How Carbon-negative Concrete Contributes to Sustainable Development

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Evolution and Objectives

Concrete, a fundamental building material in modern construction, has historically been a significant contributor to global carbon emissions. The evolution of carbon-negative concrete represents a paradigm shift in construction technology, moving from environmentally harmful practices to sustainable solutions that actively combat climate change. Traditional concrete production accounts for approximately 8% of global CO2 emissions, primarily due to the energy-intensive process of cement manufacturing. This environmental burden has driven researchers and industry stakeholders to reimagine concrete formulation and production methods.

The journey toward carbon-negative concrete began in the early 2000s with initial explorations into alternative cementitious materials. By 2010, researchers had developed the first commercially viable low-carbon concrete formulations, which reduced emissions but remained carbon-positive. The breakthrough toward carbon-negative solutions emerged around 2015, when technologies enabling carbon capture and utilization within concrete were first demonstrated at laboratory scale.

Recent technological advancements have accelerated this evolution, with carbon-negative concrete now moving from experimental phases to commercial applications. These innovative formulations incorporate CO2 sequestration mechanisms, either through carbonation processes during curing or through the integration of carbon-absorbing materials such as industrial byproducts and novel aggregates. Some cutting-edge solutions utilize biomass-derived components that have already captured carbon during their growth phase.

The primary objective of carbon-negative concrete development is to transform the construction industry from a major carbon emitter to a potential carbon sink. Specific technical goals include achieving a negative carbon footprint of at least -50 kg CO2 per cubic meter of concrete while maintaining or exceeding the performance characteristics of traditional concrete in terms of strength, durability, and workability. Additionally, researchers aim to develop formulations that can be produced using existing manufacturing infrastructure to facilitate rapid industry adoption.

Beyond environmental benefits, carbon-negative concrete technology seeks to establish economic viability through reduced material costs, potential carbon credit revenues, and alignment with increasingly stringent building regulations worldwide. The technology aims to address the full lifecycle of concrete structures, from production through service life to eventual recycling or disposal.

The evolution trajectory suggests that by 2030, carbon-negative concrete could become the industry standard in developed markets, with global adoption following in subsequent decades. This transition represents not merely an incremental improvement but a fundamental reimagining of one of humanity's most widely used materials to address the urgent challenges of climate change while supporting sustainable development goals.

The journey toward carbon-negative concrete began in the early 2000s with initial explorations into alternative cementitious materials. By 2010, researchers had developed the first commercially viable low-carbon concrete formulations, which reduced emissions but remained carbon-positive. The breakthrough toward carbon-negative solutions emerged around 2015, when technologies enabling carbon capture and utilization within concrete were first demonstrated at laboratory scale.

Recent technological advancements have accelerated this evolution, with carbon-negative concrete now moving from experimental phases to commercial applications. These innovative formulations incorporate CO2 sequestration mechanisms, either through carbonation processes during curing or through the integration of carbon-absorbing materials such as industrial byproducts and novel aggregates. Some cutting-edge solutions utilize biomass-derived components that have already captured carbon during their growth phase.

The primary objective of carbon-negative concrete development is to transform the construction industry from a major carbon emitter to a potential carbon sink. Specific technical goals include achieving a negative carbon footprint of at least -50 kg CO2 per cubic meter of concrete while maintaining or exceeding the performance characteristics of traditional concrete in terms of strength, durability, and workability. Additionally, researchers aim to develop formulations that can be produced using existing manufacturing infrastructure to facilitate rapid industry adoption.

Beyond environmental benefits, carbon-negative concrete technology seeks to establish economic viability through reduced material costs, potential carbon credit revenues, and alignment with increasingly stringent building regulations worldwide. The technology aims to address the full lifecycle of concrete structures, from production through service life to eventual recycling or disposal.

The evolution trajectory suggests that by 2030, carbon-negative concrete could become the industry standard in developed markets, with global adoption following in subsequent decades. This transition represents not merely an incremental improvement but a fundamental reimagining of one of humanity's most widely used materials to address the urgent challenges of climate change while supporting sustainable development goals.

Market Demand for Sustainable Construction Materials

The global construction industry is experiencing a significant shift towards sustainable materials, driven by increasing environmental concerns and regulatory pressures. The market for sustainable construction materials, particularly carbon-negative concrete, has shown remarkable growth in recent years. According to recent market analyses, the global green concrete market was valued at approximately $26.2 billion in 2021 and is projected to reach $65.8 billion by 2030, growing at a CAGR of 10.7% during the forecast period.

This growth is primarily fueled by stringent environmental regulations aimed at reducing carbon emissions in the construction sector, which accounts for nearly 40% of global CO2 emissions. The Paris Agreement and subsequent national climate policies have established concrete targets for carbon reduction, creating a regulatory environment that favors carbon-negative building materials.

Consumer preferences are also evolving rapidly, with a growing segment of environmentally conscious buyers willing to pay premium prices for sustainable buildings. Commercial real estate developers increasingly recognize that green buildings command higher rental rates and have lower vacancy rates compared to conventional structures. Studies indicate that buildings with green certifications can achieve 7-10% higher rental premiums and 16-17% higher sale prices.

The public sector represents another significant driver of demand, with governments worldwide implementing green procurement policies. Many countries have introduced incentives such as tax benefits, expedited permitting, and density bonuses for projects utilizing sustainable materials, further stimulating market growth for carbon-negative concrete.

Regional market analysis reveals varying adoption rates across different geographies. Europe leads in the adoption of sustainable construction materials, followed by North America, while the Asia-Pacific region shows the highest growth potential due to rapid urbanization and infrastructure development. China's commitment to carbon neutrality by 2060 has particularly accelerated the demand for green building materials in the region.

Industry stakeholders are increasingly recognizing the economic benefits of carbon-negative concrete beyond environmental considerations. Life-cycle cost analyses demonstrate that despite potentially higher initial costs, sustainable concrete solutions often result in lower total ownership costs due to improved durability, reduced maintenance requirements, and energy efficiency benefits.

The COVID-19 pandemic has further accelerated this market trend, with post-pandemic recovery plans in many countries emphasizing green infrastructure investments. The European Union's Recovery and Resilience Facility, for instance, allocates 37% of its €672.5 billion fund to climate-related projects, creating substantial opportunities for carbon-negative construction materials.

This growth is primarily fueled by stringent environmental regulations aimed at reducing carbon emissions in the construction sector, which accounts for nearly 40% of global CO2 emissions. The Paris Agreement and subsequent national climate policies have established concrete targets for carbon reduction, creating a regulatory environment that favors carbon-negative building materials.

Consumer preferences are also evolving rapidly, with a growing segment of environmentally conscious buyers willing to pay premium prices for sustainable buildings. Commercial real estate developers increasingly recognize that green buildings command higher rental rates and have lower vacancy rates compared to conventional structures. Studies indicate that buildings with green certifications can achieve 7-10% higher rental premiums and 16-17% higher sale prices.

The public sector represents another significant driver of demand, with governments worldwide implementing green procurement policies. Many countries have introduced incentives such as tax benefits, expedited permitting, and density bonuses for projects utilizing sustainable materials, further stimulating market growth for carbon-negative concrete.

Regional market analysis reveals varying adoption rates across different geographies. Europe leads in the adoption of sustainable construction materials, followed by North America, while the Asia-Pacific region shows the highest growth potential due to rapid urbanization and infrastructure development. China's commitment to carbon neutrality by 2060 has particularly accelerated the demand for green building materials in the region.

Industry stakeholders are increasingly recognizing the economic benefits of carbon-negative concrete beyond environmental considerations. Life-cycle cost analyses demonstrate that despite potentially higher initial costs, sustainable concrete solutions often result in lower total ownership costs due to improved durability, reduced maintenance requirements, and energy efficiency benefits.

The COVID-19 pandemic has further accelerated this market trend, with post-pandemic recovery plans in many countries emphasizing green infrastructure investments. The European Union's Recovery and Resilience Facility, for instance, allocates 37% of its €672.5 billion fund to climate-related projects, creating substantial opportunities for carbon-negative construction materials.

Technical Barriers in Carbon-negative Concrete Development

Despite the promising potential of carbon-negative concrete, several significant technical barriers impede its widespread adoption and development. The primary challenge lies in the carbon capture and utilization (CCU) technologies required for creating truly carbon-negative products. Current CCU methods often demand substantial energy inputs, potentially offsetting carbon benefits when considering lifecycle emissions. Additionally, the energy requirements for carbonation processes remain high, with many systems requiring elevated temperatures and pressures to achieve optimal CO2 absorption rates.

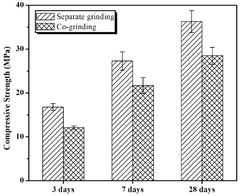

Material science challenges present another major obstacle. Developing binders that can effectively replace traditional Portland cement while maintaining or improving structural performance requires complex formulation expertise. The chemical interactions between alternative binders and CO2 during carbonation are not fully understood, creating uncertainties in long-term performance prediction. Furthermore, achieving consistent quality across production batches remains difficult due to variations in raw material properties and carbonation conditions.

Scalability issues represent a critical barrier to commercial viability. Many carbon-negative concrete technologies have been demonstrated only at laboratory or pilot scales. The transition to industrial-scale production introduces numerous engineering challenges, including designing efficient carbonation chambers, developing appropriate material handling systems, and ensuring consistent product quality across larger volumes. The capital investment required for such scaling is substantial, deterring many potential market entrants.

Performance verification and standardization gaps further complicate adoption. Current building codes and standards are primarily designed for traditional concrete, creating regulatory hurdles for innovative carbon-negative alternatives. The lack of standardized testing protocols specifically designed for carbon-negative concrete makes it difficult to verify performance claims and ensure safety compliance. This regulatory uncertainty increases perceived risk among potential adopters.

Economic viability remains perhaps the most significant barrier. The production costs for carbon-negative concrete currently exceed those of conventional concrete, primarily due to higher material costs, energy requirements, and capital investments in specialized equipment. Without carbon pricing mechanisms or other policy incentives, the business case for carbon-negative concrete relies heavily on premium market segments willing to pay for sustainability benefits.

Infrastructure limitations also pose challenges. The CO2 supply chain infrastructure necessary for widespread carbon-negative concrete production is underdeveloped in many regions. Capturing, purifying, transporting, and storing CO2 requires specialized equipment and expertise not readily available in traditional concrete manufacturing facilities. This infrastructure gap creates logistical barriers to implementation, particularly in developing regions.

Material science challenges present another major obstacle. Developing binders that can effectively replace traditional Portland cement while maintaining or improving structural performance requires complex formulation expertise. The chemical interactions between alternative binders and CO2 during carbonation are not fully understood, creating uncertainties in long-term performance prediction. Furthermore, achieving consistent quality across production batches remains difficult due to variations in raw material properties and carbonation conditions.

Scalability issues represent a critical barrier to commercial viability. Many carbon-negative concrete technologies have been demonstrated only at laboratory or pilot scales. The transition to industrial-scale production introduces numerous engineering challenges, including designing efficient carbonation chambers, developing appropriate material handling systems, and ensuring consistent product quality across larger volumes. The capital investment required for such scaling is substantial, deterring many potential market entrants.

Performance verification and standardization gaps further complicate adoption. Current building codes and standards are primarily designed for traditional concrete, creating regulatory hurdles for innovative carbon-negative alternatives. The lack of standardized testing protocols specifically designed for carbon-negative concrete makes it difficult to verify performance claims and ensure safety compliance. This regulatory uncertainty increases perceived risk among potential adopters.

Economic viability remains perhaps the most significant barrier. The production costs for carbon-negative concrete currently exceed those of conventional concrete, primarily due to higher material costs, energy requirements, and capital investments in specialized equipment. Without carbon pricing mechanisms or other policy incentives, the business case for carbon-negative concrete relies heavily on premium market segments willing to pay for sustainability benefits.

Infrastructure limitations also pose challenges. The CO2 supply chain infrastructure necessary for widespread carbon-negative concrete production is underdeveloped in many regions. Capturing, purifying, transporting, and storing CO2 requires specialized equipment and expertise not readily available in traditional concrete manufacturing facilities. This infrastructure gap creates logistical barriers to implementation, particularly in developing regions.

Current Carbon-negative Concrete Formulations and Methods

01 Carbon sequestration in concrete production

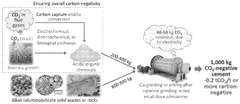

Carbon-negative concrete can be achieved through processes that sequester more carbon dioxide than is emitted during production. This involves capturing CO2 from industrial sources or directly from the atmosphere and incorporating it into the concrete matrix through carbonation reactions. The sequestered carbon becomes permanently bound in the concrete, effectively removing it from the carbon cycle and creating a carbon sink.- Carbon sequestration in concrete production: Carbon-negative concrete can be achieved through carbon sequestration processes during production. These methods involve capturing and permanently storing CO2 within the concrete matrix, effectively removing carbon dioxide from the atmosphere. The sequestration can occur through carbonation of cement components or through the incorporation of materials that naturally absorb CO2 during curing, resulting in a net reduction of carbon emissions over the concrete's lifecycle.

- Alternative binders and supplementary cementitious materials: The use of alternative binders and supplementary cementitious materials (SCMs) can significantly reduce the carbon footprint of concrete. These materials, such as fly ash, slag, silica fume, and natural pozzolans, can partially replace traditional Portland cement, which is responsible for the majority of concrete's carbon emissions. Some novel binders can even absorb more CO2 during their service life than was emitted during their production, contributing to carbon negativity.

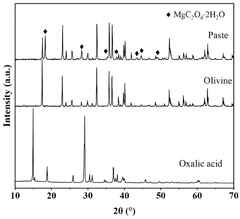

- CO2 utilization in concrete curing: Innovative curing techniques involve the injection of CO2 into fresh concrete during the manufacturing process. This CO2 reacts with calcium compounds in the concrete to form calcium carbonate, effectively sequestering the carbon dioxide while simultaneously improving the concrete's strength and durability properties. This approach transforms a greenhouse gas into a valuable input for concrete production, contributing to carbon negativity.

- Biomass incorporation and carbon-negative aggregates: The incorporation of biomass materials or carbon-negative aggregates into concrete mixtures can enhance carbon sequestration. These materials, which may include agricultural waste products, biochar, or specially processed minerals that absorb CO2, can be integrated into the concrete matrix to create a carbon sink. When these materials replace traditional aggregates, they can significantly reduce the overall carbon footprint of the concrete while maintaining necessary structural properties.

- Life cycle carbon accounting and certification systems: Comprehensive life cycle assessment methodologies and certification systems have been developed to accurately measure and verify the carbon negativity of concrete products. These systems account for all emissions throughout the concrete's life cycle, from raw material extraction through manufacturing, use, and end-of-life scenarios. They also quantify carbon sequestration to determine if a concrete product truly achieves carbon-negative status, providing standardized metrics for environmental performance evaluation.

02 Alternative cementitious materials for carbon reduction

Using alternative cementitious materials such as supplementary cementitious materials (SCMs), geopolymers, or alkali-activated materials can significantly reduce the carbon footprint of concrete. These materials often replace traditional Portland cement, which is responsible for substantial CO2 emissions. Materials like fly ash, slag, silica fume, and natural pozzolans can be incorporated into concrete mixtures to decrease the overall carbon intensity.Expand Specific Solutions03 Innovative carbonation curing techniques

Specialized curing techniques that expose fresh concrete to CO2-rich environments can accelerate carbonation and increase carbon uptake. These methods enhance the mechanical properties of concrete while simultaneously sequestering carbon dioxide. The process involves controlling temperature, pressure, and CO2 concentration to optimize the carbonation reaction, resulting in concrete products with negative carbon footprints.Expand Specific Solutions04 Biomass incorporation and biogenic materials

Incorporating biomass or biogenic materials into concrete can contribute to carbon negativity. These materials, which have already sequestered carbon during their growth phase, can be used as aggregates, fillers, or as precursors for binders. Examples include agricultural waste products, wood derivatives, and other plant-based materials that can partially replace conventional concrete components while maintaining structural integrity.Expand Specific Solutions05 Carbon accounting and lifecycle assessment methods

Developing standardized methods for carbon accounting and lifecycle assessment is crucial for verifying carbon negativity claims in concrete production. These methodologies consider all emissions throughout the concrete lifecycle, from raw material extraction to end-of-life scenarios, and compare them against the amount of carbon sequestered. This comprehensive approach ensures accurate quantification of the net carbon impact and helps identify opportunities for further improvement.Expand Specific Solutions

Leading Companies and Research Institutions in Green Concrete

Carbon-negative concrete technology is currently in an early growth phase, with increasing market adoption driven by sustainability demands. The global market for sustainable concrete is expanding rapidly, projected to reach significant scale as construction industries seek to reduce carbon footprints. Technologically, various approaches are emerging with different maturity levels. Academic institutions like MIT, Colorado School of Mines, and Hong Kong Polytechnic University are advancing fundamental research, while companies such as Solidia Technologies, Carbon Limit Co., and Ecocem Materials are commercializing innovative solutions. Traditional cement manufacturers including Huaxin Cement and Nippon Hume are also adapting their processes. The competitive landscape features collaboration between research institutions and industry players, with technology transfer accelerating as regulatory pressures for carbon reduction intensify.

Solidia Technologies, Inc.

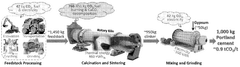

Technical Solution: Solidia Technologies has developed a revolutionary carbon-negative concrete technology that fundamentally changes the chemistry of cement. Their process uses a non-hydraulic calcium silicate cement that cures by carbonation rather than hydration, consuming CO2 during the curing process. This proprietary technology reduces the carbon footprint of concrete production by up to 70% compared to traditional Portland cement concrete. The process involves two key innovations: (1) a low-temperature cement production method that reduces energy consumption and CO2 emissions by 30-40%, and (2) a CO2-curing process that permanently sequesters carbon dioxide, converting it into solid calcium carbonate within the concrete matrix. Solidia's concrete products can sequester up to 240 kg of CO2 per ton of cement used, effectively making their concrete a carbon sink rather than a carbon source. The technology is compatible with existing concrete manufacturing equipment, requiring minimal capital investment for adoption, and produces concrete with enhanced durability and reduced efflorescence.

Strengths: Achieves significant carbon reduction (up to 70%) through both manufacturing and carbon sequestration; compatible with existing production equipment; produces stronger and more durable concrete products. Weaknesses: Currently more applicable to precast concrete applications than ready-mix; requires a controlled environment for CO2 curing; market adoption faces challenges from the conservative construction industry.

Huaxin Cement Co., Ltd.

Technical Solution: Huaxin Cement has developed a comprehensive carbon-negative concrete technology platform that integrates multiple approaches to carbon reduction throughout the concrete lifecycle. Their system combines alternative raw materials, energy efficiency improvements, and carbon capture utilization and storage (CCUS) technologies. At the heart of their innovation is a calcium looping carbon capture system integrated directly into their cement kilns, which can capture up to 85% of process emissions. The captured CO2 is then utilized in their carbonation curing technology, where specially formulated concrete mixes undergo accelerated carbonation, permanently sequestering CO2 as stable calcium carbonates within the concrete matrix. Huaxin has also pioneered the use of industrial byproducts such as steel slag, fly ash, and carbide slag as supplementary cementitious materials, reducing the clinker factor to below 50% in some applications. Their most advanced product line incorporates novel magnesium-based binders that actively absorb CO2 throughout the concrete's service life, potentially sequestering up to 100-150 kg of CO2 per cubic meter of concrete over a 50-year period.

Strengths: Integrated approach addressing emissions across the entire value chain; significant production scale allows for meaningful carbon impact; strong R&D capabilities with over 200 patents in low-carbon cement technologies. Weaknesses: Capital-intensive CCUS implementation; regional limitations on alternative material availability; varying regulatory environments across their operational territories affecting carbon credit mechanisms.

Key Patents and Innovations in CO2 Sequestration for Concrete

Multi-fold carbon-negative organic alternative cement

PatentWO2025024556A1

Innovation

- A method of forming alternative cement by mixing a mineral base with an acidic component, such as oxalic acid or its salts, to create a carbon-negative organic cement. The acidic component is derived from sources like CO2, biomass, or organic acids, and the mineral base includes non-carbonate rocks, minerals, or industrial wastes.

Carbon negative concrete production through the use of sustainable materials

PatentInactiveUS20230002276A1

Innovation

- Incorporating biochar, a high-carbon residue produced through low-oxygen pyrolysis, into concrete mixtures to sequester carbon and reduce emissions, while optimizing pyrolysis processes to power plants using syngas for self-sustainability and carbon neutrality.

Life Cycle Assessment of Carbon-negative Concrete Solutions

Life Cycle Assessment (LCA) of carbon-negative concrete solutions provides a comprehensive framework for evaluating the environmental impacts throughout the entire lifecycle of these innovative materials. The assessment typically begins with raw material extraction and continues through manufacturing, transportation, use phase, and end-of-life disposal or recycling. For carbon-negative concrete, this analysis reveals significant environmental advantages compared to traditional Portland cement concrete.

The production phase analysis demonstrates that carbon-negative concrete solutions can sequester more CO2 than they emit during manufacturing. This is achieved through innovative binding materials that actively absorb carbon dioxide during the curing process. Companies like Carbicrete and CarbonCure have developed technologies that inject captured CO2 into concrete mixtures, where it mineralizes and becomes permanently embedded in the material structure.

Transportation impacts are generally reduced with carbon-negative concrete solutions due to the potential for localized production and the use of waste materials that would otherwise require transportation to disposal sites. The assessment shows that utilizing locally sourced supplementary cementitious materials (SCMs) like fly ash, slag, and silica fume significantly reduces the carbon footprint associated with material transportation.

During the use phase, carbon-negative concrete continues to absorb CO2 from the atmosphere through natural carbonation processes. This ongoing carbon sequestration effect enhances the material's environmental benefits over its service life, which typically spans several decades. The durability characteristics of these innovative concretes often match or exceed those of conventional concrete, reducing the need for replacement and associated environmental impacts.

End-of-life considerations reveal additional sustainability advantages. When carbon-negative concrete structures are eventually demolished, the crushed material can continue to absorb CO2 due to increased surface area exposure. Furthermore, these materials can be recycled as aggregate in new concrete applications, creating a circular economy approach that further reduces environmental impact.

Comparative LCA studies indicate that carbon-negative concrete solutions can achieve net carbon reductions of 100-150 kg CO2e per cubic meter of concrete, whereas traditional concrete typically emits 300-400 kg CO2e per cubic meter. This represents a potential swing of up to 550 kg CO2e per cubic meter, highlighting the transformative potential of these materials in addressing climate change challenges in the construction sector.

The production phase analysis demonstrates that carbon-negative concrete solutions can sequester more CO2 than they emit during manufacturing. This is achieved through innovative binding materials that actively absorb carbon dioxide during the curing process. Companies like Carbicrete and CarbonCure have developed technologies that inject captured CO2 into concrete mixtures, where it mineralizes and becomes permanently embedded in the material structure.

Transportation impacts are generally reduced with carbon-negative concrete solutions due to the potential for localized production and the use of waste materials that would otherwise require transportation to disposal sites. The assessment shows that utilizing locally sourced supplementary cementitious materials (SCMs) like fly ash, slag, and silica fume significantly reduces the carbon footprint associated with material transportation.

During the use phase, carbon-negative concrete continues to absorb CO2 from the atmosphere through natural carbonation processes. This ongoing carbon sequestration effect enhances the material's environmental benefits over its service life, which typically spans several decades. The durability characteristics of these innovative concretes often match or exceed those of conventional concrete, reducing the need for replacement and associated environmental impacts.

End-of-life considerations reveal additional sustainability advantages. When carbon-negative concrete structures are eventually demolished, the crushed material can continue to absorb CO2 due to increased surface area exposure. Furthermore, these materials can be recycled as aggregate in new concrete applications, creating a circular economy approach that further reduces environmental impact.

Comparative LCA studies indicate that carbon-negative concrete solutions can achieve net carbon reductions of 100-150 kg CO2e per cubic meter of concrete, whereas traditional concrete typically emits 300-400 kg CO2e per cubic meter. This represents a potential swing of up to 550 kg CO2e per cubic meter, highlighting the transformative potential of these materials in addressing climate change challenges in the construction sector.

Policy Frameworks Supporting Low-Carbon Building Materials

The global policy landscape for low-carbon building materials has evolved significantly in recent years, with governments increasingly recognizing the crucial role of construction materials in achieving climate goals. Carbon-negative concrete represents a revolutionary advancement that aligns perfectly with these emerging policy frameworks. Currently, over 30 countries have implemented specific regulations targeting embodied carbon in construction materials, creating a supportive environment for carbon-negative concrete adoption.

The European Union leads with its ambitious Construction Products Regulation (CPR) and the European Green Deal, which mandates lifecycle assessments for building materials and sets progressive carbon reduction targets. The EU Taxonomy for Sustainable Activities specifically recognizes carbon-negative materials as sustainable investments, providing financial incentives for their development and implementation.

In North America, both Canada and the United States have developed green procurement policies that prioritize low-carbon building materials for public infrastructure projects. The Buy Clean California Act represents a pioneering example, requiring Environmental Product Declarations (EPDs) for construction materials used in state-funded projects and establishing maximum acceptable global warming potential values.

Asia-Pacific nations have similarly advanced their regulatory frameworks, with Singapore's Green Mark certification system and Japan's Top Runner Program offering preferential treatment for carbon-negative building materials. China's recent inclusion of cement in its national emissions trading scheme creates significant market incentives for carbon-negative alternatives.

Financial mechanisms supporting these policy frameworks include carbon pricing systems, green bonds, and tax incentives specifically designed for sustainable construction materials. The International Finance Corporation's green building certification programs have incorporated criteria for embodied carbon, further incentivizing carbon-negative concrete adoption in developing markets.

Standardization efforts have accelerated globally, with organizations like ISO, ASTM International, and CEN developing specific standards for measuring and verifying carbon negativity in concrete products. These standards provide the technical foundation necessary for policy implementation and market acceptance.

Local building codes represent another critical policy lever, with cities like Vancouver, Oslo, and Copenhagen implementing embodied carbon limits in their construction regulations. These municipal initiatives often serve as testing grounds for policies later adopted at national levels.

The integration of carbon-negative concrete into national climate action plans under the Paris Agreement framework demonstrates the growing recognition of construction materials as a key sector for emissions reduction. Several countries have explicitly included concrete decarbonization in their Nationally Determined Contributions (NDCs), creating long-term policy stability for carbon-negative innovations.

The European Union leads with its ambitious Construction Products Regulation (CPR) and the European Green Deal, which mandates lifecycle assessments for building materials and sets progressive carbon reduction targets. The EU Taxonomy for Sustainable Activities specifically recognizes carbon-negative materials as sustainable investments, providing financial incentives for their development and implementation.

In North America, both Canada and the United States have developed green procurement policies that prioritize low-carbon building materials for public infrastructure projects. The Buy Clean California Act represents a pioneering example, requiring Environmental Product Declarations (EPDs) for construction materials used in state-funded projects and establishing maximum acceptable global warming potential values.

Asia-Pacific nations have similarly advanced their regulatory frameworks, with Singapore's Green Mark certification system and Japan's Top Runner Program offering preferential treatment for carbon-negative building materials. China's recent inclusion of cement in its national emissions trading scheme creates significant market incentives for carbon-negative alternatives.

Financial mechanisms supporting these policy frameworks include carbon pricing systems, green bonds, and tax incentives specifically designed for sustainable construction materials. The International Finance Corporation's green building certification programs have incorporated criteria for embodied carbon, further incentivizing carbon-negative concrete adoption in developing markets.

Standardization efforts have accelerated globally, with organizations like ISO, ASTM International, and CEN developing specific standards for measuring and verifying carbon negativity in concrete products. These standards provide the technical foundation necessary for policy implementation and market acceptance.

Local building codes represent another critical policy lever, with cities like Vancouver, Oslo, and Copenhagen implementing embodied carbon limits in their construction regulations. These municipal initiatives often serve as testing grounds for policies later adopted at national levels.

The integration of carbon-negative concrete into national climate action plans under the Paris Agreement framework demonstrates the growing recognition of construction materials as a key sector for emissions reduction. Several countries have explicitly included concrete decarbonization in their Nationally Determined Contributions (NDCs), creating long-term policy stability for carbon-negative innovations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!