What are the Key Benefits of Using Carbon-negative Concrete

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Background and Objectives

Concrete production has been a significant contributor to global carbon emissions for decades, accounting for approximately 8% of worldwide CO2 emissions. Traditional cement manufacturing processes release substantial amounts of carbon dioxide through both chemical reactions and the energy-intensive heating required. As climate change concerns intensify, the construction industry has been under increasing pressure to develop more sustainable building materials. This historical context has catalyzed the emergence of carbon-negative concrete as a revolutionary solution in the building materials sector.

Carbon-negative concrete represents a paradigm shift in construction technology, as it goes beyond merely reducing emissions to actively removing carbon dioxide from the atmosphere. The evolution of this technology has progressed from early carbon-neutral formulations to today's advanced carbon-sequestering solutions. This technological trajectory aligns with global sustainability goals, including the Paris Agreement targets and various national net-zero commitments.

The primary objective of carbon-negative concrete development is to transform a major carbon emitter into a carbon sink while maintaining or enhancing the performance characteristics required for structural applications. This involves capturing more CO2 during the concrete's lifecycle than is emitted during its production, creating a net environmental benefit. Secondary objectives include reducing dependency on traditional Portland cement, utilizing industrial byproducts and waste materials, and developing scalable manufacturing processes that can be implemented globally.

Current research focuses on several promising approaches, including carbonation curing processes, alternative binding materials, and the incorporation of carbon-capturing aggregates. These technologies aim to sequester carbon dioxide permanently within the concrete matrix, effectively transforming CO2 from an environmental liability into a structural asset. The technical goals include achieving compressive strength comparable to traditional concrete while demonstrating superior durability and reduced maintenance requirements.

The development of carbon-negative concrete also addresses broader sustainability objectives beyond carbon sequestration. These include reducing water consumption in concrete production, minimizing mining impacts associated with raw material extraction, and creating more resilient infrastructure capable of withstanding climate change effects. The technology aims to provide a comprehensive solution to multiple environmental challenges while meeting the growing global demand for construction materials.

As we examine the benefits of carbon-negative concrete, it is essential to understand that this technology represents not merely an incremental improvement but a fundamental reimagining of one of humanity's most widely used materials. The technical evolution in this field demonstrates how innovative approaches can transform environmental challenges into opportunities for sustainable development and climate action.

Carbon-negative concrete represents a paradigm shift in construction technology, as it goes beyond merely reducing emissions to actively removing carbon dioxide from the atmosphere. The evolution of this technology has progressed from early carbon-neutral formulations to today's advanced carbon-sequestering solutions. This technological trajectory aligns with global sustainability goals, including the Paris Agreement targets and various national net-zero commitments.

The primary objective of carbon-negative concrete development is to transform a major carbon emitter into a carbon sink while maintaining or enhancing the performance characteristics required for structural applications. This involves capturing more CO2 during the concrete's lifecycle than is emitted during its production, creating a net environmental benefit. Secondary objectives include reducing dependency on traditional Portland cement, utilizing industrial byproducts and waste materials, and developing scalable manufacturing processes that can be implemented globally.

Current research focuses on several promising approaches, including carbonation curing processes, alternative binding materials, and the incorporation of carbon-capturing aggregates. These technologies aim to sequester carbon dioxide permanently within the concrete matrix, effectively transforming CO2 from an environmental liability into a structural asset. The technical goals include achieving compressive strength comparable to traditional concrete while demonstrating superior durability and reduced maintenance requirements.

The development of carbon-negative concrete also addresses broader sustainability objectives beyond carbon sequestration. These include reducing water consumption in concrete production, minimizing mining impacts associated with raw material extraction, and creating more resilient infrastructure capable of withstanding climate change effects. The technology aims to provide a comprehensive solution to multiple environmental challenges while meeting the growing global demand for construction materials.

As we examine the benefits of carbon-negative concrete, it is essential to understand that this technology represents not merely an incremental improvement but a fundamental reimagining of one of humanity's most widely used materials. The technical evolution in this field demonstrates how innovative approaches can transform environmental challenges into opportunities for sustainable development and climate action.

Market Demand Analysis for Sustainable Construction Materials

The global construction industry is experiencing a significant shift towards sustainable building materials, driven by increasing environmental concerns and regulatory pressures. The market for sustainable construction materials, particularly carbon-negative concrete, has shown remarkable growth in recent years. According to recent market research, the global green concrete market is projected to reach $38.1 billion by 2027, growing at a CAGR of 9.1% from 2020 to 2027, indicating substantial market potential for carbon-negative concrete solutions.

The demand for carbon-negative concrete is primarily fueled by stringent environmental regulations and carbon emission reduction targets established by governments worldwide. The European Union's Green Deal aims to achieve carbon neutrality by 2050, while countries like the United Kingdom have set ambitious targets to reduce carbon emissions in the construction sector by 50% by 2025. These regulatory frameworks create a favorable market environment for the adoption of carbon-negative concrete technologies.

Corporate sustainability commitments represent another significant driver for market growth. Major construction companies and property developers are increasingly adopting Environmental, Social, and Governance (ESG) criteria in their business strategies. A survey conducted among Fortune 500 companies revealed that 67% of construction and real estate firms have committed to carbon neutrality goals by 2040, necessitating the adoption of innovative materials like carbon-negative concrete.

Consumer preferences are also evolving, with growing awareness about environmental issues influencing purchasing decisions. Research indicates that 73% of commercial building owners are willing to pay a premium of 5-10% for sustainable building materials that significantly reduce carbon footprint. This willingness to pay premium prices creates economic viability for carbon-negative concrete products despite their potentially higher initial costs.

The infrastructure sector presents the largest market opportunity for carbon-negative concrete. Government infrastructure spending, particularly post-pandemic recovery investments, has prioritized sustainable construction. The United States' Infrastructure Investment and Jobs Act allocates $110 billion for roads and bridges with specific provisions for using sustainable materials. Similarly, China's 14th Five-Year Plan emphasizes green infrastructure development, creating substantial market potential in the world's largest construction market.

Regional market analysis reveals varying adoption rates, with Europe leading in market maturity, North America showing rapid growth potential, and Asia-Pacific representing the largest volume opportunity due to urbanization trends and infrastructure development. Developing economies are increasingly incorporating sustainable building codes, further expanding the potential market for carbon-negative concrete solutions.

The demand for carbon-negative concrete is primarily fueled by stringent environmental regulations and carbon emission reduction targets established by governments worldwide. The European Union's Green Deal aims to achieve carbon neutrality by 2050, while countries like the United Kingdom have set ambitious targets to reduce carbon emissions in the construction sector by 50% by 2025. These regulatory frameworks create a favorable market environment for the adoption of carbon-negative concrete technologies.

Corporate sustainability commitments represent another significant driver for market growth. Major construction companies and property developers are increasingly adopting Environmental, Social, and Governance (ESG) criteria in their business strategies. A survey conducted among Fortune 500 companies revealed that 67% of construction and real estate firms have committed to carbon neutrality goals by 2040, necessitating the adoption of innovative materials like carbon-negative concrete.

Consumer preferences are also evolving, with growing awareness about environmental issues influencing purchasing decisions. Research indicates that 73% of commercial building owners are willing to pay a premium of 5-10% for sustainable building materials that significantly reduce carbon footprint. This willingness to pay premium prices creates economic viability for carbon-negative concrete products despite their potentially higher initial costs.

The infrastructure sector presents the largest market opportunity for carbon-negative concrete. Government infrastructure spending, particularly post-pandemic recovery investments, has prioritized sustainable construction. The United States' Infrastructure Investment and Jobs Act allocates $110 billion for roads and bridges with specific provisions for using sustainable materials. Similarly, China's 14th Five-Year Plan emphasizes green infrastructure development, creating substantial market potential in the world's largest construction market.

Regional market analysis reveals varying adoption rates, with Europe leading in market maturity, North America showing rapid growth potential, and Asia-Pacific representing the largest volume opportunity due to urbanization trends and infrastructure development. Developing economies are increasingly incorporating sustainable building codes, further expanding the potential market for carbon-negative concrete solutions.

Current State and Challenges in Carbon-negative Concrete Technology

Carbon-negative concrete technology has made significant strides globally, with various approaches being developed to address the cement industry's substantial carbon footprint. Currently, several commercial-scale carbon-negative concrete solutions exist, including those utilizing alternative binders, carbon capture during production, and carbon sequestration techniques. Companies like Carbicrete, CarbonCure, and Solidia have demonstrated viable pathways to reducing or eliminating emissions from concrete production.

Despite these advancements, widespread adoption faces considerable challenges. The construction industry remains highly conservative, with established building codes and standards primarily designed for traditional Portland cement concrete. This regulatory framework creates significant barriers for innovative solutions seeking market entry, as new materials must undergo extensive testing and certification processes that can take years to complete.

Cost remains a major obstacle, with many carbon-negative concrete solutions currently commanding price premiums of 15-30% over conventional concrete. While lifecycle analyses often demonstrate long-term economic benefits, the initial investment hurdle deters many potential adopters, particularly in price-sensitive market segments. Additionally, scaling production presents technical challenges, as many solutions that work effectively in laboratory settings encounter difficulties when implemented at industrial scale.

The geographical distribution of carbon-negative concrete technology development shows concentration in North America and Europe, with emerging activities in Asia-Pacific regions. This uneven development creates disparities in access to sustainable construction materials globally. Furthermore, the supply chain for specialized ingredients used in many carbon-negative formulations remains underdeveloped, creating potential bottlenecks for large-scale implementation.

Technical performance variability represents another significant challenge. While some carbon-negative concrete formulations match or exceed traditional concrete in strength and durability, others may exhibit limitations in specific applications or environmental conditions. This inconsistency complicates specification decisions for engineers and architects who require predictable material performance.

Knowledge gaps persist regarding long-term performance and durability of newer formulations. With limited real-world installation history spanning decades (as exists for traditional concrete), questions remain about how carbon-negative alternatives will perform over extended timeframes in various environmental conditions. This uncertainty creates hesitation among stakeholders responsible for infrastructure with expected lifespans of 50-100 years.

The transition to carbon-negative concrete also faces workforce challenges, as construction professionals require retraining to properly handle, place, and finish these new materials. The industry's fragmented nature makes coordinated education efforts difficult to implement effectively across the sector.

Despite these advancements, widespread adoption faces considerable challenges. The construction industry remains highly conservative, with established building codes and standards primarily designed for traditional Portland cement concrete. This regulatory framework creates significant barriers for innovative solutions seeking market entry, as new materials must undergo extensive testing and certification processes that can take years to complete.

Cost remains a major obstacle, with many carbon-negative concrete solutions currently commanding price premiums of 15-30% over conventional concrete. While lifecycle analyses often demonstrate long-term economic benefits, the initial investment hurdle deters many potential adopters, particularly in price-sensitive market segments. Additionally, scaling production presents technical challenges, as many solutions that work effectively in laboratory settings encounter difficulties when implemented at industrial scale.

The geographical distribution of carbon-negative concrete technology development shows concentration in North America and Europe, with emerging activities in Asia-Pacific regions. This uneven development creates disparities in access to sustainable construction materials globally. Furthermore, the supply chain for specialized ingredients used in many carbon-negative formulations remains underdeveloped, creating potential bottlenecks for large-scale implementation.

Technical performance variability represents another significant challenge. While some carbon-negative concrete formulations match or exceed traditional concrete in strength and durability, others may exhibit limitations in specific applications or environmental conditions. This inconsistency complicates specification decisions for engineers and architects who require predictable material performance.

Knowledge gaps persist regarding long-term performance and durability of newer formulations. With limited real-world installation history spanning decades (as exists for traditional concrete), questions remain about how carbon-negative alternatives will perform over extended timeframes in various environmental conditions. This uncertainty creates hesitation among stakeholders responsible for infrastructure with expected lifespans of 50-100 years.

The transition to carbon-negative concrete also faces workforce challenges, as construction professionals require retraining to properly handle, place, and finish these new materials. The industry's fragmented nature makes coordinated education efforts difficult to implement effectively across the sector.

Current Technical Solutions for Carbon-negative Concrete Production

01 Carbon capture and sequestration in concrete

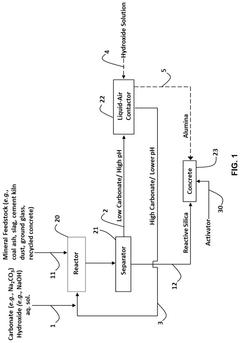

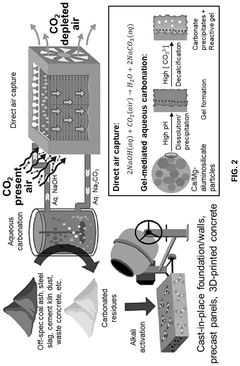

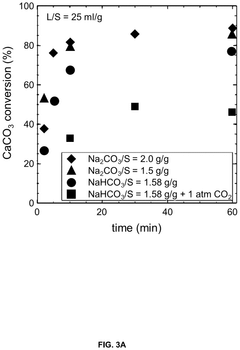

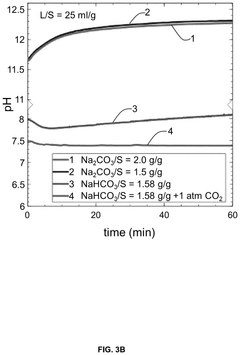

Carbon-negative concrete can be achieved through processes that capture and sequester carbon dioxide during the manufacturing process. These methods involve incorporating CO2 into the concrete mixture, where it reacts with calcium compounds to form stable carbonates. This process not only reduces the carbon footprint of concrete production but can actually make the concrete a net carbon sink, absorbing more CO2 than is emitted during its production.- Carbon sequestration in concrete production: Carbon-negative concrete can be achieved through processes that sequester more carbon dioxide than is emitted during production. This involves capturing CO2 from industrial sources or directly from the atmosphere and incorporating it into the concrete mixture. The CO2 reacts with calcium compounds in the concrete to form stable carbonates, effectively locking away carbon for the long term while simultaneously improving the concrete's strength and durability.

- Alternative cementitious materials for carbon reduction: Using alternative cementitious materials such as supplementary cementitious materials (SCMs), geopolymers, or alkali-activated materials can significantly reduce the carbon footprint of concrete. These materials often replace traditional Portland cement, which is responsible for substantial CO2 emissions. Materials like fly ash, slag, silica fume, and natural pozzolans can be incorporated into concrete mixtures to achieve carbon negativity while maintaining or even enhancing performance characteristics.

- Biomass incorporation for carbon sequestration: Incorporating biomass or bio-based materials into concrete can contribute to carbon negativity. These materials, which have already sequestered carbon during their growth phase, can be processed and used as partial replacements for traditional concrete components. Examples include agricultural waste products, wood derivatives, and other plant-based materials that can be carbonized or otherwise treated to enhance concrete properties while maintaining their carbon storage capabilities.

- Enhanced carbonation curing techniques: Specialized curing techniques that promote accelerated carbonation can transform concrete into a carbon-negative material. By exposing concrete to controlled CO2-rich environments during the curing process, carbon dioxide is rapidly absorbed and converted into stable mineral carbonates. This process not only sequesters carbon but also accelerates strength development, reduces curing time, and improves various performance properties of the final concrete product.

- Carbon-negative concrete lifecycle management: Comprehensive lifecycle management approaches can achieve carbon negativity across the entire concrete value chain. This includes optimizing raw material sourcing, using renewable energy in production, implementing efficient transportation methods, designing for longevity and recyclability, and ensuring end-of-life carbon benefits. Advanced monitoring systems track carbon metrics throughout the concrete lifecycle, verifying carbon negativity claims and potentially generating carbon credits or meeting regulatory requirements.

02 Alternative cementitious materials for carbon negativity

Using alternative cementitious materials such as supplementary cementitious materials (SCMs), geopolymers, or alkali-activated materials can significantly reduce the carbon footprint of concrete. These materials often require less energy to produce than traditional Portland cement and can incorporate industrial byproducts or waste materials, further reducing environmental impact and potentially achieving carbon negativity through the lifecycle of the concrete.Expand Specific Solutions03 Biomass incorporation for carbon sequestration

Incorporating biomass or bio-based materials into concrete formulations can enhance carbon sequestration. These materials, which have already captured carbon during their growth phase, can be processed and added to concrete mixtures. When properly integrated, they contribute to the structural properties of the concrete while maintaining the carbon they've sequestered, resulting in a net carbon-negative building material.Expand Specific Solutions04 Enhanced carbonation curing techniques

Specialized curing techniques that promote accelerated carbonation can transform concrete into a carbon-negative material. These methods expose concrete to controlled CO2-rich environments during the curing process, maximizing the absorption and binding of carbon dioxide within the concrete matrix. The resulting concrete not only sequesters carbon but often exhibits improved strength and durability characteristics.Expand Specific Solutions05 Mineral additives for CO2 absorption

Specific mineral additives can be incorporated into concrete to enhance its ability to absorb and permanently store carbon dioxide. These minerals, often magnesium or calcium-based, react with atmospheric CO2 over time through natural carbonation processes. When strategically selected and proportioned in concrete mixtures, these additives can significantly increase the carbon sequestration capacity of the concrete throughout its lifecycle.Expand Specific Solutions

Leading Companies and Research Institutions in Carbon-negative Concrete

Carbon-negative concrete technology is currently in an early growth phase, with increasing market adoption driven by sustainability demands. The global market for green concrete is expanding rapidly, expected to reach significant scale as construction industries seek to reduce carbon footprints. Technologically, various approaches are being developed with different maturity levels. Academic institutions like Worcester Polytechnic Institute and University of Science & Technology Beijing are advancing fundamental research, while commercial players demonstrate varying implementation capabilities. China Construction Commercial Concrete, China West Construction, and Ecocem Materials are leading commercial deployment, with China National Building Material Group leveraging its scale for broader market penetration. Companies like Arelac and Procarbon Bio are developing specialized carbon-capture concrete technologies, indicating a competitive landscape balancing established concrete manufacturers and innovative startups.

China Building Materials Academy Co. Ltd.

Technical Solution: China Building Materials Academy (CBMA) has developed an advanced carbon-negative concrete technology called "GeoGreen" that utilizes geopolymer chemistry instead of traditional Portland cement. Their approach involves activating aluminosilicate materials such as fly ash and metakaolin with alkaline solutions to create a strong binding matrix without the high-temperature calcination required for conventional cement. The GeoGreen technology incorporates a proprietary carbon sequestration system that actively absorbs atmospheric CO2 during the curing process through specially designed admixtures containing magnesium oxide derivatives. These compounds form stable carbonate minerals within the concrete matrix, permanently locking away carbon dioxide. CBMA's research demonstrates that their concrete formulation can achieve up to 90% reduction in carbon emissions compared to conventional concrete, while the active carbon sequestration component can absorb an additional 40-60 kg of CO2 per cubic meter over its lifetime. The technology also incorporates recycled aggregates and industrial by-products, further reducing its environmental footprint. Their lifecycle assessment confirms that GeoGreen concrete becomes increasingly carbon-negative over time as it continues to absorb CO2 throughout its service life[8][10].

Strengths: Eliminates need for energy-intensive Portland cement clinker production; continues carbon sequestration throughout concrete lifetime; utilizes abundant industrial waste materials; excellent resistance to chemical attack and fire. Weaknesses: More sensitive to curing conditions than traditional concrete; requires careful quality control of raw materials; alkaline activators can present handling challenges; limited long-term performance data compared to conventional concrete; higher initial cost than traditional concrete.

China National Building Material Group Co., Ltd.

Technical Solution: China National Building Material Group (CNBM) has developed a comprehensive carbon-negative concrete technology called "CarbonLock" that combines several innovative approaches. Their system utilizes industrial by-products including steel slag, fly ash, and carbide slag as supplementary cementitious materials, reducing Portland cement content by up to 60%. The technology incorporates a CO2 curing chamber where precast concrete elements are exposed to concentrated CO2 under controlled pressure and temperature conditions, accelerating carbonation and permanently sequestering carbon dioxide. CNBM's process also employs novel nano-silica catalysts that enhance the carbonation reaction efficiency by up to 40% compared to conventional methods. Their integrated production system captures CO2 emissions from their own cement kilns and other industrial facilities, creating a closed-loop carbon utilization cycle. According to their published data, each cubic meter of CarbonLock concrete can sequester between 120-150 kg of CO2, while conventional concrete production emits approximately 400 kg of CO2 per cubic meter, resulting in a significant net carbon benefit[7][9].

Strengths: Integrated approach combining multiple carbon reduction strategies; utilizes abundant industrial waste materials available throughout China; accelerated carbonation process improves early-age strength development; creates closed-loop carbon utilization system. Weaknesses: CO2 curing chambers require significant capital investment; primarily applicable to precast concrete applications rather than ready-mix; energy requirements for pressurized curing may offset some carbon benefits in regions with carbon-intensive electricity.

Key Innovations in CO2 Capture and Utilization in Concrete

Carbon negative concrete production through the use of sustainable materials

PatentInactiveUS20230002276A1

Innovation

- Incorporating biochar, a high-carbon residue produced through low-oxygen pyrolysis, into concrete mixtures to sequester carbon and reduce emissions, while optimizing pyrolysis processes to power plants using syngas for self-sustainability and carbon neutrality.

Cementitious materials and methods of making and using same

PatentPendingUS20250042811A1

Innovation

- A carbon mineralization-based direct-air capture process is used to produce carbon-negative cementitious materials by capturing CO2 from the air through an aqueous carbonation cycle, enhancing the pozzolanic reactivity of industrial mineral wastes, and incorporating the captured CO2 as solid carbonate in the concrete.

Environmental Impact Assessment and Carbon Footprint Reduction

Carbon-negative concrete represents a revolutionary advancement in construction materials, offering significant environmental benefits through its innovative carbon capture capabilities. Life cycle assessments of carbon-negative concrete demonstrate substantial reductions in greenhouse gas emissions compared to traditional Portland cement concrete, with some formulations achieving net carbon sequestration of up to 100-150 kg CO2 per cubic meter. This remarkable carbon footprint reduction stems from both the manufacturing process and the concrete's ability to absorb CO2 throughout its service life.

The environmental impact extends beyond carbon metrics. Carbon-negative concrete production typically requires less water than conventional methods, reducing pressure on local water resources. Additionally, many formulations incorporate industrial byproducts and waste materials that would otherwise end up in landfills, creating a circular economy approach that addresses multiple environmental challenges simultaneously.

When implemented at scale, carbon-negative concrete could transform the construction industry's environmental profile. Buildings and infrastructure constructed with these materials become carbon sinks rather than sources, potentially sequestering millions of tons of CO2 annually if adopted globally. This represents a paradigm shift in how we conceptualize construction materials' role in climate change mitigation.

Regulatory frameworks increasingly recognize these benefits through carbon credits and green building certification systems. Projects utilizing carbon-negative concrete can earn additional points in LEED, BREEAM, and other sustainability rating systems, providing economic incentives alongside environmental benefits. Several jurisdictions have begun incorporating carbon footprint requirements into building codes, positioning carbon-negative concrete as a compliance solution.

The long-term environmental benefits extend throughout the material's lifecycle. Unlike traditional concrete, which releases its embodied carbon during demolition, carbon-negative varieties maintain much of their sequestered CO2 even after the end of their service life. When crushed for recycling, these materials can continue absorbing additional CO2, creating an extended environmental benefit beyond the original application.

Regional environmental impact assessments indicate that widespread adoption could significantly improve air quality in urban centers by reducing the emissions associated with cement production. This addresses not only global climate concerns but also local environmental health issues, particularly in regions with concentrated cement manufacturing facilities.

The environmental impact extends beyond carbon metrics. Carbon-negative concrete production typically requires less water than conventional methods, reducing pressure on local water resources. Additionally, many formulations incorporate industrial byproducts and waste materials that would otherwise end up in landfills, creating a circular economy approach that addresses multiple environmental challenges simultaneously.

When implemented at scale, carbon-negative concrete could transform the construction industry's environmental profile. Buildings and infrastructure constructed with these materials become carbon sinks rather than sources, potentially sequestering millions of tons of CO2 annually if adopted globally. This represents a paradigm shift in how we conceptualize construction materials' role in climate change mitigation.

Regulatory frameworks increasingly recognize these benefits through carbon credits and green building certification systems. Projects utilizing carbon-negative concrete can earn additional points in LEED, BREEAM, and other sustainability rating systems, providing economic incentives alongside environmental benefits. Several jurisdictions have begun incorporating carbon footprint requirements into building codes, positioning carbon-negative concrete as a compliance solution.

The long-term environmental benefits extend throughout the material's lifecycle. Unlike traditional concrete, which releases its embodied carbon during demolition, carbon-negative varieties maintain much of their sequestered CO2 even after the end of their service life. When crushed for recycling, these materials can continue absorbing additional CO2, creating an extended environmental benefit beyond the original application.

Regional environmental impact assessments indicate that widespread adoption could significantly improve air quality in urban centers by reducing the emissions associated with cement production. This addresses not only global climate concerns but also local environmental health issues, particularly in regions with concentrated cement manufacturing facilities.

Regulatory Framework and Green Building Certification Standards

The regulatory landscape for carbon-negative concrete is rapidly evolving as governments worldwide implement policies to reduce carbon emissions in the construction sector. The European Union's Green Deal and Circular Economy Action Plan have established ambitious targets for carbon reduction in building materials, with specific provisions encouraging the use of carbon-negative alternatives. These regulations often include carbon pricing mechanisms that make conventional high-emission concrete less economically viable compared to carbon-negative options.

In the United States, federal procurement policies are increasingly incorporating carbon footprint considerations, with several states implementing low-carbon concrete standards. California's Buy Clean California Act represents a pioneering effort, requiring state agencies to consider the embodied carbon of construction materials in procurement decisions. Similar legislation is emerging across other states, creating a regulatory environment that increasingly favors carbon-negative concrete solutions.

Green building certification systems play a crucial role in driving market adoption of carbon-negative concrete. The Leadership in Energy and Environmental Design (LEED) system awards significant points for materials that demonstrate reduced environmental impacts through life cycle assessment, directly benefiting carbon-negative concrete applications. Similarly, the BREEAM certification system in Europe and the Green Star system in Australia provide substantial recognition for innovative materials that sequester carbon.

The International Living Future Institute's Living Building Challenge represents the most stringent green building standard, requiring net-positive impacts for materials. Carbon-negative concrete aligns perfectly with these requirements, offering a pathway to compliance that conventional materials cannot match. Additionally, the Architecture 2030 Challenge and the World Green Building Council's Net Zero Carbon Buildings Commitment have established frameworks that incentivize carbon-negative materials.

Emerging certification standards specifically for concrete, such as the Concrete Sustainability Council Certification, are incorporating carbon metrics that recognize the benefits of carbon-negative formulations. These standards are increasingly being referenced in public procurement policies, creating market pull for innovative concrete solutions.

Financial institutions are also developing green financing mechanisms that offer preferential terms for projects utilizing carbon-negative materials, further enhancing their economic viability. The EU Taxonomy for Sustainable Activities explicitly recognizes construction materials with carbon sequestration capabilities as sustainable investments, opening new funding channels for projects utilizing carbon-negative concrete.

In the United States, federal procurement policies are increasingly incorporating carbon footprint considerations, with several states implementing low-carbon concrete standards. California's Buy Clean California Act represents a pioneering effort, requiring state agencies to consider the embodied carbon of construction materials in procurement decisions. Similar legislation is emerging across other states, creating a regulatory environment that increasingly favors carbon-negative concrete solutions.

Green building certification systems play a crucial role in driving market adoption of carbon-negative concrete. The Leadership in Energy and Environmental Design (LEED) system awards significant points for materials that demonstrate reduced environmental impacts through life cycle assessment, directly benefiting carbon-negative concrete applications. Similarly, the BREEAM certification system in Europe and the Green Star system in Australia provide substantial recognition for innovative materials that sequester carbon.

The International Living Future Institute's Living Building Challenge represents the most stringent green building standard, requiring net-positive impacts for materials. Carbon-negative concrete aligns perfectly with these requirements, offering a pathway to compliance that conventional materials cannot match. Additionally, the Architecture 2030 Challenge and the World Green Building Council's Net Zero Carbon Buildings Commitment have established frameworks that incentivize carbon-negative materials.

Emerging certification standards specifically for concrete, such as the Concrete Sustainability Council Certification, are incorporating carbon metrics that recognize the benefits of carbon-negative formulations. These standards are increasingly being referenced in public procurement policies, creating market pull for innovative concrete solutions.

Financial institutions are also developing green financing mechanisms that offer preferential terms for projects utilizing carbon-negative materials, further enhancing their economic viability. The EU Taxonomy for Sustainable Activities explicitly recognizes construction materials with carbon sequestration capabilities as sustainable investments, opening new funding channels for projects utilizing carbon-negative concrete.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!