Theoretical Approaches to Carbon-negative Concrete Catalysis

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Technology Background and Objectives

Concrete production currently accounts for approximately 8% of global carbon emissions, making it one of the most significant contributors to climate change within the industrial sector. The evolution of concrete technology has progressed from traditional Portland cement-based formulations to more environmentally conscious alternatives over the past century. Recent technological trends indicate a paradigm shift toward carbon-negative approaches, where concrete not only reduces emissions but actively sequesters carbon dioxide throughout its lifecycle.

The primary objective of carbon-negative concrete catalysis research is to develop concrete formulations and manufacturing processes that absorb more carbon dioxide than they emit during production. This ambitious goal represents a fundamental reimagining of concrete's role in the built environment—transforming it from an environmental liability to a climate solution. Specifically, researchers aim to achieve a net carbon sequestration of at least 100kg CO2 per cubic meter of concrete while maintaining or improving upon conventional concrete's structural properties and economic viability.

Historical developments in this field began with early carbon capture techniques in the 1990s, followed by the introduction of supplementary cementitious materials to reduce clinker content in the 2000s. The past decade has witnessed accelerated innovation in catalytic processes that enhance carbonation reactions within concrete matrices. These catalysts, ranging from metallic compounds to engineered enzymes, significantly increase the rate and capacity of CO2 absorption during curing and throughout the concrete's service life.

The technological trajectory suggests three primary pathways for achieving carbon-negative concrete: alternative binding materials that inherently absorb CO2, enhanced carbonation processes through novel catalysts, and the incorporation of carbon-sequestering aggregates. Each approach presents unique advantages and challenges regarding implementation scale, cost-effectiveness, and compatibility with existing infrastructure.

Current research focuses on understanding the fundamental chemical mechanisms that govern carbon sequestration in cementitious systems. Particular attention is being paid to the role of catalysts in accelerating carbonation reactions without compromising structural integrity. These catalysts typically function by lowering activation energy barriers for the conversion of gaseous CO2 into stable carbonate minerals within the concrete matrix.

The field is rapidly evolving toward multifunctional catalytic systems that not only enhance carbon sequestration but also improve concrete durability, reduce water requirements, and accelerate curing times. These synergistic benefits are essential for ensuring that carbon-negative concrete technologies achieve widespread commercial adoption and make meaningful contributions to global decarbonization efforts.

The primary objective of carbon-negative concrete catalysis research is to develop concrete formulations and manufacturing processes that absorb more carbon dioxide than they emit during production. This ambitious goal represents a fundamental reimagining of concrete's role in the built environment—transforming it from an environmental liability to a climate solution. Specifically, researchers aim to achieve a net carbon sequestration of at least 100kg CO2 per cubic meter of concrete while maintaining or improving upon conventional concrete's structural properties and economic viability.

Historical developments in this field began with early carbon capture techniques in the 1990s, followed by the introduction of supplementary cementitious materials to reduce clinker content in the 2000s. The past decade has witnessed accelerated innovation in catalytic processes that enhance carbonation reactions within concrete matrices. These catalysts, ranging from metallic compounds to engineered enzymes, significantly increase the rate and capacity of CO2 absorption during curing and throughout the concrete's service life.

The technological trajectory suggests three primary pathways for achieving carbon-negative concrete: alternative binding materials that inherently absorb CO2, enhanced carbonation processes through novel catalysts, and the incorporation of carbon-sequestering aggregates. Each approach presents unique advantages and challenges regarding implementation scale, cost-effectiveness, and compatibility with existing infrastructure.

Current research focuses on understanding the fundamental chemical mechanisms that govern carbon sequestration in cementitious systems. Particular attention is being paid to the role of catalysts in accelerating carbonation reactions without compromising structural integrity. These catalysts typically function by lowering activation energy barriers for the conversion of gaseous CO2 into stable carbonate minerals within the concrete matrix.

The field is rapidly evolving toward multifunctional catalytic systems that not only enhance carbon sequestration but also improve concrete durability, reduce water requirements, and accelerate curing times. These synergistic benefits are essential for ensuring that carbon-negative concrete technologies achieve widespread commercial adoption and make meaningful contributions to global decarbonization efforts.

Market Analysis for Carbon-negative Construction Materials

The global market for carbon-negative construction materials is experiencing unprecedented growth, driven by increasing environmental regulations and a growing awareness of the construction industry's carbon footprint. Currently valued at approximately $21.4 billion in 2023, this market segment is projected to reach $49.8 billion by 2030, representing a compound annual growth rate (CAGR) of 12.8%. Carbon-negative concrete technologies, particularly those involving advanced catalysis methods, are positioned as the fastest-growing subsegment within this market.

Regionally, Europe leads the adoption of carbon-negative construction materials, accounting for 38% of the global market share. This dominance stems from stringent EU regulations on carbon emissions and substantial government incentives for green building practices. North America follows at 29%, with the Asia-Pacific region rapidly expanding at a CAGR of 15.2%, primarily driven by China and India's massive infrastructure development coupled with their recent climate commitments.

Demand analysis reveals three primary market drivers for carbon-negative concrete catalysis technologies. First, regulatory pressure has intensified, with 67 countries now incorporating carbon reduction requirements into building codes. Second, corporate sustainability commitments have surged, with 78% of Fortune 500 construction and materials companies pledging net-zero targets by 2050. Third, green building certification systems like LEED and BREEAM have updated their criteria to award significant points for carbon-negative materials.

The customer landscape is evolving beyond traditional construction firms. Government infrastructure projects now constitute 42% of the market demand, followed by commercial real estate developers (27%), residential construction (18%), and specialized green building projects (13%). Notably, public procurement policies in 23 countries now mandate carbon footprint considerations for infrastructure projects, creating a guaranteed market for carbon-negative solutions.

Price sensitivity analysis indicates that carbon-negative concrete currently commands a 15-30% premium over conventional alternatives. However, this premium is projected to decrease to 5-10% by 2028 as production scales and technology matures. The willingness to pay this premium varies significantly by sector, with public infrastructure and premium commercial developments demonstrating the highest acceptance rates.

Market barriers include initial cost concerns, technical performance uncertainties, and limited production capacity. However, these barriers are rapidly diminishing as successful case studies demonstrate the long-term economic benefits of carbon-negative materials, including carbon credits, regulatory compliance advantages, and improved building performance metrics.

Regionally, Europe leads the adoption of carbon-negative construction materials, accounting for 38% of the global market share. This dominance stems from stringent EU regulations on carbon emissions and substantial government incentives for green building practices. North America follows at 29%, with the Asia-Pacific region rapidly expanding at a CAGR of 15.2%, primarily driven by China and India's massive infrastructure development coupled with their recent climate commitments.

Demand analysis reveals three primary market drivers for carbon-negative concrete catalysis technologies. First, regulatory pressure has intensified, with 67 countries now incorporating carbon reduction requirements into building codes. Second, corporate sustainability commitments have surged, with 78% of Fortune 500 construction and materials companies pledging net-zero targets by 2050. Third, green building certification systems like LEED and BREEAM have updated their criteria to award significant points for carbon-negative materials.

The customer landscape is evolving beyond traditional construction firms. Government infrastructure projects now constitute 42% of the market demand, followed by commercial real estate developers (27%), residential construction (18%), and specialized green building projects (13%). Notably, public procurement policies in 23 countries now mandate carbon footprint considerations for infrastructure projects, creating a guaranteed market for carbon-negative solutions.

Price sensitivity analysis indicates that carbon-negative concrete currently commands a 15-30% premium over conventional alternatives. However, this premium is projected to decrease to 5-10% by 2028 as production scales and technology matures. The willingness to pay this premium varies significantly by sector, with public infrastructure and premium commercial developments demonstrating the highest acceptance rates.

Market barriers include initial cost concerns, technical performance uncertainties, and limited production capacity. However, these barriers are rapidly diminishing as successful case studies demonstrate the long-term economic benefits of carbon-negative materials, including carbon credits, regulatory compliance advantages, and improved building performance metrics.

Current Catalysis Technologies and Challenges

Current catalysis technologies for carbon-negative concrete face significant challenges despite promising advancements. Traditional cement production catalysts primarily focus on energy efficiency rather than carbon capture, creating a fundamental gap in the industry's approach to sustainability. Existing catalytic systems typically employ metal oxides, zeolites, and transition metal complexes that accelerate cement hydration but fail to address CO2 emissions adequately.

The most advanced current technology involves calcium-silicate-hydrate (C-S-H) catalysts that can incorporate CO2 during concrete curing. However, these systems typically achieve only carbon-neutral status rather than the desired carbon-negative outcome. The catalytic efficiency remains below 40% in industrial settings, significantly limiting practical implementation.

Temperature and pressure dependencies present another major challenge. Most promising carbon-capturing catalysts require specific conditions (60-80°C, 2-5 bar pressure) that are difficult to maintain in standard construction environments. This creates a substantial barrier to widespread adoption outside controlled manufacturing facilities.

Catalyst deactivation represents a persistent issue, with most systems losing 30-50% efficiency after 3-5 cycles due to poisoning from sulfur compounds and physical degradation. This necessitates frequent replacement, increasing both economic and environmental costs of implementation.

Scale-up challenges further complicate industrial adoption. Laboratory-scale catalysts demonstrating 70-80% carbon capture efficiency typically show dramatic performance decreases (to 20-30%) when scaled to industrial production volumes. The heterogeneity of concrete mixtures across different applications exacerbates this problem.

Economic viability remains questionable with current technologies adding approximately $15-25 per ton to concrete production costs. Without regulatory incentives or carbon pricing mechanisms, this premium significantly hinders market adoption despite environmental benefits.

Recent innovations in metal-organic frameworks (MOFs) and biologically-inspired catalysts show theoretical promise for carbon-negative concrete but remain in early research stages. These systems demonstrate superior CO2 absorption capacity in laboratory conditions but face stability issues in alkaline concrete environments and manufacturing scalability challenges.

The integration of catalytic systems with renewable energy sources represents another frontier, as energy-intensive catalyst regeneration currently offsets some environmental benefits. Emerging electrochemical approaches that utilize renewable electricity for catalyst activation could potentially address this limitation but require significant further development.

The most advanced current technology involves calcium-silicate-hydrate (C-S-H) catalysts that can incorporate CO2 during concrete curing. However, these systems typically achieve only carbon-neutral status rather than the desired carbon-negative outcome. The catalytic efficiency remains below 40% in industrial settings, significantly limiting practical implementation.

Temperature and pressure dependencies present another major challenge. Most promising carbon-capturing catalysts require specific conditions (60-80°C, 2-5 bar pressure) that are difficult to maintain in standard construction environments. This creates a substantial barrier to widespread adoption outside controlled manufacturing facilities.

Catalyst deactivation represents a persistent issue, with most systems losing 30-50% efficiency after 3-5 cycles due to poisoning from sulfur compounds and physical degradation. This necessitates frequent replacement, increasing both economic and environmental costs of implementation.

Scale-up challenges further complicate industrial adoption. Laboratory-scale catalysts demonstrating 70-80% carbon capture efficiency typically show dramatic performance decreases (to 20-30%) when scaled to industrial production volumes. The heterogeneity of concrete mixtures across different applications exacerbates this problem.

Economic viability remains questionable with current technologies adding approximately $15-25 per ton to concrete production costs. Without regulatory incentives or carbon pricing mechanisms, this premium significantly hinders market adoption despite environmental benefits.

Recent innovations in metal-organic frameworks (MOFs) and biologically-inspired catalysts show theoretical promise for carbon-negative concrete but remain in early research stages. These systems demonstrate superior CO2 absorption capacity in laboratory conditions but face stability issues in alkaline concrete environments and manufacturing scalability challenges.

The integration of catalytic systems with renewable energy sources represents another frontier, as energy-intensive catalyst regeneration currently offsets some environmental benefits. Emerging electrochemical approaches that utilize renewable electricity for catalyst activation could potentially address this limitation but require significant further development.

Current Catalytic Solutions for CO2 Sequestration in Concrete

01 CO2 capture and sequestration in concrete production

Technologies that capture and sequester carbon dioxide during concrete manufacturing processes, effectively making the concrete carbon-negative. These methods involve the absorption of CO2 during the curing process, which not only reduces carbon emissions but also improves the mechanical properties of the concrete. The captured carbon becomes permanently bound in the concrete matrix, contributing to long-term carbon storage while enhancing durability.- CO2 capture and sequestration in concrete production: Carbon-negative concrete can be achieved through processes that capture and sequester CO2 during production. These methods involve incorporating CO2 directly into the concrete mixture where it reacts with calcium compounds to form stable carbonates. This mineralization process not only sequesters carbon dioxide permanently but also can improve concrete properties such as strength and durability, effectively turning concrete from a carbon source into a carbon sink.

- Alternative cementitious materials for carbon reduction: The use of alternative cementitious materials can significantly reduce the carbon footprint of concrete. These include supplementary cementitious materials (SCMs) like fly ash, slag, silica fume, and natural pozzolans that partially replace traditional Portland cement. Additionally, novel binders such as alkali-activated materials and geopolymers can be used to create concrete with substantially lower carbon emissions or even negative carbon footprints when combined with carbon sequestration techniques.

- Catalytic processes for enhanced carbonation: Catalytic processes can accelerate the carbonation reactions in concrete, enhancing CO2 uptake and sequestration efficiency. These catalysts facilitate the reaction between CO2 and calcium-rich components in concrete, allowing for faster and more complete carbonation. The enhanced carbonation not only increases the carbon negativity of concrete but can also improve its mechanical properties and durability, making the material both environmentally beneficial and structurally superior.

- Biomass incorporation and carbon-negative additives: Incorporating biomass-derived materials and carbon-negative additives into concrete formulations can contribute to carbon negativity. These materials, which have already sequestered carbon during their growth or production, can include biochar, agricultural waste products, or engineered carbon-negative fillers. When these materials are incorporated into concrete, they bring their sequestered carbon with them, effectively making the concrete a carbon sink while potentially enhancing certain material properties.

- Energy-efficient production methods and renewable energy integration: Carbon-negative concrete production can be achieved through energy-efficient manufacturing processes and the integration of renewable energy sources. By reducing the energy requirements of concrete production and powering these processes with renewable energy, the carbon footprint of concrete manufacturing can be significantly reduced. When combined with carbon capture technologies, these approaches can result in truly carbon-negative concrete products that help mitigate climate change rather than contribute to it.

02 Alternative low-carbon binders and catalysts

Development of novel binders and catalytic materials that reduce or eliminate the need for traditional Portland cement, which is carbon-intensive. These alternative materials include geopolymers, alkali-activated materials, and innovative catalysts that facilitate carbon-negative reactions during concrete formation. The catalysts enhance the carbonation process and promote the incorporation of CO2 into the concrete structure.Expand Specific Solutions03 Biomass incorporation and carbon mineralization

Integration of biomass materials and carbon mineralization processes in concrete formulations to achieve carbon negativity. These approaches utilize agricultural waste, biochar, or other biomass derivatives that have already sequestered carbon during their growth phase. The mineralization processes convert CO2 into stable carbonate minerals within the concrete, providing permanent carbon storage while maintaining structural integrity.Expand Specific Solutions04 Enhanced carbonation techniques

Advanced methods to accelerate and optimize the carbonation process in concrete, allowing for greater CO2 absorption. These techniques include controlled exposure to CO2-rich environments, pressure-assisted carbonation, and the use of specific additives that promote carbon uptake. The enhanced carbonation not only contributes to carbon negativity but also improves concrete strength and reduces permeability.Expand Specific Solutions05 Industrial waste utilization for carbon-negative concrete

Methods for incorporating industrial waste materials such as fly ash, slag, and silica fume into concrete formulations to reduce carbon footprint. These waste materials, which would otherwise contribute to environmental pollution, replace portions of traditional cement and serve as reactive components that can absorb CO2. The resulting concrete exhibits carbon-negative properties while providing comparable or superior performance to conventional concrete.Expand Specific Solutions

Leading Organizations in Carbon-negative Concrete Research

Carbon-negative concrete catalysis is in an early development stage, with a growing market driven by sustainability demands. The technology is maturing rapidly, with key players demonstrating different approaches to CO2 sequestration in concrete. Solidia Technologies and CarbonCure Technologies lead with commercial-scale CO2 utilization technologies, while Carbon Limit and Concrete4Change are developing innovative mineralization processes. Established companies like Taiheiyo Cement, BASF, and Kobe Steel are investing in research, while academic institutions including Southeast University and Worcester Polytechnic Institute contribute fundamental research. The competitive landscape shows a mix of startups, established corporations, and research institutions working toward scalable solutions that can significantly reduce concrete's carbon footprint.

Solidia Technologies, Inc.

Technical Solution: Solidia Technologies has developed a revolutionary carbon-negative concrete technology that fundamentally alters the chemistry of cement. Their approach replaces traditional Ordinary Portland Cement with a low-lime content calcium silicate cement that cures through carbonation rather than hydration. This process consumes CO2 during curing, permanently sequestering carbon dioxide within the concrete matrix. Their patented technology reduces the carbon footprint of concrete by up to 70% compared to traditional methods, with approximately 30% coming from reduced emissions during manufacturing and 40% from CO2 sequestration during curing. Solidia's process requires significantly less energy and water (reducing water usage by up to 80%), while producing concrete with superior strength and durability characteristics. The company has successfully scaled this technology through partnerships with major industry players and has implemented it in commercial applications across multiple markets.

Strengths: Achieves significant carbon reduction (up to 70%) through both manufacturing efficiency and direct CO2 sequestration; produces stronger, more durable concrete products; requires less water and energy. Weaknesses: Requires modification of existing manufacturing infrastructure; curing process needs controlled CO2 exposure; market adoption faces industry inertia and regulatory hurdles.

CarbonCure Technologies, Inc.

Technical Solution: CarbonCure Technologies has pioneered a retrofit technology that injects captured CO2 into fresh concrete during mixing, where it undergoes a mineralization process to become permanently embedded as calcium carbonate nanoparticles. This innovative approach not only sequesters CO2 but also improves the concrete's compressive strength, allowing for cement reduction while maintaining performance standards. Their system can be integrated into existing concrete production facilities with minimal disruption, requiring only a small CO2 storage tank and proprietary injection system. The technology has been validated to reduce the carbon footprint of concrete by 5-8% per cubic yard while maintaining or improving concrete performance. CarbonCure has deployed their technology in hundreds of concrete plants across North America and internationally, demonstrating scalability and commercial viability. Their approach is particularly notable for its ability to create a circular carbon economy by utilizing CO2 captured from industrial emitters.

Strengths: Easily retrofits into existing concrete plants with minimal capital investment; improves concrete strength while reducing cement content; creates immediate economic benefits for producers through material savings. Weaknesses: Achieves more modest carbon reduction compared to some alternative approaches; requires reliable supply chain for captured CO2; effectiveness varies depending on concrete mix design and production conditions.

Key Catalysis Mechanisms and Patent Analysis

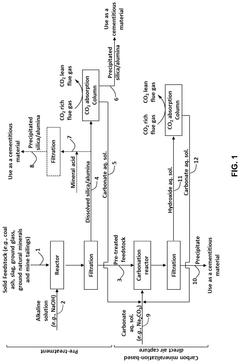

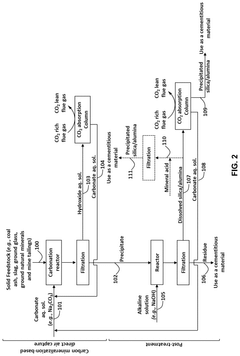

Pre- and post-treatment methods for producing carbon-negative supplementary cementitious materials by direct air capture and sequestration of carbon dioxide

PatentPendingUS20250042812A1

Innovation

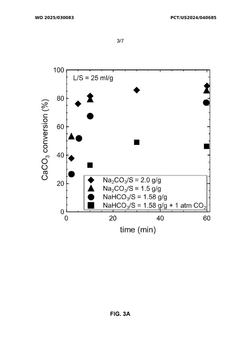

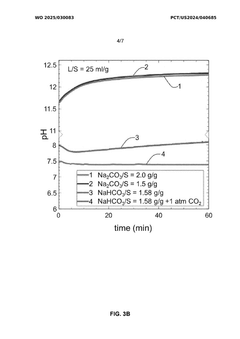

- A carbon mineralization-based direct-air capture process that captures CO2 from the air using an aqueous carbonation cycle and processes industrial mineral wastes to enhance their cementitious reactivity, producing carbon-negative cementitious materials.

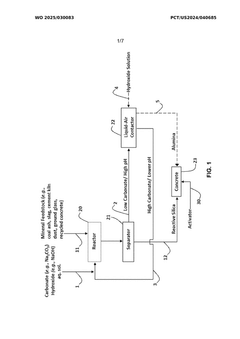

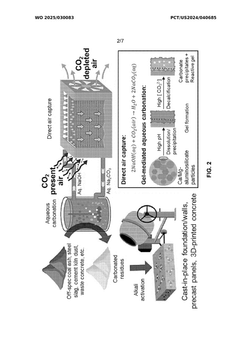

Cementitious materials and methods of making and using same

PatentWO2025030083A1

Innovation

- The method involves a carbon mineralization-based direct-air capture process using an aqueous carbonation cycle to capture CO2 from the air and enhance the pozzolanic reactivity of industrial mineral wastes, which are then used to produce carbon-negative cementitious materials that can replace or reduce Portland cement in concrete production.

Environmental Impact Assessment and Carbon Accounting Methods

The environmental impact assessment of carbon-negative concrete catalysis requires robust methodologies to accurately quantify carbon sequestration and overall ecological footprint. Current carbon accounting frameworks typically employ Life Cycle Assessment (LCA) methodologies that track emissions from raw material extraction through manufacturing, use, and end-of-life phases. However, these traditional approaches often inadequately capture the unique carbon dynamics of negative-emission concrete technologies.

Advanced carbon accounting for carbon-negative concrete must incorporate both direct and indirect emissions pathways. Direct pathways include CO2 absorption during curing processes and long-term carbonation, while indirect pathways encompass avoided emissions from traditional cement production. The development of standardized protocols specifically designed for carbon-negative materials remains a critical gap in the field, with organizations like the World Resources Institute and ISO working to establish consistent measurement frameworks.

Temporal considerations present particular challenges in environmental impact assessment of carbon-negative concrete. Unlike conventional materials, the carbon benefits accrue over extended timeframes, requiring accounting methods that can effectively model carbon fluxes across decades. Dynamic Life Cycle Assessment (DLCA) approaches offer promising solutions by incorporating time-dependent variables and enabling more accurate representation of long-term environmental impacts.

Boundary definition represents another methodological challenge. Comprehensive assessments must determine appropriate system boundaries that include upstream production emissions, transportation impacts, construction processes, in-use performance, and end-of-life scenarios. Expanding these boundaries to include secondary effects such as albedo changes and potential impacts on urban heat island effects provides a more complete environmental profile but increases assessment complexity.

Uncertainty quantification is essential for credible environmental impact assessment. Monte Carlo simulations and sensitivity analyses can help characterize variability in carbon accounting results, particularly important given the emerging nature of carbon-negative concrete technologies. These probabilistic approaches enable more transparent communication of environmental benefits and risks to stakeholders and policymakers.

Verification and certification systems are developing to validate carbon-negative claims. Third-party verification protocols, similar to those used in carbon offset markets, are being adapted for construction materials. These systems typically require transparent documentation of carbon accounting methodologies, independent verification of results, and ongoing monitoring to ensure continued performance throughout the material's lifecycle.

Advanced carbon accounting for carbon-negative concrete must incorporate both direct and indirect emissions pathways. Direct pathways include CO2 absorption during curing processes and long-term carbonation, while indirect pathways encompass avoided emissions from traditional cement production. The development of standardized protocols specifically designed for carbon-negative materials remains a critical gap in the field, with organizations like the World Resources Institute and ISO working to establish consistent measurement frameworks.

Temporal considerations present particular challenges in environmental impact assessment of carbon-negative concrete. Unlike conventional materials, the carbon benefits accrue over extended timeframes, requiring accounting methods that can effectively model carbon fluxes across decades. Dynamic Life Cycle Assessment (DLCA) approaches offer promising solutions by incorporating time-dependent variables and enabling more accurate representation of long-term environmental impacts.

Boundary definition represents another methodological challenge. Comprehensive assessments must determine appropriate system boundaries that include upstream production emissions, transportation impacts, construction processes, in-use performance, and end-of-life scenarios. Expanding these boundaries to include secondary effects such as albedo changes and potential impacts on urban heat island effects provides a more complete environmental profile but increases assessment complexity.

Uncertainty quantification is essential for credible environmental impact assessment. Monte Carlo simulations and sensitivity analyses can help characterize variability in carbon accounting results, particularly important given the emerging nature of carbon-negative concrete technologies. These probabilistic approaches enable more transparent communication of environmental benefits and risks to stakeholders and policymakers.

Verification and certification systems are developing to validate carbon-negative claims. Third-party verification protocols, similar to those used in carbon offset markets, are being adapted for construction materials. These systems typically require transparent documentation of carbon accounting methodologies, independent verification of results, and ongoing monitoring to ensure continued performance throughout the material's lifecycle.

Regulatory Framework and Carbon Credit Opportunities

The global regulatory landscape for carbon-negative concrete technologies is rapidly evolving, creating both compliance challenges and significant economic opportunities. Carbon pricing mechanisms, including cap-and-trade systems and carbon taxes, have emerged as powerful policy instruments across various jurisdictions. The European Union's Emissions Trading System (EU ETS) has recently expanded coverage to include cement production more comprehensively, while similar frameworks are developing in North America, Asia, and Oceania with varying implementation timelines and stringency levels.

National building codes and construction standards are increasingly incorporating carbon footprint requirements, with several countries mandating life-cycle assessments for major infrastructure projects. These regulatory shifts are creating market pull for carbon-negative concrete solutions, particularly in jurisdictions with aggressive decarbonization targets. The International Organization for Standardization (ISO) has developed specific standards for measuring embodied carbon in construction materials, providing essential frameworks for verification and compliance.

Carbon credit opportunities represent a significant economic incentive for advancing carbon-negative concrete catalysis technologies. The voluntary carbon market has seen substantial growth, with specialized methodologies emerging for quantifying and verifying carbon sequestration in concrete applications. Premium pricing for high-quality carbon removal credits—particularly those with permanence guarantees exceeding 100 years—creates favorable economics for catalytic approaches that achieve deep carbonation and permanent CO₂ storage.

Project developers can potentially access multiple revenue streams through carbon credit stacking, combining regulatory compliance credits with voluntary market premiums for co-benefits such as enhanced durability and reduced resource consumption. Forward-looking policy innovations include carbon border adjustment mechanisms that may create competitive advantages for low-carbon materials in international trade, and procurement preferences that assign value to carbon-negative attributes in public infrastructure projects.

Emerging financial instruments, including green bonds specifically designed for carbon-negative technologies, are creating new funding pathways for research and commercialization efforts. Several jurisdictions have established innovation funds that provide matching grants for carbon-negative concrete demonstration projects, particularly those incorporating novel catalytic approaches with scalability potential.

The regulatory environment exhibits significant regional variation, with the EU, California, and parts of Asia implementing the most progressive frameworks. This geographic disparity creates strategic opportunities for technology developers to target early adoption in favorable regulatory environments while preparing for broader global deployment as policies converge toward more stringent carbon constraints in the construction sector.

National building codes and construction standards are increasingly incorporating carbon footprint requirements, with several countries mandating life-cycle assessments for major infrastructure projects. These regulatory shifts are creating market pull for carbon-negative concrete solutions, particularly in jurisdictions with aggressive decarbonization targets. The International Organization for Standardization (ISO) has developed specific standards for measuring embodied carbon in construction materials, providing essential frameworks for verification and compliance.

Carbon credit opportunities represent a significant economic incentive for advancing carbon-negative concrete catalysis technologies. The voluntary carbon market has seen substantial growth, with specialized methodologies emerging for quantifying and verifying carbon sequestration in concrete applications. Premium pricing for high-quality carbon removal credits—particularly those with permanence guarantees exceeding 100 years—creates favorable economics for catalytic approaches that achieve deep carbonation and permanent CO₂ storage.

Project developers can potentially access multiple revenue streams through carbon credit stacking, combining regulatory compliance credits with voluntary market premiums for co-benefits such as enhanced durability and reduced resource consumption. Forward-looking policy innovations include carbon border adjustment mechanisms that may create competitive advantages for low-carbon materials in international trade, and procurement preferences that assign value to carbon-negative attributes in public infrastructure projects.

Emerging financial instruments, including green bonds specifically designed for carbon-negative technologies, are creating new funding pathways for research and commercialization efforts. Several jurisdictions have established innovation funds that provide matching grants for carbon-negative concrete demonstration projects, particularly those incorporating novel catalytic approaches with scalability potential.

The regulatory environment exhibits significant regional variation, with the EU, California, and parts of Asia implementing the most progressive frameworks. This geographic disparity creates strategic opportunities for technology developers to target early adoption in favorable regulatory environments while preparing for broader global deployment as policies converge toward more stringent carbon constraints in the construction sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!