Why Carbon-negative Concrete is Pivotal in Reducing CO2 Outputs

OCT 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Technology Background and Objectives

Concrete, the most widely used building material globally, has a significant carbon footprint, accounting for approximately 8% of global CO2 emissions. Traditional cement production, a key component of concrete, is particularly carbon-intensive due to the calcination process and energy requirements. This environmental impact has driven research and development efforts toward carbon-negative concrete technologies over the past two decades, marking a paradigm shift in construction materials science.

Carbon-negative concrete represents an innovative approach that goes beyond merely reducing emissions to actively removing CO2 from the atmosphere during its lifecycle. The evolution of this technology can be traced through several key phases: from early carbon-neutral formulations in the early 2000s to the current advanced carbon-sequestering solutions. This progression reflects the construction industry's growing commitment to addressing climate change challenges.

The primary technical objective of carbon-negative concrete development is to create a building material that maintains or exceeds the performance characteristics of traditional concrete while achieving a negative carbon balance. This involves redesigning the chemical composition and manufacturing processes to incorporate CO2 absorption mechanisms. Secondary objectives include ensuring cost-competitiveness, scalability, and compliance with existing building codes and standards.

Recent technological breakthroughs have accelerated progress in this field, particularly in carbon mineralization processes, alternative binding agents, and innovative curing methods. These advancements have been supported by interdisciplinary research combining materials science, chemistry, and environmental engineering. The convergence of these disciplines has enabled more sophisticated approaches to carbon sequestration in concrete.

The trajectory of carbon-negative concrete technology is closely aligned with global climate goals, particularly the Paris Agreement targets and various national net-zero commitments. As regulatory frameworks increasingly incorporate carbon pricing and emissions standards, the demand for carbon-negative building materials is expected to grow substantially. This regulatory environment is creating both technical challenges and market opportunities for innovative solutions.

Looking forward, the technical roadmap for carbon-negative concrete includes enhancing CO2 absorption capacity, improving long-term durability, and developing more energy-efficient production methods. These objectives are guided by the ultimate goal of transforming concrete from a significant source of carbon emissions to a potential carbon sink, thereby revolutionizing its role in sustainable construction and climate change mitigation strategies.

Carbon-negative concrete represents an innovative approach that goes beyond merely reducing emissions to actively removing CO2 from the atmosphere during its lifecycle. The evolution of this technology can be traced through several key phases: from early carbon-neutral formulations in the early 2000s to the current advanced carbon-sequestering solutions. This progression reflects the construction industry's growing commitment to addressing climate change challenges.

The primary technical objective of carbon-negative concrete development is to create a building material that maintains or exceeds the performance characteristics of traditional concrete while achieving a negative carbon balance. This involves redesigning the chemical composition and manufacturing processes to incorporate CO2 absorption mechanisms. Secondary objectives include ensuring cost-competitiveness, scalability, and compliance with existing building codes and standards.

Recent technological breakthroughs have accelerated progress in this field, particularly in carbon mineralization processes, alternative binding agents, and innovative curing methods. These advancements have been supported by interdisciplinary research combining materials science, chemistry, and environmental engineering. The convergence of these disciplines has enabled more sophisticated approaches to carbon sequestration in concrete.

The trajectory of carbon-negative concrete technology is closely aligned with global climate goals, particularly the Paris Agreement targets and various national net-zero commitments. As regulatory frameworks increasingly incorporate carbon pricing and emissions standards, the demand for carbon-negative building materials is expected to grow substantially. This regulatory environment is creating both technical challenges and market opportunities for innovative solutions.

Looking forward, the technical roadmap for carbon-negative concrete includes enhancing CO2 absorption capacity, improving long-term durability, and developing more energy-efficient production methods. These objectives are guided by the ultimate goal of transforming concrete from a significant source of carbon emissions to a potential carbon sink, thereby revolutionizing its role in sustainable construction and climate change mitigation strategies.

Market Analysis for Sustainable Construction Materials

The sustainable construction materials market is experiencing unprecedented growth, driven by increasing environmental concerns and regulatory pressures to reduce carbon emissions in the building sector. Currently valued at approximately $299 billion globally, this market is projected to reach $641 billion by 2030, with a compound annual growth rate of 11.4% between 2023 and 2030. Carbon-negative concrete represents one of the fastest-growing segments within this category, with market adoption accelerating as climate targets become more stringent.

Demand for carbon-negative concrete is particularly strong in regions with ambitious climate goals, including the European Union, North America, and increasingly in Asia-Pacific markets. The EU's Green Deal and Circular Economy Action Plan have created significant market pull, while in North America, government procurement policies favoring low-carbon building materials have stimulated demand. China's recent commitment to carbon neutrality by 2060 has also catalyzed interest in carbon-negative construction materials.

Market segmentation reveals that commercial construction currently dominates the carbon-negative concrete market, accounting for 42% of applications, followed by infrastructure projects at 31%, residential construction at 21%, and other applications at 6%. This distribution reflects the greater willingness of commercial developers to adopt innovative materials to meet sustainability goals and corporate environmental commitments.

Consumer behavior analysis indicates a growing willingness to pay premium prices for sustainable building materials, with surveys showing that 68% of commercial developers and 47% of residential developers are prepared to accept a 5-15% cost premium for carbon-negative alternatives. This price tolerance is creating viable market entry points for innovative products despite their typically higher initial costs.

The competitive landscape features both established concrete manufacturers pivoting toward sustainable offerings and innovative startups focused exclusively on carbon-negative solutions. Major players include CarbonCure Technologies, Solidia Technologies, and Carbon8 Systems, alongside traditional concrete giants like LafargeHolcim and HeidelbergCement that are investing heavily in carbon-negative research and development.

Market barriers include cost considerations, with carbon-negative concrete currently commanding a 15-30% premium over conventional products, though this gap is narrowing as production scales. Technical challenges related to performance verification and long-term durability testing also remain, creating hesitancy among some potential adopters. Additionally, fragmented building codes and standards across different regions create regulatory uncertainty that slows market penetration.

Future market growth will likely be driven by increasingly stringent carbon regulations, growing corporate commitments to net-zero construction, and continued technological innovations that reduce production costs while enhancing performance characteristics of carbon-negative concrete products.

Demand for carbon-negative concrete is particularly strong in regions with ambitious climate goals, including the European Union, North America, and increasingly in Asia-Pacific markets. The EU's Green Deal and Circular Economy Action Plan have created significant market pull, while in North America, government procurement policies favoring low-carbon building materials have stimulated demand. China's recent commitment to carbon neutrality by 2060 has also catalyzed interest in carbon-negative construction materials.

Market segmentation reveals that commercial construction currently dominates the carbon-negative concrete market, accounting for 42% of applications, followed by infrastructure projects at 31%, residential construction at 21%, and other applications at 6%. This distribution reflects the greater willingness of commercial developers to adopt innovative materials to meet sustainability goals and corporate environmental commitments.

Consumer behavior analysis indicates a growing willingness to pay premium prices for sustainable building materials, with surveys showing that 68% of commercial developers and 47% of residential developers are prepared to accept a 5-15% cost premium for carbon-negative alternatives. This price tolerance is creating viable market entry points for innovative products despite their typically higher initial costs.

The competitive landscape features both established concrete manufacturers pivoting toward sustainable offerings and innovative startups focused exclusively on carbon-negative solutions. Major players include CarbonCure Technologies, Solidia Technologies, and Carbon8 Systems, alongside traditional concrete giants like LafargeHolcim and HeidelbergCement that are investing heavily in carbon-negative research and development.

Market barriers include cost considerations, with carbon-negative concrete currently commanding a 15-30% premium over conventional products, though this gap is narrowing as production scales. Technical challenges related to performance verification and long-term durability testing also remain, creating hesitancy among some potential adopters. Additionally, fragmented building codes and standards across different regions create regulatory uncertainty that slows market penetration.

Future market growth will likely be driven by increasingly stringent carbon regulations, growing corporate commitments to net-zero construction, and continued technological innovations that reduce production costs while enhancing performance characteristics of carbon-negative concrete products.

Global Status and Challenges in Carbon-negative Concrete

The global concrete industry currently accounts for approximately 8% of worldwide CO2 emissions, making it one of the largest contributors to greenhouse gas emissions. Carbon-negative concrete technologies have emerged as a promising solution, with various approaches being developed and tested across different regions. In North America, companies like CarbonCure and Solidia Technologies have made significant progress in commercializing carbon-capturing concrete solutions, while European firms such as Carbicrete and Carbon8 Systems are advancing similar technologies with strong governmental support.

In Asia, particularly China and Japan, research institutions and construction companies are investing heavily in carbon-negative concrete research, though commercial implementation remains limited compared to Western markets. The Middle East has shown growing interest, with several pilot projects underway in the UAE and Saudi Arabia as part of their economic diversification strategies.

Despite these advancements, carbon-negative concrete faces significant technical challenges. The primary obstacle is scalability - while laboratory results are promising, scaling these technologies to meet global construction demands remains difficult. Current carbon capture processes in concrete production are often energy-intensive, potentially offsetting some environmental benefits unless powered by renewable energy sources.

Material performance consistency presents another major challenge. Carbon-negative concrete must maintain or exceed the structural properties of traditional concrete to gain widespread adoption. Current formulations sometimes exhibit variable strength characteristics depending on curing conditions and carbon content, creating hesitation among engineers and builders.

Regulatory frameworks globally remain inconsistent, with building codes and standards in many countries not yet updated to accommodate these innovative materials. This regulatory lag creates market uncertainty and slows adoption rates. Additionally, the cost premium associated with carbon-negative concrete - typically 15-30% higher than conventional concrete - presents a significant market barrier despite long-term environmental benefits.

Supply chain limitations further complicate widespread adoption. Many carbon-negative concrete technologies require specialized additives or processing equipment not readily available in developing markets. The geographical distribution of necessary raw materials also creates logistical challenges for global implementation.

Knowledge gaps persist regarding the long-term performance of carbon-negative concrete structures. With limited real-world data spanning decades, questions remain about durability under various environmental conditions, maintenance requirements, and end-of-life considerations. These uncertainties contribute to cautious adoption rates among conservative construction industries worldwide.

In Asia, particularly China and Japan, research institutions and construction companies are investing heavily in carbon-negative concrete research, though commercial implementation remains limited compared to Western markets. The Middle East has shown growing interest, with several pilot projects underway in the UAE and Saudi Arabia as part of their economic diversification strategies.

Despite these advancements, carbon-negative concrete faces significant technical challenges. The primary obstacle is scalability - while laboratory results are promising, scaling these technologies to meet global construction demands remains difficult. Current carbon capture processes in concrete production are often energy-intensive, potentially offsetting some environmental benefits unless powered by renewable energy sources.

Material performance consistency presents another major challenge. Carbon-negative concrete must maintain or exceed the structural properties of traditional concrete to gain widespread adoption. Current formulations sometimes exhibit variable strength characteristics depending on curing conditions and carbon content, creating hesitation among engineers and builders.

Regulatory frameworks globally remain inconsistent, with building codes and standards in many countries not yet updated to accommodate these innovative materials. This regulatory lag creates market uncertainty and slows adoption rates. Additionally, the cost premium associated with carbon-negative concrete - typically 15-30% higher than conventional concrete - presents a significant market barrier despite long-term environmental benefits.

Supply chain limitations further complicate widespread adoption. Many carbon-negative concrete technologies require specialized additives or processing equipment not readily available in developing markets. The geographical distribution of necessary raw materials also creates logistical challenges for global implementation.

Knowledge gaps persist regarding the long-term performance of carbon-negative concrete structures. With limited real-world data spanning decades, questions remain about durability under various environmental conditions, maintenance requirements, and end-of-life considerations. These uncertainties contribute to cautious adoption rates among conservative construction industries worldwide.

Current Carbon-negative Concrete Solutions and Implementation

01 CO2 capture and sequestration in concrete production

Carbon-negative concrete can be achieved by capturing and sequestering CO2 during the production process. This approach involves technologies that absorb CO2 from the atmosphere or industrial emissions and permanently store it within the concrete matrix. The captured CO2 reacts with calcium-containing materials to form stable carbonate compounds, effectively locking away carbon while simultaneously improving concrete properties such as strength and durability.- CO2 capture and mineralization in concrete production: Technologies that capture CO2 during or after concrete production and convert it into stable mineral carbonates within the concrete matrix. These processes typically involve exposing cement or concrete to CO2 under controlled conditions, allowing the gas to react with calcium-containing compounds to form calcium carbonate. This mineralization process not only sequesters CO2 permanently but can also improve concrete strength and durability, creating a carbon-negative building material.

- Alternative low-carbon binders and supplementary cementitious materials: Development of novel cement formulations that replace traditional Portland cement with alternative binders that have significantly lower carbon footprints. These include geopolymers, alkali-activated materials, and various industrial byproducts such as fly ash, slag, and silica fume. By reducing the amount of conventional cement required, these materials can substantially decrease the CO2 emissions associated with concrete production while maintaining or enhancing performance characteristics.

- Carbon-negative concrete manufacturing processes: Innovative manufacturing processes designed to produce concrete with a negative carbon footprint. These approaches integrate renewable energy sources, efficient kiln technologies, and carbon capture systems throughout the production chain. Some methods involve specialized curing techniques that accelerate CO2 absorption or incorporate biomass-derived materials that have already sequestered carbon during their growth phase, resulting in concrete products that store more carbon than is emitted during their manufacture.

- CO2 utilization in concrete additives and aggregates: Methods for converting captured CO2 into valuable concrete ingredients such as synthetic aggregates or chemical additives. These processes transform waste CO2 into solid carbonate materials that can replace natural aggregates or enhance concrete properties. By incorporating these CO2-derived materials into concrete formulations, manufacturers can create products with reduced or negative carbon footprints while potentially improving performance characteristics such as strength, durability, and workability.

- Monitoring and quantification of carbon sequestration in concrete: Systems and methods for accurately measuring, monitoring, and verifying the amount of CO2 sequestered in concrete products. These technologies include specialized sensors, testing protocols, and lifecycle assessment tools that enable precise quantification of carbon uptake and emissions throughout the concrete lifecycle. Such measurement capabilities are essential for validating carbon-negative claims, accessing carbon credits or incentives, and optimizing formulations to maximize CO2 sequestration while maintaining desired performance properties.

02 Alternative cementitious materials with lower carbon footprint

The use of alternative cementitious materials can significantly reduce the carbon footprint of concrete. These materials include supplementary cementitious materials (SCMs) like fly ash, slag, silica fume, and natural pozzolans that can partially replace traditional Portland cement. Additionally, novel binders such as geopolymers, alkali-activated materials, and magnesium-based cements can be used to create concrete with substantially lower CO2 emissions compared to conventional concrete.Expand Specific Solutions03 Carbonation curing processes for concrete products

Carbonation curing involves exposing freshly cast concrete products to CO2-rich environments during the curing phase. This process accelerates the hardening of concrete while simultaneously sequestering CO2. The carbon dioxide reacts with calcium hydroxide in the concrete to form calcium carbonate, which improves the material's properties while creating a carbon sink. This technique can be applied to precast concrete products and can transform conventional concrete manufacturing into a carbon-negative process.Expand Specific Solutions04 Biomass incorporation and carbon-negative aggregates

Incorporating biomass or carbon-negative aggregates into concrete mixtures can reduce the overall carbon footprint. These materials include agricultural waste products, biochar, or specially processed aggregates that have sequestered CO2 during their production. When these carbon-negative components are incorporated into concrete, they bring their sequestered carbon with them, offsetting emissions from other ingredients and potentially making the final product carbon-negative.Expand Specific Solutions05 Carbon accounting and lifecycle assessment methods for concrete

Advanced carbon accounting and lifecycle assessment methods are essential for accurately measuring the carbon footprint of concrete products. These methodologies consider all emissions throughout the concrete lifecycle, from raw material extraction to end-of-life scenarios. They also account for carbon sequestration during the concrete's service life through natural carbonation processes. Such comprehensive assessment tools enable manufacturers to verify carbon-negative claims and optimize their production processes to minimize CO2 outputs.Expand Specific Solutions

Leading Companies and Research Institutions in Green Concrete

Carbon-negative concrete technology is emerging as a critical solution in the construction industry's decarbonization efforts, currently in its early growth phase. The global market for sustainable concrete is expanding rapidly, projected to reach significant scale as regulatory pressures increase. Technologically, the field shows varying maturity levels across different approaches. Leading players include established cement manufacturers like Lafarge, Taiheiyo Cement, and Holcim Technology, alongside innovative startups such as Solidia Technologies and Carbon Limit Co. Academic institutions including MIT, University of Tokyo, and Southeast University are driving fundamental research. The competitive landscape features collaboration between traditional industry players and technology innovators, with increasing investment in scalable carbon capture and utilization technologies specifically designed for concrete applications.

Lafarge SA

Technical Solution: Lafarge has developed a comprehensive carbon-negative concrete solution called "SustainCrete" that combines multiple innovative approaches. Their technology incorporates a novel clinker substitute derived from industrial by-products, reducing the limestone calcination process that traditionally accounts for approximately 60% of cement's carbon emissions. Lafarge's process also utilizes renewable energy in manufacturing and employs carbon capture technologies at production facilities. The captured CO2 is then used in their concrete curing process, where it becomes permanently mineralized within the concrete matrix. Additionally, Lafarge has pioneered the use of biogenic materials as partial aggregate replacements, further enhancing carbon sequestration. Their concrete formulations achieve carbon negativity through careful lifecycle assessment, with third-party verification confirming net carbon sequestration of approximately 30-50 kg CO2 per cubic meter of concrete. Lafarge has successfully implemented this technology in commercial projects across Europe and North America, demonstrating scalability and performance comparable to traditional concrete.

Strengths: Comprehensive approach addressing multiple carbon emission sources; successfully commercialized with proven performance in real-world applications; compatible with existing construction standards and practices; creates valuable use case for captured carbon. Weaknesses: Requires sophisticated supply chain for specialized ingredients; higher initial production costs compared to traditional concrete; variable performance depending on local material availability and climate conditions.

Solidia Technologies, Inc.

Technical Solution: Solidia Technologies has developed a revolutionary carbon-negative concrete technology that fundamentally alters the chemistry of cement. Their process replaces traditional Ordinary Portland Cement (OPC) with a low-lime content cement that requires lower kiln temperatures during manufacturing, reducing CO2 emissions by up to 30% in the production phase alone. The innovation continues with their curing process, which uses CO2 instead of water, enabling the concrete to sequester carbon dioxide permanently. This carbon-curing technology can absorb up to 400 kg of CO2 per ton of cement used, effectively making their concrete products carbon-negative. Solidia's technology is compatible with existing concrete manufacturing equipment, requiring minimal retrofitting, which facilitates industry adoption. Their products have demonstrated comparable or superior performance characteristics to traditional concrete, including higher early strength development, reduced efflorescence, and improved freeze-thaw durability.

Strengths: Reduces overall carbon footprint by up to 70% compared to traditional concrete; requires 60-80% less water; achieves full strength in 24 hours versus 28 days for traditional concrete; utilizes existing manufacturing infrastructure. Weaknesses: Requires reliable access to captured CO2 for curing process; initial market penetration challenges due to industry's conservative adoption of new technologies; potential higher upfront costs for implementation.

Key Patents and Innovations in CO2 Sequestration for Concrete

Cementitious materials and methods of making and using same

PatentPendingUS20250042811A1

Innovation

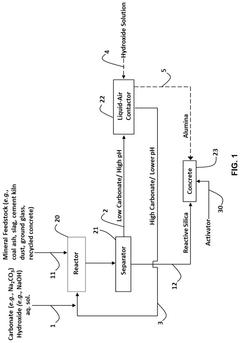

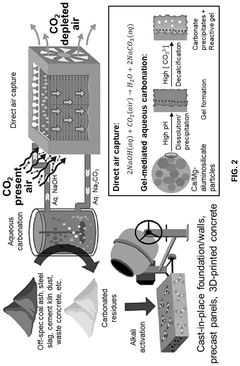

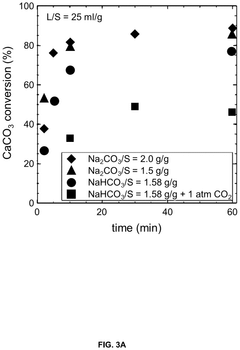

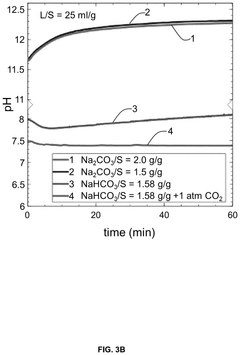

- A carbon mineralization-based direct-air capture process is used to produce carbon-negative cementitious materials by capturing CO2 from the air through an aqueous carbonation cycle, enhancing the pozzolanic reactivity of industrial mineral wastes, and incorporating the captured CO2 as solid carbonate in the concrete.

Carbon negative concrete production through the use of sustainable materials

PatentInactiveUS20230002276A1

Innovation

- Incorporating biochar, a high-carbon residue produced through low-oxygen pyrolysis, into concrete mixtures to sequester carbon and reduce emissions, while optimizing pyrolysis processes to power plants using syngas for self-sustainability and carbon neutrality.

Environmental Impact Assessment and Carbon Footprint Metrics

The concrete industry currently accounts for approximately 8% of global CO2 emissions, making it one of the most significant contributors to greenhouse gas emissions worldwide. Traditional concrete production processes release carbon dioxide through two primary mechanisms: the calcination process in cement production and the energy consumption required for manufacturing. These combined factors result in approximately 0.9 tons of CO2 emissions per ton of cement produced.

Carbon-negative concrete technologies represent a paradigm shift in environmental impact assessment, as they fundamentally alter the carbon equation from net emission to net sequestration. Comprehensive life cycle assessments (LCAs) of carbon-negative concrete solutions demonstrate potential carbon sequestration capabilities ranging from 50-300 kg CO2 per cubic meter of concrete, depending on the specific technology employed and implementation methods.

The environmental impact metrics for carbon-negative concrete must be evaluated across multiple dimensions, including raw material sourcing, manufacturing processes, transportation logistics, installation methods, service life performance, and end-of-life considerations. This holistic approach provides a more accurate representation of the true carbon footprint compared to traditional single-point-in-time emissions calculations.

Carbon accounting methodologies for these innovative concrete solutions require standardization to ensure consistent measurement and reporting. Current frameworks such as the Greenhouse Gas Protocol and ISO 14067 provide baseline guidance, but industry-specific metrics are being developed to address the unique characteristics of carbon-negative concrete technologies, particularly regarding long-term carbon sequestration verification.

The environmental benefits extend beyond carbon sequestration to include reduced water consumption, decreased particulate emissions, and minimized waste generation compared to traditional concrete production. Some carbon-negative concrete formulations demonstrate up to 60% reduction in water usage and 40% reduction in particulate matter emissions during manufacturing processes.

Regional variations in environmental impact assessments must be considered, as factors such as local energy grid carbon intensity, transportation distances, and available raw materials significantly influence the overall carbon footprint. Studies indicate that implementation in regions with carbon-intensive energy grids offers the greatest immediate environmental benefit, with potential carbon footprint reductions of 110-150% compared to conventional concrete.

Monitoring and verification protocols are being established to track the long-term carbon sequestration performance of these materials, ensuring that the promised environmental benefits are realized throughout the concrete's service life. These protocols typically include periodic testing and documentation to validate continued carbon storage and structural integrity over decades of use.

Carbon-negative concrete technologies represent a paradigm shift in environmental impact assessment, as they fundamentally alter the carbon equation from net emission to net sequestration. Comprehensive life cycle assessments (LCAs) of carbon-negative concrete solutions demonstrate potential carbon sequestration capabilities ranging from 50-300 kg CO2 per cubic meter of concrete, depending on the specific technology employed and implementation methods.

The environmental impact metrics for carbon-negative concrete must be evaluated across multiple dimensions, including raw material sourcing, manufacturing processes, transportation logistics, installation methods, service life performance, and end-of-life considerations. This holistic approach provides a more accurate representation of the true carbon footprint compared to traditional single-point-in-time emissions calculations.

Carbon accounting methodologies for these innovative concrete solutions require standardization to ensure consistent measurement and reporting. Current frameworks such as the Greenhouse Gas Protocol and ISO 14067 provide baseline guidance, but industry-specific metrics are being developed to address the unique characteristics of carbon-negative concrete technologies, particularly regarding long-term carbon sequestration verification.

The environmental benefits extend beyond carbon sequestration to include reduced water consumption, decreased particulate emissions, and minimized waste generation compared to traditional concrete production. Some carbon-negative concrete formulations demonstrate up to 60% reduction in water usage and 40% reduction in particulate matter emissions during manufacturing processes.

Regional variations in environmental impact assessments must be considered, as factors such as local energy grid carbon intensity, transportation distances, and available raw materials significantly influence the overall carbon footprint. Studies indicate that implementation in regions with carbon-intensive energy grids offers the greatest immediate environmental benefit, with potential carbon footprint reductions of 110-150% compared to conventional concrete.

Monitoring and verification protocols are being established to track the long-term carbon sequestration performance of these materials, ensuring that the promised environmental benefits are realized throughout the concrete's service life. These protocols typically include periodic testing and documentation to validate continued carbon storage and structural integrity over decades of use.

Policy Frameworks and Incentives for Low-Carbon Construction

The global construction industry faces mounting pressure to reduce its environmental footprint, with concrete production alone accounting for approximately 8% of worldwide CO2 emissions. Effective policy frameworks and incentives are essential to accelerate the adoption of carbon-negative concrete technologies and transform construction practices across the industry.

Carbon pricing mechanisms represent a cornerstone policy approach, with carbon taxes and cap-and-trade systems creating financial incentives for construction companies to transition to low-carbon alternatives. The European Union's Emissions Trading System (ETS) has demonstrated how such mechanisms can drive industry-wide changes, though implementation challenges remain in accurately measuring and verifying emissions reductions in construction materials.

Building codes and standards are evolving to incorporate carbon performance metrics alongside traditional safety and durability requirements. Leading jurisdictions like California and British Columbia have pioneered low-carbon concrete standards that establish maximum acceptable carbon intensities for different concrete applications, creating regulatory pressure for innovation while maintaining performance requirements.

Public procurement policies have emerged as powerful market drivers, with governments leveraging their substantial purchasing power to create demand for carbon-negative construction materials. The Buy Clean California Act exemplifies this approach by requiring Environmental Product Declarations (EPDs) for construction materials used in public projects and establishing maximum acceptable global warming potential thresholds.

Financial incentives, including tax credits, grants, and subsidies, are being deployed to offset the higher initial costs of carbon-negative concrete technologies. The 45Q tax credit in the United States provides up to $50 per metric ton of CO2 permanently sequestered, creating significant economic incentives for carbon capture in concrete production.

Research and development support through public funding programs accelerates innovation in carbon-negative concrete technologies. The EU's Horizon Europe program and the U.S. Department of Energy's Advanced Research Projects Agency-Energy (ARPA-E) have allocated substantial resources to developing next-generation construction materials with enhanced carbon sequestration capabilities.

International cooperation frameworks facilitate knowledge sharing and technology transfer across borders. The Global Alliance for Buildings and Construction and the Clean Energy Ministerial's Carbon Capture Innovation Challenge exemplify multilateral efforts to coordinate policy approaches and accelerate the global transition to low-carbon construction practices.

Effective policy frameworks must balance regulatory requirements with market-based incentives while providing clear, long-term signals to industry stakeholders. As carbon-negative concrete technologies mature, policy approaches will need to evolve from supporting early-stage innovation to facilitating widespread market adoption and standardization.

Carbon pricing mechanisms represent a cornerstone policy approach, with carbon taxes and cap-and-trade systems creating financial incentives for construction companies to transition to low-carbon alternatives. The European Union's Emissions Trading System (ETS) has demonstrated how such mechanisms can drive industry-wide changes, though implementation challenges remain in accurately measuring and verifying emissions reductions in construction materials.

Building codes and standards are evolving to incorporate carbon performance metrics alongside traditional safety and durability requirements. Leading jurisdictions like California and British Columbia have pioneered low-carbon concrete standards that establish maximum acceptable carbon intensities for different concrete applications, creating regulatory pressure for innovation while maintaining performance requirements.

Public procurement policies have emerged as powerful market drivers, with governments leveraging their substantial purchasing power to create demand for carbon-negative construction materials. The Buy Clean California Act exemplifies this approach by requiring Environmental Product Declarations (EPDs) for construction materials used in public projects and establishing maximum acceptable global warming potential thresholds.

Financial incentives, including tax credits, grants, and subsidies, are being deployed to offset the higher initial costs of carbon-negative concrete technologies. The 45Q tax credit in the United States provides up to $50 per metric ton of CO2 permanently sequestered, creating significant economic incentives for carbon capture in concrete production.

Research and development support through public funding programs accelerates innovation in carbon-negative concrete technologies. The EU's Horizon Europe program and the U.S. Department of Energy's Advanced Research Projects Agency-Energy (ARPA-E) have allocated substantial resources to developing next-generation construction materials with enhanced carbon sequestration capabilities.

International cooperation frameworks facilitate knowledge sharing and technology transfer across borders. The Global Alliance for Buildings and Construction and the Clean Energy Ministerial's Carbon Capture Innovation Challenge exemplify multilateral efforts to coordinate policy approaches and accelerate the global transition to low-carbon construction practices.

Effective policy frameworks must balance regulatory requirements with market-based incentives while providing clear, long-term signals to industry stakeholders. As carbon-negative concrete technologies mature, policy approaches will need to evolve from supporting early-stage innovation to facilitating widespread market adoption and standardization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!