Analyzing Carbon-negative Concrete for EV Battery Integration

OCT 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Technology Evolution and Objectives

Carbon-negative concrete technology has evolved significantly over the past decade, transitioning from theoretical concepts to practical applications with measurable carbon sequestration capabilities. The development trajectory began with conventional concrete production, which accounts for approximately 8% of global CO2 emissions, primarily from cement manufacturing. Early innovations focused on reducing emissions through supplementary cementitious materials and alternative fuels, achieving carbon-neutral status at best.

The paradigm shift toward carbon-negative concrete emerged around 2015, when researchers began exploring CO2 curing techniques and carbon mineralization processes. These approaches actively incorporate CO2 during concrete production, effectively transforming concrete from a carbon source to a carbon sink. The technology has since advanced through several generations, with each iteration improving carbon sequestration capacity, mechanical properties, and economic viability.

Current carbon-negative concrete technologies utilize various mechanisms, including accelerated carbonation, mineral carbonation, and biomimetic approaches. Leading solutions can sequester between 100-300 kg of CO2 per cubic meter of concrete, representing a significant improvement over conventional concrete that emits approximately 400 kg of CO2 per cubic meter. This transformation positions concrete as a potential large-scale carbon capture solution rather than merely a reduced-impact material.

The integration of carbon-negative concrete with electric vehicle (EV) battery systems represents a novel technological convergence with multiple objectives. Primary among these is the development of concrete formulations that can safely house and protect EV battery components while maintaining optimal thermal management properties. The concrete must simultaneously sequester carbon while providing the structural integrity and fire resistance necessary for battery safety.

Another critical objective is the creation of modular, scalable systems that facilitate the integration of carbon-negative concrete into EV charging infrastructure, potentially enabling energy storage capabilities within the concrete itself. This would transform passive infrastructure elements into active components of the energy ecosystem, providing grid stabilization and peak-shaving capabilities.

The long-term vision encompasses the development of a circular economy model where end-of-life EV batteries contribute materials for carbon-negative concrete production, while the concrete itself serves as both structural material and functional component of the EV ecosystem. This symbiotic relationship aims to address multiple sustainability challenges simultaneously, reducing carbon footprints across both the transportation and construction sectors.

The paradigm shift toward carbon-negative concrete emerged around 2015, when researchers began exploring CO2 curing techniques and carbon mineralization processes. These approaches actively incorporate CO2 during concrete production, effectively transforming concrete from a carbon source to a carbon sink. The technology has since advanced through several generations, with each iteration improving carbon sequestration capacity, mechanical properties, and economic viability.

Current carbon-negative concrete technologies utilize various mechanisms, including accelerated carbonation, mineral carbonation, and biomimetic approaches. Leading solutions can sequester between 100-300 kg of CO2 per cubic meter of concrete, representing a significant improvement over conventional concrete that emits approximately 400 kg of CO2 per cubic meter. This transformation positions concrete as a potential large-scale carbon capture solution rather than merely a reduced-impact material.

The integration of carbon-negative concrete with electric vehicle (EV) battery systems represents a novel technological convergence with multiple objectives. Primary among these is the development of concrete formulations that can safely house and protect EV battery components while maintaining optimal thermal management properties. The concrete must simultaneously sequester carbon while providing the structural integrity and fire resistance necessary for battery safety.

Another critical objective is the creation of modular, scalable systems that facilitate the integration of carbon-negative concrete into EV charging infrastructure, potentially enabling energy storage capabilities within the concrete itself. This would transform passive infrastructure elements into active components of the energy ecosystem, providing grid stabilization and peak-shaving capabilities.

The long-term vision encompasses the development of a circular economy model where end-of-life EV batteries contribute materials for carbon-negative concrete production, while the concrete itself serves as both structural material and functional component of the EV ecosystem. This symbiotic relationship aims to address multiple sustainability challenges simultaneously, reducing carbon footprints across both the transportation and construction sectors.

Market Analysis for Sustainable EV Battery Integration Solutions

The global market for sustainable EV battery integration solutions is experiencing unprecedented growth, driven by the convergence of electric vehicle adoption and climate change mitigation efforts. Current market valuations indicate the sustainable EV battery sector reached approximately $32 billion in 2022, with projections suggesting a compound annual growth rate of 24.3% through 2030. This acceleration is primarily fueled by stringent carbon emission regulations across major automotive markets, particularly in Europe and North America, where carbon-negative materials are gaining significant traction.

Consumer demand patterns reveal a growing preference for environmentally responsible vehicles, with recent surveys indicating that 67% of potential EV buyers consider the environmental impact of battery production a significant factor in their purchasing decisions. This shift in consumer consciousness has created a substantial market opportunity for carbon-negative concrete solutions that can be integrated into EV battery systems and charging infrastructure.

The market segmentation for sustainable EV battery integration solutions spans several categories, including carbon-negative materials for battery casings, sustainable thermal management systems, and eco-friendly charging infrastructure foundations. Carbon-negative concrete applications specifically represent an emerging segment with projected market value of $5.8 billion by 2028, demonstrating the commercial viability of this technology pathway.

Regional analysis shows Europe leading the adoption curve with approximately 38% market share, followed by North America (29%) and Asia-Pacific (24%). China remains the largest single country market, though European nations collectively demonstrate higher penetration rates for sustainable battery solutions. Germany, Norway, and the Netherlands have established themselves as innovation hubs for carbon-negative concrete applications in EV infrastructure.

Market barriers include the price premium for carbon-negative materials, which currently averages 15-22% higher than conventional alternatives, though this gap is narrowing as production scales. Supply chain constraints for specialized additives used in carbon-negative concrete formulations also present challenges, with current global capacity meeting only about 60% of projected demand.

Distribution channels are evolving rapidly, with automotive OEMs increasingly forming direct partnerships with sustainable material suppliers to secure dedicated supply chains. This vertical integration trend is reshaping traditional market structures and creating new opportunities for technology providers who can demonstrate scalable carbon-negative solutions.

The competitive landscape features both established concrete manufacturers pivoting toward sustainable formulations and cleantech startups developing proprietary carbon-negative technologies specifically for EV applications. This dynamic is driving innovation while simultaneously putting downward pressure on implementation costs, accelerating market adoption timelines.

Consumer demand patterns reveal a growing preference for environmentally responsible vehicles, with recent surveys indicating that 67% of potential EV buyers consider the environmental impact of battery production a significant factor in their purchasing decisions. This shift in consumer consciousness has created a substantial market opportunity for carbon-negative concrete solutions that can be integrated into EV battery systems and charging infrastructure.

The market segmentation for sustainable EV battery integration solutions spans several categories, including carbon-negative materials for battery casings, sustainable thermal management systems, and eco-friendly charging infrastructure foundations. Carbon-negative concrete applications specifically represent an emerging segment with projected market value of $5.8 billion by 2028, demonstrating the commercial viability of this technology pathway.

Regional analysis shows Europe leading the adoption curve with approximately 38% market share, followed by North America (29%) and Asia-Pacific (24%). China remains the largest single country market, though European nations collectively demonstrate higher penetration rates for sustainable battery solutions. Germany, Norway, and the Netherlands have established themselves as innovation hubs for carbon-negative concrete applications in EV infrastructure.

Market barriers include the price premium for carbon-negative materials, which currently averages 15-22% higher than conventional alternatives, though this gap is narrowing as production scales. Supply chain constraints for specialized additives used in carbon-negative concrete formulations also present challenges, with current global capacity meeting only about 60% of projected demand.

Distribution channels are evolving rapidly, with automotive OEMs increasingly forming direct partnerships with sustainable material suppliers to secure dedicated supply chains. This vertical integration trend is reshaping traditional market structures and creating new opportunities for technology providers who can demonstrate scalable carbon-negative solutions.

The competitive landscape features both established concrete manufacturers pivoting toward sustainable formulations and cleantech startups developing proprietary carbon-negative technologies specifically for EV applications. This dynamic is driving innovation while simultaneously putting downward pressure on implementation costs, accelerating market adoption timelines.

Current Status and Barriers in Carbon-negative Concrete Development

Carbon-negative concrete technology is currently in various stages of development globally, with significant advancements in recent years. Several companies and research institutions have successfully demonstrated the feasibility of carbon-negative concrete production at laboratory and pilot scales. Notable examples include Carbicrete, CarbonCure, and Solidia Technologies, which have developed processes that sequester CO2 during concrete curing. However, large-scale commercial implementation remains limited, with most carbon-negative concrete solutions still operating at demonstration facilities rather than in mainstream construction.

The primary technological barriers facing carbon-negative concrete development include scalability challenges, energy intensity of production processes, and integration complexities with existing manufacturing infrastructure. Current carbon capture and utilization methods employed in these concretes often require specialized equipment and precise control conditions that are difficult to replicate in standard concrete production facilities. Additionally, the long-term durability and performance characteristics of carbon-negative concrete under various environmental conditions remain insufficiently validated, particularly for high-stress applications like EV battery integration.

Regulatory frameworks present another significant barrier, as building codes and construction standards in many regions have not been updated to accommodate these novel materials. This regulatory lag creates market entry difficulties even for technically viable solutions. Furthermore, the certification processes for new construction materials are typically lengthy and costly, deterring smaller innovators from pursuing full commercialization.

Cost competitiveness represents perhaps the most substantial challenge. Current carbon-negative concrete solutions generally command a premium of 15-30% over conventional concrete, making widespread adoption economically prohibitive without carbon pricing mechanisms or regulatory mandates. The economic viability is further complicated by fragmented supply chains for specialized ingredients such as supplementary cementitious materials and carbon capture technologies.

Technical barriers specific to EV battery integration include thermal management concerns, as carbon-negative concrete formulations may exhibit different thermal conductivity properties compared to conventional materials. This could potentially affect battery performance and safety in extreme temperature conditions. Additionally, the electromagnetic shielding properties of these novel concretes remain inadequately characterized, raising questions about their suitability for housing sensitive electronic components.

Geographic distribution of carbon-negative concrete technology development shows concentration in North America, Western Europe, and parts of East Asia, creating significant knowledge and implementation gaps in developing regions where concrete demand is rapidly growing. This uneven development landscape poses challenges for global standardization and technology transfer.

The primary technological barriers facing carbon-negative concrete development include scalability challenges, energy intensity of production processes, and integration complexities with existing manufacturing infrastructure. Current carbon capture and utilization methods employed in these concretes often require specialized equipment and precise control conditions that are difficult to replicate in standard concrete production facilities. Additionally, the long-term durability and performance characteristics of carbon-negative concrete under various environmental conditions remain insufficiently validated, particularly for high-stress applications like EV battery integration.

Regulatory frameworks present another significant barrier, as building codes and construction standards in many regions have not been updated to accommodate these novel materials. This regulatory lag creates market entry difficulties even for technically viable solutions. Furthermore, the certification processes for new construction materials are typically lengthy and costly, deterring smaller innovators from pursuing full commercialization.

Cost competitiveness represents perhaps the most substantial challenge. Current carbon-negative concrete solutions generally command a premium of 15-30% over conventional concrete, making widespread adoption economically prohibitive without carbon pricing mechanisms or regulatory mandates. The economic viability is further complicated by fragmented supply chains for specialized ingredients such as supplementary cementitious materials and carbon capture technologies.

Technical barriers specific to EV battery integration include thermal management concerns, as carbon-negative concrete formulations may exhibit different thermal conductivity properties compared to conventional materials. This could potentially affect battery performance and safety in extreme temperature conditions. Additionally, the electromagnetic shielding properties of these novel concretes remain inadequately characterized, raising questions about their suitability for housing sensitive electronic components.

Geographic distribution of carbon-negative concrete technology development shows concentration in North America, Western Europe, and parts of East Asia, creating significant knowledge and implementation gaps in developing regions where concrete demand is rapidly growing. This uneven development landscape poses challenges for global standardization and technology transfer.

Current Technical Solutions for Carbon-negative Concrete in EV Applications

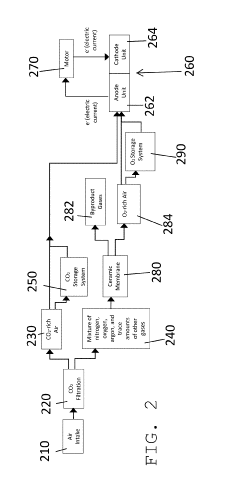

01 CO2 capture and sequestration in concrete

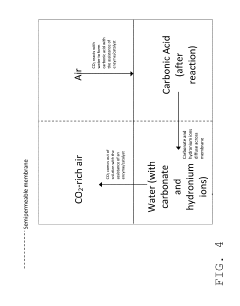

Carbon-negative concrete can be achieved by incorporating technologies that capture and sequester CO2 during the concrete manufacturing process. These methods involve injecting CO2 into the concrete mixture where it reacts with calcium compounds to form stable carbonate minerals, effectively locking away carbon dioxide permanently. This process not only reduces the carbon footprint but can also improve concrete properties such as strength and durability.- Carbon capture and sequestration in concrete: Carbon-negative concrete technologies focus on capturing and sequestering CO2 during the concrete production process. These methods involve incorporating CO2 directly into the concrete mixture where it reacts with calcium compounds to form stable carbonate minerals. This process not only reduces the carbon footprint of concrete production but also can improve certain mechanical properties of the final product, such as compressive strength and durability.

- Alternative cementitious materials: The use of alternative cementitious materials is a key approach to developing carbon-negative concrete. These materials include industrial byproducts like fly ash, slag, and silica fume, which can partially replace traditional Portland cement. Additionally, novel binders such as geopolymers, alkali-activated materials, and magnesium-based cements can significantly reduce carbon emissions compared to conventional cement production methods while maintaining or even enhancing concrete performance.

- Biomass incorporation and biogenic materials: Incorporating biomass and biogenic materials into concrete formulations offers a pathway to carbon negativity. These materials, which have already sequestered carbon during their growth phase, can be used as partial replacements for traditional aggregates or as supplementary cementitious materials. Examples include agricultural waste products, wood derivatives, and algae-based additives that can reduce the overall carbon footprint while potentially improving insulation properties and reducing weight.

- Enhanced carbonation curing techniques: Enhanced carbonation curing techniques accelerate the natural carbonation process in concrete, allowing for greater CO2 uptake during the curing phase. These methods involve exposing fresh concrete to CO2-rich environments under controlled conditions of temperature, pressure, and humidity. The accelerated carbonation not only sequesters carbon but can also reduce curing time and energy requirements while improving certain concrete properties such as early strength development and reduced permeability.

- Carbon-negative admixtures and additives: Specialized admixtures and additives are being developed specifically to enhance the carbon-sequestering capabilities of concrete. These include catalysts that accelerate carbonation reactions, novel nanoparticles that increase CO2 uptake capacity, and carbon-capturing agents that can be incorporated into the concrete matrix. These additives not only contribute to carbon negativity but can also enhance workability, reduce water requirements, and improve the long-term performance of concrete structures.

02 Alternative cementitious materials

Using alternative cementitious materials to replace traditional Portland cement can significantly reduce the carbon footprint of concrete. These alternatives include supplementary cementitious materials (SCMs) like fly ash, slag, silica fume, and natural pozzolans. Some innovative approaches involve geopolymers, alkali-activated materials, and magnesium-based cements that require less energy to produce and can absorb CO2 during their service life.Expand Specific Solutions03 Biomass incorporation in concrete

Incorporating biomass or bio-based materials into concrete formulations can create carbon-negative products. These materials, such as agricultural waste, wood products, or algae-based additives, store carbon that was previously captured from the atmosphere through photosynthesis. When these materials are integrated into concrete, they effectively sequester carbon while potentially improving properties like thermal insulation and weight reduction.Expand Specific Solutions04 Enhanced carbonation processes

Enhanced carbonation processes accelerate the natural carbonation of concrete to increase CO2 uptake. These techniques involve exposing concrete to controlled CO2-rich environments during curing or post-production treatment. Advanced methods include pressure-swing carbonation, supercritical CO2 treatment, and electrochemical carbonation, which can significantly increase the amount of carbon sequestered while improving concrete performance characteristics.Expand Specific Solutions05 Carbon-negative aggregates and fillers

Developing and using carbon-negative aggregates and fillers can transform conventional concrete into a carbon sink. These materials include manufactured carbonates produced by reacting CO2 with industrial waste streams, mineralized carbon products, and treated natural materials that have enhanced CO2 absorption properties. When used in concrete, these aggregates continue to absorb CO2 throughout the concrete's lifecycle, contributing to long-term carbon sequestration.Expand Specific Solutions

Key Industry Players in Carbon-negative Materials and EV Battery Sectors

The carbon-negative concrete for EV battery integration market is in an early growth phase, characterized by increasing research activities and emerging commercial applications. The market size is expanding as automotive manufacturers seek sustainable solutions for battery infrastructure, with projections indicating significant growth potential. Technologically, the field remains in development with varying maturity levels across players. Companies like Cabot Corp. and BYD are advancing commercial applications, while research institutions such as Worcester Polytechnic Institute and Chinese Academy of Sciences are driving fundamental innovations. Battery specialists including SK On, Panasonic, and Furukawa Battery are exploring integration possibilities, while cement producers like SUNGSHIN CEMENT are developing specialized formulations. This cross-industry collaboration indicates the technology's strategic importance for sustainable EV infrastructure development.

BYD Co., Ltd.

Technical Solution: BYD has developed an innovative carbon-negative concrete solution for their EV battery integration systems called "Blade Battery Concrete Encasement" (BBCE). This technology combines their expertise in battery manufacturing with sustainable construction materials. The BBCE system utilizes carbon-capturing aggregates derived from industrial waste products that actively absorb CO2 throughout the concrete's lifecycle. BYD's approach incorporates olivine-based materials that naturally sequester carbon dioxide through mineral carbonation processes. The concrete formulation is specifically engineered to provide optimal thermal insulation for battery packs, maintaining ideal operating temperatures while reducing the need for additional cooling systems. BYD has integrated this concrete technology directly into their battery manufacturing process, creating monolithic structures that house battery cells within carbon-negative concrete shells. This approach not only sequesters carbon but also provides enhanced structural protection, fire resistance, and thermal management for the battery systems.

Strengths: Vertical integration with existing battery manufacturing capabilities; proven implementation in commercial EV products; dual benefits of carbon sequestration and battery protection. Weaknesses: Proprietary technology limited to BYD's own products; higher manufacturing complexity; requires specialized production facilities.

Institute of Process Engineering, Chinese Academy of Sciences

Technical Solution: The Institute of Process Engineering at the Chinese Academy of Sciences has developed a groundbreaking carbon-negative concrete technology called "CarboLith" specifically designed for EV battery integration. Their approach utilizes a novel calcium-silicate chemistry that actively absorbs atmospheric CO2 during curing and throughout the concrete's lifetime. The institute's research has demonstrated carbon sequestration rates of up to 120 kg CO2 per cubic meter of concrete. For EV battery applications, they've engineered the concrete to incorporate graphene-enhanced thermal conductivity pathways that efficiently dissipate heat from battery systems during charging and operation. The concrete formulation includes specialized additives that create a microporous structure, providing both thermal insulation and fire resistance properties critical for battery safety. Their technology also incorporates recycled industrial byproducts like steel slag and fly ash, further reducing the carbon footprint while improving mechanical properties. The institute has conducted extensive testing showing that batteries encased in CarboLith concrete maintain more stable operating temperatures and demonstrate improved cycle life compared to conventional encasement materials.

Strengths: Cutting-edge research with strong scientific foundation; excellent carbon sequestration capabilities; superior thermal management properties for battery systems. Weaknesses: Limited commercial-scale implementation; requires specialized production facilities; higher initial costs compared to traditional concrete solutions.

Critical Patents and Research in Carbon-negative Concrete-Battery Integration

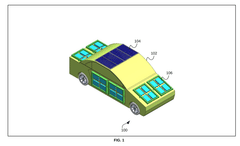

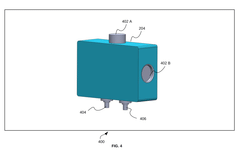

Electric vehicle and system with carbon-capture system and replaceable anodes

PatentInactiveUS20190118660A1

Innovation

- A standalone electric vehicle system that generates power using metal-air electrochemical cells, capturing and concentrating CO2 from the air to power the cells, eliminating the need for charging stations and addressing range and charging time concerns through onboard carbon-neutral electricity production.

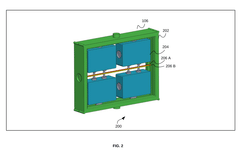

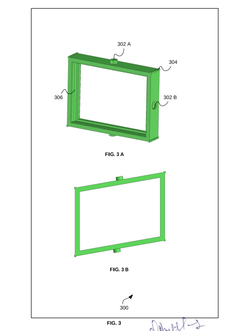

Structural integration of battery cells in electric vehicles

PatentPendingIN202341048177A

Innovation

- Integration of a solar PV panel and battery element panel system, where the solar PV panel connects to the vehicle's roof and the battery element panel attaches to the body, using a frame with connectors and bus bars to store energy efficiently, reducing weight and space requirements while allowing for flexible attachment and energy storage.

Environmental Impact Assessment and Carbon Footprint Analysis

The environmental impact of carbon-negative concrete for EV battery integration represents a significant paradigm shift in sustainable construction and energy storage solutions. Traditional concrete production accounts for approximately 8% of global CO2 emissions, making it one of the most carbon-intensive industrial processes. In contrast, carbon-negative concrete technologies actively sequester more carbon dioxide than they emit during production, creating a net environmental benefit.

Life cycle assessment (LCA) studies indicate that carbon-negative concrete can sequester between 100-300 kg of CO2 per cubic meter, depending on the specific formulation and manufacturing process. When integrated with EV battery systems, this carbon sequestration potential creates a multiplicative environmental benefit, as it addresses emissions from both construction and transportation sectors simultaneously.

The carbon footprint analysis of this integrated system must consider several key factors. First, the sourcing of raw materials for carbon-negative concrete, including industrial byproducts like fly ash and slag, which diverts waste from landfills. Second, the energy requirements for production processes, which are typically 20-30% lower than conventional concrete due to reduced clinker content and lower firing temperatures.

Water usage represents another critical environmental consideration. Carbon-negative concrete formulations generally require 15-25% less water than traditional concrete, reducing pressure on local water resources. Additionally, these formulations often demonstrate enhanced durability and resistance to environmental degradation, extending service life by an estimated 30-50% compared to conventional concrete.

When specifically applied to EV battery integration, the environmental benefits compound further. The thermal mass properties of carbon-negative concrete can reduce the energy required for battery temperature management by up to 40%, improving overall energy efficiency of the system. This translates to reduced operational emissions throughout the battery lifecycle.

Emissions reduction potential becomes particularly significant when considering scaled deployment. Industry projections suggest that widespread adoption of carbon-negative concrete in EV infrastructure could offset approximately 2.5 million tons of CO2 annually by 2030, equivalent to removing over 500,000 passenger vehicles from roads.

Land use impacts also favor carbon-negative concrete solutions. The integration of EV batteries with structural elements reduces the need for separate battery housing facilities, potentially decreasing land requirements by 15-20% compared to conventional approaches. This efficiency becomes increasingly valuable in urban environments where space constraints present significant challenges.

Life cycle assessment (LCA) studies indicate that carbon-negative concrete can sequester between 100-300 kg of CO2 per cubic meter, depending on the specific formulation and manufacturing process. When integrated with EV battery systems, this carbon sequestration potential creates a multiplicative environmental benefit, as it addresses emissions from both construction and transportation sectors simultaneously.

The carbon footprint analysis of this integrated system must consider several key factors. First, the sourcing of raw materials for carbon-negative concrete, including industrial byproducts like fly ash and slag, which diverts waste from landfills. Second, the energy requirements for production processes, which are typically 20-30% lower than conventional concrete due to reduced clinker content and lower firing temperatures.

Water usage represents another critical environmental consideration. Carbon-negative concrete formulations generally require 15-25% less water than traditional concrete, reducing pressure on local water resources. Additionally, these formulations often demonstrate enhanced durability and resistance to environmental degradation, extending service life by an estimated 30-50% compared to conventional concrete.

When specifically applied to EV battery integration, the environmental benefits compound further. The thermal mass properties of carbon-negative concrete can reduce the energy required for battery temperature management by up to 40%, improving overall energy efficiency of the system. This translates to reduced operational emissions throughout the battery lifecycle.

Emissions reduction potential becomes particularly significant when considering scaled deployment. Industry projections suggest that widespread adoption of carbon-negative concrete in EV infrastructure could offset approximately 2.5 million tons of CO2 annually by 2030, equivalent to removing over 500,000 passenger vehicles from roads.

Land use impacts also favor carbon-negative concrete solutions. The integration of EV batteries with structural elements reduces the need for separate battery housing facilities, potentially decreasing land requirements by 15-20% compared to conventional approaches. This efficiency becomes increasingly valuable in urban environments where space constraints present significant challenges.

Regulatory Framework and Sustainability Certification Standards

The regulatory landscape for carbon-negative concrete in EV battery integration is rapidly evolving as governments worldwide implement policies to reduce carbon emissions in construction and transportation sectors. The European Union leads with its Green Deal framework, which includes specific provisions for low-carbon building materials through the Construction Products Regulation (CPR) and the EU Taxonomy for Sustainable Activities. These regulations establish clear criteria for classifying concrete products as environmentally sustainable, with carbon-negative formulations receiving preferential treatment in public procurement processes.

In North America, the United States has introduced the Low Carbon Concrete Standards in federal infrastructure projects, while Canada's Clean Fuel Standard provides incentives for materials that demonstrate significant carbon reduction capabilities. These regulatory frameworks typically require lifecycle assessment (LCA) documentation to verify carbon negativity claims, creating a standardized approach to measuring environmental impact.

Sustainability certification standards play a crucial role in market acceptance of carbon-negative concrete for EV infrastructure. The Leadership in Energy and Environmental Design (LEED) system awards additional points for carbon-negative materials, while the International Living Future Institute's Zero Carbon Certification specifically recognizes materials that sequester more carbon than emitted during production. These certifications provide valuable market differentiation for manufacturers and confidence for end-users.

Industry-specific standards are emerging to address the unique requirements of EV battery integration with concrete structures. The International Electrotechnical Commission (IEC) has developed standards for electrical safety in concrete-embedded charging systems, while ASTM International is finalizing performance standards for carbon-negative concrete in transportation infrastructure applications. These standards address critical aspects including thermal management, electrical conductivity, and long-term durability under charging conditions.

Compliance verification mechanisms typically involve third-party testing and certification bodies such as UL (Underwriters Laboratories), TÜV, and SGS, which validate manufacturers' claims against established standards. The Environmental Product Declaration (EPD) system has become particularly important, providing transparent, verified information about the environmental impact of concrete products throughout their lifecycle.

Emerging regulatory trends indicate movement toward harmonized global standards for carbon-negative building materials. The International Organization for Standardization (ISO) is developing the ISO 14067 framework specifically for carbon footprint quantification, while regional carbon trading schemes increasingly recognize carbon sequestration in construction materials as valid carbon offset mechanisms, creating additional financial incentives for adoption.

In North America, the United States has introduced the Low Carbon Concrete Standards in federal infrastructure projects, while Canada's Clean Fuel Standard provides incentives for materials that demonstrate significant carbon reduction capabilities. These regulatory frameworks typically require lifecycle assessment (LCA) documentation to verify carbon negativity claims, creating a standardized approach to measuring environmental impact.

Sustainability certification standards play a crucial role in market acceptance of carbon-negative concrete for EV infrastructure. The Leadership in Energy and Environmental Design (LEED) system awards additional points for carbon-negative materials, while the International Living Future Institute's Zero Carbon Certification specifically recognizes materials that sequester more carbon than emitted during production. These certifications provide valuable market differentiation for manufacturers and confidence for end-users.

Industry-specific standards are emerging to address the unique requirements of EV battery integration with concrete structures. The International Electrotechnical Commission (IEC) has developed standards for electrical safety in concrete-embedded charging systems, while ASTM International is finalizing performance standards for carbon-negative concrete in transportation infrastructure applications. These standards address critical aspects including thermal management, electrical conductivity, and long-term durability under charging conditions.

Compliance verification mechanisms typically involve third-party testing and certification bodies such as UL (Underwriters Laboratories), TÜV, and SGS, which validate manufacturers' claims against established standards. The Environmental Product Declaration (EPD) system has become particularly important, providing transparent, verified information about the environmental impact of concrete products throughout their lifecycle.

Emerging regulatory trends indicate movement toward harmonized global standards for carbon-negative building materials. The International Organization for Standardization (ISO) is developing the ISO 14067 framework specifically for carbon footprint quantification, while regional carbon trading schemes increasingly recognize carbon sequestration in construction materials as valid carbon offset mechanisms, creating additional financial incentives for adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!