Exploring the Material Science of Carbon-negative Concrete

OCT 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Evolution and Objectives

Concrete, as one of the most widely used construction materials globally, has traditionally been associated with significant carbon emissions. The evolution of carbon-negative concrete represents a paradigm shift in construction material science, moving from carbon-intensive processes toward solutions that actively remove carbon dioxide from the atmosphere. This technological trajectory began in the early 2000s with initial research into alternative cementitious materials, followed by breakthrough developments around 2010 when researchers successfully demonstrated the first carbon-sequestering concrete prototypes.

The evolution accelerated significantly between 2015 and 2020, with several startups and research institutions developing commercially viable carbon-negative concrete formulations. These innovations primarily leverage two approaches: substituting traditional Portland cement with alternative binders that require less energy to produce, and incorporating materials that can absorb and permanently store CO2 during the curing process. Notable milestones include the development of geopolymer cements, alkali-activated materials, and calcium silicate-based formulations that can absorb CO2 while maintaining or even improving structural performance.

Recent technological advancements have focused on enhancing carbon sequestration capacity while ensuring that the resulting concrete meets or exceeds industry standards for strength, durability, and workability. Current state-of-the-art carbon-negative concrete can sequester approximately 100-150 kg of CO2 per cubic meter, representing a significant improvement from earlier iterations that achieved only minimal carbon reduction.

The primary objective of carbon-negative concrete development is to transform the construction industry from a major carbon emitter to a potential carbon sink. Specific technical goals include increasing CO2 sequestration capacity to over 200 kg per cubic meter by 2030, reducing production costs to achieve price parity with conventional concrete, and scaling manufacturing processes to meet global demand. Additionally, researchers aim to optimize the longevity of carbon sequestration, ensuring that captured carbon remains permanently bound within the material throughout its lifecycle and eventual recycling.

Another critical objective is the standardization and certification of carbon-negative concrete, establishing clear metrics for measuring carbon sequestration performance and developing industry-accepted testing protocols. This standardization will facilitate wider adoption by providing stakeholders with reliable performance data and enabling regulatory frameworks that incentivize or mandate low-carbon building materials.

The evolution accelerated significantly between 2015 and 2020, with several startups and research institutions developing commercially viable carbon-negative concrete formulations. These innovations primarily leverage two approaches: substituting traditional Portland cement with alternative binders that require less energy to produce, and incorporating materials that can absorb and permanently store CO2 during the curing process. Notable milestones include the development of geopolymer cements, alkali-activated materials, and calcium silicate-based formulations that can absorb CO2 while maintaining or even improving structural performance.

Recent technological advancements have focused on enhancing carbon sequestration capacity while ensuring that the resulting concrete meets or exceeds industry standards for strength, durability, and workability. Current state-of-the-art carbon-negative concrete can sequester approximately 100-150 kg of CO2 per cubic meter, representing a significant improvement from earlier iterations that achieved only minimal carbon reduction.

The primary objective of carbon-negative concrete development is to transform the construction industry from a major carbon emitter to a potential carbon sink. Specific technical goals include increasing CO2 sequestration capacity to over 200 kg per cubic meter by 2030, reducing production costs to achieve price parity with conventional concrete, and scaling manufacturing processes to meet global demand. Additionally, researchers aim to optimize the longevity of carbon sequestration, ensuring that captured carbon remains permanently bound within the material throughout its lifecycle and eventual recycling.

Another critical objective is the standardization and certification of carbon-negative concrete, establishing clear metrics for measuring carbon sequestration performance and developing industry-accepted testing protocols. This standardization will facilitate wider adoption by providing stakeholders with reliable performance data and enabling regulatory frameworks that incentivize or mandate low-carbon building materials.

Market Analysis for Sustainable Construction Materials

The global construction materials market is experiencing a significant shift towards sustainable alternatives, with carbon-negative concrete emerging as a revolutionary solution addressing both infrastructure needs and environmental concerns. Current market analysis indicates that the traditional concrete industry contributes approximately 8% of global carbon emissions, creating an urgent demand for greener alternatives. The sustainable construction materials market was valued at $251.5 billion in 2022 and is projected to reach $432.4 billion by 2030, growing at a CAGR of 11.2%.

Carbon-negative concrete represents a particularly promising segment within this market. Unlike conventional concrete which releases substantial CO2 during production, carbon-negative variants actively sequester carbon dioxide, transforming a major climate liability into an environmental asset. Market penetration remains relatively low at 3-5% of total concrete production, but adoption rates are accelerating as regulatory pressures increase and corporate sustainability commitments expand.

Regional market dynamics show considerable variation. Europe leads in adoption with stringent carbon regulations and ambitious climate targets driving implementation. The European Green Deal has established concrete targets for carbon reduction in construction materials, creating a favorable market environment. North America follows with growing interest, particularly in urban centers with green building initiatives. The Asia-Pacific region represents the largest potential market by volume, though adoption remains concentrated in developed economies like Japan, South Korea, and Singapore.

Consumer willingness to pay premiums for sustainable construction materials varies significantly by sector. Commercial construction demonstrates the highest acceptance of price premiums (15-25%) for carbon-negative materials, driven by corporate ESG commitments and green building certification requirements. Public infrastructure projects increasingly incorporate sustainability requirements in procurement specifications, though price sensitivity remains higher. Residential construction shows growing interest but remains more price-sensitive, with acceptable premiums typically under 10%.

Key market drivers include tightening building codes and regulations, expanding green building certification programs, corporate carbon neutrality pledges, and increasing carbon pricing mechanisms. Barriers to wider adoption include higher initial costs, limited production capacity, technical performance concerns, and fragmented building codes. However, as economies of scale improve and carbon pricing becomes more widespread, the economic equation increasingly favors carbon-negative alternatives.

The competitive landscape features both established construction material companies pivoting toward sustainability and innovative startups developing proprietary carbon-negative formulations. Strategic partnerships between material scientists, concrete producers, and carbon capture specialists are accelerating commercialization timelines and expanding market reach.

Carbon-negative concrete represents a particularly promising segment within this market. Unlike conventional concrete which releases substantial CO2 during production, carbon-negative variants actively sequester carbon dioxide, transforming a major climate liability into an environmental asset. Market penetration remains relatively low at 3-5% of total concrete production, but adoption rates are accelerating as regulatory pressures increase and corporate sustainability commitments expand.

Regional market dynamics show considerable variation. Europe leads in adoption with stringent carbon regulations and ambitious climate targets driving implementation. The European Green Deal has established concrete targets for carbon reduction in construction materials, creating a favorable market environment. North America follows with growing interest, particularly in urban centers with green building initiatives. The Asia-Pacific region represents the largest potential market by volume, though adoption remains concentrated in developed economies like Japan, South Korea, and Singapore.

Consumer willingness to pay premiums for sustainable construction materials varies significantly by sector. Commercial construction demonstrates the highest acceptance of price premiums (15-25%) for carbon-negative materials, driven by corporate ESG commitments and green building certification requirements. Public infrastructure projects increasingly incorporate sustainability requirements in procurement specifications, though price sensitivity remains higher. Residential construction shows growing interest but remains more price-sensitive, with acceptable premiums typically under 10%.

Key market drivers include tightening building codes and regulations, expanding green building certification programs, corporate carbon neutrality pledges, and increasing carbon pricing mechanisms. Barriers to wider adoption include higher initial costs, limited production capacity, technical performance concerns, and fragmented building codes. However, as economies of scale improve and carbon pricing becomes more widespread, the economic equation increasingly favors carbon-negative alternatives.

The competitive landscape features both established construction material companies pivoting toward sustainability and innovative startups developing proprietary carbon-negative formulations. Strategic partnerships between material scientists, concrete producers, and carbon capture specialists are accelerating commercialization timelines and expanding market reach.

Current Challenges in Carbon-negative Concrete Development

Despite significant advancements in carbon-negative concrete technology, several critical challenges continue to impede widespread adoption and commercialization. The primary technical obstacle remains the scalability of carbon capture mechanisms within concrete production. Current methods for CO2 sequestration during curing processes achieve varying degrees of efficiency but struggle to maintain consistent performance when scaled to industrial production volumes.

Material inconsistency presents another significant challenge. Alternative cementitious materials such as calcined clays, industrial by-products, and novel binders demonstrate promising carbon-negative potential in laboratory settings but exhibit unpredictable behavior when subjected to diverse environmental conditions and varying raw material sources. This inconsistency creates difficulties in establishing standardized production protocols and quality assurance measures.

The energy intensity of carbon-negative concrete production paradoxically undermines its environmental benefits in many cases. Processes like mineral carbonation and specialized curing techniques often require substantial energy inputs, potentially offsetting carbon reduction gains. The industry faces the complex challenge of developing energy-efficient production methods that maintain carbon-negative credentials throughout the entire life cycle.

Durability and long-term performance verification remain inadequately addressed. While conventional concrete benefits from decades of performance data, carbon-negative alternatives lack comprehensive long-term testing. Questions persist regarding their resistance to freeze-thaw cycles, chemical exposure, and structural integrity over extended periods, creating hesitation among engineers and building code authorities.

Economic viability constitutes perhaps the most significant barrier to widespread implementation. Current production costs for carbon-negative concrete typically exceed those of conventional concrete by 20-150%, depending on the technology employed. This premium stems from specialized materials, additional processing steps, and quality control requirements. Without regulatory incentives or carbon pricing mechanisms, market penetration remains limited to niche applications and demonstration projects.

Regulatory frameworks and standardization processes have not kept pace with technological innovation. Building codes and material standards worldwide still primarily reference traditional concrete compositions, creating compliance challenges for novel carbon-negative formulations. The certification process for new concrete technologies often requires years of testing and documentation, significantly delaying market entry.

Supply chain limitations further constrain scaling efforts. Many carbon-negative concrete technologies rely on specific industrial by-products or specialized additives with limited availability. Establishing reliable, consistent supply chains for these critical components presents logistical challenges, particularly in regions without developed industrial infrastructure.

Material inconsistency presents another significant challenge. Alternative cementitious materials such as calcined clays, industrial by-products, and novel binders demonstrate promising carbon-negative potential in laboratory settings but exhibit unpredictable behavior when subjected to diverse environmental conditions and varying raw material sources. This inconsistency creates difficulties in establishing standardized production protocols and quality assurance measures.

The energy intensity of carbon-negative concrete production paradoxically undermines its environmental benefits in many cases. Processes like mineral carbonation and specialized curing techniques often require substantial energy inputs, potentially offsetting carbon reduction gains. The industry faces the complex challenge of developing energy-efficient production methods that maintain carbon-negative credentials throughout the entire life cycle.

Durability and long-term performance verification remain inadequately addressed. While conventional concrete benefits from decades of performance data, carbon-negative alternatives lack comprehensive long-term testing. Questions persist regarding their resistance to freeze-thaw cycles, chemical exposure, and structural integrity over extended periods, creating hesitation among engineers and building code authorities.

Economic viability constitutes perhaps the most significant barrier to widespread implementation. Current production costs for carbon-negative concrete typically exceed those of conventional concrete by 20-150%, depending on the technology employed. This premium stems from specialized materials, additional processing steps, and quality control requirements. Without regulatory incentives or carbon pricing mechanisms, market penetration remains limited to niche applications and demonstration projects.

Regulatory frameworks and standardization processes have not kept pace with technological innovation. Building codes and material standards worldwide still primarily reference traditional concrete compositions, creating compliance challenges for novel carbon-negative formulations. The certification process for new concrete technologies often requires years of testing and documentation, significantly delaying market entry.

Supply chain limitations further constrain scaling efforts. Many carbon-negative concrete technologies rely on specific industrial by-products or specialized additives with limited availability. Establishing reliable, consistent supply chains for these critical components presents logistical challenges, particularly in regions without developed industrial infrastructure.

Current Carbon-negative Concrete Formulations and Methods

01 Carbon sequestration in concrete production

Carbon-negative concrete can be achieved through processes that sequester more carbon dioxide than is emitted during production. These methods involve capturing CO2 from industrial sources or directly from the atmosphere and incorporating it into the concrete matrix during curing. The carbonation process converts CO2 into stable carbonate minerals, effectively locking carbon away permanently while simultaneously improving concrete strength and durability.- Carbon capture and sequestration in concrete: Carbon-negative concrete can be achieved through technologies that capture and sequester carbon dioxide during the concrete production process. These methods involve incorporating CO2 into the concrete mixture, where it reacts with calcium compounds to form stable carbonates. This process not only reduces the carbon footprint of concrete production but can actually result in net carbon sequestration, making the concrete carbon-negative over its lifecycle.

- Alternative cementitious materials for carbon reduction: The use of alternative cementitious materials such as supplementary cementitious materials (SCMs), geopolymers, and alkali-activated materials can significantly reduce the carbon footprint of concrete. These materials can partially or completely replace traditional Portland cement, which is responsible for the majority of carbon emissions in concrete production. By incorporating industrial byproducts like fly ash, slag, and silica fume, concrete can achieve carbon negativity while maintaining or improving performance characteristics.

- Biomass incorporation and carbonation curing: Incorporating biomass materials into concrete mixtures and utilizing carbonation curing techniques can create carbon-negative concrete products. Biomass materials, which have sequestered carbon during their growth, contribute to the overall carbon negativity. Additionally, accelerated carbonation curing processes expose fresh concrete to CO2-rich environments, promoting rapid carbon uptake and improving the mechanical properties of the final product.

- Carbon mineralization and enhanced weathering: Carbon mineralization and enhanced weathering techniques involve the conversion of CO2 into stable mineral carbonates within the concrete matrix. These processes accelerate natural weathering reactions that would otherwise take thousands of years. By engineering concrete formulations to promote these reactions, carbon dioxide can be permanently sequestered in mineral form, creating truly carbon-negative building materials that continue to absorb CO2 throughout their service life.

- Life cycle assessment and carbon credit systems: Comprehensive life cycle assessment methodologies and carbon credit systems have been developed specifically for carbon-negative concrete. These systems quantify the carbon sequestration potential of various concrete formulations and production methods, enabling accurate measurement of carbon negativity. Such frameworks are essential for validating carbon reduction claims, facilitating carbon trading, and incentivizing the adoption of carbon-negative concrete technologies in the construction industry.

02 Alternative cementitious materials for carbon reduction

Using alternative cementitious materials such as supplementary cementitious materials (SCMs), geopolymers, and alkali-activated materials can significantly reduce the carbon footprint of concrete. These materials often replace traditional Portland cement, which is responsible for substantial CO2 emissions. Materials like fly ash, slag, calcined clays, and natural pozzolans can be incorporated into concrete mixtures to achieve carbon negativity while maintaining or improving performance characteristics.Expand Specific Solutions03 Biomass incorporation and biogenic materials

Incorporating biomass and biogenic materials into concrete formulations can contribute to carbon negativity. These materials, which have already sequestered carbon during their growth phase, can be processed and used as partial replacements for traditional concrete components. Examples include agricultural waste products, wood derivatives, and other plant-based materials that can be carbonated or mineralized to create durable building materials with a negative carbon footprint.Expand Specific Solutions04 Enhanced carbonation techniques

Enhanced carbonation techniques accelerate and optimize the natural process of concrete carbonation to increase carbon sequestration. These methods include pressurized carbonation, elevated temperature carbonation, and the use of catalysts to promote the reaction between CO2 and calcium-rich components in concrete. By controlling the carbonation environment, concrete can be engineered to absorb significant amounts of CO2 during its lifecycle, contributing to carbon negativity.Expand Specific Solutions05 Carbon-negative concrete lifecycle management

Carbon-negative concrete can be achieved through comprehensive lifecycle management approaches that consider carbon impacts from raw material extraction through end-of-life recycling. This includes optimizing transportation logistics, using renewable energy in production, implementing carbon capture during manufacturing, designing for durability to extend service life, and developing methods for concrete recycling that maintain or enhance carbon sequestration properties. These integrated approaches ensure that the concrete remains carbon-negative throughout its entire lifecycle.Expand Specific Solutions

Leading Companies and Research Institutions in Green Concrete

The carbon-negative concrete market is in an early growth phase, characterized by increasing research activity and commercial pilot projects. The global market size is expanding rapidly, driven by construction industry sustainability goals and regulatory pressures to reduce carbon emissions. Technologically, carbon-negative concrete remains in development with varying maturity levels across approaches. Leading players include established construction materials companies like Holcim Technology and China National Building Material Group pursuing industrial-scale solutions, alongside innovative startups such as Carbon Limit Co. developing proprietary carbon capture technologies. Academic institutions including Central South University, Worcester Polytechnic Institute, and Shenzhen University are advancing fundamental research, while specialized research organizations like China Building Materials Academy and Tianjin Cement Industry Design & Research Institute bridge the gap between laboratory discoveries and commercial applications.

China Building Materials Academy Co. Ltd.

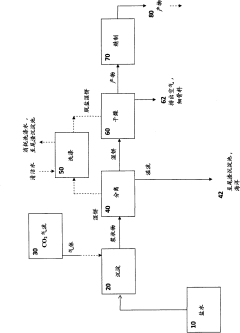

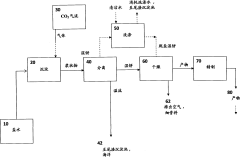

Technical Solution: China Building Materials Academy (CBMA) has developed an innovative carbon-negative concrete technology called "Carbonate Looping Cement" (CLC). This technology integrates carbon capture directly into the cement production process by using calcium looping, where calcium oxide captures CO2 during cement manufacturing and is then regenerated through calcination. The captured CO2 is subsequently mineralized within the concrete through their proprietary "Enhanced Mineral Carbonation" process. CBMA has also pioneered the use of novel supplementary cementitious materials derived from industrial solid wastes, including steel slag, phosphogypsum, and carbide slag, which are activated through their mechanochemical processing technology. Their research has yielded concrete formulations that can achieve up to 70% reduction in carbon emissions compared to conventional concrete while maintaining equivalent mechanical properties. Additionally, CBMA has developed specialized admixtures that enhance CO2 uptake during concrete curing, effectively turning the material into a carbon sink over its lifecycle.

Strengths: Comprehensive approach addressing both production emissions and carbon sequestration; utilizes abundant industrial waste materials available in China; technology can be implemented in existing cement plants with moderate modifications. Weaknesses: Energy requirements for calcium looping process may offset some carbon benefits; performance in freeze-thaw conditions needs further validation; technology optimization still ongoing for different concrete applications.

China National Building Material Group Co., Ltd.

Technical Solution: China National Building Material Group (CNBM) has developed a comprehensive carbon-negative concrete solution centered around their "Low Carbon Cement Matrix" technology. This approach incorporates multiple strategies including clinker substitution with calcined clay and industrial by-products like fly ash and slag at optimized ratios. CNBM's innovation includes a proprietary activation process that enhances the pozzolanic reactivity of these supplementary materials, allowing for higher replacement rates without compromising performance. Their technology also incorporates carbon capture directly at cement kilns, where the captured CO2 is then utilized in concrete curing chambers through a process called "Accelerated Mineral Carbonation." This process not only sequesters carbon but also improves early strength development. CNBM has further advanced the use of alternative fuels in cement production, including biomass and waste-derived fuels, which significantly reduces the carbon footprint of the manufacturing process while creating carbon credits.

Strengths: Vertical integration from cement production to concrete application allows for comprehensive carbon reduction; massive production scale enables significant industry-wide impact; technology maintains concrete performance while reducing carbon footprint. Weaknesses: Implementation requires substantial capital investment in production facilities; optimization needed for different regional raw materials; longer curing times may be required for some applications.

Key Patents and Innovations in CO2 Absorbing Materials

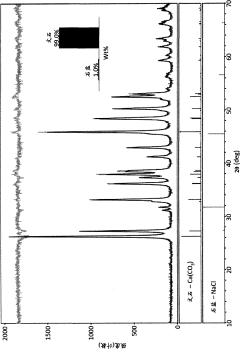

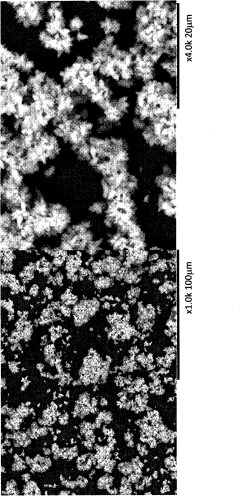

Co2-sequestering formed building materials

PatentActiveCN101990523A

Innovation

- Development of carbon-negative concrete using carbonate/bicarbonate components that can sequester up to 1 ton or more of CO2 per ton of material, achieving carbon reduction of up to 2 tons or more.

- Creation of blended cements using CO2-sequestering supplementary cementitious materials (SCMs) in combination with fly ash, slag, and/or Portland cement that achieve high compressive strength (≥2500 psi) in 28 days or less while maintaining a low, neutral, or negative carbon footprint.

- Development of carbon-negative concrete mixtures incorporating both CO2-sequestering SCMs and CO2-sequestering aggregates (coarse and fine) with high CO2 content (≥20%) that can achieve compressive strengths of 4000 psi in 28 days.

Negative carbon structure material and preparation method thereof

PatentActiveCN115403314A

Innovation

- By using carbonic anhydrase catalysis without using cement, carbon dioxide is used as one of the raw materials of structural materials, combined with calcium and magnesium ions and organic cross-linking agents to form negative carbon structural materials. The materials continue to absorb during the preparation and use process. Carbon dioxide achieves carbon negative effect.

Environmental Impact Assessment and Carbon Lifecycle Analysis

Carbon-negative concrete represents a revolutionary approach to construction materials that actively removes more carbon dioxide from the atmosphere than it emits during production. Comprehensive environmental impact assessment and carbon lifecycle analysis are essential to validate these claims and quantify the true sustainability benefits of these innovative materials.

Life Cycle Assessment (LCA) studies of carbon-negative concrete reveal significant potential for greenhouse gas reduction compared to traditional Portland cement concrete. While conventional concrete production accounts for approximately 8% of global CO2 emissions, carbon-negative alternatives can achieve net carbon sequestration through innovative material science approaches. These include incorporation of CO2-absorbing aggregates, alternative binders that require less energy to produce, and manufacturing processes that actively capture carbon.

The carbon lifecycle of these materials must be analyzed across multiple phases: raw material extraction, processing, manufacturing, transportation, installation, use phase, and end-of-life scenarios. Research indicates that carbon-negative concrete can sequester between 10-30 kg of CO2 per cubic meter, depending on the specific formulation and production methods employed. This represents a dramatic improvement over conventional concrete, which typically emits 300-400 kg of CO2 per cubic meter.

Environmental impact assessments must also consider other ecological factors beyond carbon footprint. Water usage in carbon-negative concrete production can be significantly lower than traditional methods, with some formulations requiring up to 60% less water. Additionally, many carbon-negative concrete technologies utilize industrial byproducts and waste materials, reducing landfill burden and resource extraction impacts.

Air quality impacts present another important consideration. The production of traditional cement creates significant particulate matter and SOx/NOx emissions. Carbon-negative alternatives often demonstrate reduced air pollutant emissions due to lower kiln temperatures and alternative material processing methods, though comprehensive data across all formulations remains limited.

Long-term durability represents a critical factor in true environmental assessment. If carbon-negative concrete demonstrates shorter service life than traditional materials, the embodied carbon benefits may be offset by more frequent replacement cycles. Current research indicates promising durability characteristics for many formulations, though long-term performance data beyond laboratory settings remains an area requiring further investigation.

Standardized methodologies for carbon accounting in these materials are still evolving. Challenges include accurately measuring carbon sequestration rates over time, accounting for geographical and climate variations in performance, and establishing industry-accepted verification protocols. Organizations including ASTM International and the International Organization for Standardization are actively developing frameworks to address these challenges.

Life Cycle Assessment (LCA) studies of carbon-negative concrete reveal significant potential for greenhouse gas reduction compared to traditional Portland cement concrete. While conventional concrete production accounts for approximately 8% of global CO2 emissions, carbon-negative alternatives can achieve net carbon sequestration through innovative material science approaches. These include incorporation of CO2-absorbing aggregates, alternative binders that require less energy to produce, and manufacturing processes that actively capture carbon.

The carbon lifecycle of these materials must be analyzed across multiple phases: raw material extraction, processing, manufacturing, transportation, installation, use phase, and end-of-life scenarios. Research indicates that carbon-negative concrete can sequester between 10-30 kg of CO2 per cubic meter, depending on the specific formulation and production methods employed. This represents a dramatic improvement over conventional concrete, which typically emits 300-400 kg of CO2 per cubic meter.

Environmental impact assessments must also consider other ecological factors beyond carbon footprint. Water usage in carbon-negative concrete production can be significantly lower than traditional methods, with some formulations requiring up to 60% less water. Additionally, many carbon-negative concrete technologies utilize industrial byproducts and waste materials, reducing landfill burden and resource extraction impacts.

Air quality impacts present another important consideration. The production of traditional cement creates significant particulate matter and SOx/NOx emissions. Carbon-negative alternatives often demonstrate reduced air pollutant emissions due to lower kiln temperatures and alternative material processing methods, though comprehensive data across all formulations remains limited.

Long-term durability represents a critical factor in true environmental assessment. If carbon-negative concrete demonstrates shorter service life than traditional materials, the embodied carbon benefits may be offset by more frequent replacement cycles. Current research indicates promising durability characteristics for many formulations, though long-term performance data beyond laboratory settings remains an area requiring further investigation.

Standardized methodologies for carbon accounting in these materials are still evolving. Challenges include accurately measuring carbon sequestration rates over time, accounting for geographical and climate variations in performance, and establishing industry-accepted verification protocols. Organizations including ASTM International and the International Organization for Standardization are actively developing frameworks to address these challenges.

Regulatory Framework and Green Building Standards

The regulatory landscape for carbon-negative concrete is rapidly evolving as governments worldwide implement policies to reduce carbon emissions in the construction sector. The European Union leads with its Green Deal and Circular Economy Action Plan, which specifically targets construction materials and incentivizes low-carbon alternatives. These regulations establish carbon intensity thresholds for building materials and provide financial mechanisms to support the adoption of carbon-negative concrete technologies.

In the United States, regulations vary by state, with California's Buy Clean California Act setting precedent by requiring Environmental Product Declarations (EPDs) for construction materials used in state-funded projects. This approach creates market pressure for lower-carbon concrete solutions. Similarly, New York and Washington have implemented procurement policies that favor carbon-negative building materials, creating regional markets for innovative concrete technologies.

Green building certification systems play a crucial role in driving market adoption of carbon-negative concrete. LEED (Leadership in Energy and Environmental Design) has updated its materials credits to reward carbon reduction strategies, including points specifically for using carbon-negative concrete. The Living Building Challenge goes further, requiring carbon-neutral or carbon-negative materials for its certification. These standards create significant market pull for innovative concrete solutions.

The Embodied Carbon in Construction Calculator (EC3) tool has emerged as an industry standard for measuring and comparing the carbon footprint of building materials. This tool enables project teams to make informed decisions about material selection based on verified carbon data, facilitating compliance with both regulations and certification requirements.

International standards organizations are developing specific protocols for carbon-negative materials. ISO is working on standards for carbon capture, utilization, and storage in building materials, while ASTM International is developing testing methods to verify carbon sequestration claims in concrete products. These standards will provide the technical foundation for regulatory frameworks and ensure consistency in carbon accounting.

Financial incentives are increasingly aligned with regulatory frameworks. Carbon pricing mechanisms, tax credits for carbon-negative materials, and green bonds specifically supporting low-carbon infrastructure create economic drivers for adoption. The EU Taxonomy for Sustainable Activities explicitly recognizes carbon-negative concrete as an environmentally sustainable investment, directing capital toward these technologies.

Procurement policies represent another powerful regulatory tool. Several countries have implemented carbon-based procurement requirements for public infrastructure projects, creating guaranteed markets for carbon-negative concrete products and accelerating their commercial development and deployment.

In the United States, regulations vary by state, with California's Buy Clean California Act setting precedent by requiring Environmental Product Declarations (EPDs) for construction materials used in state-funded projects. This approach creates market pressure for lower-carbon concrete solutions. Similarly, New York and Washington have implemented procurement policies that favor carbon-negative building materials, creating regional markets for innovative concrete technologies.

Green building certification systems play a crucial role in driving market adoption of carbon-negative concrete. LEED (Leadership in Energy and Environmental Design) has updated its materials credits to reward carbon reduction strategies, including points specifically for using carbon-negative concrete. The Living Building Challenge goes further, requiring carbon-neutral or carbon-negative materials for its certification. These standards create significant market pull for innovative concrete solutions.

The Embodied Carbon in Construction Calculator (EC3) tool has emerged as an industry standard for measuring and comparing the carbon footprint of building materials. This tool enables project teams to make informed decisions about material selection based on verified carbon data, facilitating compliance with both regulations and certification requirements.

International standards organizations are developing specific protocols for carbon-negative materials. ISO is working on standards for carbon capture, utilization, and storage in building materials, while ASTM International is developing testing methods to verify carbon sequestration claims in concrete products. These standards will provide the technical foundation for regulatory frameworks and ensure consistency in carbon accounting.

Financial incentives are increasingly aligned with regulatory frameworks. Carbon pricing mechanisms, tax credits for carbon-negative materials, and green bonds specifically supporting low-carbon infrastructure create economic drivers for adoption. The EU Taxonomy for Sustainable Activities explicitly recognizes carbon-negative concrete as an environmentally sustainable investment, directing capital toward these technologies.

Procurement policies represent another powerful regulatory tool. Several countries have implemented carbon-based procurement requirements for public infrastructure projects, creating guaranteed markets for carbon-negative concrete products and accelerating their commercial development and deployment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!