Research Analysis of the Chemical Bonding in Carbon-negative Concrete

OCT 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Technology Background and Objectives

Carbon-negative concrete represents a revolutionary advancement in construction materials, emerging as a response to the significant environmental challenges posed by traditional cement production. Conventional concrete manufacturing accounts for approximately 8% of global CO2 emissions, making it one of the largest industrial contributors to climate change. The evolution of carbon-negative concrete technology began in the early 2000s with initial research into alternative cementitious materials, but has gained substantial momentum over the past decade as climate concerns have intensified.

The fundamental principle behind carbon-negative concrete involves reformulating the chemical composition and manufacturing processes to not only reduce emissions but actually sequester more carbon dioxide than is released during production. This represents a paradigm shift from carbon-neutral approaches to truly negative carbon footprint solutions. The technology has progressed through several key developmental phases, from laboratory concepts to pilot implementations, with significant breakthroughs in chemical bonding mechanisms occurring between 2015 and 2020.

Current technological trajectories indicate a convergence of multiple approaches, including alternative binding agents, carbon capture integration, and novel curing methodologies. The chemical bonding in carbon-negative concrete typically involves innovative calcium silicate formations that can absorb CO2 during the hardening process, as well as the incorporation of industrial byproducts like fly ash and slag that reduce the need for traditional Portland cement.

The primary technical objective in this field is to develop commercially viable carbon-negative concrete formulations that maintain or exceed the performance characteristics of conventional concrete while achieving significant carbon sequestration. Specific goals include achieving compressive strength comparable to traditional concrete (30-40 MPa), ensuring durability under various environmental conditions, and developing scalable production methods that can be implemented within existing concrete manufacturing infrastructure.

Secondary objectives focus on optimizing the carbon sequestration capacity, targeting minimum absorption rates of 100-150 kg of CO2 per cubic meter of concrete, while maintaining cost competitiveness. The industry aims to reduce the current price premium of 15-30% over conventional concrete to under 10% through economies of scale and process refinements by 2025.

The technological evolution is expected to continue along several promising pathways, including the development of novel clinker substitutes, enhancement of carbonation processes, and integration with renewable energy sources to further reduce the embodied carbon. Research priorities include improving the understanding of long-term carbon stability in these materials and developing standardized testing protocols to verify carbon sequestration claims.

The fundamental principle behind carbon-negative concrete involves reformulating the chemical composition and manufacturing processes to not only reduce emissions but actually sequester more carbon dioxide than is released during production. This represents a paradigm shift from carbon-neutral approaches to truly negative carbon footprint solutions. The technology has progressed through several key developmental phases, from laboratory concepts to pilot implementations, with significant breakthroughs in chemical bonding mechanisms occurring between 2015 and 2020.

Current technological trajectories indicate a convergence of multiple approaches, including alternative binding agents, carbon capture integration, and novel curing methodologies. The chemical bonding in carbon-negative concrete typically involves innovative calcium silicate formations that can absorb CO2 during the hardening process, as well as the incorporation of industrial byproducts like fly ash and slag that reduce the need for traditional Portland cement.

The primary technical objective in this field is to develop commercially viable carbon-negative concrete formulations that maintain or exceed the performance characteristics of conventional concrete while achieving significant carbon sequestration. Specific goals include achieving compressive strength comparable to traditional concrete (30-40 MPa), ensuring durability under various environmental conditions, and developing scalable production methods that can be implemented within existing concrete manufacturing infrastructure.

Secondary objectives focus on optimizing the carbon sequestration capacity, targeting minimum absorption rates of 100-150 kg of CO2 per cubic meter of concrete, while maintaining cost competitiveness. The industry aims to reduce the current price premium of 15-30% over conventional concrete to under 10% through economies of scale and process refinements by 2025.

The technological evolution is expected to continue along several promising pathways, including the development of novel clinker substitutes, enhancement of carbonation processes, and integration with renewable energy sources to further reduce the embodied carbon. Research priorities include improving the understanding of long-term carbon stability in these materials and developing standardized testing protocols to verify carbon sequestration claims.

Market Analysis for Carbon-negative Construction Materials

The global market for carbon-negative construction materials is experiencing unprecedented growth, driven by increasing environmental regulations, corporate sustainability commitments, and consumer demand for greener building solutions. The carbon-negative concrete sector specifically has emerged as a focal point for innovation, with market projections indicating a compound annual growth rate of 9.7% between 2023 and 2030, potentially reaching a market value of $3.1 billion by 2030.

Regionally, Europe currently leads the carbon-negative construction materials market, accounting for approximately 38% of global market share. This dominance stems from stringent EU carbon regulations, ambitious climate targets, and substantial government incentives for green building materials. North America follows with 29% market share, while the Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with projected growth rates exceeding 12% annually.

Demand drivers for carbon-negative concrete are multifaceted. Primary factors include increasingly stringent building codes and environmental regulations across major economies, with over 65 countries having incorporated carbon reduction targets into their construction standards. Corporate sustainability initiatives also play a crucial role, as major construction and real estate firms commit to net-zero carbon portfolios. Additionally, government procurement policies increasingly favor low-carbon materials, with several countries implementing carbon taxes and incentives that directly benefit carbon-negative alternatives.

Market segmentation reveals distinct customer profiles. Commercial construction represents the largest segment (41%), followed by residential (32%), infrastructure (21%), and specialized applications (6%). Within these segments, early adopters typically include environmentally-conscious developers, public infrastructure projects with sustainability mandates, and high-profile commercial developments seeking green building certifications.

Pricing analysis indicates that carbon-negative concrete currently commands a premium of 15-25% over conventional products. However, this premium is projected to decrease to 5-10% by 2028 as production scales and technologies mature. Total cost of ownership calculations increasingly favor carbon-negative solutions when factoring in carbon credits, regulatory compliance benefits, and enhanced building performance characteristics.

Market barriers include limited production capacity, regulatory uncertainties regarding performance standards, and knowledge gaps among architects and engineers. Despite these challenges, the market demonstrates strong growth potential, particularly as carbon pricing mechanisms become more widespread and as the technology behind carbon-negative concrete continues to advance, improving both performance characteristics and economic viability.

Regionally, Europe currently leads the carbon-negative construction materials market, accounting for approximately 38% of global market share. This dominance stems from stringent EU carbon regulations, ambitious climate targets, and substantial government incentives for green building materials. North America follows with 29% market share, while the Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with projected growth rates exceeding 12% annually.

Demand drivers for carbon-negative concrete are multifaceted. Primary factors include increasingly stringent building codes and environmental regulations across major economies, with over 65 countries having incorporated carbon reduction targets into their construction standards. Corporate sustainability initiatives also play a crucial role, as major construction and real estate firms commit to net-zero carbon portfolios. Additionally, government procurement policies increasingly favor low-carbon materials, with several countries implementing carbon taxes and incentives that directly benefit carbon-negative alternatives.

Market segmentation reveals distinct customer profiles. Commercial construction represents the largest segment (41%), followed by residential (32%), infrastructure (21%), and specialized applications (6%). Within these segments, early adopters typically include environmentally-conscious developers, public infrastructure projects with sustainability mandates, and high-profile commercial developments seeking green building certifications.

Pricing analysis indicates that carbon-negative concrete currently commands a premium of 15-25% over conventional products. However, this premium is projected to decrease to 5-10% by 2028 as production scales and technologies mature. Total cost of ownership calculations increasingly favor carbon-negative solutions when factoring in carbon credits, regulatory compliance benefits, and enhanced building performance characteristics.

Market barriers include limited production capacity, regulatory uncertainties regarding performance standards, and knowledge gaps among architects and engineers. Despite these challenges, the market demonstrates strong growth potential, particularly as carbon pricing mechanisms become more widespread and as the technology behind carbon-negative concrete continues to advance, improving both performance characteristics and economic viability.

Current State and Challenges in Carbon-negative Concrete Chemistry

Carbon-negative concrete technology has witnessed significant advancements globally, yet faces substantial technical challenges. Current state-of-the-art approaches primarily focus on alternative cementitious materials, carbon capture during production, and novel binding mechanisms that sequester CO2. Leading research institutions in North America, Europe, and Asia have demonstrated promising results in laboratory settings, with several pilot projects showing up to 30% reduction in carbon emissions compared to traditional Portland cement concrete.

The fundamental challenge in carbon-negative concrete chemistry lies in the molecular restructuring of calcium silicate hydrates (C-S-H), the primary binding phase in conventional concrete. Researchers have identified that substituting traditional calcium sources with magnesium-based alternatives can potentially increase CO2 absorption capacity by 20-40%, but this substitution introduces significant challenges in maintaining structural integrity and long-term durability.

Another critical limitation is the kinetics of carbonation reactions. While accelerated carbonation can enhance CO2 uptake, it often results in reduced mechanical strength and increased susceptibility to environmental degradation. Recent studies from MIT and ETH Zurich have demonstrated that controlling the microstructure through precise particle size distribution and pore network engineering can optimize the carbonation process without compromising mechanical properties.

The availability and scalability of alternative raw materials present additional constraints. Supplementary cementitious materials (SCMs) like fly ash and slag are becoming increasingly scarce as coal power plants are decommissioned globally. This scarcity has driven research toward novel sources such as calcined clays, natural pozzolans, and industrial by-products, though standardization and quality control remain problematic.

Energy requirements for processing alternative binders often offset carbon reduction benefits. Current manufacturing processes for magnesium-based cements require temperatures exceeding 700°C, compared to approximately 1450°C for Portland cement. While this represents energy savings, the overall carbon footprint remains substantial without renewable energy integration.

Regulatory frameworks and industry standards present non-technical barriers to adoption. Most building codes worldwide are based on Portland cement concrete performance criteria, creating certification challenges for novel carbon-negative alternatives. The absence of standardized testing protocols for carbon sequestration capacity further complicates market acceptance.

Recent breakthroughs in alkali-activated materials and carbonatable calcium silicate systems show promise, with laboratory specimens demonstrating net carbon sequestration of 50-100 kg CO2 per cubic meter of concrete. However, scaling these technologies to industrial production volumes while maintaining performance consistency remains an unresolved challenge that requires interdisciplinary collaboration between materials scientists, chemical engineers, and construction professionals.

The fundamental challenge in carbon-negative concrete chemistry lies in the molecular restructuring of calcium silicate hydrates (C-S-H), the primary binding phase in conventional concrete. Researchers have identified that substituting traditional calcium sources with magnesium-based alternatives can potentially increase CO2 absorption capacity by 20-40%, but this substitution introduces significant challenges in maintaining structural integrity and long-term durability.

Another critical limitation is the kinetics of carbonation reactions. While accelerated carbonation can enhance CO2 uptake, it often results in reduced mechanical strength and increased susceptibility to environmental degradation. Recent studies from MIT and ETH Zurich have demonstrated that controlling the microstructure through precise particle size distribution and pore network engineering can optimize the carbonation process without compromising mechanical properties.

The availability and scalability of alternative raw materials present additional constraints. Supplementary cementitious materials (SCMs) like fly ash and slag are becoming increasingly scarce as coal power plants are decommissioned globally. This scarcity has driven research toward novel sources such as calcined clays, natural pozzolans, and industrial by-products, though standardization and quality control remain problematic.

Energy requirements for processing alternative binders often offset carbon reduction benefits. Current manufacturing processes for magnesium-based cements require temperatures exceeding 700°C, compared to approximately 1450°C for Portland cement. While this represents energy savings, the overall carbon footprint remains substantial without renewable energy integration.

Regulatory frameworks and industry standards present non-technical barriers to adoption. Most building codes worldwide are based on Portland cement concrete performance criteria, creating certification challenges for novel carbon-negative alternatives. The absence of standardized testing protocols for carbon sequestration capacity further complicates market acceptance.

Recent breakthroughs in alkali-activated materials and carbonatable calcium silicate systems show promise, with laboratory specimens demonstrating net carbon sequestration of 50-100 kg CO2 per cubic meter of concrete. However, scaling these technologies to industrial production volumes while maintaining performance consistency remains an unresolved challenge that requires interdisciplinary collaboration between materials scientists, chemical engineers, and construction professionals.

Current Chemical Bonding Solutions in Carbon-negative Concrete

01 CO2 capture and mineralization in concrete

Carbon-negative concrete can be achieved through CO2 mineralization processes where carbon dioxide is chemically bonded with calcium or magnesium compounds to form stable carbonate minerals. This process not only sequesters CO2 but also improves concrete properties such as strength and durability. The mineralization reaction typically involves the conversion of calcium silicates or hydroxides into calcium carbonates, creating a permanent carbon sink within the concrete structure.- CO2 Sequestration Mechanisms in Concrete: Carbon-negative concrete formulations incorporate mechanisms to sequester CO2 during the curing process. These technologies utilize chemical reactions where carbon dioxide is permanently bound within the concrete matrix, converting it from a greenhouse gas to a solid carbonate structure. This carbonation process not only reduces the carbon footprint but also can enhance certain mechanical properties of the concrete, creating a more sustainable building material that actively removes CO2 from the atmosphere.

- Alternative Cementitious Materials for Carbon Reduction: Novel cementitious materials are being developed to replace traditional Portland cement, which is carbon-intensive. These alternatives include geopolymers, alkali-activated materials, and supplementary cementitious materials that form chemical bonds with significantly lower carbon emissions. By modifying the fundamental chemistry of the binding agents, these materials can achieve carbon-negative status through reduced manufacturing emissions and enhanced CO2 absorption capabilities during their lifecycle.

- Mineral Carbonation Technologies: Mineral carbonation involves the reaction of CO2 with calcium or magnesium-rich minerals to form stable carbonate compounds. In carbon-negative concrete applications, this process is engineered to maximize CO2 uptake through optimized chemical bonding pathways. The technology leverages specific mineral additives that have high affinity for carbon dioxide, creating permanent chemical bonds that sequester carbon while contributing to the structural integrity of the concrete.

- Accelerated Carbonation Curing Processes: Accelerated carbonation techniques expose concrete to controlled CO2-rich environments during the curing phase to enhance carbon sequestration. These processes optimize the chemical bonding of carbon dioxide within the concrete matrix by manipulating factors such as pressure, temperature, and humidity. The accelerated carbonation creates a more rapid and efficient carbon capture mechanism, resulting in concrete products that have sequestered significant amounts of CO2 before even leaving the manufacturing facility.

- Carbon-Capturing Additives and Catalysts: Specialized additives and catalysts are incorporated into concrete mixtures to enhance CO2 absorption and chemical bonding. These materials facilitate the conversion of gaseous carbon dioxide into solid carbonates through improved reaction kinetics and increased binding sites. The additives can include engineered particles with high surface areas, reactive minerals, or novel synthetic compounds designed specifically to maximize carbon sequestration through optimized chemical interactions within the concrete matrix.

02 Alternative cementitious materials for carbon reduction

Novel cementitious materials can be formulated to reduce or eliminate the carbon footprint of traditional Portland cement. These include geopolymers, alkali-activated materials, and supplementary cementitious materials that form chemical bonds through different mechanisms than conventional cement. These materials often utilize industrial byproducts like fly ash, slag, or silica fume, which react with alkaline activators to form strong binding phases while significantly reducing carbon emissions.Expand Specific Solutions03 Carbon-sequestering aggregates and fillers

Specialized aggregates and fillers can be incorporated into concrete mixtures to enhance carbon sequestration. These materials are designed to chemically bond with CO2 either during curing or throughout the concrete's lifetime. Some approaches involve pre-carbonated aggregates that have already absorbed CO2, while others use reactive materials that continue to capture carbon over time through various chemical bonding mechanisms, contributing to the overall carbon-negative profile of the concrete.Expand Specific Solutions04 Catalysts and additives for enhanced carbonation

Chemical additives and catalysts can be incorporated into concrete formulations to accelerate and enhance the carbonation process. These additives modify the chemical bonding environment to favor CO2 uptake and conversion to stable carbonate compounds. Some catalysts target specific reaction pathways to maximize carbon sequestration efficiency, while others improve the kinetics of the carbonation reaction, allowing for greater carbon capture within practical timeframes.Expand Specific Solutions05 Novel curing technologies for carbon sequestration

Advanced curing technologies can be employed to promote carbon sequestration during the concrete hardening process. These methods often involve controlled exposure to CO2-rich environments where chemical bonding between the gas and concrete components is optimized. Some approaches use pressure vessels, while others employ specialized atmospheric conditions to facilitate the carbonation reaction. These technologies can transform the curing process from a carbon-emitting to a carbon-absorbing phase in concrete production.Expand Specific Solutions

Leading Organizations in Carbon-negative Concrete Research

The carbon-negative concrete market is in an early growth phase, characterized by increasing research activity and emerging commercial applications. The global market is expanding rapidly, driven by sustainability demands and carbon reduction initiatives, though still representing a small fraction of the $400+ billion concrete industry. Technologically, the field shows varied maturity levels, with academic institutions like Wuhan University of Technology, Chongqing University, and Waseda University advancing fundamental chemical bonding research, while companies demonstrate different commercialization stages. Carbon Limit Co. has developed concrete that permanently captures atmospheric CO2, Holcim Technology is scaling industrial applications, and Shin-Etsu Chemical contributes specialized chemical binding agents. The ecosystem includes both established construction materials giants and innovative startups, indicating a dynamic competitive landscape with significant growth potential.

Wuhan University of Technology

Technical Solution: Wuhan University of Technology has developed a groundbreaking approach to carbon-negative concrete through their advanced mineral carbonation research. Their technology focuses on enhancing the chemical bonding between CO2 and calcium silicate hydrates (C-S-H) in concrete. The university's research team has engineered a novel class of reactive MgO-based additives that create additional nucleation sites for carbon mineralization. Their process involves a controlled carbonation reaction where CO2 is introduced during both mixing and curing phases, forming stable magnesium carbonate compounds that become permanently sequestered within the concrete matrix. The university has pioneered the use of nano-silica particles to accelerate carbonation kinetics by increasing the reactive surface area available for CO2 uptake. Their formulations incorporate industrial by-products such as steel slag and coal fly ash as supplementary cementitious materials, which provide additional reactive sites for CO2 sequestration while reducing the carbon footprint associated with traditional cement production. Laboratory studies have demonstrated that their concrete formulations can sequester up to 140kg of CO2 per cubic meter while maintaining mechanical properties comparable to conventional concrete.

Strengths: Cutting-edge research in nano-enhanced carbonation mechanisms; formulations achieve high CO2 sequestration rates; utilizes readily available industrial waste streams as raw materials. Weaknesses: Technology remains primarily in research phase with limited field implementation; requires specialized equipment for optimal CO2 exposure during curing; economic viability at commercial scale still being evaluated.

Carbon Limit Co.

Technical Solution: Carbon Limit has pioneered a revolutionary approach to carbon-negative concrete through their proprietary CarbonX technology. Their solution focuses on enhanced mineral carbonation processes that maximize CO2 sequestration within the concrete matrix. The technology utilizes specially engineered calcium silicate additives that create additional nucleation sites for carbon mineralization. Carbon Limit's process involves a two-stage chemical bonding mechanism: first, accelerated carbonation of calcium hydroxide to form calcium carbonate, and second, the incorporation of novel magnesium-based binders that form stable hydromagnesite compounds when exposed to CO2. This dual-pathway approach significantly increases the carbon sequestration capacity compared to conventional carbonation methods. Their concrete formulations incorporate recycled industrial waste materials as supplementary cementitious materials, further reducing the carbon footprint. Independent testing has verified that their concrete products can sequester up to 150kg of CO2 per cubic meter while maintaining structural performance comparable to traditional concrete.

Strengths: Industry-leading carbon sequestration capacity; technology can be implemented with minimal modifications to existing concrete production facilities; products meet or exceed industry performance standards. Weaknesses: Relatively new market entrant with limited commercial-scale implementation history; higher material costs compared to conventional concrete; requires careful quality control of raw material inputs to ensure consistent performance.

Key Chemical Mechanisms and Innovations in CO2 Sequestration

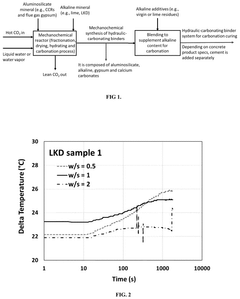

Process for production of hydraulic-carbonating binder systems through mechanochemical activation of minerals

PatentPendingUS20250059087A1

Innovation

- A process for synthesizing hydraulic-carbonating binder systems through mechanochemical activation, involving the blending of aluminosilicate and alkaline-rich mineral materials, followed by simultaneous fractionation and carbonation in a mechanochemical reactor, to enhance reactivity and carbonation reactions.

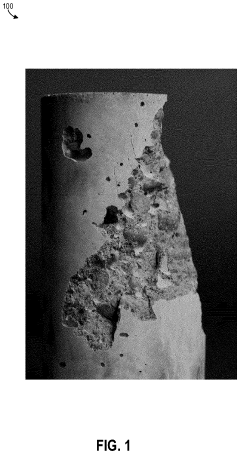

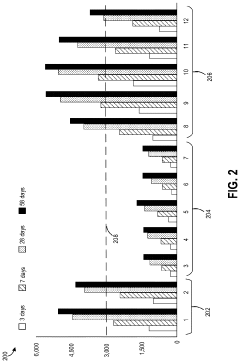

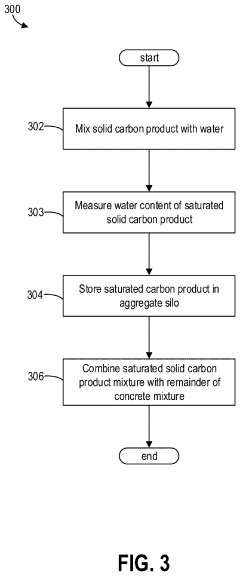

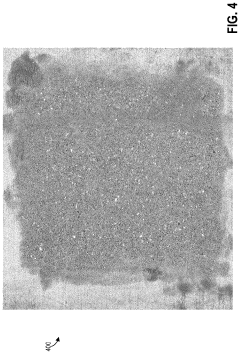

Concrete mixture including solid carbon

PatentPendingUS20230382794A1

Innovation

- A concrete formulation incorporating a solid carbon product with less than 75% carbon by weight and greater than 25% ash by weight, which can be used in higher quantities to achieve carbon-neutral or carbon-negative status without degrading concrete performance, and is compatible with existing batching systems, maintaining at least 90% of the compressive and flexural strength of control mixes while adhering to ASTM standards.

Environmental Impact Assessment of Carbon-negative Concrete

Carbon-negative concrete represents a significant advancement in sustainable construction materials, offering substantial environmental benefits compared to traditional Portland cement concrete. The environmental impact assessment of carbon-negative concrete reveals multiple dimensions of ecological advantage that extend beyond mere carbon sequestration.

The production of conventional concrete accounts for approximately 8% of global CO2 emissions, primarily due to the energy-intensive calcination process in cement manufacturing. In contrast, carbon-negative concrete technologies actively remove CO2 from the atmosphere through various mechanisms, including carbonation curing processes and the incorporation of carbon-capturing supplementary cementitious materials.

Life cycle assessment (LCA) studies indicate that carbon-negative concrete can sequester between 100-300 kg of CO2 per cubic meter of material, depending on the specific formulation and manufacturing process. This represents a dramatic improvement over conventional concrete, which typically emits 400-500 kg of CO2 per cubic meter. The net environmental benefit becomes particularly significant when considering large-scale infrastructure projects.

Beyond carbon metrics, these innovative concretes demonstrate reduced environmental impacts across multiple categories. Water consumption during production can be decreased by up to 60% compared to traditional concrete manufacturing processes. Additionally, many carbon-negative formulations utilize industrial byproducts and waste materials as precursors, diverting these materials from landfills and creating valuable circular economy opportunities.

The chemical bonding mechanisms in carbon-negative concrete contribute to enhanced durability characteristics, potentially extending service life by 20-30% compared to conventional concrete structures. This longevity factor compounds the environmental benefits through reduced maintenance requirements and delayed replacement cycles, further lowering the material's lifetime carbon footprint.

Regional environmental impact variations are notable, with carbon-negative concrete offering particularly significant benefits in urban environments with high construction density and elevated atmospheric CO2 levels. Implementation in these areas can contribute to localized air quality improvements while addressing embodied carbon in the built environment.

Challenges remain in scaling production while maintaining environmental performance. Current manufacturing processes for certain carbon-negative concrete formulations require specialized equipment and precise control conditions, potentially limiting widespread adoption. However, ongoing research into chemical bonding optimization promises to simplify production requirements while maintaining or enhancing environmental benefits.

The production of conventional concrete accounts for approximately 8% of global CO2 emissions, primarily due to the energy-intensive calcination process in cement manufacturing. In contrast, carbon-negative concrete technologies actively remove CO2 from the atmosphere through various mechanisms, including carbonation curing processes and the incorporation of carbon-capturing supplementary cementitious materials.

Life cycle assessment (LCA) studies indicate that carbon-negative concrete can sequester between 100-300 kg of CO2 per cubic meter of material, depending on the specific formulation and manufacturing process. This represents a dramatic improvement over conventional concrete, which typically emits 400-500 kg of CO2 per cubic meter. The net environmental benefit becomes particularly significant when considering large-scale infrastructure projects.

Beyond carbon metrics, these innovative concretes demonstrate reduced environmental impacts across multiple categories. Water consumption during production can be decreased by up to 60% compared to traditional concrete manufacturing processes. Additionally, many carbon-negative formulations utilize industrial byproducts and waste materials as precursors, diverting these materials from landfills and creating valuable circular economy opportunities.

The chemical bonding mechanisms in carbon-negative concrete contribute to enhanced durability characteristics, potentially extending service life by 20-30% compared to conventional concrete structures. This longevity factor compounds the environmental benefits through reduced maintenance requirements and delayed replacement cycles, further lowering the material's lifetime carbon footprint.

Regional environmental impact variations are notable, with carbon-negative concrete offering particularly significant benefits in urban environments with high construction density and elevated atmospheric CO2 levels. Implementation in these areas can contribute to localized air quality improvements while addressing embodied carbon in the built environment.

Challenges remain in scaling production while maintaining environmental performance. Current manufacturing processes for certain carbon-negative concrete formulations require specialized equipment and precise control conditions, potentially limiting widespread adoption. However, ongoing research into chemical bonding optimization promises to simplify production requirements while maintaining or enhancing environmental benefits.

Regulatory Framework for Low-Carbon Construction Materials

The regulatory landscape for low-carbon construction materials is evolving rapidly as governments worldwide implement policies to reduce carbon emissions in the building sector. Carbon-negative concrete, with its unique chemical bonding properties, faces a complex regulatory environment that varies significantly across regions. In the European Union, the Construction Products Regulation (CPR) has been updated to include specific provisions for sustainable building materials, with the EU Taxonomy for Sustainable Activities establishing clear criteria for what constitutes environmentally sustainable construction materials.

In North America, regulatory frameworks are more fragmented. The United States has implemented green building codes such as ASHRAE 189.1 and the International Green Construction Code (IgCC), which provide guidelines for sustainable construction materials. However, these codes often lack specific provisions for carbon-negative concrete technologies, creating regulatory uncertainty for manufacturers and developers.

The Asia-Pacific region demonstrates varying levels of regulatory maturity. Countries like Singapore and Japan have established comprehensive green building regulations that incentivize the use of low-carbon construction materials. China's recent Five-Year Plan includes ambitious targets for reducing carbon emissions in the construction sector, with specific provisions for innovative concrete technologies.

Performance-based standards rather than prescriptive requirements are becoming increasingly common in regulatory frameworks globally. This approach allows for innovation in chemical bonding techniques for carbon-negative concrete while ensuring safety and durability. Standards organizations such as ASTM International and the International Organization for Standardization (ISO) have developed testing protocols specifically for evaluating the performance of alternative cementitious materials.

Carbon pricing mechanisms and embodied carbon regulations are emerging as powerful regulatory tools. The Netherlands has implemented a carbon ceiling for infrastructure projects, while France's RE2020 regulation requires lifecycle carbon assessment for new buildings. These mechanisms create economic incentives for the adoption of carbon-negative concrete technologies by internalizing the environmental costs of traditional cement production.

Certification systems like LEED, BREEAM, and Green Star have incorporated criteria for low-carbon construction materials, influencing market demand and regulatory development. These voluntary standards often precede mandatory regulations and help establish market acceptance for innovative materials with novel chemical bonding properties.

Regulatory harmonization remains a significant challenge. Differences in testing methods, performance criteria, and certification requirements across jurisdictions create barriers to the global adoption of carbon-negative concrete technologies. International efforts to standardize regulatory approaches, such as the International Energy Agency's Technology Collaboration Programme on Energy in Buildings and Communities, are working to address these challenges.

In North America, regulatory frameworks are more fragmented. The United States has implemented green building codes such as ASHRAE 189.1 and the International Green Construction Code (IgCC), which provide guidelines for sustainable construction materials. However, these codes often lack specific provisions for carbon-negative concrete technologies, creating regulatory uncertainty for manufacturers and developers.

The Asia-Pacific region demonstrates varying levels of regulatory maturity. Countries like Singapore and Japan have established comprehensive green building regulations that incentivize the use of low-carbon construction materials. China's recent Five-Year Plan includes ambitious targets for reducing carbon emissions in the construction sector, with specific provisions for innovative concrete technologies.

Performance-based standards rather than prescriptive requirements are becoming increasingly common in regulatory frameworks globally. This approach allows for innovation in chemical bonding techniques for carbon-negative concrete while ensuring safety and durability. Standards organizations such as ASTM International and the International Organization for Standardization (ISO) have developed testing protocols specifically for evaluating the performance of alternative cementitious materials.

Carbon pricing mechanisms and embodied carbon regulations are emerging as powerful regulatory tools. The Netherlands has implemented a carbon ceiling for infrastructure projects, while France's RE2020 regulation requires lifecycle carbon assessment for new buildings. These mechanisms create economic incentives for the adoption of carbon-negative concrete technologies by internalizing the environmental costs of traditional cement production.

Certification systems like LEED, BREEAM, and Green Star have incorporated criteria for low-carbon construction materials, influencing market demand and regulatory development. These voluntary standards often precede mandatory regulations and help establish market acceptance for innovative materials with novel chemical bonding properties.

Regulatory harmonization remains a significant challenge. Differences in testing methods, performance criteria, and certification requirements across jurisdictions create barriers to the global adoption of carbon-negative concrete technologies. International efforts to standardize regulatory approaches, such as the International Energy Agency's Technology Collaboration Programme on Energy in Buildings and Communities, are working to address these challenges.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!