The Potential of Carbon-negative Concrete in Renewable Energy

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Evolution and Objectives

Concrete, a fundamental building material in modern civilization, has undergone significant evolution since its inception in ancient Rome. Traditional concrete production is notably carbon-intensive, contributing approximately 8% of global CO2 emissions primarily through the calcination process of limestone and the energy-intensive manufacturing of cement. The emergence of carbon-negative concrete represents a paradigm shift in construction materials technology, aiming to transform concrete from a carbon source to a carbon sink.

The evolution of carbon-negative concrete began in the early 2000s with initial research into alternative cementitious materials. By 2010, several research institutions had developed preliminary formulations incorporating CO2-absorbing components. The breakthrough came around 2015 when companies like Carbicrete and CarbonCure pioneered commercially viable technologies that could sequester carbon dioxide within the concrete matrix during curing processes.

Recent technological advancements have accelerated development, with carbon-negative concrete now capable of sequestering up to 100-150 kg of CO2 per cubic meter, effectively offsetting the emissions typically associated with conventional concrete production. This evolution has been driven by both environmental imperatives and economic incentives, including carbon credits and increasingly stringent building regulations worldwide.

In the renewable energy sector, carbon-negative concrete presents unique synergistic opportunities. Wind turbine foundations, solar panel mounting structures, and hydroelectric dam constructions represent significant concrete consumption points within renewable energy infrastructure. The integration of carbon-negative concrete into these applications could substantially enhance the net carbon benefit of renewable energy systems throughout their lifecycle.

The primary technical objectives for carbon-negative concrete in renewable energy applications include: enhancing durability under extreme environmental conditions typical of renewable energy installations; optimizing structural performance for the specific load requirements of energy-generating equipment; scaling production capacity to meet growing renewable energy infrastructure demands; and reducing costs to achieve price parity with conventional concrete.

Long-term objectives extend to creating closed-loop systems where carbon captured from renewable energy operations could be directly incorporated into concrete used for expanding those same energy systems. Additionally, researchers aim to develop specialized formulations that address the unique requirements of different renewable energy applications, such as vibration dampening for wind turbines or thermal stability for concentrated solar power installations.

The convergence of carbon-negative concrete technology with renewable energy infrastructure represents a powerful opportunity to amplify climate mitigation efforts, potentially transforming two carbon-intensive sectors into integrated carbon-negative systems.

The evolution of carbon-negative concrete began in the early 2000s with initial research into alternative cementitious materials. By 2010, several research institutions had developed preliminary formulations incorporating CO2-absorbing components. The breakthrough came around 2015 when companies like Carbicrete and CarbonCure pioneered commercially viable technologies that could sequester carbon dioxide within the concrete matrix during curing processes.

Recent technological advancements have accelerated development, with carbon-negative concrete now capable of sequestering up to 100-150 kg of CO2 per cubic meter, effectively offsetting the emissions typically associated with conventional concrete production. This evolution has been driven by both environmental imperatives and economic incentives, including carbon credits and increasingly stringent building regulations worldwide.

In the renewable energy sector, carbon-negative concrete presents unique synergistic opportunities. Wind turbine foundations, solar panel mounting structures, and hydroelectric dam constructions represent significant concrete consumption points within renewable energy infrastructure. The integration of carbon-negative concrete into these applications could substantially enhance the net carbon benefit of renewable energy systems throughout their lifecycle.

The primary technical objectives for carbon-negative concrete in renewable energy applications include: enhancing durability under extreme environmental conditions typical of renewable energy installations; optimizing structural performance for the specific load requirements of energy-generating equipment; scaling production capacity to meet growing renewable energy infrastructure demands; and reducing costs to achieve price parity with conventional concrete.

Long-term objectives extend to creating closed-loop systems where carbon captured from renewable energy operations could be directly incorporated into concrete used for expanding those same energy systems. Additionally, researchers aim to develop specialized formulations that address the unique requirements of different renewable energy applications, such as vibration dampening for wind turbines or thermal stability for concentrated solar power installations.

The convergence of carbon-negative concrete technology with renewable energy infrastructure represents a powerful opportunity to amplify climate mitigation efforts, potentially transforming two carbon-intensive sectors into integrated carbon-negative systems.

Renewable Energy Sector Demand Analysis

The renewable energy sector is experiencing unprecedented growth globally, creating a significant demand for sustainable construction materials like carbon-negative concrete. Market analysis indicates that renewable energy infrastructure development will require approximately 6.4 billion cubic meters of concrete by 2030, representing a substantial opportunity for carbon-negative alternatives. This demand is primarily driven by the construction of foundations for wind turbines, solar panel mounting structures, hydroelectric dams, and geothermal power plants.

Wind energy installations, particularly offshore wind farms, constitute a major market segment for specialized concrete. These structures require foundations capable of withstanding extreme marine conditions while maintaining structural integrity for decades. The Global Wind Energy Council reports that the offshore wind sector alone is projected to grow at a compound annual growth rate of 12% through 2030, necessitating concrete solutions that can reduce the carbon footprint of these massive structures.

Solar energy infrastructure presents another significant market opportunity. Utility-scale solar installations require substantial concrete foundations for mounting systems, especially in regions with challenging terrain or extreme weather conditions. The International Renewable Energy Agency forecasts solar capacity additions of 270-330 GW annually by 2030, each requiring concrete foundations that could benefit from carbon-negative properties.

Hydroelectric power facilities represent perhaps the most concrete-intensive renewable energy application. Modern dam construction typically consumes hundreds of thousands of cubic meters of concrete. With over 3,700 major hydropower projects planned or under construction globally, the potential for carbon-negative concrete adoption in this subsector is substantial.

Energy storage facilities, particularly pumped hydro storage and foundations for battery storage systems, constitute an emerging market for specialized concrete applications. As grid-scale energy storage deployment accelerates to support intermittent renewable generation, concrete requirements for these facilities are expected to grow at 20% annually through 2035.

Market research indicates that renewable energy developers are increasingly prioritizing carbon footprint reduction across their supply chains. A survey of major renewable energy project developers revealed that 78% have established carbon reduction targets for construction materials, with 42% specifically mentioning concrete as a priority material for decarbonization efforts.

Regulatory trends further support market growth for carbon-negative concrete in renewable energy applications. Several major markets, including the European Union, California, and Canada, have implemented or proposed carbon intensity standards for construction materials used in public infrastructure projects, including renewable energy installations. These regulations create market pull for innovative concrete solutions that can demonstrate verifiable carbon sequestration capabilities.

Wind energy installations, particularly offshore wind farms, constitute a major market segment for specialized concrete. These structures require foundations capable of withstanding extreme marine conditions while maintaining structural integrity for decades. The Global Wind Energy Council reports that the offshore wind sector alone is projected to grow at a compound annual growth rate of 12% through 2030, necessitating concrete solutions that can reduce the carbon footprint of these massive structures.

Solar energy infrastructure presents another significant market opportunity. Utility-scale solar installations require substantial concrete foundations for mounting systems, especially in regions with challenging terrain or extreme weather conditions. The International Renewable Energy Agency forecasts solar capacity additions of 270-330 GW annually by 2030, each requiring concrete foundations that could benefit from carbon-negative properties.

Hydroelectric power facilities represent perhaps the most concrete-intensive renewable energy application. Modern dam construction typically consumes hundreds of thousands of cubic meters of concrete. With over 3,700 major hydropower projects planned or under construction globally, the potential for carbon-negative concrete adoption in this subsector is substantial.

Energy storage facilities, particularly pumped hydro storage and foundations for battery storage systems, constitute an emerging market for specialized concrete applications. As grid-scale energy storage deployment accelerates to support intermittent renewable generation, concrete requirements for these facilities are expected to grow at 20% annually through 2035.

Market research indicates that renewable energy developers are increasingly prioritizing carbon footprint reduction across their supply chains. A survey of major renewable energy project developers revealed that 78% have established carbon reduction targets for construction materials, with 42% specifically mentioning concrete as a priority material for decarbonization efforts.

Regulatory trends further support market growth for carbon-negative concrete in renewable energy applications. Several major markets, including the European Union, California, and Canada, have implemented or proposed carbon intensity standards for construction materials used in public infrastructure projects, including renewable energy installations. These regulations create market pull for innovative concrete solutions that can demonstrate verifiable carbon sequestration capabilities.

Global Status and Technical Barriers

Carbon-negative concrete technology has gained significant traction globally, with varying levels of development and implementation across different regions. In North America, companies like CarbonCure and Solidia Technologies have successfully commercialized carbon-capturing concrete solutions, with pilot projects demonstrating up to 30% carbon reduction compared to traditional concrete. The European Union leads in regulatory frameworks supporting low-carbon building materials, with countries like Sweden and Norway implementing carbon taxes that incentivize adoption of carbon-negative alternatives.

Asia-Pacific represents the fastest-growing market, particularly in China and India where massive infrastructure development creates both challenges and opportunities for sustainable concrete implementation. However, adoption remains limited to pilot projects and premium construction segments, with carbon-negative concrete representing less than 2% of the global concrete market.

Despite promising developments, significant technical barriers impede widespread adoption. The primary challenge involves scalability of carbon sequestration processes, as current methods can only capture limited amounts of CO2 during curing. Most technologies achieve carbon reduction rather than true carbon negativity when accounting for full lifecycle emissions. The energy intensity of carbon capture processes presents another obstacle, particularly when renewable energy sources are not available for production.

Material performance inconsistency remains problematic, with some carbon-negative formulations showing reduced durability under extreme weather conditions or diminished strength compared to Portland cement. This creates hesitation among engineers and contractors regarding long-term reliability, especially for critical infrastructure applications in renewable energy installations like wind turbine foundations.

Cost premiums of 15-40% over conventional concrete constitute a significant market barrier, though this gap has narrowed in recent years. The lack of standardized testing protocols and certification systems for carbon-negative concrete further complicates market acceptance and regulatory approval.

Supply chain limitations present additional challenges, particularly regarding the availability of supplementary cementitious materials like fly ash and slag, which are essential components in many carbon-negative formulations. As coal power plants are decommissioned globally, alternative sources for these materials must be developed.

Integration with renewable energy infrastructure introduces unique technical requirements, including resistance to extreme weather conditions, vibration dampening for wind turbines, and specialized formulations for solar mounting systems. These application-specific demands further complicate the development of universally applicable carbon-negative concrete solutions.

Asia-Pacific represents the fastest-growing market, particularly in China and India where massive infrastructure development creates both challenges and opportunities for sustainable concrete implementation. However, adoption remains limited to pilot projects and premium construction segments, with carbon-negative concrete representing less than 2% of the global concrete market.

Despite promising developments, significant technical barriers impede widespread adoption. The primary challenge involves scalability of carbon sequestration processes, as current methods can only capture limited amounts of CO2 during curing. Most technologies achieve carbon reduction rather than true carbon negativity when accounting for full lifecycle emissions. The energy intensity of carbon capture processes presents another obstacle, particularly when renewable energy sources are not available for production.

Material performance inconsistency remains problematic, with some carbon-negative formulations showing reduced durability under extreme weather conditions or diminished strength compared to Portland cement. This creates hesitation among engineers and contractors regarding long-term reliability, especially for critical infrastructure applications in renewable energy installations like wind turbine foundations.

Cost premiums of 15-40% over conventional concrete constitute a significant market barrier, though this gap has narrowed in recent years. The lack of standardized testing protocols and certification systems for carbon-negative concrete further complicates market acceptance and regulatory approval.

Supply chain limitations present additional challenges, particularly regarding the availability of supplementary cementitious materials like fly ash and slag, which are essential components in many carbon-negative formulations. As coal power plants are decommissioned globally, alternative sources for these materials must be developed.

Integration with renewable energy infrastructure introduces unique technical requirements, including resistance to extreme weather conditions, vibration dampening for wind turbines, and specialized formulations for solar mounting systems. These application-specific demands further complicate the development of universally applicable carbon-negative concrete solutions.

Current Carbon-negative Concrete Technologies

01 Carbon capture and sequestration in concrete

Carbon-negative concrete can be achieved through the incorporation of carbon capture and sequestration technologies. These methods involve capturing CO2 from industrial processes or directly from the atmosphere and permanently storing it within the concrete matrix. This approach not only reduces the carbon footprint of concrete production but can actually make the concrete a carbon sink, absorbing more CO2 than is emitted during its production.- Carbon sequestration in concrete production: Carbon-negative concrete can be achieved through processes that sequester more carbon dioxide than is emitted during production. This involves capturing CO2 from industrial sources or directly from the atmosphere and incorporating it into the concrete mixture. The CO2 reacts with calcium compounds in the concrete to form stable carbonates, effectively locking away carbon for the long term while simultaneously improving the concrete's strength and durability.

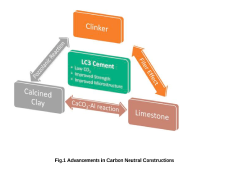

- Alternative cementitious materials for carbon reduction: Using alternative cementitious materials such as supplementary cementitious materials (SCMs), geopolymers, or alkali-activated materials can significantly reduce the carbon footprint of concrete. These materials often replace traditional Portland cement, which is responsible for substantial CO2 emissions. Materials like fly ash, slag, calcined clays, and natural pozzolans can be incorporated into concrete mixtures to achieve carbon negativity while maintaining or enhancing performance characteristics.

- Biomass incorporation and carbonation curing techniques: Incorporating biomass materials into concrete formulations can store biogenic carbon while enhancing certain properties. Additionally, accelerated carbonation curing techniques expose fresh concrete to CO2-rich environments, promoting rapid carbon uptake during the curing process. These approaches can transform concrete from a carbon source to a carbon sink, particularly when combined with other carbon reduction strategies.

- Carbon capture and utilization systems for concrete manufacturing: Integrated carbon capture and utilization systems can be implemented in concrete manufacturing facilities to capture emissions directly from production processes. The captured CO2 can then be recycled back into the concrete production process or used in other applications. These closed-loop systems help minimize the carbon footprint of concrete production while potentially improving the economics of carbon capture technologies.

- Life cycle assessment and carbon accounting methodologies: Developing standardized methodologies for life cycle assessment and carbon accounting is crucial for verifying carbon-negative claims in concrete production. These frameworks consider all emissions throughout the concrete life cycle, from raw material extraction to end-of-life scenarios. Advanced monitoring technologies and transparent reporting mechanisms help quantify carbon sequestration and validate the carbon-negative status of concrete products.

02 Alternative cementitious materials for carbon negativity

The use of alternative cementitious materials can significantly reduce or eliminate the carbon emissions associated with traditional Portland cement. Materials such as geopolymers, alkali-activated materials, and supplementary cementitious materials (SCMs) like fly ash and slag can be formulated to create carbon-negative concrete. These materials often require less energy to produce and can incorporate industrial byproducts, further reducing environmental impact.Expand Specific Solutions03 Carbonation curing processes

Specialized carbonation curing processes can be employed to accelerate and enhance the absorption of CO2 in concrete. These processes involve exposing fresh concrete to CO2-rich environments under controlled conditions, promoting the conversion of calcium hydroxide to calcium carbonate. This not only sequesters carbon but also improves the mechanical properties and durability of the concrete, making it a promising approach for achieving carbon negativity.Expand Specific Solutions04 Biomass incorporation for carbon reduction

Incorporating biomass or bio-based materials into concrete formulations can contribute to carbon negativity. These materials, which have sequestered carbon during their growth phase, can replace portions of traditional concrete ingredients. Examples include agricultural waste products, wood fibers, and other plant-derived materials. When these bio-based materials are integrated into concrete, they bring their sequestered carbon with them, helping to offset emissions from other components.Expand Specific Solutions05 Mineral carbonation technologies

Mineral carbonation involves the reaction of CO2 with calcium or magnesium-rich minerals to form stable carbonate compounds. This process can be integrated into concrete production to create carbon-negative products. By using waste materials rich in these minerals, such as steel slag, mining tailings, or certain industrial byproducts, concrete manufacturers can sequester significant amounts of CO2 while also addressing waste management challenges.Expand Specific Solutions

Industry Leaders and Competitive Landscape

The carbon-negative concrete market in renewable energy is in an early growth phase, with increasing market potential driven by global decarbonization efforts. The technology is advancing from research to commercialization, with academic institutions (MIT, Colorado School of Mines, Tongji University) leading fundamental research while companies like CarbonCure Technologies and Huaxin Cement are developing practical applications. The competitive landscape features collaboration between research institutions and industry players, with both established cement manufacturers and innovative startups entering the space. Technical challenges remain in scaling production while maintaining performance, though recent breakthroughs in CO2 sequestration methods and alternative binding materials show promise for widespread adoption in renewable energy infrastructure.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered electrochemical methods for producing carbon-negative concrete through their revolutionary process that eliminates emissions from cement production while enabling CO2 absorption. Their approach involves a two-stage process: first, an electrochemical system that produces cement without releasing CO2, and second, developing concrete formulations that actively absorb CO2 throughout their lifetime. MIT researchers have created a novel cement production method using electrolysis to separate limestone into calcium hydroxide and carbonic acid without thermal decomposition, eliminating the primary source of emissions in traditional cement manufacturing. Additionally, they've engineered concrete mixtures with enhanced carbonation properties, allowing structures to function as carbon sinks over their lifecycle. Their research indicates potential for net-negative emissions of up to 125 kg CO2 per ton of cement, representing a paradigm shift in construction materials for renewable energy infrastructure.

Strengths: Fundamental breakthrough in cement chemistry that addresses the root cause of emissions; potential for truly carbon-negative (not just carbon-neutral) concrete; backed by rigorous academic research and validation. Weaknesses: Still primarily in research phase with limited large-scale implementation; requires significant changes to existing cement production infrastructure; higher initial production costs compared to conventional methods.

Huaxin Cement Co., Ltd.

Technical Solution: Huaxin Cement has developed an integrated carbon-negative concrete solution specifically targeting renewable energy infrastructure. Their approach combines alternative cementitious materials (ACMs) with carbon capture utilization and storage (CCUS) technology at their production facilities. Huaxin has pioneered the use of industrial by-products like steel slag, fly ash, and carbide slag as cement substitutes, reducing the clinker factor to below 50% in specialized mixes. Their manufacturing facilities incorporate innovative carbon capture systems that not only reduce emissions but utilize the captured CO2 in concrete curing processes, enhancing strength development while permanently sequestering carbon. For renewable energy applications, Huaxin has developed specialized concrete formulations for solar panel mounting systems and wind turbine foundations that offer improved durability in extreme weather conditions while significantly reducing embodied carbon. Their pilot projects demonstrate carbon reductions of approximately 70% compared to conventional concrete, with some formulations achieving carbon-negative status when accounting for lifetime carbon sequestration.

Strengths: Vertical integration from cement production to concrete applications; large-scale implementation capability; combines multiple carbon reduction strategies; specialized formulations for renewable energy infrastructure. Weaknesses: Uneven implementation across different production facilities; regional limitations in alternative material availability; higher initial costs compared to conventional concrete; requires specialized expertise for quality control.

Key Patents and Research Breakthroughs

Development of sustainable concrete for structural applications

PatentPendingIN202331073958A

Innovation

- The use of precipitated calcium carbonate (PCC) to replace up to 30% of Portland cement and upcycled recycled concrete aggregate (UCA) to replace both fine and coarse aggregates in concrete mixes, leveraging waste products from the sugar industry and recycled concrete materials to enhance mechanical properties and reduce carbon footprint.

Carbon-neutral concrete solutions for sustainable infrastructure

PatentPendingIN202441036149A

Innovation

- The use of supplementary cementitious materials like fly ash, slag, and calcined clays, combined with carbon capture technologies and recycled aggregates, along with lifecycle assessment and carbon offsetting initiatives, aims to minimize emissions and enhance the sustainability of concrete production.

Environmental Impact Assessment

Carbon-negative concrete represents a significant advancement in sustainable construction materials with profound environmental implications. The lifecycle assessment of carbon-negative concrete reveals substantial reductions in greenhouse gas emissions compared to traditional Portland cement concrete, which accounts for approximately 8% of global CO2 emissions. When integrated with renewable energy infrastructure, this innovative material can transform construction projects from carbon sources to carbon sinks.

The production process of carbon-negative concrete involves CO2 sequestration technologies that capture more carbon than emitted during manufacturing. This creates a net negative carbon footprint, with some formulations capable of sequestering up to 400 kg of CO2 per cubic meter of concrete. When used in renewable energy installations such as wind turbine foundations or solar panel mounting structures, the environmental benefits are multiplied through both embodied carbon reduction and support for clean energy generation.

Water consumption metrics also demonstrate environmental advantages, with carbon-negative concrete typically requiring 20-30% less water during production compared to conventional concrete. This reduction is particularly valuable in water-stressed regions where renewable energy projects are often located, such as solar farms in arid environments.

Land use impact assessments indicate that carbon-negative concrete can contribute to biodiversity preservation through reduced raw material extraction. Traditional concrete production requires extensive quarrying for limestone and aggregates, while many carbon-negative formulations utilize industrial byproducts and waste materials, minimizing habitat disruption and landscape alteration.

Air quality improvements extend beyond carbon reduction, as the manufacturing processes for carbon-negative concrete often produce fewer particulate emissions and other air pollutants. This is especially relevant for renewable energy installations in urban or suburban settings where air quality concerns are paramount.

The durability characteristics of carbon-negative concrete further enhance its environmental profile. With potential service lifespans exceeding 100 years for certain formulations, the need for replacement and associated environmental impacts are significantly reduced. This longevity is particularly valuable for renewable energy infrastructure, which requires stable, long-lasting foundations to maximize clean energy production over decades.

End-of-life considerations reveal additional environmental benefits, as carbon-negative concrete can be crushed and recycled as aggregate for new concrete, creating a circular material flow that further reduces environmental impact. Some formulations even continue to sequester carbon during their service life, providing ongoing environmental benefits throughout the renewable energy project lifecycle.

The production process of carbon-negative concrete involves CO2 sequestration technologies that capture more carbon than emitted during manufacturing. This creates a net negative carbon footprint, with some formulations capable of sequestering up to 400 kg of CO2 per cubic meter of concrete. When used in renewable energy installations such as wind turbine foundations or solar panel mounting structures, the environmental benefits are multiplied through both embodied carbon reduction and support for clean energy generation.

Water consumption metrics also demonstrate environmental advantages, with carbon-negative concrete typically requiring 20-30% less water during production compared to conventional concrete. This reduction is particularly valuable in water-stressed regions where renewable energy projects are often located, such as solar farms in arid environments.

Land use impact assessments indicate that carbon-negative concrete can contribute to biodiversity preservation through reduced raw material extraction. Traditional concrete production requires extensive quarrying for limestone and aggregates, while many carbon-negative formulations utilize industrial byproducts and waste materials, minimizing habitat disruption and landscape alteration.

Air quality improvements extend beyond carbon reduction, as the manufacturing processes for carbon-negative concrete often produce fewer particulate emissions and other air pollutants. This is especially relevant for renewable energy installations in urban or suburban settings where air quality concerns are paramount.

The durability characteristics of carbon-negative concrete further enhance its environmental profile. With potential service lifespans exceeding 100 years for certain formulations, the need for replacement and associated environmental impacts are significantly reduced. This longevity is particularly valuable for renewable energy infrastructure, which requires stable, long-lasting foundations to maximize clean energy production over decades.

End-of-life considerations reveal additional environmental benefits, as carbon-negative concrete can be crushed and recycled as aggregate for new concrete, creating a circular material flow that further reduces environmental impact. Some formulations even continue to sequester carbon during their service life, providing ongoing environmental benefits throughout the renewable energy project lifecycle.

Policy Frameworks and Incentives

The development of carbon-negative concrete in renewable energy infrastructure requires robust policy frameworks and incentives to overcome market barriers and accelerate adoption. Currently, several jurisdictions have implemented carbon pricing mechanisms that indirectly benefit low-carbon construction materials. The European Union's Emissions Trading System (EU ETS) and carbon taxes in countries like Sweden and Norway have created economic signals that favor carbon-negative alternatives, though concrete-specific policies remain limited.

Government procurement policies represent a significant driver for market transformation. Countries including the Netherlands, Sweden, and Finland have introduced carbon-based procurement criteria for public infrastructure projects, effectively creating demand for carbon-negative concrete solutions. These policies typically establish maximum carbon footprint thresholds for construction materials or award additional points in tender evaluations for solutions with superior environmental performance.

Tax incentives and subsidies form another critical policy lever. The United States has implemented investment tax credits for carbon capture technologies that can be applied to concrete production processes. Similarly, Canada's Clean Growth Program provides funding for innovative low-carbon industrial processes, including those in the concrete sector. These financial incentives help offset the higher initial costs associated with carbon-negative concrete technologies.

Building codes and standards are gradually evolving to accommodate and encourage carbon-negative materials. Several jurisdictions have begun incorporating embodied carbon considerations into building regulations, though widespread adoption remains a challenge. The development of standardized measurement protocols and certification systems for carbon-negative concrete is essential for policy implementation and market confidence.

Research and development support represents a fundamental policy approach. Public funding for research into carbon-negative concrete technologies has increased significantly in recent years, with programs like Horizon Europe and ARPA-E dedicating resources to breakthrough materials science. These initiatives help address technical barriers and reduce costs through innovation.

International cooperation frameworks, including the Mission Innovation initiative and the Clean Energy Ministerial, have established platforms for knowledge sharing and policy coordination regarding carbon-negative building materials. These collaborative efforts help harmonize standards and accelerate global deployment of sustainable concrete technologies in renewable energy infrastructure.

Looking forward, policy integration between renewable energy deployment and sustainable materials usage presents significant opportunities. Policies that explicitly link carbon-negative concrete requirements to renewable energy project approvals could create powerful synergies and accelerate the transition to truly sustainable energy systems.

Government procurement policies represent a significant driver for market transformation. Countries including the Netherlands, Sweden, and Finland have introduced carbon-based procurement criteria for public infrastructure projects, effectively creating demand for carbon-negative concrete solutions. These policies typically establish maximum carbon footprint thresholds for construction materials or award additional points in tender evaluations for solutions with superior environmental performance.

Tax incentives and subsidies form another critical policy lever. The United States has implemented investment tax credits for carbon capture technologies that can be applied to concrete production processes. Similarly, Canada's Clean Growth Program provides funding for innovative low-carbon industrial processes, including those in the concrete sector. These financial incentives help offset the higher initial costs associated with carbon-negative concrete technologies.

Building codes and standards are gradually evolving to accommodate and encourage carbon-negative materials. Several jurisdictions have begun incorporating embodied carbon considerations into building regulations, though widespread adoption remains a challenge. The development of standardized measurement protocols and certification systems for carbon-negative concrete is essential for policy implementation and market confidence.

Research and development support represents a fundamental policy approach. Public funding for research into carbon-negative concrete technologies has increased significantly in recent years, with programs like Horizon Europe and ARPA-E dedicating resources to breakthrough materials science. These initiatives help address technical barriers and reduce costs through innovation.

International cooperation frameworks, including the Mission Innovation initiative and the Clean Energy Ministerial, have established platforms for knowledge sharing and policy coordination regarding carbon-negative building materials. These collaborative efforts help harmonize standards and accelerate global deployment of sustainable concrete technologies in renewable energy infrastructure.

Looking forward, policy integration between renewable energy deployment and sustainable materials usage presents significant opportunities. Policies that explicitly link carbon-negative concrete requirements to renewable energy project approvals could create powerful synergies and accelerate the transition to truly sustainable energy systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!