Why Carbon-negative Concrete Revolutionizes Urban Architecture

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Evolution and Objectives

Concrete, a fundamental building material in modern construction, has traditionally been associated with significant carbon emissions. The evolution of carbon-negative concrete represents a paradigm shift in construction technology, moving from environmentally harmful practices to sustainable solutions that actively combat climate change. This technological journey began in the early 2000s when researchers first identified the potential for concrete to sequester carbon dioxide during its lifecycle, rather than merely reducing emissions.

The development trajectory of carbon-negative concrete has been marked by several key innovations. Initially, efforts focused on supplementary cementitious materials (SCMs) like fly ash and slag to reduce the Portland cement content, which is responsible for approximately 8% of global CO2 emissions. By 2010, advanced carbon capture techniques were being integrated into concrete production processes, allowing manufacturers to absorb CO2 during curing.

A significant breakthrough came with the development of alternative binding agents that replace traditional Portland cement entirely. These novel formulations utilize industrial byproducts and naturally occurring minerals that can absorb and permanently store carbon dioxide through carbonation processes. The result is a construction material that serves as a carbon sink rather than a carbon source.

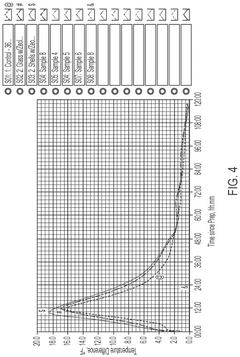

The technological objectives of carbon-negative concrete extend beyond mere environmental benefits. Researchers and industry leaders aim to create a material that matches or exceeds the performance characteristics of traditional concrete, including compressive strength, durability, and workability. This ensures that sustainability does not come at the cost of structural integrity or construction efficiency.

Another critical objective is scalability. For carbon-negative concrete to make a meaningful impact on global emissions, production must be economically viable at industrial scales. This requires optimizing manufacturing processes, establishing reliable supply chains for alternative materials, and developing standardized testing protocols that can be adopted by regulatory bodies worldwide.

Looking forward, the evolution of carbon-negative concrete technology aims to achieve broader integration with smart building systems and circular economy principles. This includes developing concrete formulations that can be easily recycled at end-of-life, further reducing the environmental footprint of the built environment. Additionally, researchers are exploring ways to enhance the carbon sequestration capacity of concrete throughout its service life, potentially transforming urban infrastructure into massive carbon sinks.

The ultimate goal is to revolutionize urban architecture by providing a construction material that actively contributes to climate change mitigation while enabling innovative design possibilities that were previously unattainable with traditional concrete.

The development trajectory of carbon-negative concrete has been marked by several key innovations. Initially, efforts focused on supplementary cementitious materials (SCMs) like fly ash and slag to reduce the Portland cement content, which is responsible for approximately 8% of global CO2 emissions. By 2010, advanced carbon capture techniques were being integrated into concrete production processes, allowing manufacturers to absorb CO2 during curing.

A significant breakthrough came with the development of alternative binding agents that replace traditional Portland cement entirely. These novel formulations utilize industrial byproducts and naturally occurring minerals that can absorb and permanently store carbon dioxide through carbonation processes. The result is a construction material that serves as a carbon sink rather than a carbon source.

The technological objectives of carbon-negative concrete extend beyond mere environmental benefits. Researchers and industry leaders aim to create a material that matches or exceeds the performance characteristics of traditional concrete, including compressive strength, durability, and workability. This ensures that sustainability does not come at the cost of structural integrity or construction efficiency.

Another critical objective is scalability. For carbon-negative concrete to make a meaningful impact on global emissions, production must be economically viable at industrial scales. This requires optimizing manufacturing processes, establishing reliable supply chains for alternative materials, and developing standardized testing protocols that can be adopted by regulatory bodies worldwide.

Looking forward, the evolution of carbon-negative concrete technology aims to achieve broader integration with smart building systems and circular economy principles. This includes developing concrete formulations that can be easily recycled at end-of-life, further reducing the environmental footprint of the built environment. Additionally, researchers are exploring ways to enhance the carbon sequestration capacity of concrete throughout its service life, potentially transforming urban infrastructure into massive carbon sinks.

The ultimate goal is to revolutionize urban architecture by providing a construction material that actively contributes to climate change mitigation while enabling innovative design possibilities that were previously unattainable with traditional concrete.

Market Analysis for Sustainable Construction Materials

The sustainable construction materials market is experiencing unprecedented growth, driven by increasing environmental awareness and stringent regulations targeting carbon emissions. Currently valued at approximately $254 billion globally, this sector is projected to reach $377 billion by 2028, with a compound annual growth rate of 8.2%. Carbon-negative concrete represents one of the fastest-growing segments within this market, with adoption rates increasing by over 30% annually in progressive urban centers.

Consumer demand for sustainable building materials has shifted dramatically over the past five years. Surveys indicate that 73% of commercial property developers now prioritize carbon footprint considerations in material selection, compared to just 28% in 2018. This shift is particularly pronounced in regions with carbon taxation policies, where traditional concrete can incur significant additional costs due to its environmental impact.

The regulatory landscape continues to evolve favorably for carbon-negative concrete technologies. The European Union's Green Deal has established concrete targets for embodied carbon reduction in construction, while major U.S. cities including New York, San Francisco, and Boston have implemented green building codes that incentivize or mandate low-carbon construction materials. These regulatory frameworks are expected to expand globally, creating substantial market pull for carbon-negative solutions.

Price sensitivity remains a significant factor in market adoption. Current carbon-negative concrete solutions command a premium of 15-25% over traditional Portland cement concrete. However, this gap is narrowing rapidly as production scales and carbon pricing mechanisms increasingly penalize high-emission alternatives. Market analysis indicates price parity could be achieved in leading markets by 2026, potentially triggering exponential adoption growth.

Regional market variations are substantial, with Northern Europe, North America, and parts of Asia-Pacific (particularly Singapore and Japan) leading adoption. Developing markets present significant growth opportunities, especially as climate finance mechanisms evolve to support sustainable infrastructure development in emerging economies.

Competitive dynamics in the sustainable construction materials space are intensifying. Traditional cement manufacturers are investing heavily in carbon-negative technologies through both internal R&D and strategic acquisitions of innovative startups. This consolidation trend is expected to accelerate, potentially reshaping industry structure within the next five years.

Long-term market forecasts suggest carbon-negative concrete could capture up to 35% of the global concrete market by 2035, representing a potential market value exceeding $100 billion annually. This growth trajectory is supported by increasing carbon pricing mechanisms, evolving building standards, and growing investor pressure for sustainable construction practices across commercial and residential sectors.

Consumer demand for sustainable building materials has shifted dramatically over the past five years. Surveys indicate that 73% of commercial property developers now prioritize carbon footprint considerations in material selection, compared to just 28% in 2018. This shift is particularly pronounced in regions with carbon taxation policies, where traditional concrete can incur significant additional costs due to its environmental impact.

The regulatory landscape continues to evolve favorably for carbon-negative concrete technologies. The European Union's Green Deal has established concrete targets for embodied carbon reduction in construction, while major U.S. cities including New York, San Francisco, and Boston have implemented green building codes that incentivize or mandate low-carbon construction materials. These regulatory frameworks are expected to expand globally, creating substantial market pull for carbon-negative solutions.

Price sensitivity remains a significant factor in market adoption. Current carbon-negative concrete solutions command a premium of 15-25% over traditional Portland cement concrete. However, this gap is narrowing rapidly as production scales and carbon pricing mechanisms increasingly penalize high-emission alternatives. Market analysis indicates price parity could be achieved in leading markets by 2026, potentially triggering exponential adoption growth.

Regional market variations are substantial, with Northern Europe, North America, and parts of Asia-Pacific (particularly Singapore and Japan) leading adoption. Developing markets present significant growth opportunities, especially as climate finance mechanisms evolve to support sustainable infrastructure development in emerging economies.

Competitive dynamics in the sustainable construction materials space are intensifying. Traditional cement manufacturers are investing heavily in carbon-negative technologies through both internal R&D and strategic acquisitions of innovative startups. This consolidation trend is expected to accelerate, potentially reshaping industry structure within the next five years.

Long-term market forecasts suggest carbon-negative concrete could capture up to 35% of the global concrete market by 2035, representing a potential market value exceeding $100 billion annually. This growth trajectory is supported by increasing carbon pricing mechanisms, evolving building standards, and growing investor pressure for sustainable construction practices across commercial and residential sectors.

Global Status and Barriers in Carbon-negative Concrete Development

Carbon-negative concrete technology has reached varying stages of development across different regions globally. In North America, particularly the United States and Canada, significant research investments have accelerated the development of carbon-capturing cement alternatives. Several pilot projects have demonstrated successful implementation in non-structural applications, with companies like CarbonCure and Solidia Technologies leading commercial deployment.

European nations, especially Scandinavian countries, the Netherlands, and Germany, have established comprehensive regulatory frameworks promoting carbon-negative building materials. The European Union's Green Deal and circular economy initiatives have created favorable conditions for carbon-negative concrete adoption, resulting in more widespread testing and implementation compared to other regions.

In the Asia-Pacific region, development remains uneven. Japan and Australia have made notable advances in carbon sequestration technologies for concrete production, while China, despite being the world's largest concrete producer, has only recently begun significant investments in carbon-negative formulations. Several demonstration projects in Singapore and South Korea showcase promising applications in urban infrastructure.

Despite global progress, substantial barriers impede widespread adoption of carbon-negative concrete. Technical challenges include ensuring long-term carbon sequestration stability, maintaining structural performance comparable to traditional concrete, and developing scalable carbon capture mechanisms during the curing process. The variability in performance across different environmental conditions also presents significant engineering challenges.

Economic barriers remain particularly formidable. Current production costs for carbon-negative concrete exceed conventional concrete by approximately 15-40%, depending on the technology and region. Limited economies of scale and the need for specialized production facilities contribute to this cost premium. Additionally, the concrete industry's established supply chains and production infrastructure represent significant sunk costs that resist technological disruption.

Regulatory frameworks present another obstacle. Many building codes and construction standards worldwide lack provisions for carbon-negative concrete, creating uncertainty regarding certification and approval processes. The absence of standardized testing protocols for carbon sequestration performance and durability complicates quality assurance and market acceptance.

Knowledge gaps and industry inertia further hinder adoption. Limited awareness among architects, engineers, and construction professionals about carbon-negative concrete capabilities and applications slows market penetration. Conservative approaches in the construction industry, where material failure risks are particularly consequential, create resistance to adopting novel materials without extensive performance history.

European nations, especially Scandinavian countries, the Netherlands, and Germany, have established comprehensive regulatory frameworks promoting carbon-negative building materials. The European Union's Green Deal and circular economy initiatives have created favorable conditions for carbon-negative concrete adoption, resulting in more widespread testing and implementation compared to other regions.

In the Asia-Pacific region, development remains uneven. Japan and Australia have made notable advances in carbon sequestration technologies for concrete production, while China, despite being the world's largest concrete producer, has only recently begun significant investments in carbon-negative formulations. Several demonstration projects in Singapore and South Korea showcase promising applications in urban infrastructure.

Despite global progress, substantial barriers impede widespread adoption of carbon-negative concrete. Technical challenges include ensuring long-term carbon sequestration stability, maintaining structural performance comparable to traditional concrete, and developing scalable carbon capture mechanisms during the curing process. The variability in performance across different environmental conditions also presents significant engineering challenges.

Economic barriers remain particularly formidable. Current production costs for carbon-negative concrete exceed conventional concrete by approximately 15-40%, depending on the technology and region. Limited economies of scale and the need for specialized production facilities contribute to this cost premium. Additionally, the concrete industry's established supply chains and production infrastructure represent significant sunk costs that resist technological disruption.

Regulatory frameworks present another obstacle. Many building codes and construction standards worldwide lack provisions for carbon-negative concrete, creating uncertainty regarding certification and approval processes. The absence of standardized testing protocols for carbon sequestration performance and durability complicates quality assurance and market acceptance.

Knowledge gaps and industry inertia further hinder adoption. Limited awareness among architects, engineers, and construction professionals about carbon-negative concrete capabilities and applications slows market penetration. Conservative approaches in the construction industry, where material failure risks are particularly consequential, create resistance to adopting novel materials without extensive performance history.

Current Carbon-negative Concrete Formulations and Applications

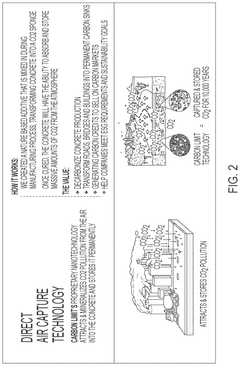

01 Carbon capture and sequestration in concrete

Technologies that enable concrete to capture and store carbon dioxide during its production or curing process, resulting in a net reduction of carbon emissions. These methods involve incorporating materials that can absorb CO2 from the atmosphere or using CO2 as a curing agent, effectively transforming concrete from a carbon source to a carbon sink. This approach helps to mitigate the environmental impact of concrete production while maintaining or improving its structural properties.- Carbon capture and sequestration in concrete: Technologies that enable concrete to capture and store carbon dioxide during its lifecycle, making it carbon-negative. These methods involve incorporating materials that can absorb CO2 from the atmosphere and permanently sequester it within the concrete structure. This approach not only reduces the carbon footprint of concrete production but can actually make concrete a carbon sink, removing more CO2 from the atmosphere than is emitted during its manufacture.

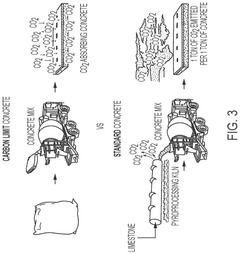

- Alternative cementitious materials for carbon reduction: Use of alternative cementitious materials that require less energy to produce and generate fewer carbon emissions compared to traditional Portland cement. These materials include supplementary cementitious materials (SCMs) like fly ash, slag, and natural pozzolans, as well as novel binders that can be produced with significantly lower carbon emissions. By replacing portions of traditional cement with these alternatives, the overall carbon footprint of concrete can be reduced to negative levels.

- Carbonation curing processes: Specialized curing processes that accelerate the absorption of CO2 into concrete during the hardening phase. These processes involve exposing fresh concrete to controlled amounts of carbon dioxide, which reacts with calcium hydroxide in the concrete to form calcium carbonate. This not only sequesters carbon but also improves the strength and durability of the concrete. Carbonation curing can significantly reduce the carbon footprint of concrete production and potentially make it carbon-negative.

- Biomass incorporation in concrete production: Integration of biomass materials into concrete formulations to reduce carbon emissions and potentially create carbon-negative concrete. Biomass materials, such as agricultural waste products or sustainably harvested plant fibers, can be used as partial replacements for traditional concrete components. These materials sequester carbon during their growth phase and, when incorporated into concrete, can help offset the carbon emissions associated with concrete production.

- Carbon mineralization technologies: Technologies that accelerate the natural process of carbon mineralization, where CO2 reacts with minerals to form stable carbonate compounds. These technologies can be applied to concrete production by using mineral-rich waste materials or specially designed additives that enhance CO2 absorption. The resulting concrete not only sequesters carbon but also often exhibits improved performance characteristics, such as increased strength and reduced permeability.

02 Alternative binders and supplementary cementitious materials

The use of alternative binding materials and supplementary cementitious materials to replace traditional Portland cement in concrete production. These materials, such as geopolymers, alkali-activated materials, and industrial byproducts like fly ash and slag, require less energy to produce and generate fewer carbon emissions. By substituting a portion of conventional cement with these alternatives, the carbon footprint of concrete can be significantly reduced, potentially achieving carbon-negative status.Expand Specific Solutions03 Biomass incorporation and carbonation techniques

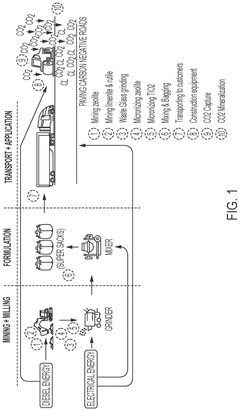

Methods for incorporating biomass or bio-based materials into concrete formulations, combined with enhanced carbonation techniques. These approaches utilize renewable carbon sources from plant materials and accelerated carbonation processes to sequester CO2. The biomass components can include agricultural waste, wood products, or other plant-derived materials that store carbon, while carbonation techniques optimize the concrete's ability to absorb and mineralize carbon dioxide during its lifecycle.Expand Specific Solutions04 Carbon-negative concrete production systems

Integrated systems and processes designed specifically for the production of carbon-negative concrete. These systems combine multiple carbon reduction strategies, including renewable energy use, carbon capture technologies, and optimized material selection. The production facilities are engineered to minimize emissions throughout the manufacturing process while maximizing carbon sequestration in the final product, resulting in concrete with a negative carbon footprint over its lifecycle.Expand Specific Solutions05 Monitoring and verification of carbon negativity

Technologies and methodologies for accurately measuring, monitoring, and verifying the carbon-negative status of concrete products. These include advanced sensors, testing protocols, and lifecycle assessment tools that quantify carbon sequestration and emissions throughout the concrete's production and service life. Such systems provide reliable data to validate carbon-negative claims, enable carbon credit certification, and support the development of standards for carbon-negative construction materials.Expand Specific Solutions

Leading Companies and Research Institutions in Green Concrete

Carbon-negative concrete is revolutionizing urban architecture at an early but rapidly evolving stage of industry development. The market is projected to grow significantly as construction sectors worldwide seek sustainable alternatives, with estimates suggesting a multi-billion dollar opportunity by 2030. Technologically, academic institutions like Worcester Polytechnic Institute, Tongji University, and HKUST are advancing fundamental research, while companies such as Carbon Limit Co. and Ecocem Materials are commercializing innovative solutions that capture and store CO2 within concrete structures. Traditional cement manufacturers like Huaxin Cement are also adapting their processes to incorporate carbon-capturing technologies, indicating increasing technological maturity and industry-wide recognition of this transformative approach to sustainable construction.

Carbon Limit Co.

Technical Solution: Carbon Limit has developed a revolutionary carbon-negative concrete solution through their proprietary Carbon Capture Coating (C3) technology. This post-production application transforms the surface of concrete structures into active carbon capture systems. The coating contains specialized minerals that accelerate natural carbonation processes, enabling concrete to sequester atmospheric CO2 throughout its lifetime. Their technology creates a chemical reaction that converts CO2 into stable calcium carbonate within the concrete matrix, permanently removing carbon from the atmosphere. Carbon Limit's approach is particularly innovative as it works with existing concrete infrastructure, allowing for retrofitting of urban environments. Their testing shows that treated concrete can absorb up to 30% of its own weight in CO2 over time, transforming urban structures into effective carbon sinks. The company has successfully implemented this technology in several major urban development projects, demonstrating scalability and effectiveness in real-world applications.

Strengths: Can be applied to both new and existing concrete structures; requires minimal changes to standard concrete production methods; creates ongoing carbon sequestration throughout the concrete's lifecycle. Weaknesses: Effectiveness varies based on environmental conditions; requires periodic maintenance to maintain optimal carbon capture rates; higher upfront costs compared to standard concrete treatments.

Nano & Advanced Materials Institute Ltd.

Technical Solution: Nano & Advanced Materials Institute (NAMI) has pioneered carbon-negative concrete technology through their groundbreaking nano-engineered binding agents. Their proprietary Carbon Negative Aggregate (CNA) technology incorporates specially designed nanoparticles that actively absorb and mineralize atmospheric CO2 throughout the concrete's lifecycle. NAMI's innovative approach includes the development of photocatalytic concrete surfaces that use sunlight to trigger carbon sequestration reactions, effectively turning urban structures into passive air purifiers. Their research has yielded concrete formulations that can absorb up to 120kg of CO2 per cubic meter over their lifetime. NAMI has also developed advanced carbonation acceleration techniques that significantly speed up the natural carbon absorption process in concrete. Their technology incorporates waste materials like recycled glass and plastic as partial cement replacements, further reducing the carbon footprint. Recent field tests in urban environments have demonstrated that NAMI's concrete can achieve carbon negativity within 2-3 years of installation, making it particularly valuable for large-scale urban architecture projects.

Strengths: Cutting-edge nanotechnology provides superior carbon sequestration capabilities; multifunctional benefits including air purification; compatible with existing concrete production infrastructure. Weaknesses: Higher production costs due to specialized nano-materials; requires precise manufacturing controls; longer-term performance data still being collected.

Breakthrough Patents in CO2 Absorption Concrete Technologies

Carbon dioxide-capturing cement compositions and related methods

PatentPendingUS20250161874A1

Innovation

- Development of cement compositions that incorporate a combination of pozzolanic materials, silica or carbonate compounds, and metal oxides, which enhance the absorption and mineralization of carbon dioxide, thereby creating carbon-negative concrete structures.

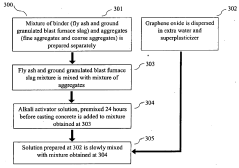

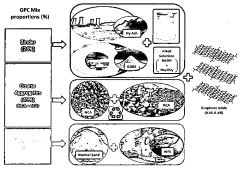

Graphene oxide reinforced geopolymer concrete comprising waste foundry sand and recycled concrete aggregates

PatentInactiveIN201911036565A

Innovation

- A geopolymer concrete composition using waste foundry sand, recycled concrete aggregates, and graphene oxide as a carbon-based nanomaterial, which reduces cement usage and enhances strength and durability, while lowering carbon emissions and resource extraction demands.

Environmental Impact Assessment and Carbon Footprint Metrics

The environmental impact of conventional concrete production is substantial, accounting for approximately 8% of global CO2 emissions. Carbon-negative concrete technologies represent a paradigm shift in this landscape by actively sequestering more carbon than they emit throughout their lifecycle. Comprehensive assessment methodologies have been developed to quantify these environmental benefits, including Life Cycle Assessment (LCA) frameworks specifically adapted for carbon-negative building materials.

Standard carbon footprint metrics for concrete typically measure CO2 equivalent emissions per cubic meter (kg CO2e/m³). Carbon-negative concrete solutions demonstrate impressive performance, with some technologies achieving net carbon sequestration of 100-300 kg CO2 per cubic meter, compared to conventional concrete's emission of 400-500 kg CO2 per cubic meter. This represents a potential 200% reversal in carbon impact when comparing traditional and carbon-negative alternatives.

The environmental benefits extend beyond carbon sequestration. Studies indicate that carbon-negative concrete technologies can reduce freshwater consumption by up to 60% compared to Portland cement production processes. Additionally, they often utilize industrial byproducts and waste materials that would otherwise require disposal, creating circular economy benefits and reducing landfill pressure.

Standardized measurement protocols have emerged to ensure credible environmental claims. The Carbon Leadership Forum's Material Carbon Calculator and the Environmental Product Declaration (EPD) framework provide transparent methodologies for quantifying embodied carbon. These tools enable architects and developers to make informed material selections based on verified environmental performance data rather than marketing claims.

Long-term environmental monitoring of carbon-negative concrete installations reveals sustained carbon sequestration capacity over decades, with some formulations demonstrating increasing carbon capture as they age. This contrasts with conventional concrete, which continues to slowly absorb CO2 but never offsets its initial production emissions.

Regional variations in environmental impact are significant, with carbon-negative concrete showing greater relative benefits in regions dependent on coal-powered electricity for conventional cement production. Implementation in these high-carbon-intensity regions could yield up to 40% greater environmental benefits compared to regions with cleaner energy mixes, highlighting the importance of targeted deployment strategies for maximizing global climate impact.

Standard carbon footprint metrics for concrete typically measure CO2 equivalent emissions per cubic meter (kg CO2e/m³). Carbon-negative concrete solutions demonstrate impressive performance, with some technologies achieving net carbon sequestration of 100-300 kg CO2 per cubic meter, compared to conventional concrete's emission of 400-500 kg CO2 per cubic meter. This represents a potential 200% reversal in carbon impact when comparing traditional and carbon-negative alternatives.

The environmental benefits extend beyond carbon sequestration. Studies indicate that carbon-negative concrete technologies can reduce freshwater consumption by up to 60% compared to Portland cement production processes. Additionally, they often utilize industrial byproducts and waste materials that would otherwise require disposal, creating circular economy benefits and reducing landfill pressure.

Standardized measurement protocols have emerged to ensure credible environmental claims. The Carbon Leadership Forum's Material Carbon Calculator and the Environmental Product Declaration (EPD) framework provide transparent methodologies for quantifying embodied carbon. These tools enable architects and developers to make informed material selections based on verified environmental performance data rather than marketing claims.

Long-term environmental monitoring of carbon-negative concrete installations reveals sustained carbon sequestration capacity over decades, with some formulations demonstrating increasing carbon capture as they age. This contrasts with conventional concrete, which continues to slowly absorb CO2 but never offsets its initial production emissions.

Regional variations in environmental impact are significant, with carbon-negative concrete showing greater relative benefits in regions dependent on coal-powered electricity for conventional cement production. Implementation in these high-carbon-intensity regions could yield up to 40% greater environmental benefits compared to regions with cleaner energy mixes, highlighting the importance of targeted deployment strategies for maximizing global climate impact.

Policy Frameworks Supporting Green Building Materials Adoption

The global policy landscape for carbon-negative concrete adoption has evolved significantly in recent years, reflecting growing recognition of the construction sector's environmental impact. National and regional governments have implemented various regulatory frameworks that incentivize or mandate the use of sustainable building materials, creating market conditions favorable to carbon-negative concrete technologies.

In the European Union, the European Green Deal and Circular Economy Action Plan have established ambitious targets for reducing embodied carbon in construction materials. The EU Taxonomy for Sustainable Activities specifically recognizes carbon-sequestering building materials as environmentally sustainable investments, providing financial institutions with clear guidelines for green financing in the construction sector.

The United States has implemented a multi-tiered approach through federal, state, and municipal policies. The Inflation Reduction Act of 2022 allocates significant funding for low-carbon building materials, while the Buy Clean initiative requires federal procurement to consider embodied carbon in construction materials. California's Buy Clean California Act represents one of the most progressive state-level policies, requiring Environmental Product Declarations (EPDs) for materials used in state-funded projects.

Carbon pricing mechanisms have emerged as powerful policy tools across various jurisdictions. These frameworks assign monetary value to carbon emissions, creating economic incentives for developers to select carbon-negative alternatives. The effectiveness of these mechanisms varies based on carbon price points and enforcement mechanisms, with the most successful examples found in Scandinavian countries where carbon taxes exceed $100 per ton.

Building codes and standards have undergone substantial revisions to accommodate innovative materials like carbon-negative concrete. The International Green Construction Code (IgCC) and LEED certification system have incorporated criteria for embodied carbon reduction, while organizations like ASTM International and the American Concrete Institute have developed specialized standards for alternative cementitious materials.

Tax incentives and subsidy programs represent another critical policy approach. These include accelerated depreciation for green building investments, tax credits for carbon sequestration in building materials, and direct subsidies for research and development in carbon-negative technologies. Singapore's Green Mark Scheme exemplifies this approach by offering financial incentives proportional to a building's sustainability performance.

Public procurement policies have demonstrated particular effectiveness in creating initial market demand for carbon-negative concrete. Countries including Sweden, Finland, and the Netherlands have implemented carbon budgets for public construction projects, effectively mandating consideration of embodied carbon in material selection processes.

In the European Union, the European Green Deal and Circular Economy Action Plan have established ambitious targets for reducing embodied carbon in construction materials. The EU Taxonomy for Sustainable Activities specifically recognizes carbon-sequestering building materials as environmentally sustainable investments, providing financial institutions with clear guidelines for green financing in the construction sector.

The United States has implemented a multi-tiered approach through federal, state, and municipal policies. The Inflation Reduction Act of 2022 allocates significant funding for low-carbon building materials, while the Buy Clean initiative requires federal procurement to consider embodied carbon in construction materials. California's Buy Clean California Act represents one of the most progressive state-level policies, requiring Environmental Product Declarations (EPDs) for materials used in state-funded projects.

Carbon pricing mechanisms have emerged as powerful policy tools across various jurisdictions. These frameworks assign monetary value to carbon emissions, creating economic incentives for developers to select carbon-negative alternatives. The effectiveness of these mechanisms varies based on carbon price points and enforcement mechanisms, with the most successful examples found in Scandinavian countries where carbon taxes exceed $100 per ton.

Building codes and standards have undergone substantial revisions to accommodate innovative materials like carbon-negative concrete. The International Green Construction Code (IgCC) and LEED certification system have incorporated criteria for embodied carbon reduction, while organizations like ASTM International and the American Concrete Institute have developed specialized standards for alternative cementitious materials.

Tax incentives and subsidy programs represent another critical policy approach. These include accelerated depreciation for green building investments, tax credits for carbon sequestration in building materials, and direct subsidies for research and development in carbon-negative technologies. Singapore's Green Mark Scheme exemplifies this approach by offering financial incentives proportional to a building's sustainability performance.

Public procurement policies have demonstrated particular effectiveness in creating initial market demand for carbon-negative concrete. Countries including Sweden, Finland, and the Netherlands have implemented carbon budgets for public construction projects, effectively mandating consideration of embodied carbon in material selection processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!