Analysis of Volumetric 3D printing patent landscape and innovation trends

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Volumetric 3D Printing Evolution and Objectives

Volumetric 3D printing represents a paradigm shift in additive manufacturing technology, evolving from traditional layer-by-layer approaches to a revolutionary method that creates entire objects simultaneously. This technology emerged in the early 2000s as researchers sought to overcome the speed limitations and mechanical anisotropy inherent in conventional 3D printing methods. The fundamental concept involves projecting light patterns into photosensitive resin to solidify an entire volume at once, dramatically reducing production time from hours to minutes.

The evolution of volumetric 3D printing can be traced through several key developmental phases. Initially, researchers focused on proof-of-concept demonstrations using computed tomography principles in reverse. By 2017, significant breakthroughs occurred with the introduction of computed axial lithography (CAL), which utilized synchronized multiple-angle projections to create complex three-dimensional structures. Subsequently, advancements in photochemistry and optical systems have continuously refined the technology, improving resolution capabilities from millimeter to micrometer scales.

Material development has played a crucial role in this evolution, transitioning from basic photopolymers to sophisticated resins with tailored mechanical, optical, and biological properties. Concurrently, computational algorithms for volumetric image reconstruction have become increasingly sophisticated, enabling more complex geometries and higher precision in printed objects.

The primary objectives driving volumetric 3D printing research include achieving unprecedented production speeds while maintaining high resolution and material quality. Researchers aim to expand the material palette beyond photopolymers to include ceramics, metals, and biomaterials, thereby broadening potential applications. Another critical goal involves scaling the technology to accommodate larger build volumes without sacrificing resolution or speed advantages.

From an industrial perspective, objectives focus on developing commercially viable systems that can integrate seamlessly into existing manufacturing workflows. This includes creating user-friendly software interfaces, establishing standardized processes, and ensuring reproducibility across different production environments. Additionally, there is significant interest in reducing equipment costs to facilitate wider adoption across various sectors.

Looking forward, the field is moving toward multi-material volumetric printing capabilities, which would enable the creation of functionally graded materials and complex composite structures in a single printing process. Researchers are also exploring the integration of volumetric printing with other manufacturing technologies to create hybrid production systems that leverage the strengths of each approach.

The evolution of volumetric 3D printing can be traced through several key developmental phases. Initially, researchers focused on proof-of-concept demonstrations using computed tomography principles in reverse. By 2017, significant breakthroughs occurred with the introduction of computed axial lithography (CAL), which utilized synchronized multiple-angle projections to create complex three-dimensional structures. Subsequently, advancements in photochemistry and optical systems have continuously refined the technology, improving resolution capabilities from millimeter to micrometer scales.

Material development has played a crucial role in this evolution, transitioning from basic photopolymers to sophisticated resins with tailored mechanical, optical, and biological properties. Concurrently, computational algorithms for volumetric image reconstruction have become increasingly sophisticated, enabling more complex geometries and higher precision in printed objects.

The primary objectives driving volumetric 3D printing research include achieving unprecedented production speeds while maintaining high resolution and material quality. Researchers aim to expand the material palette beyond photopolymers to include ceramics, metals, and biomaterials, thereby broadening potential applications. Another critical goal involves scaling the technology to accommodate larger build volumes without sacrificing resolution or speed advantages.

From an industrial perspective, objectives focus on developing commercially viable systems that can integrate seamlessly into existing manufacturing workflows. This includes creating user-friendly software interfaces, establishing standardized processes, and ensuring reproducibility across different production environments. Additionally, there is significant interest in reducing equipment costs to facilitate wider adoption across various sectors.

Looking forward, the field is moving toward multi-material volumetric printing capabilities, which would enable the creation of functionally graded materials and complex composite structures in a single printing process. Researchers are also exploring the integration of volumetric printing with other manufacturing technologies to create hybrid production systems that leverage the strengths of each approach.

Market Analysis for Volumetric 3D Printing Applications

The volumetric 3D printing market is experiencing significant growth, driven by increasing demand across multiple industries seeking faster, more efficient additive manufacturing solutions. Current market estimates value the volumetric 3D printing sector at approximately $450 million, with projections indicating a compound annual growth rate of 25-30% over the next five years. This accelerated growth trajectory is primarily fueled by the technology's unique value proposition: the ability to produce complex structures in seconds rather than hours.

Healthcare represents the largest application segment, accounting for nearly 40% of the current market. The ability to rapidly produce patient-specific implants, anatomical models, and tissue scaffolds with complex internal structures has positioned volumetric printing as a transformative technology in medical device manufacturing and bioprinting. Dental applications, particularly for custom aligners and prosthetics, have shown particularly strong adoption rates.

The aerospace and automotive sectors collectively represent approximately 30% of market applications, with emphasis on lightweight components with complex internal geometries that would be impossible to manufacture using traditional methods. These industries value volumetric printing's ability to create parts with optimized weight-to-strength ratios and integrated functionality.

Consumer electronics manufacturers have begun exploring volumetric printing for rapid prototyping and specialized component production, representing about 15% of current applications. The remaining market share is distributed across jewelry, education, and research institutions.

Geographically, North America leads adoption with approximately 45% market share, followed by Europe (30%) and Asia-Pacific (20%). The Asia-Pacific region, particularly China and Japan, is expected to demonstrate the fastest growth rate over the next decade as manufacturing infrastructure develops and industrial policies increasingly support advanced manufacturing technologies.

Market analysis indicates several key drivers accelerating adoption: decreasing equipment costs (with entry-level systems now available below $100,000), expanding material compatibility beyond photopolymers to include ceramics and composite materials, and increasing awareness of the technology's capabilities among design engineers. The development of specialized software tools optimized for volumetric design is also removing barriers to implementation.

Despite promising growth, market penetration faces challenges including limited material selection compared to traditional 3D printing methods, relatively high initial investment costs for industrial-grade systems, and the need for specialized technical expertise. Additionally, quality control and standardization remain developing areas that will require industry-wide collaboration to fully address.

Healthcare represents the largest application segment, accounting for nearly 40% of the current market. The ability to rapidly produce patient-specific implants, anatomical models, and tissue scaffolds with complex internal structures has positioned volumetric printing as a transformative technology in medical device manufacturing and bioprinting. Dental applications, particularly for custom aligners and prosthetics, have shown particularly strong adoption rates.

The aerospace and automotive sectors collectively represent approximately 30% of market applications, with emphasis on lightweight components with complex internal geometries that would be impossible to manufacture using traditional methods. These industries value volumetric printing's ability to create parts with optimized weight-to-strength ratios and integrated functionality.

Consumer electronics manufacturers have begun exploring volumetric printing for rapid prototyping and specialized component production, representing about 15% of current applications. The remaining market share is distributed across jewelry, education, and research institutions.

Geographically, North America leads adoption with approximately 45% market share, followed by Europe (30%) and Asia-Pacific (20%). The Asia-Pacific region, particularly China and Japan, is expected to demonstrate the fastest growth rate over the next decade as manufacturing infrastructure develops and industrial policies increasingly support advanced manufacturing technologies.

Market analysis indicates several key drivers accelerating adoption: decreasing equipment costs (with entry-level systems now available below $100,000), expanding material compatibility beyond photopolymers to include ceramics and composite materials, and increasing awareness of the technology's capabilities among design engineers. The development of specialized software tools optimized for volumetric design is also removing barriers to implementation.

Despite promising growth, market penetration faces challenges including limited material selection compared to traditional 3D printing methods, relatively high initial investment costs for industrial-grade systems, and the need for specialized technical expertise. Additionally, quality control and standardization remain developing areas that will require industry-wide collaboration to fully address.

Global Landscape and Technical Barriers in Volumetric Printing

Volumetric 3D printing represents a paradigm shift in additive manufacturing technology, enabling the simultaneous solidification of an entire volume rather than layer-by-layer fabrication. The global landscape of volumetric printing reveals significant disparities in technological development and adoption across different regions. North America, particularly the United States, leads in patent filings and research publications, with major contributions from institutions like Lawrence Livermore National Laboratory and University of California, Berkeley.

Europe follows closely, with Switzerland's EPFL and Germany's Fraunhofer Institute making substantial advancements in tomographic volumetric printing techniques. The Asia-Pacific region, especially China and Japan, has shown rapid growth in patent applications related to volumetric printing, focusing primarily on material development and industrial applications.

Despite promising developments, volumetric printing faces several critical technical barriers. The foremost challenge lies in achieving high resolution while maintaining reasonable printing speeds. Current systems struggle to produce features below 100 microns without significantly extending printing times, limiting applications in fields requiring microscale precision.

Material limitations constitute another significant barrier. The photopolymer resins compatible with volumetric techniques remain restricted compared to those available for conventional 3D printing. These materials often lack the mechanical properties, biocompatibility, or thermal stability required for advanced applications, particularly in medical devices and aerospace components.

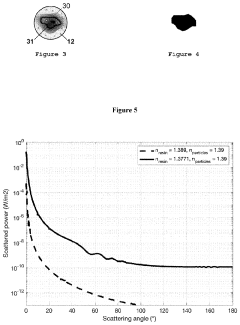

Optical constraints present additional challenges. The need for uniform light distribution throughout the resin volume creates difficulties in printing large objects or using highly absorbing materials. Light scattering and absorption effects can lead to inconsistent curing and structural defects, especially in geometrically complex parts.

Computational demands represent a substantial hurdle. The calculation of optimal light patterns for tomographic volumetric printing requires significant processing power and sophisticated algorithms. Real-time adjustment capabilities remain limited, restricting the ability to compensate for material variations or printing anomalies during fabrication.

Scaling volumetric printing for industrial applications faces economic barriers as well. The specialized equipment, including high-speed spatial light modulators and synchronized projection systems, involves considerable capital investment. This cost factor, combined with limited material options, has constrained widespread industrial adoption despite the technology's theoretical advantages in production speed.

Europe follows closely, with Switzerland's EPFL and Germany's Fraunhofer Institute making substantial advancements in tomographic volumetric printing techniques. The Asia-Pacific region, especially China and Japan, has shown rapid growth in patent applications related to volumetric printing, focusing primarily on material development and industrial applications.

Despite promising developments, volumetric printing faces several critical technical barriers. The foremost challenge lies in achieving high resolution while maintaining reasonable printing speeds. Current systems struggle to produce features below 100 microns without significantly extending printing times, limiting applications in fields requiring microscale precision.

Material limitations constitute another significant barrier. The photopolymer resins compatible with volumetric techniques remain restricted compared to those available for conventional 3D printing. These materials often lack the mechanical properties, biocompatibility, or thermal stability required for advanced applications, particularly in medical devices and aerospace components.

Optical constraints present additional challenges. The need for uniform light distribution throughout the resin volume creates difficulties in printing large objects or using highly absorbing materials. Light scattering and absorption effects can lead to inconsistent curing and structural defects, especially in geometrically complex parts.

Computational demands represent a substantial hurdle. The calculation of optimal light patterns for tomographic volumetric printing requires significant processing power and sophisticated algorithms. Real-time adjustment capabilities remain limited, restricting the ability to compensate for material variations or printing anomalies during fabrication.

Scaling volumetric printing for industrial applications faces economic barriers as well. The specialized equipment, including high-speed spatial light modulators and synchronized projection systems, involves considerable capital investment. This cost factor, combined with limited material options, has constrained widespread industrial adoption despite the technology's theoretical advantages in production speed.

Current Patent-Protected Volumetric Printing Solutions

01 Volumetric 3D printing technologies and methods

Various technologies and methods for volumetric 3D printing have been developed, enabling the creation of three-dimensional objects through different approaches. These methods include tomographic techniques, holographic printing, and other novel approaches that allow for the rapid formation of complete 3D structures. These technologies often focus on creating objects by solidifying entire volumes at once rather than layer-by-layer, significantly reducing printing time and enabling more complex geometries.- Volumetric 3D printing technologies and methods: Various technologies and methods for volumetric 3D printing have been developed, enabling the creation of three-dimensional objects through different approaches. These methods include tomographic techniques, holographic printing, and other novel approaches that allow for the rapid formation of entire volumes rather than layer-by-layer construction. These technologies offer advantages in terms of speed, resolution, and the ability to create complex geometries that might be challenging with traditional additive manufacturing methods.

- Materials and formulations for volumetric 3D printing: Specialized materials and formulations have been developed specifically for volumetric 3D printing applications. These include photosensitive resins, hydrogels, and other materials that can be cured or solidified through various energy inputs such as light or heat. The development of these materials focuses on properties such as cure speed, optical clarity, mechanical strength, and biocompatibility, depending on the intended application of the printed objects.

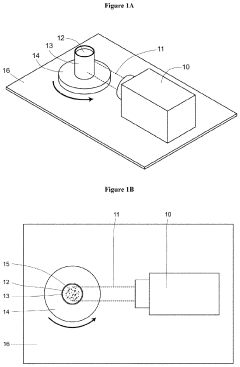

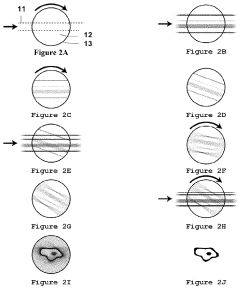

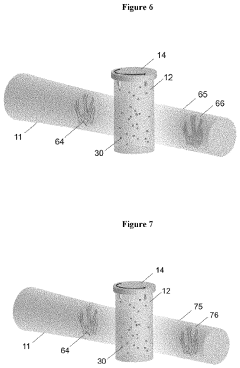

- Imaging and projection systems for volumetric printing: Advanced imaging and projection systems are crucial components of volumetric 3D printing technologies. These systems include specialized light sources, spatial light modulators, holographic projectors, and other optical components that enable the precise delivery of energy to specific points within a volume of printable material. Innovations in this area focus on improving resolution, reducing distortion, and enabling faster printing speeds through more efficient energy delivery systems.

- Software and computational methods for volumetric printing: Specialized software and computational methods have been developed to support volumetric 3D printing processes. These include algorithms for tomographic reconstruction, holographic pattern generation, and real-time control systems that coordinate the various components of volumetric printers. Advanced computational techniques such as machine learning and optimization algorithms are also being applied to improve print quality, reduce artifacts, and enable more complex geometries to be printed accurately.

- Applications and integration of volumetric 3D printing: Volumetric 3D printing technologies are being applied across various fields including medical devices, tissue engineering, consumer products, and industrial components. These applications leverage the unique capabilities of volumetric printing such as speed, resolution, and the ability to create complex internal structures. Additionally, innovations focus on integrating volumetric printing with other manufacturing processes, quality control systems, and end-use applications to create comprehensive production solutions.

02 Materials and formulations for volumetric 3D printing

Specialized materials and formulations have been developed specifically for volumetric 3D printing applications. These include photosensitive resins, hydrogels, and other materials that can be selectively cured or solidified using light, heat, or other energy sources. The development of these materials focuses on properties such as rapid curing, optical clarity, and mechanical strength to enable efficient and effective volumetric printing processes.Expand Specific Solutions03 Imaging and projection systems for volumetric printing

Advanced imaging and projection systems play a crucial role in volumetric 3D printing technologies. These systems include specialized optics, light sources, and control mechanisms that enable precise spatial control of energy delivery within printing volumes. Innovations in this area focus on improving resolution, speed, and accuracy of the printing process through novel projection techniques, multi-angle illumination, and synchronized imaging systems.Expand Specific Solutions04 Data processing and computational methods for volumetric printing

Sophisticated data processing and computational methods are essential for volumetric 3D printing. These include algorithms for volumetric data representation, real-time processing of 3D models, and optimization techniques for energy delivery patterns. Innovations in this area focus on improving the efficiency and accuracy of converting digital designs into printable volumetric patterns, handling complex geometries, and optimizing printing parameters for different materials and applications.Expand Specific Solutions05 Applications and integration of volumetric 3D printing

Volumetric 3D printing technologies are being applied across various fields and integrated with other manufacturing processes. Applications include medical device fabrication, tissue engineering, rapid prototyping, and custom manufacturing. Innovations in this area focus on adapting volumetric printing techniques for specific use cases, integrating these technologies with existing workflows, and developing specialized systems for particular industries or applications.Expand Specific Solutions

Industry Leaders and Competitive Dynamics in Volumetric Printing

The volumetric 3D printing market is currently in a growth phase, with an expanding ecosystem of academic institutions and commercial players driving innovation. The market is projected to reach significant scale as the technology matures from experimental to commercial applications. Universities like Zhejiang University, Southeast University, and École Polytechnique Fédérale de Lausanne are advancing fundamental research, while companies represent diverse segments of the value chain. Chinese firms such as Zhuhai Sailner Technology and Shenzhen Creality are developing specialized printing technologies, while global corporations like Intel and Sony are exploring integration opportunities. The competitive landscape shows regional clusters in China's eastern seaboard and international collaboration patterns, with patent activity suggesting the technology is transitioning from early-stage research toward commercial viability.

Carl Zeiss Industrielle Messtechnik GmbH

Technical Solution: Carl Zeiss has developed advanced volumetric 3D printing technology leveraging their expertise in optical systems. Their approach utilizes multi-beam stereolithography with precisely controlled optical paths to achieve exceptional resolution and accuracy in volumetric printing. The company's patents cover sophisticated optical arrangements that enable simultaneous curing at multiple focal points within a photosensitive resin. This technology employs computational holography techniques to generate complex interference patterns, allowing for the creation of intricate internal structures without support requirements. Zeiss's implementation includes proprietary calibration methods that compensate for optical aberrations and refractive index variations within the printing medium. Their system achieves sub-micron precision for applications in microfluidics, optical components, and biomedical devices, representing a significant advancement in high-precision volumetric fabrication capabilities for specialized industrial applications.

Strengths: Exceptional precision and resolution capabilities; ability to create complex internal geometries; leverages Zeiss's extensive optical expertise. Weaknesses: Limited to relatively small build volumes; requires specialized and expensive optical components; primarily suitable for high-value, precision applications rather than general manufacturing.

Intel Corp.

Technical Solution: Intel has developed volumetric 3D printing technology focused on semiconductor and electronics applications. Their approach utilizes a hybrid system combining directed energy deposition with holographic projection techniques to achieve multi-material printing capabilities at micro and nano scales. Intel's patents cover novel methods for precise deposition of conductive, semiconductive, and insulating materials within a single volumetric printing process. The technology employs sophisticated real-time feedback systems using interferometry to monitor and adjust the printing process at nanometer scales. Their implementation includes proprietary algorithms for calculating optimal energy distribution patterns and specialized material formulations compatible with semiconductor manufacturing requirements. Intel's system achieves sub-micron resolution while enabling the creation of complex 3D electronic components with embedded functionality, representing a significant advancement in additive manufacturing for electronics applications.

Strengths: Multi-material capability critical for electronic components; integration with existing semiconductor manufacturing processes; exceptional precision at micro/nano scales. Weaknesses: Extremely specialized application focus; requires highly controlled manufacturing environments; significant technical complexity limiting accessibility to specialized facilities.

Key Patent Analysis and Technical Breakthroughs

Method and apparatus for volumetric additive manufacturing of cell-loaded resins

PatentPendingUS20220274326A1

Innovation

- The method involves adjusting the refractive index of the photoresponsive material to match that of the scattering particles and using a light source emitting wavelengths longer than 630 nm, such as between 630 nm to 1000 nm, to reduce light scattering and improve the accuracy of three-dimensional object formation by creating a controlled three-dimensional dose distribution.

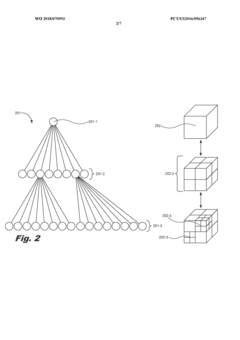

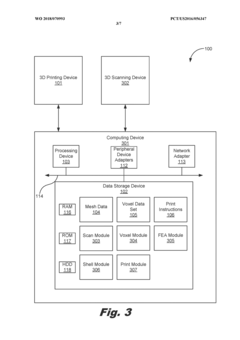

Generating data for a three-dimensional (3D) printable object

PatentWO2018070993A1

Innovation

- A computer program product converts mesh data into volumetric voxel data sets organized as N-ary trees, which are then used to generate truss structures for 3D printing, optimizing material usage by assigning scalar values and performing finite element analysis to adjust voxel sizes and properties, and generating shell structures to reduce material thickness.

IP Strategy and Patent Portfolio Management

In the rapidly evolving landscape of volumetric 3D printing technology, strategic intellectual property management has become a critical factor for companies seeking competitive advantage. Effective IP strategy requires a comprehensive understanding of the patent landscape, identification of white spaces, and development of defensive and offensive patent portfolios.

Patent portfolio management for volumetric 3D printing should focus on protecting core technologies while maintaining flexibility for future innovations. Companies must balance between broad claims that cover fundamental principles and specific claims that address unique implementation details. This dual approach ensures both wide protection and defensibility against prior art challenges.

Cross-licensing opportunities represent a significant strategic consideration in this field. As volumetric 3D printing involves multiple technological domains including optics, materials science, and software control systems, companies rarely possess all necessary IP internally. Strategic partnerships through cross-licensing agreements can provide access to complementary technologies while reducing litigation risks.

Freedom-to-operate (FTO) analysis is particularly important given the complex patent landscape. Regular FTO assessments help identify potential infringement risks before significant R&D investments are made. Companies should establish systematic processes for monitoring new patent publications in adjacent technical fields that might impact volumetric printing operations.

Geographic considerations play a crucial role in patent strategy. While the United States, Europe, and Japan have historically dominated volumetric 3D printing patents, China has emerged as a rapidly growing force in this space. Companies should tailor their filing strategies to prioritize jurisdictions based on manufacturing locations, key markets, and competitor presence.

Patent quality metrics should be established to evaluate portfolio strength beyond mere quantity. These metrics might include citation rates, claim scope analysis, and alignment with product roadmaps. High-quality patents that protect commercially valuable implementations should be prioritized over numerous narrow patents with limited commercial relevance.

Defensive publication strategies can complement traditional patenting approaches. For non-core innovations or incremental improvements that may not warrant full patent protection, defensive publications can prevent competitors from obtaining patents while preserving the company's freedom to operate. This hybrid approach optimizes IP investment while maintaining competitive positioning in the volumetric 3D printing ecosystem.

Patent portfolio management for volumetric 3D printing should focus on protecting core technologies while maintaining flexibility for future innovations. Companies must balance between broad claims that cover fundamental principles and specific claims that address unique implementation details. This dual approach ensures both wide protection and defensibility against prior art challenges.

Cross-licensing opportunities represent a significant strategic consideration in this field. As volumetric 3D printing involves multiple technological domains including optics, materials science, and software control systems, companies rarely possess all necessary IP internally. Strategic partnerships through cross-licensing agreements can provide access to complementary technologies while reducing litigation risks.

Freedom-to-operate (FTO) analysis is particularly important given the complex patent landscape. Regular FTO assessments help identify potential infringement risks before significant R&D investments are made. Companies should establish systematic processes for monitoring new patent publications in adjacent technical fields that might impact volumetric printing operations.

Geographic considerations play a crucial role in patent strategy. While the United States, Europe, and Japan have historically dominated volumetric 3D printing patents, China has emerged as a rapidly growing force in this space. Companies should tailor their filing strategies to prioritize jurisdictions based on manufacturing locations, key markets, and competitor presence.

Patent quality metrics should be established to evaluate portfolio strength beyond mere quantity. These metrics might include citation rates, claim scope analysis, and alignment with product roadmaps. High-quality patents that protect commercially valuable implementations should be prioritized over numerous narrow patents with limited commercial relevance.

Defensive publication strategies can complement traditional patenting approaches. For non-core innovations or incremental improvements that may not warrant full patent protection, defensive publications can prevent competitors from obtaining patents while preserving the company's freedom to operate. This hybrid approach optimizes IP investment while maintaining competitive positioning in the volumetric 3D printing ecosystem.

Cross-Industry Applications and Material Compatibility

Volumetric 3D printing technology has demonstrated remarkable versatility across multiple industries, with applications extending far beyond traditional manufacturing sectors. In healthcare, this technology enables the production of patient-specific implants, anatomical models for surgical planning, and even bioprinted tissues with complex internal structures. The ability to create gradient material properties within a single print has revolutionized medical device manufacturing, allowing for implants that better mimic natural tissue transitions.

The aerospace and automotive industries have embraced volumetric 3D printing for lightweight component production, where complex internal lattice structures can be created without the layer-by-layer limitations of conventional additive manufacturing. This has resulted in significant weight reduction while maintaining structural integrity, directly translating to fuel efficiency improvements and reduced environmental impact.

Consumer electronics manufacturers have begun exploring volumetric printing for creating embedded electronics and multi-material housings in a single manufacturing step. This consolidation of parts reduces assembly requirements and creates opportunities for novel form factors previously impossible to manufacture.

Material compatibility represents both a significant challenge and opportunity in volumetric 3D printing. Current systems predominantly work with photopolymer resins that can be selectively cured through light-based processes. Recent patent activity shows increasing focus on expanding material options, with innovations in ceramic-loaded resins, conductive materials, and temperature-resistant polymers. Multi-material compatibility within a single print volume remains a frontier area with substantial patent activity.

The material-process relationship in volumetric printing differs fundamentally from traditional 3D printing methods. Patents reveal growing interest in developing specialized formulations that respond optimally to specific volumetric printing techniques, whether tomographic, holographic, or computed axial lithography. These materials must balance rapid curing characteristics with optical properties that allow light penetration throughout the entire volume.

Biocompatible materials represent a particularly active area of innovation, with patents covering hydrogel formulations that maintain cell viability during the printing process. These developments are enabling direct printing of tissue-like structures with embedded vasculature and functional gradients that more closely approximate natural biological systems.

The aerospace and automotive industries have embraced volumetric 3D printing for lightweight component production, where complex internal lattice structures can be created without the layer-by-layer limitations of conventional additive manufacturing. This has resulted in significant weight reduction while maintaining structural integrity, directly translating to fuel efficiency improvements and reduced environmental impact.

Consumer electronics manufacturers have begun exploring volumetric printing for creating embedded electronics and multi-material housings in a single manufacturing step. This consolidation of parts reduces assembly requirements and creates opportunities for novel form factors previously impossible to manufacture.

Material compatibility represents both a significant challenge and opportunity in volumetric 3D printing. Current systems predominantly work with photopolymer resins that can be selectively cured through light-based processes. Recent patent activity shows increasing focus on expanding material options, with innovations in ceramic-loaded resins, conductive materials, and temperature-resistant polymers. Multi-material compatibility within a single print volume remains a frontier area with substantial patent activity.

The material-process relationship in volumetric printing differs fundamentally from traditional 3D printing methods. Patents reveal growing interest in developing specialized formulations that respond optimally to specific volumetric printing techniques, whether tomographic, holographic, or computed axial lithography. These materials must balance rapid curing characteristics with optical properties that allow light penetration throughout the entire volume.

Biocompatible materials represent a particularly active area of innovation, with patents covering hydrogel formulations that maintain cell viability during the printing process. These developments are enabling direct printing of tissue-like structures with embedded vasculature and functional gradients that more closely approximate natural biological systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!