Deciphering the Patents Behind Carbon-negative Concrete Technologies

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Technology Background and Objectives

Concrete, the most widely used construction material globally, has long been associated with significant carbon emissions, contributing approximately 8% of global CO2 emissions. Carbon-negative concrete technologies represent a paradigm shift in construction materials science, aiming not only to reduce the carbon footprint of concrete production but to transform concrete into a carbon sink that actively removes CO2 from the atmosphere throughout its lifecycle.

The evolution of concrete technology has progressed from traditional Portland cement-based formulations with high carbon footprints to low-carbon alternatives, and now to carbon-negative solutions. This technological progression has been driven by increasing environmental concerns, regulatory pressures, and the construction industry's commitment to sustainability goals aligned with global climate agreements.

Carbon-negative concrete technologies operate through several mechanisms: carbon capture during the manufacturing process, CO2 utilization as a curing agent, incorporation of carbon-sequestering materials, and the development of alternative binders that require less energy to produce while offering enhanced CO2 absorption capabilities. These approaches collectively represent a fundamental reimagining of one of humanity's oldest and most essential building materials.

The primary objective of carbon-negative concrete technology development is to create commercially viable construction materials that maintain or exceed the performance characteristics of traditional concrete while actively removing carbon dioxide from the atmosphere. This involves balancing technical performance, economic feasibility, regulatory compliance, and market acceptance.

Recent technological breakthroughs have accelerated development in this field, including advances in mineralization processes, novel binding agents derived from industrial byproducts, and innovative manufacturing techniques that incorporate CO2 as a reactant rather than a byproduct. These innovations have been documented in a growing patent landscape that reveals both the technical complexity and commercial potential of carbon-negative concrete solutions.

The trajectory of carbon-negative concrete technologies indicates a convergence of materials science, chemical engineering, and environmental technology, creating interdisciplinary approaches to concrete formulation. Patent activity in this space has increased exponentially over the past decade, with particular acceleration since 2015, reflecting growing investment and research interest.

Looking forward, the technical goals for carbon-negative concrete include achieving carbon negativity while maintaining cost competitiveness with traditional concrete, ensuring durability across diverse environmental conditions, and developing scalable manufacturing processes that can be implemented globally. The ultimate aim is to transform concrete from an environmental liability into a climate solution that can be deployed at the massive scale required by global construction demands.

The evolution of concrete technology has progressed from traditional Portland cement-based formulations with high carbon footprints to low-carbon alternatives, and now to carbon-negative solutions. This technological progression has been driven by increasing environmental concerns, regulatory pressures, and the construction industry's commitment to sustainability goals aligned with global climate agreements.

Carbon-negative concrete technologies operate through several mechanisms: carbon capture during the manufacturing process, CO2 utilization as a curing agent, incorporation of carbon-sequestering materials, and the development of alternative binders that require less energy to produce while offering enhanced CO2 absorption capabilities. These approaches collectively represent a fundamental reimagining of one of humanity's oldest and most essential building materials.

The primary objective of carbon-negative concrete technology development is to create commercially viable construction materials that maintain or exceed the performance characteristics of traditional concrete while actively removing carbon dioxide from the atmosphere. This involves balancing technical performance, economic feasibility, regulatory compliance, and market acceptance.

Recent technological breakthroughs have accelerated development in this field, including advances in mineralization processes, novel binding agents derived from industrial byproducts, and innovative manufacturing techniques that incorporate CO2 as a reactant rather than a byproduct. These innovations have been documented in a growing patent landscape that reveals both the technical complexity and commercial potential of carbon-negative concrete solutions.

The trajectory of carbon-negative concrete technologies indicates a convergence of materials science, chemical engineering, and environmental technology, creating interdisciplinary approaches to concrete formulation. Patent activity in this space has increased exponentially over the past decade, with particular acceleration since 2015, reflecting growing investment and research interest.

Looking forward, the technical goals for carbon-negative concrete include achieving carbon negativity while maintaining cost competitiveness with traditional concrete, ensuring durability across diverse environmental conditions, and developing scalable manufacturing processes that can be implemented globally. The ultimate aim is to transform concrete from an environmental liability into a climate solution that can be deployed at the massive scale required by global construction demands.

Market Demand Analysis for Sustainable Construction Materials

The global construction industry is experiencing a significant shift towards sustainable materials, driven by increasing environmental concerns and regulatory pressures. The market for sustainable construction materials, particularly carbon-negative concrete technologies, has shown remarkable growth in recent years. According to recent market analyses, the global green concrete market was valued at approximately $26.2 billion in 2021 and is projected to reach $65.8 billion by 2030, growing at a CAGR of 10.7% during the forecast period.

This growth is primarily fueled by stringent environmental regulations aimed at reducing carbon emissions in the construction sector, which accounts for nearly 40% of global CO2 emissions. The European Union's Green Deal and similar initiatives worldwide have established ambitious targets for carbon neutrality, creating substantial demand for innovative construction materials that can help achieve these goals.

Carbon-negative concrete technologies represent a particularly promising segment within this market. Unlike traditional concrete production, which is responsible for approximately 8% of global CO2 emissions, carbon-negative concrete actually sequesters more carbon than it emits during production. This revolutionary approach has attracted significant attention from both public and private sectors seeking to reduce their carbon footprint.

Market research indicates that commercial buildings and infrastructure projects are the primary adopters of sustainable construction materials, with government-funded projects increasingly mandating their use. The residential sector is also showing growing interest, particularly in developed economies where environmental consciousness among homeowners is rising.

Geographically, North America and Europe currently lead the market for carbon-negative concrete, with the Asia-Pacific region expected to witness the fastest growth due to rapid urbanization and increasing environmental awareness. Countries like China, India, and Japan are implementing policies that favor sustainable construction practices, creating substantial market opportunities.

Key customer segments include government agencies, commercial developers, and large construction firms with sustainability commitments. These stakeholders are increasingly willing to pay premium prices for materials that offer verifiable carbon reduction benefits, especially when these materials can contribute to green building certifications such as LEED or BREEAM.

The market is also being driven by the financial sector's growing emphasis on ESG (Environmental, Social, and Governance) criteria in investment decisions. Construction projects utilizing carbon-negative technologies are increasingly attractive to investors seeking to reduce portfolio carbon exposure and align with global sustainability goals.

This growth is primarily fueled by stringent environmental regulations aimed at reducing carbon emissions in the construction sector, which accounts for nearly 40% of global CO2 emissions. The European Union's Green Deal and similar initiatives worldwide have established ambitious targets for carbon neutrality, creating substantial demand for innovative construction materials that can help achieve these goals.

Carbon-negative concrete technologies represent a particularly promising segment within this market. Unlike traditional concrete production, which is responsible for approximately 8% of global CO2 emissions, carbon-negative concrete actually sequesters more carbon than it emits during production. This revolutionary approach has attracted significant attention from both public and private sectors seeking to reduce their carbon footprint.

Market research indicates that commercial buildings and infrastructure projects are the primary adopters of sustainable construction materials, with government-funded projects increasingly mandating their use. The residential sector is also showing growing interest, particularly in developed economies where environmental consciousness among homeowners is rising.

Geographically, North America and Europe currently lead the market for carbon-negative concrete, with the Asia-Pacific region expected to witness the fastest growth due to rapid urbanization and increasing environmental awareness. Countries like China, India, and Japan are implementing policies that favor sustainable construction practices, creating substantial market opportunities.

Key customer segments include government agencies, commercial developers, and large construction firms with sustainability commitments. These stakeholders are increasingly willing to pay premium prices for materials that offer verifiable carbon reduction benefits, especially when these materials can contribute to green building certifications such as LEED or BREEAM.

The market is also being driven by the financial sector's growing emphasis on ESG (Environmental, Social, and Governance) criteria in investment decisions. Construction projects utilizing carbon-negative technologies are increasingly attractive to investors seeking to reduce portfolio carbon exposure and align with global sustainability goals.

Global Status and Challenges in Carbon-negative Concrete Development

Carbon-negative concrete technology has gained significant momentum globally, with research and development efforts concentrated in North America, Europe, and parts of Asia. The United States leads with substantial investments in startups and research institutions focusing on CO2 mineralization and alternative binding materials. European countries, particularly the UK, Germany, and Scandinavian nations, have established comprehensive regulatory frameworks promoting low-carbon construction materials, driving innovation in this sector.

In Asia, Japan and China are emerging as key players, with Japan focusing on advanced carbonation techniques and China scaling up production of supplementary cementitious materials. Australia has also made notable contributions through research on geopolymer concretes that utilize industrial waste products.

Despite these advancements, the global development of carbon-negative concrete faces significant challenges. Technical barriers include achieving consistent performance across varying environmental conditions and ensuring long-term durability comparable to traditional concrete. The carbon capture efficiency in current technologies remains suboptimal, with many solutions capturing only 10-30% of emissions generated during production.

Economic obstacles present another major hurdle. The production cost of carbon-negative concrete currently exceeds conventional concrete by 20-50%, creating market resistance. Limited infrastructure for carbon capture and utilization further complicates widespread implementation, while existing building codes and standards often fail to accommodate these innovative materials.

Regulatory frameworks vary significantly across regions, creating an inconsistent global landscape for development and adoption. Many countries lack specific standards for carbon-negative construction materials, hampering certification and market acceptance. Additionally, the life cycle assessment methodologies for these materials remain inconsistent, making it difficult to verify carbon-negative claims.

The knowledge gap between laboratory research and practical implementation represents another significant challenge. Many promising technologies demonstrate excellent performance in controlled environments but face scaling issues in real-world applications. The specialized expertise required for production and application is not widely available in the construction industry.

Geographic disparities in development are evident, with significant innovation concentrated in wealthy nations while developing countries with rapidly growing concrete demand have limited access to these technologies, potentially widening the global sustainability gap in construction practices.

In Asia, Japan and China are emerging as key players, with Japan focusing on advanced carbonation techniques and China scaling up production of supplementary cementitious materials. Australia has also made notable contributions through research on geopolymer concretes that utilize industrial waste products.

Despite these advancements, the global development of carbon-negative concrete faces significant challenges. Technical barriers include achieving consistent performance across varying environmental conditions and ensuring long-term durability comparable to traditional concrete. The carbon capture efficiency in current technologies remains suboptimal, with many solutions capturing only 10-30% of emissions generated during production.

Economic obstacles present another major hurdle. The production cost of carbon-negative concrete currently exceeds conventional concrete by 20-50%, creating market resistance. Limited infrastructure for carbon capture and utilization further complicates widespread implementation, while existing building codes and standards often fail to accommodate these innovative materials.

Regulatory frameworks vary significantly across regions, creating an inconsistent global landscape for development and adoption. Many countries lack specific standards for carbon-negative construction materials, hampering certification and market acceptance. Additionally, the life cycle assessment methodologies for these materials remain inconsistent, making it difficult to verify carbon-negative claims.

The knowledge gap between laboratory research and practical implementation represents another significant challenge. Many promising technologies demonstrate excellent performance in controlled environments but face scaling issues in real-world applications. The specialized expertise required for production and application is not widely available in the construction industry.

Geographic disparities in development are evident, with significant innovation concentrated in wealthy nations while developing countries with rapidly growing concrete demand have limited access to these technologies, potentially widening the global sustainability gap in construction practices.

Current Patent-protected Carbon-negative Concrete Solutions

01 CO2 capture and sequestration in concrete

Carbon-negative concrete technologies that focus on capturing and sequestering CO2 during the concrete manufacturing process. These methods involve injecting or incorporating CO2 into concrete mixtures, where it becomes permanently mineralized and locked away. This approach not only reduces the carbon footprint of concrete production but can actually make concrete a carbon sink, absorbing more CO2 than is emitted during its production.- CO2 capture and sequestration in concrete: Carbon-negative concrete technologies that focus on capturing and sequestering CO2 during the concrete manufacturing process. These methods involve injecting or incorporating CO2 into the concrete mixture, where it reacts with calcium compounds to form stable carbonate minerals. This process not only reduces the carbon footprint of concrete production but also can improve the strength and durability of the final product.

- Alternative cementitious materials: The use of alternative cementitious materials to replace traditional Portland cement, which is responsible for significant CO2 emissions. These alternatives include geopolymers, alkali-activated materials, and supplementary cementitious materials derived from industrial byproducts such as fly ash, slag, and silica fume. These materials can significantly reduce the carbon footprint of concrete while maintaining or even enhancing performance characteristics.

- Biomass incorporation in concrete: Technologies that incorporate biomass or bio-based materials into concrete formulations to achieve carbon negativity. These approaches utilize plant-derived materials that have sequestered CO2 during their growth phase. When incorporated into concrete, these materials can offset the carbon emissions associated with concrete production while potentially providing additional benefits such as improved insulation properties or reduced weight.

- Enhanced carbonation processes: Advanced carbonation processes that accelerate and optimize the natural carbonation of concrete. These technologies involve controlled exposure of concrete to CO2-rich environments under specific conditions of temperature, pressure, and humidity to maximize carbon uptake. Enhanced carbonation can be applied during curing or as a post-production treatment, turning concrete elements into effective carbon sinks throughout their lifecycle.

- Integrated carbon-negative concrete systems: Comprehensive systems that combine multiple carbon-negative approaches throughout the concrete lifecycle. These integrated solutions may include low-carbon raw material sourcing, energy-efficient production processes, carbon capture during manufacturing, and enhanced carbonation during service life. Such systems often incorporate digital monitoring and optimization technologies to maximize carbon sequestration potential and verify carbon credits or offsets.

02 Alternative cementitious materials

The use of alternative cementitious materials to replace traditional Portland cement, which is responsible for significant CO2 emissions. These alternatives include geopolymers, alkali-activated materials, and supplementary cementitious materials derived from industrial byproducts such as fly ash, slag, and silica fume. These materials can significantly reduce or even eliminate the carbon emissions associated with traditional cement production.Expand Specific Solutions03 Biomass incorporation in concrete

Technologies that incorporate biomass or bio-based materials into concrete formulations to create carbon-negative products. These approaches use plant-derived materials that have sequestered CO2 during their growth phase. When incorporated into concrete, these materials not only reduce the amount of traditional cement needed but also store the carbon that was captured by the plants, resulting in a net carbon-negative building material.Expand Specific Solutions04 Carbon mineralization processes

Advanced carbon mineralization processes that accelerate the natural carbonation of concrete. These technologies enhance the ability of concrete to absorb CO2 from the atmosphere throughout its lifecycle. By optimizing the concrete's composition and curing conditions, these processes maximize CO2 uptake, transforming concrete from a carbon source to a carbon sink. Some approaches also use waste materials as carbonation feedstock, further improving environmental benefits.Expand Specific Solutions05 Innovative production and curing methods

Novel production and curing methods that reduce energy consumption and carbon emissions in concrete manufacturing. These include low-temperature curing techniques, energy-efficient production processes, and the use of renewable energy sources in concrete production. Some technologies also incorporate special additives that improve concrete performance while reducing the carbon intensity of the material. These methods often combine multiple approaches to achieve carbon-negative outcomes.Expand Specific Solutions

Leading Companies and Research Institutions in Green Concrete

Carbon-negative concrete technology is currently in an early growth phase, with market size projected to expand significantly due to increasing environmental regulations and sustainability demands. The competitive landscape is characterized by a mix of established players and innovative startups developing proprietary solutions. Companies like CarbonCure Technologies and Solidia Technologies are leading with commercial-ready technologies that sequester CO2 in concrete, while traditional cement manufacturers such as Holcim and Shimizu Corporation are investing in R&D to adapt. Academic institutions including Worcester Polytechnic Institute and University of Michigan are contributing fundamental research. The technology is approaching commercial maturity with several players demonstrating viable carbon sequestration methods, though widespread adoption remains limited by cost considerations and industry conservatism.

CarbonCure Technologies, Inc.

Technical Solution: CarbonCure has developed a revolutionary carbon mineralization technology that injects captured CO2 into fresh concrete during mixing. Their patented system introduces CO2 in a controlled manner where it chemically converts into a mineral, calcium carbonate, becoming permanently embedded within the concrete. This mineralization process not only sequesters CO2 but also improves the concrete's compressive strength, allowing for cement reduction while maintaining performance standards. The technology requires minimal changes to existing concrete production facilities, utilizing a retrofit approach with specialized injection equipment and CO2 storage tanks. CarbonCure's solution creates a circular carbon economy by sourcing CO2 from industrial emitters and permanently sequestering it in concrete infrastructure, with each cubic yard of concrete typically sequestering 25-40 pounds of CO2 emissions[1][3]. Their system includes sophisticated dosing algorithms that optimize CO2 injection based on mix designs and environmental conditions.

Strengths: Easily retrofits into existing concrete plants without major operational changes; improves concrete strength while reducing cement content; creates permanent carbon sequestration; provides concrete producers with marketable low-carbon products. Weaknesses: Requires reliable CO2 supply chain infrastructure; achieves moderate carbon reduction compared to some alternative technologies; effectiveness varies with concrete mix designs and production conditions.

Solidia Technologies, Inc.

Technical Solution: Solidia Technologies has pioneered a comprehensive carbon-negative concrete solution through their dual-patented technology approach. Their first innovation involves a modified cement formulation that requires lower kiln temperatures (1200°C vs traditional 1450°C) during manufacturing, reducing energy consumption by approximately 30% and associated CO2 emissions. This specialized cement primarily consists of low-lime calcium silicates rather than conventional calcium silicates. The second breakthrough is their CO2-based curing process that replaces water curing in traditional concrete production. During this process, CO2 reacts with the calcium silicates to form calcium carbonates, permanently sequestering carbon dioxide within the concrete matrix. The technology can reduce the carbon footprint of concrete by up to 70% - with 30% reduction from the manufacturing process and 40% from CO2 sequestration during curing[2][5]. Solidia's patented methods also reduce water usage by up to 80% compared to conventional concrete production, addressing another environmental concern in construction materials.

Strengths: Achieves significant carbon reduction (up to 70%) through both manufacturing and curing innovations; substantially reduces water consumption; produces concrete with enhanced durability and reduced efflorescence; compatible with existing manufacturing equipment. Weaknesses: Requires controlled curing environments with CO2 exposure; necessitates changes to cement formulation; may face industry adoption challenges due to established practices; requires reliable CO2 supply infrastructure.

Key Patent Analysis and Technical Innovations

Production of supplementary cementitious materials through wet carbonation method

PatentInactiveUS20230382792A1

Innovation

- A method of pre-carbonating a low CO2 emission clinker before adding it to hydraulic cement as a supplementary cementitious material, reducing the clinker factor and incorporating carbon capture into the production of conventional hydraulic cement or concrete, thereby achieving a double environmental benefit.

Methods of making sustainable ductile cast cementitious structure for carbon dioxide sequestration

PatentPendingUS20220274876A1

Innovation

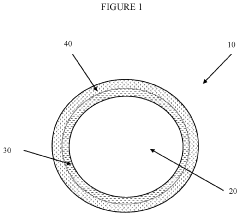

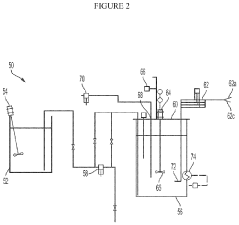

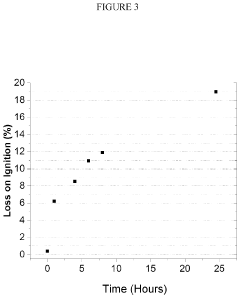

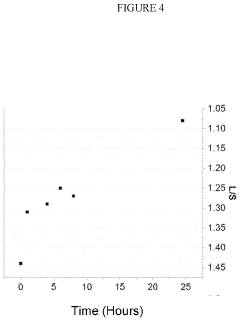

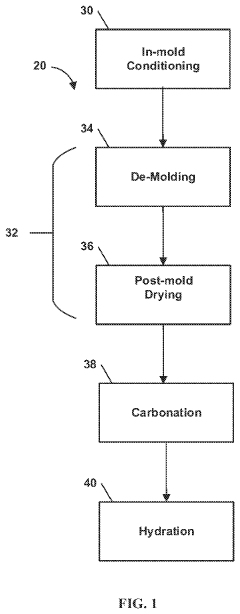

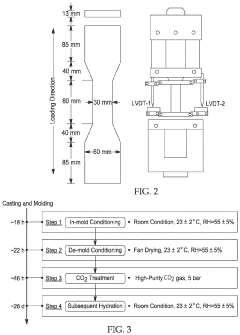

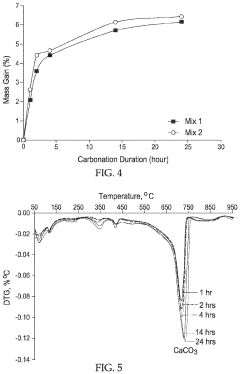

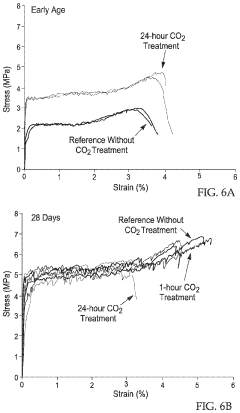

- A method for preparing cast ductile cementitious structures through controlled conditioning and carbonation processes, involving exposure to specific humidity levels and water removal to enhance carbon dioxide uptake and tensile strain capacity, potentially eliminating the need for steel reinforcement by integrating pozzolanic materials and polymeric fibers.

Environmental Impact Assessment and Carbon Accounting Methods

The environmental impact assessment of carbon-negative concrete technologies requires comprehensive methodologies to accurately quantify carbon sequestration and overall ecological footprint. Life Cycle Assessment (LCA) has emerged as the gold standard for evaluating these technologies, tracking emissions from raw material extraction through manufacturing, use, and end-of-life phases. This cradle-to-grave approach provides crucial insights into the true carbon profile of innovative concrete solutions.

Carbon accounting for these technologies presents unique challenges due to the temporal dimension of carbon sequestration. While conventional concrete releases CO2 during production and curing, carbon-negative variants actively absorb CO2 throughout their lifecycle. Current accounting frameworks must adapt to properly credit this ongoing sequestration, which may continue for decades after installation.

The development of standardized metrics has accelerated in recent years, with organizations like the World Resources Institute and ISO establishing protocols specifically for carbon-negative materials. These frameworks typically measure carbon intensity in terms of kg CO2e per cubic meter of concrete, allowing for meaningful comparisons between different formulations and traditional Portland cement concrete.

Boundary definition remains a critical consideration in assessment methodologies. Some approaches focus narrowly on production emissions, while more comprehensive models incorporate transportation, installation, maintenance, and demolition impacts. The most advanced frameworks also account for secondary effects such as albedo changes and potential reductions in building energy consumption due to thermal mass properties.

Verification protocols have evolved to ensure credibility in carbon claims. Third-party certification systems now validate carbon-negative concrete technologies through rigorous testing regimes, often involving accelerated carbonation chambers to predict long-term sequestration potential. These verification systems are increasingly linked to carbon credit markets, creating financial incentives for technology adoption.

Regional variations in assessment methodologies present challenges for global standardization. European frameworks typically emphasize embodied carbon, while North American approaches often focus more heavily on operational performance. Harmonization efforts are underway through international collaborations like the Carbon Leadership Forum, which seeks to establish globally recognized assessment protocols for carbon-negative building materials.

Carbon accounting for these technologies presents unique challenges due to the temporal dimension of carbon sequestration. While conventional concrete releases CO2 during production and curing, carbon-negative variants actively absorb CO2 throughout their lifecycle. Current accounting frameworks must adapt to properly credit this ongoing sequestration, which may continue for decades after installation.

The development of standardized metrics has accelerated in recent years, with organizations like the World Resources Institute and ISO establishing protocols specifically for carbon-negative materials. These frameworks typically measure carbon intensity in terms of kg CO2e per cubic meter of concrete, allowing for meaningful comparisons between different formulations and traditional Portland cement concrete.

Boundary definition remains a critical consideration in assessment methodologies. Some approaches focus narrowly on production emissions, while more comprehensive models incorporate transportation, installation, maintenance, and demolition impacts. The most advanced frameworks also account for secondary effects such as albedo changes and potential reductions in building energy consumption due to thermal mass properties.

Verification protocols have evolved to ensure credibility in carbon claims. Third-party certification systems now validate carbon-negative concrete technologies through rigorous testing regimes, often involving accelerated carbonation chambers to predict long-term sequestration potential. These verification systems are increasingly linked to carbon credit markets, creating financial incentives for technology adoption.

Regional variations in assessment methodologies present challenges for global standardization. European frameworks typically emphasize embodied carbon, while North American approaches often focus more heavily on operational performance. Harmonization efforts are underway through international collaborations like the Carbon Leadership Forum, which seeks to establish globally recognized assessment protocols for carbon-negative building materials.

Regulatory Framework and Policy Incentives for Green Construction

The regulatory landscape for carbon-negative concrete technologies is evolving rapidly as governments worldwide recognize the urgent need to address climate change. In the United States, the Environmental Protection Agency (EPA) has established the Clean Air Act as a foundational framework that indirectly influences concrete manufacturing by regulating greenhouse gas emissions. More directly, the 2021 Infrastructure Investment and Jobs Act allocates significant funding for sustainable construction materials, including carbon-negative concrete alternatives.

The European Union leads with its ambitious European Green Deal, which aims to achieve carbon neutrality by 2050. The EU Emissions Trading System (ETS) creates economic incentives for concrete manufacturers to reduce their carbon footprint through a cap-and-trade mechanism. Additionally, the Construction Products Regulation (CPR) is being updated to include sustainability requirements that will favor carbon-negative concrete technologies.

Financial incentives play a crucial role in accelerating adoption. Tax credits for carbon capture and utilization, such as the 45Q tax credit in the US, provide up to $50 per metric ton of CO2 permanently sequestered. Green building certification systems like LEED and BREEAM award points for using low-carbon construction materials, creating market-driven incentives for developers to choose carbon-negative concrete.

Public procurement policies are increasingly incorporating carbon footprint considerations. Several jurisdictions, including California and Sweden, have implemented "Buy Clean" policies that require disclosure of embodied carbon in construction materials used in public projects. These policies create significant market demand for carbon-negative concrete technologies.

International agreements, particularly the Paris Climate Accord, establish the broader context for national regulations. Countries' Nationally Determined Contributions (NDCs) often include commitments to reduce emissions from the building sector, indirectly supporting carbon-negative concrete adoption.

Emerging policy trends include carbon border adjustment mechanisms, which aim to prevent "carbon leakage" by imposing tariffs on carbon-intensive imports. This approach could significantly impact the global concrete market by leveling the playing field between regions with strict emissions regulations and those without. Performance-based standards rather than prescriptive requirements are also gaining traction, allowing for innovation while ensuring safety and sustainability.

The regulatory framework continues to evolve, with increasing coordination between building codes, environmental regulations, and climate policies creating a more cohesive approach to promoting carbon-negative concrete technologies in construction.

The European Union leads with its ambitious European Green Deal, which aims to achieve carbon neutrality by 2050. The EU Emissions Trading System (ETS) creates economic incentives for concrete manufacturers to reduce their carbon footprint through a cap-and-trade mechanism. Additionally, the Construction Products Regulation (CPR) is being updated to include sustainability requirements that will favor carbon-negative concrete technologies.

Financial incentives play a crucial role in accelerating adoption. Tax credits for carbon capture and utilization, such as the 45Q tax credit in the US, provide up to $50 per metric ton of CO2 permanently sequestered. Green building certification systems like LEED and BREEAM award points for using low-carbon construction materials, creating market-driven incentives for developers to choose carbon-negative concrete.

Public procurement policies are increasingly incorporating carbon footprint considerations. Several jurisdictions, including California and Sweden, have implemented "Buy Clean" policies that require disclosure of embodied carbon in construction materials used in public projects. These policies create significant market demand for carbon-negative concrete technologies.

International agreements, particularly the Paris Climate Accord, establish the broader context for national regulations. Countries' Nationally Determined Contributions (NDCs) often include commitments to reduce emissions from the building sector, indirectly supporting carbon-negative concrete adoption.

Emerging policy trends include carbon border adjustment mechanisms, which aim to prevent "carbon leakage" by imposing tariffs on carbon-intensive imports. This approach could significantly impact the global concrete market by leveling the playing field between regions with strict emissions regulations and those without. Performance-based standards rather than prescriptive requirements are also gaining traction, allowing for innovation while ensuring safety and sustainability.

The regulatory framework continues to evolve, with increasing coordination between building codes, environmental regulations, and climate policies creating a more cohesive approach to promoting carbon-negative concrete technologies in construction.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!