Research on Carbon-negative Concrete Catalytic Efficiency

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Technology Background and Objectives

Concrete production is one of the largest contributors to global carbon emissions, accounting for approximately 8% of worldwide CO2 emissions. The concept of carbon-negative concrete emerged in the early 2000s as researchers began exploring ways to not only reduce the carbon footprint of concrete but to transform it into a carbon sink. This revolutionary approach aims to sequester more carbon dioxide than is emitted during the production process, effectively making concrete a tool for climate change mitigation rather than a contributor to the problem.

The evolution of carbon-negative concrete technology has been marked by significant breakthroughs in material science and chemical engineering. Traditional Portland cement, the binding agent in conventional concrete, requires high-temperature kilns that release substantial amounts of CO2. In contrast, carbon-negative alternatives utilize alternative binders and incorporate carbon capture mechanisms directly into the material composition. The catalytic efficiency of these processes has become a central focus of research, as it determines the rate and extent of carbon sequestration possible.

Current technological objectives in this field center on enhancing the catalytic efficiency of carbon sequestration processes within concrete. Researchers aim to develop catalysts that can accelerate the carbonation reaction, allowing concrete to absorb CO2 more rapidly and in greater quantities. This includes investigating novel mineral additives, engineered microstructures, and innovative curing techniques that optimize the concrete's ability to act as a carbon sink.

The timeline of development shows an acceleration of innovation in recent years. Early carbon-negative concrete formulations achieved modest carbon sequestration rates, but recent advancements have demonstrated potential for capturing up to 100-300 kg of CO2 per cubic meter of concrete. The goal now is to further increase this capacity while maintaining or improving the structural properties of the material.

Technical objectives for the next decade include developing catalysts that can function effectively under ambient conditions, reducing energy requirements for the carbonation process, and creating scalable solutions that can be implemented in standard concrete production facilities worldwide. Additionally, researchers are working to extend the carbon sequestration period throughout the concrete's lifecycle, potentially transforming urban infrastructure into long-term carbon repositories.

The ultimate aim of this research is to establish carbon-negative concrete as a mainstream construction material that contributes significantly to global carbon reduction goals while meeting or exceeding the performance standards of conventional concrete. This would represent a paradigm shift in how we view construction materials, transforming them from environmental liabilities into assets in the fight against climate change.

The evolution of carbon-negative concrete technology has been marked by significant breakthroughs in material science and chemical engineering. Traditional Portland cement, the binding agent in conventional concrete, requires high-temperature kilns that release substantial amounts of CO2. In contrast, carbon-negative alternatives utilize alternative binders and incorporate carbon capture mechanisms directly into the material composition. The catalytic efficiency of these processes has become a central focus of research, as it determines the rate and extent of carbon sequestration possible.

Current technological objectives in this field center on enhancing the catalytic efficiency of carbon sequestration processes within concrete. Researchers aim to develop catalysts that can accelerate the carbonation reaction, allowing concrete to absorb CO2 more rapidly and in greater quantities. This includes investigating novel mineral additives, engineered microstructures, and innovative curing techniques that optimize the concrete's ability to act as a carbon sink.

The timeline of development shows an acceleration of innovation in recent years. Early carbon-negative concrete formulations achieved modest carbon sequestration rates, but recent advancements have demonstrated potential for capturing up to 100-300 kg of CO2 per cubic meter of concrete. The goal now is to further increase this capacity while maintaining or improving the structural properties of the material.

Technical objectives for the next decade include developing catalysts that can function effectively under ambient conditions, reducing energy requirements for the carbonation process, and creating scalable solutions that can be implemented in standard concrete production facilities worldwide. Additionally, researchers are working to extend the carbon sequestration period throughout the concrete's lifecycle, potentially transforming urban infrastructure into long-term carbon repositories.

The ultimate aim of this research is to establish carbon-negative concrete as a mainstream construction material that contributes significantly to global carbon reduction goals while meeting or exceeding the performance standards of conventional concrete. This would represent a paradigm shift in how we view construction materials, transforming them from environmental liabilities into assets in the fight against climate change.

Market Analysis for Carbon-negative Construction Materials

The global market for carbon-negative construction materials is experiencing unprecedented growth, driven by increasing environmental regulations and a growing commitment to sustainability across the construction industry. Current market valuations indicate that carbon-negative concrete solutions represent a rapidly expanding segment, with projections suggesting the market could reach $10 billion by 2030, growing at a compound annual growth rate of approximately 20%.

Demand patterns show significant regional variations, with Europe leading adoption rates due to stringent carbon regulations and ambitious climate targets. North America follows closely, particularly in states with progressive climate policies like California and New York. The Asia-Pacific region, despite slower initial uptake, is showing accelerating interest, especially in China and Japan where government initiatives are actively promoting green building materials.

Market research indicates that commercial building projects currently constitute the largest application segment for carbon-negative concrete, accounting for approximately 45% of market demand. Infrastructure projects represent the second-largest segment at 30%, with residential construction comprising about 25%. However, the residential segment is demonstrating the fastest growth rate as sustainability becomes increasingly important to homebuyers.

Key market drivers include tightening building codes and regulations that mandate reduced carbon footprints, growing corporate commitments to net-zero construction, and increasing carbon pricing mechanisms that make traditional concrete less economically viable. Additionally, government incentives and subsidies for green building materials are creating favorable market conditions in many regions.

Consumer sentiment analysis reveals that while price premium remains a barrier to wider adoption, the willingness to pay for sustainable construction materials is increasing. Surveys indicate that 68% of commercial developers now consider carbon footprint in material selection decisions, up from just 35% five years ago. This shift in buyer behavior is creating significant market pull for innovative solutions.

Market challenges include supply chain constraints for key ingredients in carbon-negative formulations, scaling production to meet growing demand, and the need for standardized certification systems to verify carbon-negative claims. Price competitiveness remains an issue, with carbon-negative concrete typically commanding a 15-30% premium over traditional products, though this gap is narrowing as production scales and technologies mature.

Future market growth will likely be influenced by policy developments, technological advancements in catalytic efficiency, and the evolution of carbon markets. As carbon pricing becomes more widespread, the economic case for carbon-negative materials strengthens considerably, potentially accelerating market adoption beyond current projections.

Demand patterns show significant regional variations, with Europe leading adoption rates due to stringent carbon regulations and ambitious climate targets. North America follows closely, particularly in states with progressive climate policies like California and New York. The Asia-Pacific region, despite slower initial uptake, is showing accelerating interest, especially in China and Japan where government initiatives are actively promoting green building materials.

Market research indicates that commercial building projects currently constitute the largest application segment for carbon-negative concrete, accounting for approximately 45% of market demand. Infrastructure projects represent the second-largest segment at 30%, with residential construction comprising about 25%. However, the residential segment is demonstrating the fastest growth rate as sustainability becomes increasingly important to homebuyers.

Key market drivers include tightening building codes and regulations that mandate reduced carbon footprints, growing corporate commitments to net-zero construction, and increasing carbon pricing mechanisms that make traditional concrete less economically viable. Additionally, government incentives and subsidies for green building materials are creating favorable market conditions in many regions.

Consumer sentiment analysis reveals that while price premium remains a barrier to wider adoption, the willingness to pay for sustainable construction materials is increasing. Surveys indicate that 68% of commercial developers now consider carbon footprint in material selection decisions, up from just 35% five years ago. This shift in buyer behavior is creating significant market pull for innovative solutions.

Market challenges include supply chain constraints for key ingredients in carbon-negative formulations, scaling production to meet growing demand, and the need for standardized certification systems to verify carbon-negative claims. Price competitiveness remains an issue, with carbon-negative concrete typically commanding a 15-30% premium over traditional products, though this gap is narrowing as production scales and technologies mature.

Future market growth will likely be influenced by policy developments, technological advancements in catalytic efficiency, and the evolution of carbon markets. As carbon pricing becomes more widespread, the economic case for carbon-negative materials strengthens considerably, potentially accelerating market adoption beyond current projections.

Current Catalytic Technologies and Challenges

Current catalytic technologies for carbon-negative concrete face significant challenges despite promising advancements. The dominant approach utilizes mineral carbonation processes where CO2 reacts with calcium or magnesium-rich materials to form stable carbonate compounds. Leading commercial technologies include CarbonCure's injection system that introduces CO2 during concrete mixing, Solidia's low-lime cement alternative that absorbs CO2 during curing, and Carbicrete's process that replaces cement entirely with steel slag while using CO2 as a curing agent.

The catalytic efficiency of these processes remains a critical bottleneck. Current catalysts typically achieve only 30-45% conversion rates under industrial conditions, significantly below theoretical maximums. Metal-organic frameworks (MOFs) and zeolite-based catalysts show promise but suffer from rapid deactivation in the alkaline environment of concrete mixtures, with most losing over 50% efficiency after just 5-10 cycles.

Temperature and pressure dependencies present another major challenge. Optimal carbonation reactions require precise conditions (typically 30-60°C and 5-15 bar pressure), making integration into existing concrete production facilities technically complex and energy-intensive. The energy requirements for maintaining these conditions often offset a portion of the carbon benefits gained.

Scalability issues persist across the industry. Laboratory-scale catalysts that demonstrate high efficiency frequently fail to maintain performance when scaled to industrial production volumes. The heterogeneity of concrete mixtures across different applications further complicates the development of universally applicable catalytic solutions.

Economic viability remains questionable without significant policy support. Current carbon-negative concrete technologies add approximately 15-25% to production costs compared to conventional concrete. The catalysts themselves represent 30-40% of this additional cost, with precious metal catalysts being particularly expensive and vulnerable to market price fluctuations.

Water consumption presents an overlooked challenge, as many carbonation processes require substantial water inputs. This creates a sustainability trade-off in water-stressed regions where concrete demand is high. Advanced catalytic systems that can operate efficiently in low-water environments remain underdeveloped.

Durability concerns also persist regarding how carbonated concrete performs over decades-long timeframes. Accelerated aging tests suggest potential microstructural changes that could affect long-term strength and durability, though data from real-world implementations remains limited as most technologies have been deployed for less than a decade.

The catalytic efficiency of these processes remains a critical bottleneck. Current catalysts typically achieve only 30-45% conversion rates under industrial conditions, significantly below theoretical maximums. Metal-organic frameworks (MOFs) and zeolite-based catalysts show promise but suffer from rapid deactivation in the alkaline environment of concrete mixtures, with most losing over 50% efficiency after just 5-10 cycles.

Temperature and pressure dependencies present another major challenge. Optimal carbonation reactions require precise conditions (typically 30-60°C and 5-15 bar pressure), making integration into existing concrete production facilities technically complex and energy-intensive. The energy requirements for maintaining these conditions often offset a portion of the carbon benefits gained.

Scalability issues persist across the industry. Laboratory-scale catalysts that demonstrate high efficiency frequently fail to maintain performance when scaled to industrial production volumes. The heterogeneity of concrete mixtures across different applications further complicates the development of universally applicable catalytic solutions.

Economic viability remains questionable without significant policy support. Current carbon-negative concrete technologies add approximately 15-25% to production costs compared to conventional concrete. The catalysts themselves represent 30-40% of this additional cost, with precious metal catalysts being particularly expensive and vulnerable to market price fluctuations.

Water consumption presents an overlooked challenge, as many carbonation processes require substantial water inputs. This creates a sustainability trade-off in water-stressed regions where concrete demand is high. Advanced catalytic systems that can operate efficiently in low-water environments remain underdeveloped.

Durability concerns also persist regarding how carbonated concrete performs over decades-long timeframes. Accelerated aging tests suggest potential microstructural changes that could affect long-term strength and durability, though data from real-world implementations remains limited as most technologies have been deployed for less than a decade.

Current Catalytic Efficiency Solutions

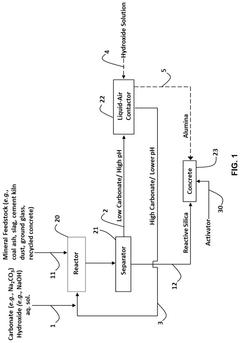

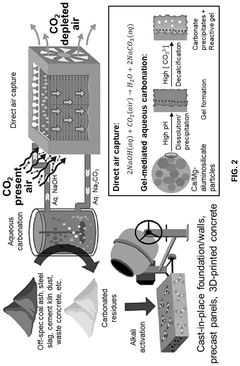

01 CO2 capture and sequestration in concrete

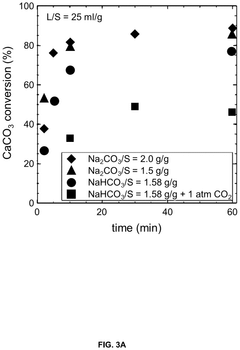

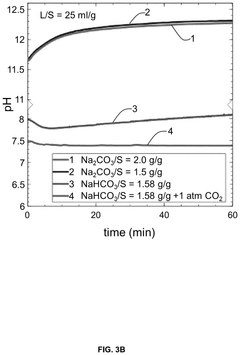

Carbon-negative concrete technologies that actively capture and sequester CO2 during the manufacturing process. These methods involve incorporating materials that can absorb CO2 from the atmosphere and lock it into the concrete structure, effectively reducing the carbon footprint of construction. Catalysts are used to enhance the carbonation reaction, improving the efficiency of CO2 absorption and conversion into stable carbonate compounds within the concrete matrix.- CO2 capture and sequestration in concrete: Technologies that enable concrete to absorb and permanently store carbon dioxide during the curing process, transforming it from a carbon source to a carbon sink. These methods involve specialized catalysts that accelerate the carbonation reaction, allowing CO2 to be chemically bound within the concrete matrix. This approach not only reduces the carbon footprint of concrete production but can potentially make concrete carbon-negative by sequestering more CO2 than is emitted during manufacturing.

- Novel catalytic materials for enhanced CO2 absorption: Development of innovative catalytic materials that significantly improve the efficiency of carbon dioxide absorption in concrete. These catalysts facilitate faster and more complete carbonation reactions, enabling concrete to absorb larger quantities of CO2. The catalysts work by lowering the activation energy required for CO2 to react with calcium-containing compounds in the concrete, resulting in accelerated carbon sequestration and improved mechanical properties of the final product.

- Alternative cementitious materials with reduced carbon footprint: Utilization of alternative materials to traditional Portland cement that inherently have lower carbon emissions during production. These include supplementary cementitious materials like fly ash, slag, and natural pozzolans, as well as novel binders that require less energy to produce. When combined with catalysts that enhance CO2 absorption, these materials can create concrete formulations that are carbon-negative throughout their lifecycle, offering a sustainable alternative to conventional concrete.

- Process optimization for carbon-negative concrete production: Methodologies and systems for optimizing the production process of carbon-negative concrete, focusing on maximizing catalytic efficiency. These approaches involve precise control of curing conditions, including temperature, pressure, and CO2 concentration, to enhance the carbonation reaction. Advanced monitoring systems track the progress of CO2 sequestration in real-time, allowing for adjustments that maximize carbon capture while maintaining or improving the concrete's structural properties.

- Integration of renewable energy in carbon-negative concrete manufacturing: Systems that incorporate renewable energy sources into the production of carbon-negative concrete, further reducing the overall carbon footprint. These innovations include solar-powered curing chambers, wind-powered grinding operations, and other clean energy applications that minimize the emissions associated with concrete manufacturing. When combined with catalytic CO2 sequestration technologies, these approaches can significantly enhance the net carbon-negative potential of concrete products.

02 Alternative cementitious materials for carbon reduction

The use of alternative cementitious materials such as geopolymers, alkali-activated materials, and supplementary cementitious materials (SCMs) to replace traditional Portland cement. These materials require less energy to produce and generate fewer CO2 emissions during manufacturing. Catalysts are employed to accelerate the curing process and enhance the mechanical properties of these alternative binders, improving their viability as carbon-negative concrete solutions.Expand Specific Solutions03 Mineral carbonation catalysts for enhanced CO2 uptake

Specialized catalysts that enhance the mineral carbonation process in concrete, allowing for greater CO2 uptake and improved reaction kinetics. These catalysts facilitate the conversion of calcium and magnesium silicates into carbonates, effectively sequestering CO2 in a stable mineral form. The catalytic efficiency is optimized through various formulations and processing techniques to maximize carbon sequestration while maintaining or improving the concrete's structural properties.Expand Specific Solutions04 Accelerated carbonation curing technologies

Advanced curing technologies that utilize controlled CO2 exposure and catalysts to accelerate the carbonation process in concrete. These methods not only sequester carbon but also improve concrete strength development and durability. The catalytic systems are designed to optimize the reaction between CO2 and calcium hydroxide in the concrete, resulting in rapid formation of calcium carbonate while reducing curing time and energy requirements.Expand Specific Solutions05 Industrial waste incorporation with catalytic activation

Methods for incorporating industrial waste materials such as fly ash, slag, and silica fume into concrete formulations with catalytic activation to enhance carbon sequestration. These waste materials, when properly activated with catalysts, can react with CO2 to form stable carbonate compounds. This approach not only reduces the carbon footprint of concrete but also provides a sustainable solution for industrial waste management while improving the concrete's performance characteristics.Expand Specific Solutions

Leading Companies and Research Institutions

The carbon-negative concrete catalytic efficiency market is in an early growth phase, characterized by increasing research activity and emerging commercial applications. The global market size is expanding rapidly, driven by sustainability mandates and construction industry decarbonization efforts. Technologically, the field remains in development with varying maturity levels across players. Academic institutions like Central South University, Chongqing University, and Carnegie Mellon lead fundamental research, while specialized companies such as Carbon Limit Co. and Carbon Upcycling Technologies are commercializing innovative solutions. Established industry players including Huaxin Cement, China Construction Commercial Concrete, and Sumitomo Osaka Cement are integrating these technologies into existing production systems, creating a competitive landscape that balances academic innovation with industrial implementation.

Nisshinbo Holdings, Inc.

Technical Solution: Nisshinbo Holdings has developed an innovative carbon-negative concrete catalyst system based on their expertise in materials science and environmental technologies. Their approach utilizes a proprietary carbon-fixing catalyst composed of modified calcium silicate hydrates enhanced with transition metal dopants that significantly increase CO2 absorption rates during concrete curing. The company's research shows their catalyst can increase carbonation efficiency by up to 400% compared to untreated concrete while maintaining structural integrity. Nisshinbo's process incorporates industrial byproducts like fly ash and silica fume as supplementary cementitious materials, reducing the carbon footprint of the initial concrete mix. Their technology includes a two-stage carbonation process: an accelerated initial phase during manufacturing and a sustained absorption phase throughout the concrete's lifecycle. This approach enables their concrete products to sequester approximately 100-150kg of CO2 per cubic meter over time, effectively offsetting the emissions from production.

Strengths: High carbonation efficiency through specialized catalyst formulation; utilizes industrial waste streams as raw materials; provides both immediate and long-term carbon sequestration. Weaknesses: Catalyst production requires specialized manufacturing processes; performance may vary under different environmental conditions; higher initial cost compared to conventional concrete.

Carbon Limit Co.

Technical Solution: Carbon Limit has pioneered a carbon-negative concrete solution through their CarbonBuilt technology, which directly incorporates CO2 from industrial and direct air capture sources into concrete formulations. Their process replaces a significant portion of traditional Portland cement with a proprietary blend of low-carbon supplementary cementitious materials (SCMs) and CO2-reactive additives. During concrete curing, CO2 is injected and permanently mineralized within the concrete matrix, forming stable calcium carbonates. This approach reduces cement content by up to 50% while sequestering approximately 30kg of CO2 per cubic meter of concrete. The technology is compatible with existing concrete manufacturing equipment, requiring minimal capital investment for implementation. Carbon Limit's process can utilize dilute CO2 streams (as low as 5% concentration), making it versatile for various emission sources without requiring energy-intensive purification.

Strengths: Direct CO2 utilization without extensive purification; compatible with existing manufacturing infrastructure; significant reduction in cement content. Weaknesses: Performance characteristics may vary with different CO2 sources; requires careful quality control during manufacturing; long-term durability data still being accumulated compared to traditional concrete.

Key Patents and Innovations in Catalytic Processes

Cementitious materials and methods of making and using same

PatentPendingUS20250042811A1

Innovation

- A carbon mineralization-based direct-air capture process is used to produce carbon-negative cementitious materials by capturing CO2 from the air through an aqueous carbonation cycle, enhancing the pozzolanic reactivity of industrial mineral wastes, and incorporating the captured CO2 as solid carbonate in the concrete.

Carbon negative concrete production through the use of sustainable materials

PatentInactiveUS20230002276A1

Innovation

- Incorporating biochar, a high-carbon residue produced through low-oxygen pyrolysis, into concrete mixtures to sequester carbon and reduce emissions, while optimizing pyrolysis processes to power plants using syngas for self-sustainability and carbon neutrality.

Environmental Impact Assessment

The environmental impact assessment of carbon-negative concrete catalytic efficiency reveals significant potential for reducing the construction industry's carbon footprint. Current concrete production accounts for approximately 8% of global CO2 emissions, making it one of the most carbon-intensive industrial processes. Carbon-negative concrete technologies utilizing advanced catalysts demonstrate the capacity to sequester between 100-300 kg of CO2 per cubic meter of concrete, effectively transforming a major emission source into a carbon sink.

Life cycle assessments indicate that catalytic processes in carbon-negative concrete can reduce the overall environmental impact by 30-45% compared to traditional Portland cement concrete. This reduction extends beyond carbon emissions to include decreased energy consumption, water usage, and particulate matter emissions. The catalytic efficiency improvements have shown particular promise in reducing the energy-intensive calcination process, which traditionally accounts for about 60% of concrete production emissions.

Water consumption metrics demonstrate that optimized catalytic processes can reduce water usage by up to 25% compared to conventional concrete production methods. This represents a significant environmental benefit in regions facing water scarcity challenges. Additionally, the reduced thermal energy requirements translate to approximately 1.2-1.8 GJ energy savings per ton of produced concrete.

Air quality improvements associated with carbon-negative concrete production are substantial, with particulate matter emissions reduced by 35-50% when utilizing high-efficiency catalytic systems. The reduction in sulfur dioxide and nitrogen oxide emissions further contributes to decreased acid rain potential and improved regional air quality around production facilities.

Land use impact assessments reveal that carbon-negative concrete production facilities utilizing advanced catalytic technologies require approximately 15-20% less land area than traditional concrete plants with equivalent output capacity. This spatial efficiency results from more compact reaction vessels and reduced raw material storage requirements.

Resource depletion indicators show that catalytic carbon-negative concrete processes can reduce limestone consumption by up to 40%, significantly extending the lifespan of natural limestone reserves. Furthermore, certain catalytic formulations enable the incorporation of industrial byproducts and waste materials, diverting up to 25% of material from landfills and further enhancing the sustainability profile.

Biodiversity impact studies indicate reduced ecosystem disruption from mining operations associated with carbon-negative concrete production, particularly when catalytic efficiency enables greater use of alternative materials and reduces virgin resource extraction requirements. This translates to approximately 0.3-0.5 hectares of habitat preserved per 10,000 tons of concrete produced.

Life cycle assessments indicate that catalytic processes in carbon-negative concrete can reduce the overall environmental impact by 30-45% compared to traditional Portland cement concrete. This reduction extends beyond carbon emissions to include decreased energy consumption, water usage, and particulate matter emissions. The catalytic efficiency improvements have shown particular promise in reducing the energy-intensive calcination process, which traditionally accounts for about 60% of concrete production emissions.

Water consumption metrics demonstrate that optimized catalytic processes can reduce water usage by up to 25% compared to conventional concrete production methods. This represents a significant environmental benefit in regions facing water scarcity challenges. Additionally, the reduced thermal energy requirements translate to approximately 1.2-1.8 GJ energy savings per ton of produced concrete.

Air quality improvements associated with carbon-negative concrete production are substantial, with particulate matter emissions reduced by 35-50% when utilizing high-efficiency catalytic systems. The reduction in sulfur dioxide and nitrogen oxide emissions further contributes to decreased acid rain potential and improved regional air quality around production facilities.

Land use impact assessments reveal that carbon-negative concrete production facilities utilizing advanced catalytic technologies require approximately 15-20% less land area than traditional concrete plants with equivalent output capacity. This spatial efficiency results from more compact reaction vessels and reduced raw material storage requirements.

Resource depletion indicators show that catalytic carbon-negative concrete processes can reduce limestone consumption by up to 40%, significantly extending the lifespan of natural limestone reserves. Furthermore, certain catalytic formulations enable the incorporation of industrial byproducts and waste materials, diverting up to 25% of material from landfills and further enhancing the sustainability profile.

Biodiversity impact studies indicate reduced ecosystem disruption from mining operations associated with carbon-negative concrete production, particularly when catalytic efficiency enables greater use of alternative materials and reduces virgin resource extraction requirements. This translates to approximately 0.3-0.5 hectares of habitat preserved per 10,000 tons of concrete produced.

Regulatory Framework and Carbon Credit Opportunities

The global regulatory landscape for carbon-negative concrete technologies is rapidly evolving, creating both compliance requirements and economic opportunities. The European Union's Carbon Border Adjustment Mechanism (CBAM) and the inclusion of cement in the EU Emissions Trading System (ETS) have established precedents for carbon pricing in construction materials. These frameworks increasingly recognize carbon-negative solutions as valuable contributors to emissions reduction targets, potentially offering regulatory advantages to early adopters of catalytic efficiency improvements in concrete production.

In the United States, recent infrastructure legislation and the Inflation Reduction Act have allocated significant funding for low-carbon building materials, with specific provisions that could benefit carbon-negative concrete technologies. The Department of Energy's Carbon Negative Shot initiative explicitly targets technologies capable of removing CO₂ from the atmosphere at scale, creating a supportive policy environment for catalytic innovations in concrete.

Carbon credit markets represent a substantial economic opportunity for developers of carbon-negative concrete technologies. The voluntary carbon market exceeded $2 billion in 2022, with projections suggesting growth to $10-40 billion by 2030. Enhanced catalytic efficiency in carbon-negative concrete could generate high-quality carbon removal credits, particularly as markets increasingly favor durable carbon sequestration solutions with verifiable permanence.

Methodologies for quantifying and verifying carbon removal through concrete are maturing, with organizations like Verra and Gold Standard developing protocols specifically for carbon mineralization and concrete-based carbon sequestration. These frameworks typically require demonstration of additionality, permanence, and accurate measurement—all areas where improved catalytic efficiency can provide competitive advantages by enhancing the rate and completeness of carbon capture.

Corporate net-zero commitments are driving demand for high-quality carbon removal credits, with technology companies like Microsoft, Stripe, and Shopify making advance purchases of carbon removal at premium prices. This creates potential revenue streams for carbon-negative concrete technologies beyond traditional material sales, effectively monetizing the climate benefits of catalytic innovations.

Regulatory harmonization remains challenging, with varying standards across jurisdictions creating compliance complexity for global deployment. However, international initiatives like the Industrial Deep Decarbonization Initiative (IDDI) are working toward standardized approaches to embodied carbon assessment in building materials, potentially streamlining market access for technologies demonstrating superior catalytic efficiency in carbon sequestration.

In the United States, recent infrastructure legislation and the Inflation Reduction Act have allocated significant funding for low-carbon building materials, with specific provisions that could benefit carbon-negative concrete technologies. The Department of Energy's Carbon Negative Shot initiative explicitly targets technologies capable of removing CO₂ from the atmosphere at scale, creating a supportive policy environment for catalytic innovations in concrete.

Carbon credit markets represent a substantial economic opportunity for developers of carbon-negative concrete technologies. The voluntary carbon market exceeded $2 billion in 2022, with projections suggesting growth to $10-40 billion by 2030. Enhanced catalytic efficiency in carbon-negative concrete could generate high-quality carbon removal credits, particularly as markets increasingly favor durable carbon sequestration solutions with verifiable permanence.

Methodologies for quantifying and verifying carbon removal through concrete are maturing, with organizations like Verra and Gold Standard developing protocols specifically for carbon mineralization and concrete-based carbon sequestration. These frameworks typically require demonstration of additionality, permanence, and accurate measurement—all areas where improved catalytic efficiency can provide competitive advantages by enhancing the rate and completeness of carbon capture.

Corporate net-zero commitments are driving demand for high-quality carbon removal credits, with technology companies like Microsoft, Stripe, and Shopify making advance purchases of carbon removal at premium prices. This creates potential revenue streams for carbon-negative concrete technologies beyond traditional material sales, effectively monetizing the climate benefits of catalytic innovations.

Regulatory harmonization remains challenging, with varying standards across jurisdictions creating compliance complexity for global deployment. However, international initiatives like the Industrial Deep Decarbonization Initiative (IDDI) are working toward standardized approaches to embodied carbon assessment in building materials, potentially streamlining market access for technologies demonstrating superior catalytic efficiency in carbon sequestration.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!