scalability challenges persist in translating laboratory successes to industrial production. Current methods like plasma treatment and chemical vapor deposition deliver excellent performance but face significant hurdles in continuous, high-throughput manufacturing environments. Roll-to-roll compatibility remains limited, with processing speeds typically below commercially viable rates.

Standardization gaps compound these challenges, as the industry lacks universally accepted testing protocols for superhydrophobic performance, particularly regarding durability assessment. This inconsistency complicates comparative analysis and technology validation across different research groups and commercial entities.

Recent technological breakthroughs offer promising directions, including hierarchical micro/nano-structured surfaces that enhance durability, bio-inspired approaches mimicking natural superhydrophobic surfaces like lotus leaves, and self-healing coatings that can restore functionality after damage. However, these innovations remain predominantly at the research stage, requiring further development before commercial implementation.

Current Technical Solutions for Textile Hydrophobicity

01 Nanoparticle-based superhydrophobic coatings

Superhydrophobic coatings can be formulated using various nanoparticles such as silica, titanium dioxide, or carbon-based materials to create nano-scale roughness on surfaces. These nanoparticles, when combined with hydrophobic binders or polymers, create a hierarchical surface structure that traps air and prevents water penetration. The resulting coatings exhibit excellent water repellency with contact angles exceeding 150 degrees and low sliding angles, making them suitable for self-cleaning and anti-fouling applications.- Nanoparticle-based superhydrophobic coatings: Superhydrophobic coatings can be formulated using various nanoparticles to create nano-scale roughness on surfaces. These nanoparticles, such as silica, titanium dioxide, or carbon-based materials, create a hierarchical surface structure that traps air and prevents water from adhering to the surface. The combination of these nanoparticles with hydrophobic binders results in surfaces with water contact angles exceeding 150 degrees, demonstrating excellent water repellency and self-cleaning properties.

- Fluoropolymer-based superhydrophobic coatings: Fluoropolymers are widely used in superhydrophobic coating formulations due to their inherently low surface energy. These polymers, including polytetrafluoroethylene (PTFE) and fluorosilanes, create highly water-repellent surfaces when combined with appropriate surface texturing techniques. The fluorine-containing compounds reduce surface energy while maintaining durability and chemical resistance, making these coatings suitable for various industrial and consumer applications.

- Environmentally friendly superhydrophobic coatings: Recent developments in superhydrophobic coatings focus on environmentally friendly formulations that avoid harmful fluorinated compounds. These green alternatives utilize bio-based materials, such as modified plant waxes, cellulose derivatives, and silica derived from natural sources. The coatings achieve superhydrophobicity through hierarchical surface structures while minimizing environmental impact and improving biodegradability compared to traditional fluorinated coatings.

- Durable and abrasion-resistant superhydrophobic coatings: Enhancing the durability and abrasion resistance of superhydrophobic coatings is critical for practical applications. These formulations incorporate hard ceramic particles, cross-linking agents, or polymer networks to improve mechanical strength while maintaining water repellency. Some approaches include multi-layer systems with a durable base layer and a superhydrophobic top layer, or self-healing mechanisms that can restore the superhydrophobic properties after physical damage.

- Application-specific superhydrophobic coatings: Superhydrophobic coatings can be tailored for specific applications such as anti-icing, anti-corrosion, or self-cleaning surfaces. These specialized formulations may include additional functional components like UV stabilizers for outdoor applications, antimicrobial agents for healthcare settings, or conductive materials for electronic applications. The coating composition and application method are optimized based on the substrate material and the intended operating environment to ensure optimal performance and longevity.

02 Fluoropolymer-based superhydrophobic coatings

Fluoropolymers and fluorinated compounds are widely used in superhydrophobic coating formulations due to their inherently low surface energy. These materials, such as polytetrafluoroethylene (PTFE) or fluorosilanes, when structured with appropriate surface roughness, create highly water-repellent surfaces. The combination of fluoropolymers with textured substrates or particulate additives enhances the superhydrophobic effect, resulting in durable coatings with excellent chemical resistance and self-cleaning properties.Expand Specific Solutions03 Biomimetic superhydrophobic coatings

Inspired by natural superhydrophobic surfaces like lotus leaves and butterfly wings, biomimetic approaches involve replicating hierarchical micro and nano-structures found in nature. These coatings typically combine micro-scale texturing with nano-scale features to create dual-scale roughness. Various fabrication methods including lithography, etching, and template-assisted growth are employed to mimic these natural structures. The resulting biomimetic coatings demonstrate exceptional water-repellency while often incorporating additional functional properties such as anti-icing or anti-bacterial capabilities.Expand Specific Solutions04 Spray-applied superhydrophobic coatings

Spray application techniques offer a versatile and scalable method for applying superhydrophobic coatings to various substrates. These formulations typically contain hydrophobic particles suspended in a solvent with binding agents that secure the particles to the substrate upon drying. The spray process creates random surface roughness that, combined with the hydrophobic components, yields superhydrophobic properties. This application method is particularly valuable for treating large areas or complex geometries where other coating methods may be impractical.Expand Specific Solutions05 Durable and self-healing superhydrophobic coatings

Enhancing the durability of superhydrophobic coatings is critical for practical applications, as conventional formulations often suffer from mechanical weakness. Advanced approaches incorporate self-healing mechanisms, abrasion-resistant components, or elastomeric materials to maintain superhydrophobicity even after physical damage. Some formulations include regenerative components that migrate to the surface when damaged, restoring the water-repellent properties. These durable coatings typically employ strong adhesion promoters, cross-linking agents, or embedded reinforcement structures to withstand harsh environmental conditions while maintaining their functional properties.Expand Specific Solutions

Key Industry Players in Superhydrophobic Coating Development

The superhydrophobic coating market in the textile industry is currently in a growth phase, with increasing adoption driven by consumer demand for functional textiles. The global market size is expanding rapidly, projected to reach significant value by 2030 due to applications in outdoor apparel, technical textiles, and protective clothing. Technologically, the field shows varying maturity levels, with academic institutions like Soochow University, Southeast University, and IIT Kanpur leading fundamental research, while companies such as Detrapel, Henkel AG, and Beijing Neatrition Technology are commercializing applications. Research organizations including A*STAR and CSIR are bridging the gap between academic innovation and industrial implementation, focusing on scalable manufacturing processes and environmentally sustainable formulations to address market challenges.

Soochow University

Technical Solution: Soochow University has developed innovative superhydrophobic coatings for textiles using a combination of silica nanoparticles and fluoropolymers. Their approach involves a two-step process: first creating micro/nano hierarchical structures on fabric surfaces, then applying low surface energy compounds to achieve water contact angles exceeding 150°. Their research has demonstrated durable coatings that maintain superhydrophobicity after 50 washing cycles through covalent bonding mechanisms between the coating and fabric fibers. The university has pioneered environmentally friendly alternatives to traditional fluorinated compounds, utilizing silica-based solutions with modified surface chemistry that reduce environmental impact while maintaining performance. Their coating technology has been successfully applied to various textile substrates including cotton, polyester, and blended fabrics, showing versatility across different material compositions.

Strengths: Superior durability with wash resistance up to 50 cycles; environmentally friendly formulations reducing fluorinated compound usage; excellent adhesion to multiple fabric types. Weaknesses: Higher production costs compared to conventional water-repellent treatments; potential for reduced breathability in heavily coated fabrics; requires specialized application equipment for optimal performance.

Nantong Textile and Silk Industry Technology Research Institute

Technical Solution: Nantong Textile and Silk Institute has developed a biomimetic superhydrophobic coating technology specifically optimized for silk and high-end textiles. Their approach utilizes a multi-layer application process incorporating modified silica nanoparticles combined with environmentally friendly fluorine-free polymers. The institute's innovation centers on preserving the natural properties of luxury textiles while imparting extreme water repellency, achieving contact angles of 152-158° without compromising the distinctive hand feel and drape of premium fabrics. Their coating technology employs a proprietary low-temperature plasma treatment as a pre-processing step, creating nanoscale surface roughness that enhances the subsequent coating adhesion and performance. The institute has successfully commercialized this technology for high-end fashion applications, demonstrating superhydrophobic properties that withstand dry cleaning processes - a critical requirement for luxury textiles. Recent advancements include the incorporation of natural waxes derived from plant sources, creating a more sustainable alternative while maintaining comparable performance to synthetic options.

Strengths: Specialized formulations for luxury and delicate textiles; preservation of natural fabric properties including drape and hand feel; compatibility with dry cleaning processes. Weaknesses: Higher production costs limiting mass-market applications; more complex application process requiring specialized equipment; slightly reduced durability compared to synthetic-based alternatives.

Core Patents and Innovations in Superhydrophobic Textile Coatings

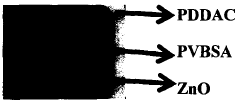

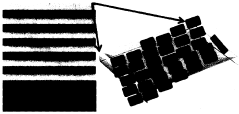

UV blocking non wetting fabric using nanoparticles

PatentInactiveIN4188CHE2013A

Innovation

- A nano fabric coated with core-shell ZnO/Si02 nanoparticles is developed, where ZnO nanoparticles enhance UV blocking properties and Si02 nanoparticles impart non-wetting characteristics through surface roughening, eliminating the need for silver coatings and additional waterproofing materials like Teflon or PVC.

Hydrophobic surface treatment compositions comprising titanium precursors

PatentWO2015036855A1

Innovation

- A method using titanium precursors hydrolyzed under acidic conditions to create titania sol solutions, which are then diluted and applied to substrates without precipitating nanoparticles, allowing for temporary or permanent hydrophobic surfaces to be achieved without additional surface energy lowering agents, and enabling transitions between different hydrophobic states.

Environmental Impact and Sustainability Considerations

The adoption of superhydrophobic coatings in the textile industry presents significant environmental implications that warrant careful consideration. Traditional textile processing involves extensive use of water, chemicals, and energy, contributing substantially to environmental degradation. Superhydrophobic coatings offer a promising pathway to mitigate these impacts through reduced water consumption, decreased chemical usage, and extended product lifecycles.

Water conservation represents one of the most substantial environmental benefits of superhydrophobic textiles. Conventional textile finishing processes typically consume 100-150 liters of water per kilogram of fabric. Implementation of superhydrophobic treatments can reduce water usage by approximately 40-60% during manufacturing and significantly decrease the frequency of consumer washing, potentially saving billions of gallons of water annually across the global textile industry.

Chemical reduction constitutes another critical environmental advantage. Many conventional water-repellent treatments rely on perfluorinated compounds (PFCs) that persist in the environment and bioaccumulate in organisms. Modern superhydrophobic coatings increasingly utilize silica-based nanoparticles, plant-derived waxes, and biodegradable polymers that demonstrate substantially lower environmental toxicity while maintaining comparable performance characteristics.

Energy efficiency improvements emerge as a third sustainability benefit. Self-cleaning properties of superhydrophobic textiles reduce washing frequency, translating to lower energy consumption throughout the product lifecycle. Research indicates that superhydrophobic-treated garments may require 30-50% less laundering, potentially reducing associated carbon emissions by millions of tons annually.

Waste reduction represents a fourth environmental consideration. By extending product lifespan through enhanced durability and stain resistance, superhydrophobic textiles contribute to decreased textile waste generation. Given that approximately 92 million tons of textile waste enter landfills annually, technologies that extend useful product life offer significant environmental benefits.

Despite these advantages, several sustainability challenges remain. Durability of superhydrophobic coatings under real-world conditions continues to present limitations, with many treatments losing effectiveness after 15-30 wash cycles. Additionally, the environmental fate of nanoparticles used in some superhydrophobic formulations remains incompletely understood, raising potential concerns about bioaccumulation and ecological impacts.

Future sustainability improvements will likely focus on developing completely biodegradable superhydrophobic treatments, enhancing coating durability to maximize lifecycle benefits, and establishing comprehensive recycling protocols for treated textiles. Industry-academic partnerships are increasingly targeting these challenges through green chemistry approaches and circular economy principles.

Water conservation represents one of the most substantial environmental benefits of superhydrophobic textiles. Conventional textile finishing processes typically consume 100-150 liters of water per kilogram of fabric. Implementation of superhydrophobic treatments can reduce water usage by approximately 40-60% during manufacturing and significantly decrease the frequency of consumer washing, potentially saving billions of gallons of water annually across the global textile industry.

Chemical reduction constitutes another critical environmental advantage. Many conventional water-repellent treatments rely on perfluorinated compounds (PFCs) that persist in the environment and bioaccumulate in organisms. Modern superhydrophobic coatings increasingly utilize silica-based nanoparticles, plant-derived waxes, and biodegradable polymers that demonstrate substantially lower environmental toxicity while maintaining comparable performance characteristics.

Energy efficiency improvements emerge as a third sustainability benefit. Self-cleaning properties of superhydrophobic textiles reduce washing frequency, translating to lower energy consumption throughout the product lifecycle. Research indicates that superhydrophobic-treated garments may require 30-50% less laundering, potentially reducing associated carbon emissions by millions of tons annually.

Waste reduction represents a fourth environmental consideration. By extending product lifespan through enhanced durability and stain resistance, superhydrophobic textiles contribute to decreased textile waste generation. Given that approximately 92 million tons of textile waste enter landfills annually, technologies that extend useful product life offer significant environmental benefits.

Despite these advantages, several sustainability challenges remain. Durability of superhydrophobic coatings under real-world conditions continues to present limitations, with many treatments losing effectiveness after 15-30 wash cycles. Additionally, the environmental fate of nanoparticles used in some superhydrophobic formulations remains incompletely understood, raising potential concerns about bioaccumulation and ecological impacts.

Future sustainability improvements will likely focus on developing completely biodegradable superhydrophobic treatments, enhancing coating durability to maximize lifecycle benefits, and establishing comprehensive recycling protocols for treated textiles. Industry-academic partnerships are increasingly targeting these challenges through green chemistry approaches and circular economy principles.

Manufacturing Scalability and Cost Analysis

The scalability of superhydrophobic coating manufacturing represents a critical challenge for widespread industrial adoption in the textile sector. Current laboratory-scale production methods often involve complex multi-step processes that are difficult to translate to high-volume manufacturing environments. Batch processing techniques commonly used in research settings yield excellent hydrophobic properties but suffer from significant throughput limitations, typically producing only a few square meters of treated fabric per hour.

Industrial implementation requires production rates of thousands of square meters daily, necessitating continuous processing methods. Roll-to-roll coating technologies show promising potential for scaling superhydrophobic treatments, with recent advancements achieving processing speeds of 15-20 meters per minute. However, maintaining coating uniformity and durability at these speeds remains problematic, with quality inconsistencies occurring as production rates increase.

Cost analysis reveals significant economic barriers to widespread adoption. Raw material expenses for high-performance superhydrophobic coatings range from $3-8 per square meter, substantially higher than conventional water-repellent treatments ($0.5-1.5 per square meter). Fluorinated compounds, which deliver superior performance, face additional scrutiny due to environmental concerns and regulatory restrictions, potentially limiting their industrial viability despite their technical advantages.

Energy consumption during manufacturing presents another cost consideration. Thermal curing processes commonly required for coating fixation consume 2-4 kWh per kilogram of treated fabric. Alternative curing methods such as UV-curing show promise for reducing energy demands by up to 70%, but require significant capital investment in specialized equipment.

Equipment modification costs for existing textile production lines average $150,000-300,000 per production line, representing a substantial barrier for small and medium manufacturers. Larger corporations have begun integrating these technologies, but ROI calculations suggest 3-5 year payback periods, longer than the 1-2 years typically acceptable in the textile industry.

Recent innovations in nanoparticle-based coatings and sol-gel processing techniques demonstrate potential for cost reduction, with projected manufacturing costs decreasing by 30-40% over the next five years. These advances, coupled with increasing consumer demand for high-performance textiles, may accelerate industrial adoption despite current economic challenges.

Industrial implementation requires production rates of thousands of square meters daily, necessitating continuous processing methods. Roll-to-roll coating technologies show promising potential for scaling superhydrophobic treatments, with recent advancements achieving processing speeds of 15-20 meters per minute. However, maintaining coating uniformity and durability at these speeds remains problematic, with quality inconsistencies occurring as production rates increase.

Cost analysis reveals significant economic barriers to widespread adoption. Raw material expenses for high-performance superhydrophobic coatings range from $3-8 per square meter, substantially higher than conventional water-repellent treatments ($0.5-1.5 per square meter). Fluorinated compounds, which deliver superior performance, face additional scrutiny due to environmental concerns and regulatory restrictions, potentially limiting their industrial viability despite their technical advantages.

Energy consumption during manufacturing presents another cost consideration. Thermal curing processes commonly required for coating fixation consume 2-4 kWh per kilogram of treated fabric. Alternative curing methods such as UV-curing show promise for reducing energy demands by up to 70%, but require significant capital investment in specialized equipment.

Equipment modification costs for existing textile production lines average $150,000-300,000 per production line, representing a substantial barrier for small and medium manufacturers. Larger corporations have begun integrating these technologies, but ROI calculations suggest 3-5 year payback periods, longer than the 1-2 years typically acceptable in the textile industry.

Recent innovations in nanoparticle-based coatings and sol-gel processing techniques demonstrate potential for cost reduction, with projected manufacturing costs decreasing by 30-40% over the next five years. These advances, coupled with increasing consumer demand for high-performance textiles, may accelerate industrial adoption despite current economic challenges.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!