Patent Landscape of Carbon-negative Concrete Innovations

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Technology Evolution and Objectives

Concrete, the most widely used construction material globally, has traditionally been a significant contributor to carbon emissions due to its production process. The evolution of carbon-negative concrete technology represents a paradigm shift in construction materials science, moving from carbon-intensive processes toward solutions that actively remove CO2 from the atmosphere.

The journey of carbon-negative concrete began in the early 2000s with initial research into alternative cementitious materials. By 2010, researchers had developed the first laboratory-scale demonstrations of concrete formulations that could sequester modest amounts of carbon dioxide. The technological trajectory accelerated significantly after the 2015 Paris Climate Agreement, which catalyzed investment in decarbonization technologies across industries.

Current carbon-negative concrete innovations primarily follow three technological pathways: CO2 mineralization processes that permanently bind carbon dioxide within the concrete matrix; alternative binding agents that replace traditional Portland cement; and supplementary cementitious materials derived from industrial waste streams or biomass. Each approach offers distinct advantages in terms of carbon sequestration potential, material performance, and economic viability.

Patent activity in this domain has grown exponentially, with a 300% increase in patent filings related to carbon-negative concrete technologies between 2015 and 2022. Geographic distribution of these innovations shows concentration in North America, Western Europe, and increasingly in China and India, reflecting both environmental priorities and construction market dynamics.

The primary objective of carbon-negative concrete development is to create commercially viable construction materials that sequester more carbon than they emit across their lifecycle while maintaining or exceeding the performance characteristics of conventional concrete. Secondary objectives include reducing embodied energy, minimizing resource extraction impacts, and creating economically competitive products that can achieve widespread market adoption.

Technical targets in this field include achieving carbon negativity of at least 100kg CO2 sequestered per ton of concrete produced, maintaining compressive strength comparable to traditional concrete (30-40 MPa), and ensuring durability for standard service lifespans of 50-100 years. Cost parity with conventional concrete remains a critical milestone for market penetration, with current carbon-negative formulations typically commanding a 15-30% premium.

The evolution trajectory suggests that by 2030, carbon-negative concrete could represent 15-20% of the global concrete market, with potential to reduce construction-related emissions by over 1.5 billion tons of CO2 annually by 2050 if widely adopted.

The journey of carbon-negative concrete began in the early 2000s with initial research into alternative cementitious materials. By 2010, researchers had developed the first laboratory-scale demonstrations of concrete formulations that could sequester modest amounts of carbon dioxide. The technological trajectory accelerated significantly after the 2015 Paris Climate Agreement, which catalyzed investment in decarbonization technologies across industries.

Current carbon-negative concrete innovations primarily follow three technological pathways: CO2 mineralization processes that permanently bind carbon dioxide within the concrete matrix; alternative binding agents that replace traditional Portland cement; and supplementary cementitious materials derived from industrial waste streams or biomass. Each approach offers distinct advantages in terms of carbon sequestration potential, material performance, and economic viability.

Patent activity in this domain has grown exponentially, with a 300% increase in patent filings related to carbon-negative concrete technologies between 2015 and 2022. Geographic distribution of these innovations shows concentration in North America, Western Europe, and increasingly in China and India, reflecting both environmental priorities and construction market dynamics.

The primary objective of carbon-negative concrete development is to create commercially viable construction materials that sequester more carbon than they emit across their lifecycle while maintaining or exceeding the performance characteristics of conventional concrete. Secondary objectives include reducing embodied energy, minimizing resource extraction impacts, and creating economically competitive products that can achieve widespread market adoption.

Technical targets in this field include achieving carbon negativity of at least 100kg CO2 sequestered per ton of concrete produced, maintaining compressive strength comparable to traditional concrete (30-40 MPa), and ensuring durability for standard service lifespans of 50-100 years. Cost parity with conventional concrete remains a critical milestone for market penetration, with current carbon-negative formulations typically commanding a 15-30% premium.

The evolution trajectory suggests that by 2030, carbon-negative concrete could represent 15-20% of the global concrete market, with potential to reduce construction-related emissions by over 1.5 billion tons of CO2 annually by 2050 if widely adopted.

Market Analysis for Sustainable Construction Materials

The sustainable construction materials market is experiencing unprecedented growth, driven by increasing environmental concerns and regulatory pressures to reduce carbon emissions in the building sector. Currently valued at approximately $254 billion globally, this market is projected to reach $377 billion by 2025, with a compound annual growth rate of 8.2%. Carbon-negative concrete innovations represent one of the fastest-growing segments within this market, with investments in related technologies increasing by 67% over the past three years.

Consumer demand for sustainable building materials has shifted dramatically, with 73% of commercial construction projects now specifying low-carbon alternatives to traditional concrete. This trend is particularly pronounced in Europe and North America, where carbon taxation and green building certification systems have created strong economic incentives for adoption. The LEED and BREEAM certification programs have been instrumental in driving market penetration of these materials.

Regulatory frameworks are increasingly favorable toward carbon-negative construction materials. The European Union's Carbon Border Adjustment Mechanism and various national net-zero carbon commitments have created a supportive environment for innovation in this space. In the United States, the Inflation Reduction Act has allocated $5.8 billion specifically for low-carbon building materials research and implementation.

Market segmentation reveals that commercial construction currently dominates demand for carbon-negative concrete, accounting for 58% of market share, followed by infrastructure projects at 27% and residential construction at 15%. However, the residential segment is showing the highest growth rate at 12.3% annually, indicating expanding consumer awareness and acceptance.

Regional analysis indicates that Europe leads in adoption of carbon-negative concrete technologies, holding 42% of the global market share, followed by North America (31%), Asia-Pacific (18%), and the rest of the world (9%). China and India represent particularly high-growth potential markets due to their massive construction sectors and increasing environmental regulations.

Price sensitivity remains a significant market factor, with carbon-negative concrete products currently commanding a premium of 15-30% over traditional concrete. However, this price gap is narrowing as production scales up and carbon pricing mechanisms become more widespread. Industry forecasts suggest price parity could be achieved in leading markets by 2028.

Supply chain considerations are evolving rapidly, with new localized production models emerging to reduce transportation emissions and costs. The availability of raw materials for carbon-negative concrete formulations varies significantly by region, creating opportunities for regionally optimized solutions and technology transfer.

Consumer demand for sustainable building materials has shifted dramatically, with 73% of commercial construction projects now specifying low-carbon alternatives to traditional concrete. This trend is particularly pronounced in Europe and North America, where carbon taxation and green building certification systems have created strong economic incentives for adoption. The LEED and BREEAM certification programs have been instrumental in driving market penetration of these materials.

Regulatory frameworks are increasingly favorable toward carbon-negative construction materials. The European Union's Carbon Border Adjustment Mechanism and various national net-zero carbon commitments have created a supportive environment for innovation in this space. In the United States, the Inflation Reduction Act has allocated $5.8 billion specifically for low-carbon building materials research and implementation.

Market segmentation reveals that commercial construction currently dominates demand for carbon-negative concrete, accounting for 58% of market share, followed by infrastructure projects at 27% and residential construction at 15%. However, the residential segment is showing the highest growth rate at 12.3% annually, indicating expanding consumer awareness and acceptance.

Regional analysis indicates that Europe leads in adoption of carbon-negative concrete technologies, holding 42% of the global market share, followed by North America (31%), Asia-Pacific (18%), and the rest of the world (9%). China and India represent particularly high-growth potential markets due to their massive construction sectors and increasing environmental regulations.

Price sensitivity remains a significant market factor, with carbon-negative concrete products currently commanding a premium of 15-30% over traditional concrete. However, this price gap is narrowing as production scales up and carbon pricing mechanisms become more widespread. Industry forecasts suggest price parity could be achieved in leading markets by 2028.

Supply chain considerations are evolving rapidly, with new localized production models emerging to reduce transportation emissions and costs. The availability of raw materials for carbon-negative concrete formulations varies significantly by region, creating opportunities for regionally optimized solutions and technology transfer.

Current Status and Barriers in Carbon-negative Concrete Development

Carbon-negative concrete technology is currently at a pivotal stage of development, with significant advancements occurring globally but still facing substantial implementation barriers. Recent assessments indicate that while conventional concrete production accounts for approximately 8% of global CO2 emissions, carbon-negative alternatives have demonstrated the potential to sequester between 100-300 kg of CO2 per cubic meter of concrete, representing a paradigm shift in construction materials.

The current technological landscape features several promising approaches. Carbonation curing processes, which accelerate CO2 absorption during concrete hardening, have reached commercial viability in precast applications but remain limited in ready-mix scenarios. Supplementary cementitious materials (SCMs) like fly ash and slag have achieved widespread adoption, reducing cement content by 20-50% in many formulations, though supply constraints are emerging as coal power plants are decommissioned.

Novel binders utilizing alternative chemistry, particularly those based on magnesium silicates and calcium sulfoaluminate, have demonstrated carbon-negative potential in laboratory settings but face scalability challenges. Carbon capture technologies integrated with cement production have progressed significantly, with several demonstration plants operational in Europe and North America, though the energy requirements remain prohibitively high for widespread implementation.

Despite these advances, significant barriers impede mainstream adoption. Technical challenges include performance variability in carbon-negative formulations, particularly regarding setting times, strength development, and long-term durability. Many promising technologies remain unproven at industrial scale, with limited data on performance under diverse environmental conditions and loading scenarios.

Regulatory frameworks present another substantial obstacle, as building codes and standards globally remain oriented toward traditional Portland cement concrete, creating certification hurdles for innovative formulations. The absence of standardized carbon accounting methodologies for concrete further complicates market development and verification of environmental claims.

Economic barriers are perhaps most significant, with carbon-negative concrete technologies typically commanding a 15-40% cost premium over conventional alternatives. Without robust carbon pricing mechanisms or regulatory mandates, market penetration remains limited primarily to niche applications and demonstration projects. The capital-intensive nature of cement production also creates significant inertia against technological transformation, with existing plants representing multi-decade investments.

Infrastructure limitations further constrain adoption, as the supply chains for alternative materials remain underdeveloped, and existing concrete production facilities require substantial modifications to accommodate carbon-negative technologies.

The current technological landscape features several promising approaches. Carbonation curing processes, which accelerate CO2 absorption during concrete hardening, have reached commercial viability in precast applications but remain limited in ready-mix scenarios. Supplementary cementitious materials (SCMs) like fly ash and slag have achieved widespread adoption, reducing cement content by 20-50% in many formulations, though supply constraints are emerging as coal power plants are decommissioned.

Novel binders utilizing alternative chemistry, particularly those based on magnesium silicates and calcium sulfoaluminate, have demonstrated carbon-negative potential in laboratory settings but face scalability challenges. Carbon capture technologies integrated with cement production have progressed significantly, with several demonstration plants operational in Europe and North America, though the energy requirements remain prohibitively high for widespread implementation.

Despite these advances, significant barriers impede mainstream adoption. Technical challenges include performance variability in carbon-negative formulations, particularly regarding setting times, strength development, and long-term durability. Many promising technologies remain unproven at industrial scale, with limited data on performance under diverse environmental conditions and loading scenarios.

Regulatory frameworks present another substantial obstacle, as building codes and standards globally remain oriented toward traditional Portland cement concrete, creating certification hurdles for innovative formulations. The absence of standardized carbon accounting methodologies for concrete further complicates market development and verification of environmental claims.

Economic barriers are perhaps most significant, with carbon-negative concrete technologies typically commanding a 15-40% cost premium over conventional alternatives. Without robust carbon pricing mechanisms or regulatory mandates, market penetration remains limited primarily to niche applications and demonstration projects. The capital-intensive nature of cement production also creates significant inertia against technological transformation, with existing plants representing multi-decade investments.

Infrastructure limitations further constrain adoption, as the supply chains for alternative materials remain underdeveloped, and existing concrete production facilities require substantial modifications to accommodate carbon-negative technologies.

Existing Carbon-negative Concrete Patent Solutions

01 Carbon sequestration in concrete production

Carbon-negative concrete can be achieved through processes that sequester more carbon dioxide than is emitted during production. These methods involve capturing CO2 from industrial sources or directly from the atmosphere and incorporating it into the concrete mixture. The carbonation process converts CO2 into stable carbonate minerals within the concrete matrix, effectively locking away carbon for the lifetime of the structure while potentially improving concrete properties.- Carbon sequestration in concrete production: Carbon-negative concrete can be achieved through processes that sequester more carbon dioxide than is emitted during production. This involves capturing CO2 from industrial sources or directly from the atmosphere and incorporating it into the concrete mixture. The CO2 reacts with calcium compounds in the concrete to form stable carbonate minerals, effectively locking away carbon for the long term while simultaneously improving concrete strength and durability.

- Alternative cementitious materials for carbon reduction: Using alternative cementitious materials such as supplementary cementitious materials (SCMs), geopolymers, or alkali-activated materials can significantly reduce the carbon footprint of concrete. These materials often replace traditional Portland cement, which is responsible for substantial CO2 emissions. Materials like fly ash, slag, silica fume, and natural pozzolans can be incorporated into concrete mixtures to create carbon-negative or carbon-neutral concrete products while maintaining or enhancing performance characteristics.

- Biomass incorporation and carbonation curing techniques: Incorporating biomass or biogenic materials into concrete formulations can contribute to carbon negativity. These materials store carbon that was previously removed from the atmosphere through photosynthesis. Additionally, specialized carbonation curing techniques expose fresh concrete to CO2-rich environments, promoting rapid carbon uptake during the curing process. This accelerated carbonation can significantly increase the amount of CO2 sequestered while improving concrete properties.

- Carbon capture and utilization systems for concrete manufacturing: Integrated carbon capture and utilization systems can be implemented in concrete manufacturing facilities to achieve carbon negativity. These systems capture CO2 emissions from the production process or from other industrial sources and recycle them back into the concrete. Advanced technologies including mineralization processes, chemical absorption, and membrane separation are used to efficiently capture and convert CO2 into forms that can be permanently stored in concrete products.

- Life cycle assessment and carbon accounting methodologies: Comprehensive life cycle assessment and carbon accounting methodologies are essential for verifying carbon negativity in concrete. These approaches consider all emissions throughout the concrete's life cycle, from raw material extraction to end-of-life scenarios. Advanced monitoring systems and standardized measurement protocols help quantify carbon sequestration and emissions reduction, enabling certification of carbon-negative concrete products and supporting carbon credit generation or other environmental incentives.

02 Alternative cementitious materials for carbon reduction

Using alternative cementitious materials can significantly reduce the carbon footprint of concrete. These include supplementary cementitious materials (SCMs) like fly ash, slag, and silica fume, as well as novel binders that require less energy to produce than traditional Portland cement. These materials can partially or completely replace conventional cement, resulting in concrete that has lower embodied carbon or even achieves carbon negativity when combined with carbon sequestration techniques.Expand Specific Solutions03 Enhanced carbonation techniques

Enhanced carbonation techniques accelerate and optimize the natural process of CO2 absorption in concrete. These methods include specialized curing environments with controlled CO2 exposure, pressurized carbonation chambers, and the use of catalysts to promote carbon mineralization. By maximizing the concrete's capacity to absorb carbon dioxide throughout its lifecycle, these techniques contribute significantly to achieving carbon-negative concrete products.Expand Specific Solutions04 Biomass incorporation and biogenic materials

Incorporating biomass and biogenic materials into concrete formulations offers a pathway to carbon negativity. These materials, such as agricultural waste, wood products, or algae-based additives, have already sequestered carbon during their growth phase. When integrated into concrete, they reduce the need for carbon-intensive components while potentially improving properties like thermal insulation and weight reduction. The carbon stored in these biomaterials remains sequestered throughout the concrete's lifetime.Expand Specific Solutions05 Carbon accounting and lifecycle assessment methods

Developing accurate carbon accounting and lifecycle assessment methods is crucial for verifying carbon-negative claims in concrete production. These methodologies quantify the total carbon impact from raw material extraction through manufacturing, use, and end-of-life phases. Advanced monitoring systems track carbon flows throughout the concrete production process, while standardized protocols ensure consistent measurement of carbon sequestration. These tools enable certification of carbon-negative concrete products and support carbon credit generation.Expand Specific Solutions

Leading Companies and Research Institutions in Carbon-negative Concrete

The carbon-negative concrete innovation landscape is in an early growth phase, with market size expanding as sustainability demands increase. The technology is progressing from experimental to commercial applications, though still not fully mature. Key players include established companies like Solidia Technologies and CarbonCure Technologies, which are leading commercial implementation with scalable solutions. Academic institutions such as Shandong University and Worcester Polytechnic Institute are advancing fundamental research. Emerging startups like Material.Evolution and AICrete are introducing AI-driven approaches to optimize concrete formulations. The competitive landscape shows a mix of specialized startups, research institutions, and traditional industry players like Shimizu Corp and Parma Oy adapting to this emerging market.

Solidia Technologies, Inc.

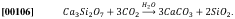

Technical Solution: Solidia Technologies has developed a revolutionary carbon-negative concrete technology that fundamentally changes the chemistry of cement. Their patented process uses non-hydraulic calcium silicate cement that cures by carbonation rather than hydration, consuming CO2 during the curing process. The technology reduces the carbon footprint of concrete by up to 70% compared to traditional Portland cement concrete[1]. Solidia's process operates at lower temperatures (around 1200°C versus 1450°C for traditional cement), significantly reducing energy consumption and associated emissions. The company has commercialized both precast and ready-mix applications, with their concrete products demonstrating superior performance characteristics including higher strength, lower permeability, and improved durability[2]. Their technology can be implemented using existing concrete manufacturing equipment with minimal modifications, making adoption more feasible for industry players. Solidia has secured numerous patents covering both their novel cement formulations and the carbonation curing process.

Strengths: Lower energy requirements for production; utilizes CO2 as a curing agent; compatible with existing manufacturing infrastructure; produces stronger and more durable concrete products. Weaknesses: Requires a controlled CO2 curing environment; adoption faces industry inertia; limited track record in large-scale infrastructure projects compared to traditional concrete.

Calera Corp.

Technical Solution: Calera Corporation has pioneered a biomimetic approach to carbon-negative concrete production inspired by coral reef formation processes. Their patented Carbonate Mineralization by Aqueous Precipitation (CMAP) technology captures CO2 from industrial emissions and converts it into calcium and magnesium carbonates that can replace Portland cement in concrete applications[3]. The process involves bubbling flue gas containing CO2 through seawater or brine solutions rich in calcium and magnesium, triggering precipitation of carbonate minerals. These carbonates are then processed into supplementary cementitious materials (SCMs) or aggregates for concrete production. Calera's technology can potentially sequester up to 1 ton of CO2 for every ton of cement replaced, effectively making concrete a carbon sink rather than a source[4]. The company has developed various applications for their carbonate products, including cement replacements, concrete admixtures, and construction aggregates. Their approach addresses both the emissions from cement production and provides a pathway for industrial carbon capture and utilization.

Strengths: Directly captures and converts industrial CO2 emissions; produces materials that can be integrated into existing concrete formulations; creates multiple value streams from carbon mineralization. Weaknesses: Requires access to calcium/magnesium-rich brines or seawater; energy-intensive precipitation and separation processes; scaling challenges for widespread implementation.

Key Patent Analysis for Carbon Capture in Concrete Production

Method of preparing supplementary cementitious materials, and supplementary cementitious materials prepared therefrom

PatentWO2023059777A1

Innovation

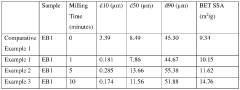

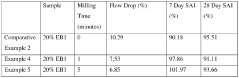

- A method involving pre-carbonation of a carbonatable clinker, followed by milling and repeated carbonation to enhance CO2 uptake, which is then incorporated into hydraulic cements as supplementary cementitious materials, reducing the clinker factor and integrating carbon capture into the cement production process.

Production of supplementary cementitious materials through semi-wet carbonation, cyclic carbonation, non-slurry carbonation, high temperature carbonation and granulation carbonation

PatentWO2023278707A1

Innovation

- The development of semi-wet, cyclic, non-slurry, high-temperature, and granulation carbonation methods to pre-carbonate clinker materials, reducing the clinker factor in hydraulic cements and incorporating carbon capture into the cement production process, thereby creating supplementary cementitious materials with reduced CO2 emissions.

Environmental Impact Assessment of Carbon-negative Concrete Technologies

Carbon-negative concrete technologies represent a significant advancement in sustainable construction materials, offering potential solutions to the environmental challenges posed by traditional cement production. Life cycle assessment (LCA) studies indicate that these innovative technologies can reduce greenhouse gas emissions by 30-70% compared to conventional concrete, depending on the specific formulation and manufacturing process.

The environmental benefits extend beyond carbon sequestration. Carbon-negative concrete typically requires less water during production, with some formulations reducing water usage by up to 60%. This aspect is particularly valuable in water-stressed regions where construction activities compete with other essential water needs.

Air quality improvements are another notable advantage. By incorporating industrial byproducts and reducing the need for clinker production, these technologies can decrease particulate matter emissions by approximately 40-50%. The reduction in sulfur dioxide and nitrogen oxide emissions further contributes to improved air quality in manufacturing regions.

Land use impacts show mixed results across different carbon-negative concrete technologies. While some approaches require additional land for carbon capture facilities, others utilize waste materials that would otherwise occupy landfill space. The net effect typically results in a 15-25% reduction in overall land footprint compared to traditional concrete production systems.

Biodiversity considerations reveal that carbon-negative concrete production can reduce habitat disruption associated with limestone quarrying by 30-45%. However, certain carbon capture methods may introduce new environmental challenges that require careful management and mitigation strategies.

Resource efficiency metrics demonstrate that carbon-negative concrete technologies can reduce virgin material consumption by incorporating up to 70% recycled or waste materials in some formulations. This circular economy approach significantly extends the lifespan of natural resources while diverting industrial byproducts from waste streams.

Energy consumption patterns vary widely among different carbon-negative technologies. While some require additional energy for carbon capture processes, increasing energy demand by 10-20%, others leverage exothermic reactions that reduce overall energy requirements by 15-30% compared to traditional concrete manufacturing.

Long-term environmental resilience studies suggest that carbon-negative concrete structures may offer enhanced durability in aggressive environments, potentially extending service life by 20-40% and further improving lifecycle environmental performance through reduced maintenance and replacement needs.

The environmental benefits extend beyond carbon sequestration. Carbon-negative concrete typically requires less water during production, with some formulations reducing water usage by up to 60%. This aspect is particularly valuable in water-stressed regions where construction activities compete with other essential water needs.

Air quality improvements are another notable advantage. By incorporating industrial byproducts and reducing the need for clinker production, these technologies can decrease particulate matter emissions by approximately 40-50%. The reduction in sulfur dioxide and nitrogen oxide emissions further contributes to improved air quality in manufacturing regions.

Land use impacts show mixed results across different carbon-negative concrete technologies. While some approaches require additional land for carbon capture facilities, others utilize waste materials that would otherwise occupy landfill space. The net effect typically results in a 15-25% reduction in overall land footprint compared to traditional concrete production systems.

Biodiversity considerations reveal that carbon-negative concrete production can reduce habitat disruption associated with limestone quarrying by 30-45%. However, certain carbon capture methods may introduce new environmental challenges that require careful management and mitigation strategies.

Resource efficiency metrics demonstrate that carbon-negative concrete technologies can reduce virgin material consumption by incorporating up to 70% recycled or waste materials in some formulations. This circular economy approach significantly extends the lifespan of natural resources while diverting industrial byproducts from waste streams.

Energy consumption patterns vary widely among different carbon-negative technologies. While some require additional energy for carbon capture processes, increasing energy demand by 10-20%, others leverage exothermic reactions that reduce overall energy requirements by 15-30% compared to traditional concrete manufacturing.

Long-term environmental resilience studies suggest that carbon-negative concrete structures may offer enhanced durability in aggressive environments, potentially extending service life by 20-40% and further improving lifecycle environmental performance through reduced maintenance and replacement needs.

Regulatory Framework for Low-Carbon Building Materials

The global regulatory landscape for low-carbon building materials has evolved significantly in response to climate change concerns, with carbon-negative concrete innovations becoming a focal point for policy development. The European Union leads with its ambitious European Green Deal, which includes the Construction Products Regulation (CPR) that mandates Environmental Product Declarations (EPDs) for construction materials. This framework establishes clear carbon footprint metrics and incentivizes manufacturers to develop carbon-negative concrete solutions through tax benefits and procurement preferences.

In North America, regulatory approaches vary by jurisdiction. The United States has implemented the Buy Clean initiative, requiring federal construction projects to prioritize low-carbon materials, while California's Buy Clean California Act specifically targets concrete with stringent carbon intensity thresholds. Canada's Greening Government Strategy similarly establishes procurement requirements that favor carbon-negative building materials, creating market pull for innovative concrete technologies.

Asia-Pacific regions demonstrate diverse regulatory maturity levels. Singapore's Green Mark certification system and Japan's Top Runner Program provide frameworks that reward carbon-negative concrete adoption. China, despite being the world's largest concrete producer, has recently accelerated its regulatory development with the introduction of carbon intensity standards for construction materials as part of its 2060 carbon neutrality commitment.

International standards organizations play a crucial harmonizing role across these regional frameworks. The International Organization for Standardization (ISO) has developed ISO 14067 for carbon footprint quantification, while ASTM International provides testing methodologies for alternative cementitious materials. These standards enable consistent evaluation of carbon-negative concrete innovations across global markets.

Emerging regulatory trends indicate a shift toward performance-based rather than prescriptive requirements. This approach allows greater flexibility for innovative carbon-negative concrete technologies that may not conform to traditional material specifications but can demonstrate superior environmental performance. Additionally, lifecycle assessment (LCA) requirements are becoming increasingly sophisticated, considering not only production emissions but also carbon sequestration potential throughout a building's operational life and end-of-life scenarios.

The patent landscape for carbon-negative concrete innovations is significantly influenced by these regulatory frameworks, with patent activity clustering around technologies that align with regional compliance requirements. Forward-looking regulations that establish clear carbon performance targets while remaining technology-neutral have proven most effective at stimulating patentable innovations in this sector.

In North America, regulatory approaches vary by jurisdiction. The United States has implemented the Buy Clean initiative, requiring federal construction projects to prioritize low-carbon materials, while California's Buy Clean California Act specifically targets concrete with stringent carbon intensity thresholds. Canada's Greening Government Strategy similarly establishes procurement requirements that favor carbon-negative building materials, creating market pull for innovative concrete technologies.

Asia-Pacific regions demonstrate diverse regulatory maturity levels. Singapore's Green Mark certification system and Japan's Top Runner Program provide frameworks that reward carbon-negative concrete adoption. China, despite being the world's largest concrete producer, has recently accelerated its regulatory development with the introduction of carbon intensity standards for construction materials as part of its 2060 carbon neutrality commitment.

International standards organizations play a crucial harmonizing role across these regional frameworks. The International Organization for Standardization (ISO) has developed ISO 14067 for carbon footprint quantification, while ASTM International provides testing methodologies for alternative cementitious materials. These standards enable consistent evaluation of carbon-negative concrete innovations across global markets.

Emerging regulatory trends indicate a shift toward performance-based rather than prescriptive requirements. This approach allows greater flexibility for innovative carbon-negative concrete technologies that may not conform to traditional material specifications but can demonstrate superior environmental performance. Additionally, lifecycle assessment (LCA) requirements are becoming increasingly sophisticated, considering not only production emissions but also carbon sequestration potential throughout a building's operational life and end-of-life scenarios.

The patent landscape for carbon-negative concrete innovations is significantly influenced by these regulatory frameworks, with patent activity clustering around technologies that align with regional compliance requirements. Forward-looking regulations that establish clear carbon performance targets while remaining technology-neutral have proven most effective at stimulating patentable innovations in this sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!