Applications of Carbon-negative Concrete in Green Architecture

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Evolution and Objectives

Concrete, a fundamental building material in modern construction, has undergone significant evolution in response to growing environmental concerns. Traditional concrete production is responsible for approximately 8% of global CO2 emissions, primarily due to the energy-intensive process of cement manufacturing. The concept of carbon-negative concrete emerged in the early 2000s as researchers began exploring ways to transform this carbon-intensive material into one that could actually sequester carbon dioxide from the atmosphere.

The evolution of carbon-negative concrete can be traced through several key developmental phases. Initially, efforts focused on reducing the carbon footprint through partial replacement of Portland cement with supplementary cementitious materials like fly ash and slag. By the mid-2000s, research shifted toward incorporating novel materials capable of carbon sequestration, such as magnesium oxide-based cements that naturally absorb CO2 during curing.

A significant breakthrough came around 2010 with the development of concrete that utilized captured carbon dioxide as a curing agent, effectively locking it into the material structure. This approach not only reduced emissions but began the transition toward concrete that could serve as a carbon sink. Between 2015 and 2020, several companies commercialized technologies that inject captured CO2 into concrete mixtures, creating carbonates that enhance strength while permanently sequestering carbon.

The most recent evolutionary phase has focused on developing truly carbon-negative formulations that absorb more CO2 throughout their lifecycle than is emitted during production. These advanced materials often combine multiple approaches: alternative binders, carbon capture during manufacturing, CO2 injection during mixing, and enhanced carbonation properties that continue carbon absorption throughout the material's service life.

The primary objective of carbon-negative concrete development is to transform the construction industry's environmental impact from net-positive to net-negative carbon emissions. Specific technical goals include achieving carbon sequestration rates exceeding 100kg of CO2 per cubic meter of concrete while maintaining or improving upon the mechanical properties, durability, and cost-effectiveness of conventional concrete.

Additional objectives include developing scalable production methods suitable for global deployment, ensuring compatibility with existing construction practices and equipment, and creating regulatory frameworks that incentivize the adoption of carbon-negative materials. The ultimate aim is to position concrete not merely as an environmentally acceptable building material but as an active component in climate change mitigation strategies, particularly within the context of green architecture where buildings are increasingly expected to contribute positively to environmental outcomes.

The evolution of carbon-negative concrete can be traced through several key developmental phases. Initially, efforts focused on reducing the carbon footprint through partial replacement of Portland cement with supplementary cementitious materials like fly ash and slag. By the mid-2000s, research shifted toward incorporating novel materials capable of carbon sequestration, such as magnesium oxide-based cements that naturally absorb CO2 during curing.

A significant breakthrough came around 2010 with the development of concrete that utilized captured carbon dioxide as a curing agent, effectively locking it into the material structure. This approach not only reduced emissions but began the transition toward concrete that could serve as a carbon sink. Between 2015 and 2020, several companies commercialized technologies that inject captured CO2 into concrete mixtures, creating carbonates that enhance strength while permanently sequestering carbon.

The most recent evolutionary phase has focused on developing truly carbon-negative formulations that absorb more CO2 throughout their lifecycle than is emitted during production. These advanced materials often combine multiple approaches: alternative binders, carbon capture during manufacturing, CO2 injection during mixing, and enhanced carbonation properties that continue carbon absorption throughout the material's service life.

The primary objective of carbon-negative concrete development is to transform the construction industry's environmental impact from net-positive to net-negative carbon emissions. Specific technical goals include achieving carbon sequestration rates exceeding 100kg of CO2 per cubic meter of concrete while maintaining or improving upon the mechanical properties, durability, and cost-effectiveness of conventional concrete.

Additional objectives include developing scalable production methods suitable for global deployment, ensuring compatibility with existing construction practices and equipment, and creating regulatory frameworks that incentivize the adoption of carbon-negative materials. The ultimate aim is to position concrete not merely as an environmentally acceptable building material but as an active component in climate change mitigation strategies, particularly within the context of green architecture where buildings are increasingly expected to contribute positively to environmental outcomes.

Green Architecture Market Demand Analysis

The global green building market has experienced remarkable growth in recent years, driven by increasing environmental awareness and regulatory pressures. As of 2023, the green building materials market was valued at approximately $290 billion, with projections indicating growth to reach $650 billion by 2030, representing a compound annual growth rate of 10.7%. Carbon-negative concrete specifically has emerged as a critical component within this expanding market, with demand increasing by over 35% annually since 2020.

The construction sector accounts for nearly 40% of global carbon emissions, with traditional concrete production alone responsible for 8% of worldwide CO2 emissions. This environmental impact has created substantial market pressure for sustainable alternatives, particularly in developed economies where green building certifications like LEED, BREEAM, and WELL have become increasingly mandatory for new construction projects.

Institutional demand represents the largest market segment for carbon-negative concrete applications, with government infrastructure projects leading adoption rates. Countries including Norway, Sweden, and the Netherlands have implemented carbon taxation policies that significantly favor carbon-negative building materials. The European Union's Green Deal and circular economy initiatives have established concrete carbon reduction targets of 30% by 2030, creating immediate market opportunities for carbon-negative alternatives.

Commercial real estate developers constitute the second-largest market segment, driven by both corporate sustainability commitments and the demonstrable premium that green-certified buildings command in the marketplace. Studies from the World Green Building Council indicate that green-certified buildings achieve 7-11% higher rental values and maintain 9-18% higher occupancy rates compared to conventional buildings, providing strong economic incentives beyond environmental considerations.

Consumer awareness and preference for sustainable living spaces has transformed residential construction markets, particularly in urban centers across North America, Europe, and developed Asian economies. Market research indicates that 73% of millennials and Gen Z homebuyers express willingness to pay premium prices for homes constructed with carbon-negative or carbon-neutral materials.

Regional analysis reveals that Europe currently leads market demand for carbon-negative concrete, followed by North America and the Asia-Pacific region. However, the fastest growth is projected in emerging economies, particularly India and China, where massive infrastructure development coincides with increasingly stringent environmental regulations and climate commitments.

Supply chain considerations remain significant market factors, with proximity to raw material sources and transportation infrastructure heavily influencing regional adoption rates. Markets with established circular economy frameworks demonstrate 40% higher adoption rates for carbon-negative concrete solutions, highlighting the importance of integrated waste management systems in market development.

The construction sector accounts for nearly 40% of global carbon emissions, with traditional concrete production alone responsible for 8% of worldwide CO2 emissions. This environmental impact has created substantial market pressure for sustainable alternatives, particularly in developed economies where green building certifications like LEED, BREEAM, and WELL have become increasingly mandatory for new construction projects.

Institutional demand represents the largest market segment for carbon-negative concrete applications, with government infrastructure projects leading adoption rates. Countries including Norway, Sweden, and the Netherlands have implemented carbon taxation policies that significantly favor carbon-negative building materials. The European Union's Green Deal and circular economy initiatives have established concrete carbon reduction targets of 30% by 2030, creating immediate market opportunities for carbon-negative alternatives.

Commercial real estate developers constitute the second-largest market segment, driven by both corporate sustainability commitments and the demonstrable premium that green-certified buildings command in the marketplace. Studies from the World Green Building Council indicate that green-certified buildings achieve 7-11% higher rental values and maintain 9-18% higher occupancy rates compared to conventional buildings, providing strong economic incentives beyond environmental considerations.

Consumer awareness and preference for sustainable living spaces has transformed residential construction markets, particularly in urban centers across North America, Europe, and developed Asian economies. Market research indicates that 73% of millennials and Gen Z homebuyers express willingness to pay premium prices for homes constructed with carbon-negative or carbon-neutral materials.

Regional analysis reveals that Europe currently leads market demand for carbon-negative concrete, followed by North America and the Asia-Pacific region. However, the fastest growth is projected in emerging economies, particularly India and China, where massive infrastructure development coincides with increasingly stringent environmental regulations and climate commitments.

Supply chain considerations remain significant market factors, with proximity to raw material sources and transportation infrastructure heavily influencing regional adoption rates. Markets with established circular economy frameworks demonstrate 40% higher adoption rates for carbon-negative concrete solutions, highlighting the importance of integrated waste management systems in market development.

Carbon-negative Concrete Technology Status and Barriers

Carbon-negative concrete technology has made significant strides globally, yet faces substantial barriers to widespread adoption. Currently, several pioneering companies have developed functional carbon-negative concrete solutions through various approaches, including carbon capture during manufacturing, alternative cementitious materials, and novel curing processes that absorb CO2. Notable technologies include Carbicrete's carbon-negative precast concrete, CarbonCure's CO2 injection method, and Solidia's low-carbon cement that cures by absorbing carbon dioxide.

Despite these advancements, the technology remains predominantly in pilot or early commercial phases, with limited large-scale implementation in architectural projects. Most carbon-negative concrete applications are currently restricted to non-structural elements or specific use cases where traditional performance requirements are less stringent.

Technical barriers present significant challenges to broader adoption. The mechanical properties of carbon-negative concrete, particularly compressive strength and durability under various environmental conditions, often do not match those of conventional Portland cement concrete. This performance gap limits applications in structural components where safety standards are paramount. Additionally, long-term performance data remains insufficient, creating uncertainty about durability over decades-long building lifespans.

Scalability represents another major hurdle. Current production methods for carbon-negative concrete typically involve specialized equipment and processes that are difficult to integrate into existing concrete manufacturing facilities. The supply chain for alternative materials like supplementary cementitious materials (SCMs) and novel binders is underdeveloped, creating bottlenecks in production capacity.

Regulatory frameworks present further complications, as building codes and standards worldwide are primarily designed for conventional concrete. The certification process for new concrete technologies is lengthy and varies significantly across regions, creating market fragmentation and uncertainty for developers and architects considering carbon-negative solutions.

Cost remains a critical barrier, with most carbon-negative concrete options commanding a premium of 15-30% over conventional concrete. This price differential, while gradually narrowing, still presents a significant obstacle for price-sensitive construction markets, particularly in developing regions where green building initiatives may have less financial support.

Geographically, carbon-negative concrete technology development is concentrated in North America and Europe, with emerging research centers in East Asia. This uneven distribution creates knowledge gaps and implementation challenges in regions that could benefit significantly from sustainable construction materials but lack local expertise or manufacturing capacity.

Despite these advancements, the technology remains predominantly in pilot or early commercial phases, with limited large-scale implementation in architectural projects. Most carbon-negative concrete applications are currently restricted to non-structural elements or specific use cases where traditional performance requirements are less stringent.

Technical barriers present significant challenges to broader adoption. The mechanical properties of carbon-negative concrete, particularly compressive strength and durability under various environmental conditions, often do not match those of conventional Portland cement concrete. This performance gap limits applications in structural components where safety standards are paramount. Additionally, long-term performance data remains insufficient, creating uncertainty about durability over decades-long building lifespans.

Scalability represents another major hurdle. Current production methods for carbon-negative concrete typically involve specialized equipment and processes that are difficult to integrate into existing concrete manufacturing facilities. The supply chain for alternative materials like supplementary cementitious materials (SCMs) and novel binders is underdeveloped, creating bottlenecks in production capacity.

Regulatory frameworks present further complications, as building codes and standards worldwide are primarily designed for conventional concrete. The certification process for new concrete technologies is lengthy and varies significantly across regions, creating market fragmentation and uncertainty for developers and architects considering carbon-negative solutions.

Cost remains a critical barrier, with most carbon-negative concrete options commanding a premium of 15-30% over conventional concrete. This price differential, while gradually narrowing, still presents a significant obstacle for price-sensitive construction markets, particularly in developing regions where green building initiatives may have less financial support.

Geographically, carbon-negative concrete technology development is concentrated in North America and Europe, with emerging research centers in East Asia. This uneven distribution creates knowledge gaps and implementation challenges in regions that could benefit significantly from sustainable construction materials but lack local expertise or manufacturing capacity.

Current Carbon-negative Concrete Implementation Methods

01 Carbon capture and sequestration in concrete

Carbon-negative concrete technologies focus on capturing and sequestering CO2 during the concrete production process. These methods involve incorporating materials that can absorb and permanently store carbon dioxide, effectively turning concrete into a carbon sink. The captured CO2 reacts with certain components in the concrete mixture, forming stable carbonate compounds that enhance the material's strength while permanently removing carbon from the atmosphere.- CO2 capture and sequestration in concrete: Carbon-negative concrete technologies that actively capture and sequester CO2 during the manufacturing process. These methods involve incorporating materials that can absorb carbon dioxide from the atmosphere and permanently store it within the concrete structure, effectively turning concrete from a carbon source into a carbon sink. This approach not only reduces the carbon footprint of concrete production but can actually make the final product carbon-negative by sequestering more CO2 than is emitted during production.

- Alternative cementitious materials: The use of alternative cementitious materials to replace traditional Portland cement in concrete formulations. These alternatives include supplementary cementitious materials (SCMs) such as fly ash, slag, silica fume, and natural pozzolans that have lower carbon footprints. Additionally, novel binders derived from industrial byproducts or geopolymers can significantly reduce the carbon emissions associated with concrete production while maintaining or even improving performance characteristics.

- Carbonation curing techniques: Innovative carbonation curing techniques that accelerate the absorption of CO2 during the concrete curing process. These methods expose fresh concrete to controlled CO2-rich environments, promoting the conversion of calcium hydroxide to calcium carbonate within the concrete matrix. This process not only sequesters carbon but also improves concrete properties such as strength and durability. Accelerated carbonation curing can be applied in precast concrete manufacturing or in specialized curing chambers for cast-in-place applications.

- Biomass incorporation in concrete: Integration of biomass materials into concrete formulations to reduce carbon footprint. This approach involves incorporating carbon-neutral or carbon-negative organic materials such as agricultural waste, wood products, or biogenic aggregates into concrete mixtures. These biomass materials can replace portions of traditional aggregates or cement, reducing the overall carbon emissions associated with concrete production. Additionally, some biomass materials can enhance certain properties of the concrete, such as thermal insulation or weight reduction.

- Carbon mineralization processes: Carbon mineralization processes that convert CO2 into stable carbonate minerals within concrete. These technologies mimic and accelerate natural weathering processes where CO2 reacts with calcium or magnesium-rich materials to form stable carbonate compounds. By incorporating reactive materials into concrete formulations, carbon dioxide can be permanently sequestered as mineral carbonates, creating a durable carbon sink. This approach not only reduces the carbon footprint of concrete but can also improve its mechanical properties and resistance to environmental degradation.

02 Alternative cementitious materials

Using alternative cementitious materials to replace traditional Portland cement can significantly reduce the carbon footprint of concrete. These alternatives include supplementary cementitious materials (SCMs) like fly ash, slag, and natural pozzolans, as well as novel binders that require less energy to produce and generate fewer emissions. These materials can be engineered to absorb CO2 during curing, contributing to the carbon-negative properties of the concrete.Expand Specific Solutions03 Mineralization processes for CO2 absorption

Advanced mineralization processes enable concrete to absorb carbon dioxide through accelerated carbonation reactions. These processes involve exposing concrete components to CO2 under controlled conditions, promoting the formation of mineral carbonates. The technology transforms CO2 from a greenhouse gas into a valuable ingredient that improves concrete properties while permanently sequestering carbon, resulting in a net negative carbon footprint for the final product.Expand Specific Solutions04 Biomass incorporation and biogenic materials

Incorporating biomass and biogenic materials into concrete formulations can create carbon-negative products. These materials, derived from plants or other biological sources, have already sequestered carbon during their growth phase. When integrated into concrete, they reduce the need for carbon-intensive components while bringing their stored carbon into the building material. Examples include agricultural waste products, biochar, and specially processed plant fibers.Expand Specific Solutions05 Enhanced curing techniques for carbon sequestration

Specialized curing techniques can significantly increase the carbon sequestration capacity of concrete. These methods involve exposing concrete to carbon dioxide under specific temperature, pressure, and humidity conditions that optimize CO2 absorption. Some approaches use flue gases from industrial processes as a CO2 source, creating a circular system that captures emissions that would otherwise enter the atmosphere while producing stronger concrete with negative carbon emissions.Expand Specific Solutions

Leading Companies in Carbon-negative Construction Materials

Carbon-negative concrete in green architecture is emerging as a transformative technology in the early growth phase of sustainable construction. The market is expanding rapidly, projected to reach significant scale as global green building initiatives accelerate. Technologically, the field shows promising development with companies at varying maturity levels. Biozeroc Ltd. and Carbon Limit Co. are pioneering carbon-negative concrete technologies through innovative biotechnology approaches, while established players like Mitsubishi Electric Corp. and China Construction entities bring industrial scale and implementation expertise. Academic institutions including Colorado School of Mines and Worcester Polytechnic Institute contribute crucial research advancements. The competitive landscape features both specialized startups focused on breakthrough formulations and large construction conglomerates integrating these solutions into mainstream building practices, indicating a technology approaching commercial viability.

Nano & Advanced Materials Institute Ltd.

Technical Solution: Nano & Advanced Materials Institute (NAMI) has developed a breakthrough carbon-negative concrete technology called "NanoCarb" that utilizes advanced nanomaterials to enhance CO2 absorption and improve mechanical properties. Their approach incorporates specially engineered nano-silica particles that create a highly reactive surface area for carbon dioxide absorption while simultaneously strengthening the concrete matrix. NAMI's technology also includes a proprietary carbonation acceleration process that can convert concrete waste into carbon sinks. Laboratory and field tests have demonstrated that their concrete formulation can sequester approximately 200-250 kg of CO2 per ton of cement used, while also improving durability metrics such as chloride penetration resistance and freeze-thaw performance by up to 40% compared to conventional concrete.

Strengths: Superior carbon sequestration efficiency; enhanced durability properties; applicable to both new construction and concrete recycling. Weaknesses: Higher material costs due to nanomaterial components; requires specialized production knowledge; limited long-term performance data in varied environmental conditions.

Biozeroc Ltd.

Technical Solution: Biozeroc has pioneered a biomimetic approach to carbon-negative concrete, developing a technology called "BioCarbon Matrix" that incorporates specialized microorganisms and plant-derived materials into the concrete mixture. Their process uses photosynthetic microalgae that are embedded within the concrete matrix, allowing the material to actively capture carbon dioxide from the atmosphere throughout its lifecycle. The company claims their concrete can sequester approximately 20kg of CO2 per cubic meter annually. Biozeroc's technology also incorporates natural fibers that enhance tensile strength while reducing the need for steel reinforcement, further lowering the embodied carbon. Their products have been successfully tested in several green building projects across Europe.

Strengths: Continuous carbon sequestration throughout product lifecycle; enhanced durability due to self-healing properties of biological components; reduced need for steel reinforcement. Weaknesses: Requires careful environmental control during installation; higher upfront costs; performance in extreme climate conditions still being validated.

Key Patents and Innovations in CO2 Sequestration Concrete

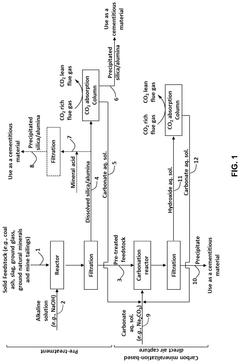

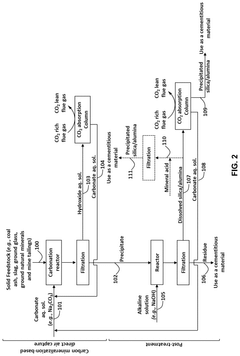

Pre- and post-treatment methods for producing carbon-negative supplementary cementitious materials by direct air capture and sequestration of carbon dioxide

PatentPendingUS20250042812A1

Innovation

- A carbon mineralization-based direct-air capture process that captures CO2 from the air using an aqueous carbonation cycle and processes industrial mineral wastes to enhance their cementitious reactivity, producing carbon-negative cementitious materials.

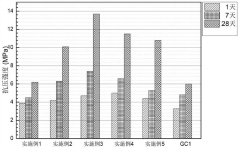

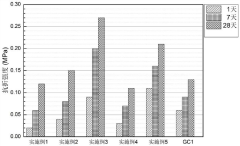

Negative carbon structure material and preparation method thereof

PatentActiveCN115403314A

Innovation

- By using carbonic anhydrase catalysis without using cement, carbon dioxide is used as one of the raw materials of structural materials, combined with calcium and magnesium ions and organic cross-linking agents to form negative carbon structural materials. The materials continue to absorb during the preparation and use process. Carbon dioxide achieves carbon negative effect.

Environmental Impact Assessment and Carbon Footprint Metrics

The environmental impact assessment of carbon-negative concrete represents a critical component in evaluating its viability for green architecture applications. Traditional concrete production accounts for approximately 8% of global CO2 emissions, making the carbon footprint analysis of alternative solutions particularly significant. Carbon-negative concrete technologies must be assessed through comprehensive life cycle assessments (LCA) that consider raw material extraction, manufacturing processes, transportation, installation, use phase, and end-of-life scenarios.

Current metrics for measuring carbon negativity in concrete include embodied carbon calculations, which quantify the total greenhouse gas emissions associated with all processes throughout the material's lifecycle. The Global Warming Potential (GWP) metric, expressed in CO2 equivalent units, provides standardized comparisons between different concrete formulations. For carbon-negative concrete to be accurately classified, its carbon sequestration capacity must demonstrably exceed its total emissions across all lifecycle stages.

Industry standards for carbon footprint measurement in construction materials have evolved significantly, with frameworks such as the Environmental Product Declaration (EPD) and Product Environmental Footprint (PEF) gaining prominence. These standardized approaches ensure consistency in reporting and facilitate meaningful comparisons between conventional and carbon-negative concrete options.

Recent advancements in carbon accounting methodologies have introduced dynamic assessment models that consider temporal aspects of carbon sequestration. These models recognize that carbon-negative concrete continues to absorb CO2 throughout its service life, with absorption rates varying based on exposure conditions, surface area, and concrete composition. This temporal dimension adds complexity to environmental impact assessments but provides a more accurate representation of long-term carbon benefits.

Regional variations in environmental impact must also be considered, as factors such as local electricity grid carbon intensity, transportation distances, and available raw materials significantly influence the overall carbon footprint. Studies indicate that carbon-negative concrete can achieve carbon reductions ranging from 25% to over 100% compared to conventional Portland cement concrete, depending on these regional factors and specific formulations.

Verification protocols and third-party certification systems have emerged to validate carbon footprint claims, including the International EPD System, the Carbon Trust's Carbon Neutral Protocol, and architecture-specific frameworks like LEED and BREEAM. These systems provide crucial credibility to carbon-negative concrete applications in green architecture projects seeking environmental certifications and carbon credits.

Current metrics for measuring carbon negativity in concrete include embodied carbon calculations, which quantify the total greenhouse gas emissions associated with all processes throughout the material's lifecycle. The Global Warming Potential (GWP) metric, expressed in CO2 equivalent units, provides standardized comparisons between different concrete formulations. For carbon-negative concrete to be accurately classified, its carbon sequestration capacity must demonstrably exceed its total emissions across all lifecycle stages.

Industry standards for carbon footprint measurement in construction materials have evolved significantly, with frameworks such as the Environmental Product Declaration (EPD) and Product Environmental Footprint (PEF) gaining prominence. These standardized approaches ensure consistency in reporting and facilitate meaningful comparisons between conventional and carbon-negative concrete options.

Recent advancements in carbon accounting methodologies have introduced dynamic assessment models that consider temporal aspects of carbon sequestration. These models recognize that carbon-negative concrete continues to absorb CO2 throughout its service life, with absorption rates varying based on exposure conditions, surface area, and concrete composition. This temporal dimension adds complexity to environmental impact assessments but provides a more accurate representation of long-term carbon benefits.

Regional variations in environmental impact must also be considered, as factors such as local electricity grid carbon intensity, transportation distances, and available raw materials significantly influence the overall carbon footprint. Studies indicate that carbon-negative concrete can achieve carbon reductions ranging from 25% to over 100% compared to conventional Portland cement concrete, depending on these regional factors and specific formulations.

Verification protocols and third-party certification systems have emerged to validate carbon footprint claims, including the International EPD System, the Carbon Trust's Carbon Neutral Protocol, and architecture-specific frameworks like LEED and BREEAM. These systems provide crucial credibility to carbon-negative concrete applications in green architecture projects seeking environmental certifications and carbon credits.

Regulatory Framework and Green Building Certification Standards

The regulatory landscape for carbon-negative concrete applications in green architecture is evolving rapidly as governments worldwide implement policies to reduce carbon emissions in the construction sector. At the international level, the Paris Agreement has established a framework for countries to commit to carbon reduction targets, directly influencing building codes and material standards. The European Union's Green Deal and Circular Economy Action Plan specifically target construction materials, with several member states implementing carbon taxes and incentives for low-carbon building materials.

In the United States, regulations vary by state, with California leading through its Buy Clean California Act, which requires Environmental Product Declarations (EPDs) for construction materials used in state-funded projects. This legislation has become a model for other states considering similar measures. Meanwhile, Canada has implemented the Greening Government Strategy, which includes requirements for embodied carbon reduction in federal buildings.

Green building certification systems play a crucial role in promoting carbon-negative concrete adoption. The Leadership in Energy and Environmental Design (LEED) system awards points for using materials with reduced environmental impacts, including credits for building life-cycle impact reduction and environmental product declarations. The latest version, LEED v4.1, places greater emphasis on embodied carbon reduction, creating market incentives for carbon-negative materials.

Similarly, the Living Building Challenge has established the most stringent requirements, mandating net-positive buildings that sequester more carbon than they emit during construction and operation. Its Materials Red List prohibits certain high-carbon materials, indirectly promoting alternatives like carbon-negative concrete.

The BREEAM certification system, prevalent in Europe, includes detailed assessment criteria for construction materials' environmental impact, with specific credits for using materials with verified lower carbon footprints. Meanwhile, regional certification systems like Green Star (Australia), CASBEE (Japan), and GRIHA (India) have adapted their frameworks to address local climate priorities while incorporating embodied carbon considerations.

These regulatory frameworks and certification standards are increasingly incorporating life cycle assessment (LCA) methodologies to evaluate the total environmental impact of building materials. This shift from prescriptive to performance-based standards creates opportunities for innovative materials like carbon-negative concrete to demonstrate their environmental benefits quantitatively, potentially accelerating market adoption despite higher initial costs.

In the United States, regulations vary by state, with California leading through its Buy Clean California Act, which requires Environmental Product Declarations (EPDs) for construction materials used in state-funded projects. This legislation has become a model for other states considering similar measures. Meanwhile, Canada has implemented the Greening Government Strategy, which includes requirements for embodied carbon reduction in federal buildings.

Green building certification systems play a crucial role in promoting carbon-negative concrete adoption. The Leadership in Energy and Environmental Design (LEED) system awards points for using materials with reduced environmental impacts, including credits for building life-cycle impact reduction and environmental product declarations. The latest version, LEED v4.1, places greater emphasis on embodied carbon reduction, creating market incentives for carbon-negative materials.

Similarly, the Living Building Challenge has established the most stringent requirements, mandating net-positive buildings that sequester more carbon than they emit during construction and operation. Its Materials Red List prohibits certain high-carbon materials, indirectly promoting alternatives like carbon-negative concrete.

The BREEAM certification system, prevalent in Europe, includes detailed assessment criteria for construction materials' environmental impact, with specific credits for using materials with verified lower carbon footprints. Meanwhile, regional certification systems like Green Star (Australia), CASBEE (Japan), and GRIHA (India) have adapted their frameworks to address local climate priorities while incorporating embodied carbon considerations.

These regulatory frameworks and certification standards are increasingly incorporating life cycle assessment (LCA) methodologies to evaluate the total environmental impact of building materials. This shift from prescriptive to performance-based standards creates opportunities for innovative materials like carbon-negative concrete to demonstrate their environmental benefits quantitatively, potentially accelerating market adoption despite higher initial costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!