Carbon-negative Concrete’s Impact on Urban Planning Standards

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Evolution and Objectives

Concrete, a fundamental building material in modern civilization, has undergone significant transformation over the past century. Traditional concrete production accounts for approximately 8% of global CO2 emissions, primarily due to the energy-intensive process of cement manufacturing. The evolution of carbon-negative concrete represents a paradigm shift in construction materials science, moving from environmentally harmful practices toward sustainable and regenerative solutions.

The journey toward carbon-negative concrete began in the early 2000s with the introduction of supplementary cementitious materials (SCMs) like fly ash and slag to reduce cement content. By 2010, researchers had developed carbon-neutral concrete formulations that balanced emissions during production with absorption during the concrete's lifetime. The breakthrough toward truly carbon-negative concrete emerged around 2015, when companies like CarbonCure and Solidia Technologies pioneered methods to inject and sequester CO2 within concrete during curing.

Recent technological advancements have accelerated this evolution, with innovations in alternative binding materials such as geopolymers and magnesium-based cements that naturally absorb CO2 during their lifecycle. The integration of carbon capture technologies with concrete production has further enhanced the carbon-sequestering capabilities of these next-generation materials.

The primary objective of carbon-negative concrete development is to transform the construction industry from a major carbon emitter to a potential carbon sink. This aligns with global climate goals established in the Paris Agreement and subsequent international frameworks. Specifically, the technology aims to reduce embodied carbon in buildings and infrastructure while maintaining or improving structural performance characteristics.

Secondary objectives include developing scalable production methods that can be implemented across diverse geographic and economic contexts, ensuring cost competitiveness with traditional concrete, and establishing standardized measurement protocols for carbon sequestration claims. The technology also seeks to address durability concerns, as carbon-negative concrete must maintain structural integrity over decades-long timeframes to truly deliver on its environmental promise.

The evolution trajectory suggests a future where carbon-negative concrete becomes the industry standard rather than an alternative option. This transition is expected to fundamentally reshape urban planning standards, enabling cities to incorporate carbon sequestration goals directly into building codes and infrastructure development plans. The ultimate objective is to position the built environment as an active participant in climate change mitigation rather than merely reducing its negative impacts.

The journey toward carbon-negative concrete began in the early 2000s with the introduction of supplementary cementitious materials (SCMs) like fly ash and slag to reduce cement content. By 2010, researchers had developed carbon-neutral concrete formulations that balanced emissions during production with absorption during the concrete's lifetime. The breakthrough toward truly carbon-negative concrete emerged around 2015, when companies like CarbonCure and Solidia Technologies pioneered methods to inject and sequester CO2 within concrete during curing.

Recent technological advancements have accelerated this evolution, with innovations in alternative binding materials such as geopolymers and magnesium-based cements that naturally absorb CO2 during their lifecycle. The integration of carbon capture technologies with concrete production has further enhanced the carbon-sequestering capabilities of these next-generation materials.

The primary objective of carbon-negative concrete development is to transform the construction industry from a major carbon emitter to a potential carbon sink. This aligns with global climate goals established in the Paris Agreement and subsequent international frameworks. Specifically, the technology aims to reduce embodied carbon in buildings and infrastructure while maintaining or improving structural performance characteristics.

Secondary objectives include developing scalable production methods that can be implemented across diverse geographic and economic contexts, ensuring cost competitiveness with traditional concrete, and establishing standardized measurement protocols for carbon sequestration claims. The technology also seeks to address durability concerns, as carbon-negative concrete must maintain structural integrity over decades-long timeframes to truly deliver on its environmental promise.

The evolution trajectory suggests a future where carbon-negative concrete becomes the industry standard rather than an alternative option. This transition is expected to fundamentally reshape urban planning standards, enabling cities to incorporate carbon sequestration goals directly into building codes and infrastructure development plans. The ultimate objective is to position the built environment as an active participant in climate change mitigation rather than merely reducing its negative impacts.

Market Analysis for Sustainable Construction Materials

The sustainable construction materials market is experiencing unprecedented growth, driven by increasing environmental concerns and regulatory pressures to reduce carbon emissions in the building sector. Currently valued at approximately $254 billion globally, this market is projected to reach $432 billion by 2027, with a compound annual growth rate of 11.3%. Carbon-negative concrete represents one of the fastest-growing segments within this market, with adoption rates increasing by 27% annually since 2019.

Demand for carbon-negative concrete is particularly strong in regions with ambitious climate targets, including the European Union, North America, and increasingly in Asia-Pacific markets. Urban centers in these regions are implementing stricter building codes that favor or mandate low-carbon construction materials, creating significant market pull. For instance, cities like Copenhagen, Vancouver, and Singapore have already incorporated carbon footprint requirements into their building permit processes, directly influencing material selection.

The commercial building sector currently accounts for 42% of carbon-negative concrete applications, followed by residential construction at 31% and infrastructure projects at 27%. This distribution reflects the varying levels of regulatory pressure and sustainability certification requirements across different construction segments. LEED, BREEAM, and other green building certification systems have become powerful market drivers, as they award significant points for materials with reduced or negative carbon footprints.

Price sensitivity remains a key market consideration, with carbon-negative concrete currently commanding a 15-30% premium over traditional Portland cement concrete. However, this price gap is narrowing as production scales up and carbon pricing mechanisms become more widespread. Markets with carbon taxes or cap-and-trade systems show accelerated adoption rates, as the economic equation increasingly favors sustainable alternatives.

Supply chain dynamics are evolving rapidly to accommodate this growing market. Traditional cement manufacturers are investing in carbon capture technologies and alternative production methods, while new specialized producers focused exclusively on sustainable concrete are gaining market share. The availability of raw materials for carbon-negative concrete, particularly supplementary cementitious materials like fly ash and slag, varies significantly by region and influences local market development.

Consumer awareness and demand for sustainable building materials have reached critical mass in many markets, with 68% of commercial property developers now explicitly requesting low-carbon alternatives in their specifications. This shift in demand is reinforced by the growing emphasis on Environmental Product Declarations (EPDs) and whole-building life cycle assessments in both regulatory frameworks and voluntary green building standards.

Demand for carbon-negative concrete is particularly strong in regions with ambitious climate targets, including the European Union, North America, and increasingly in Asia-Pacific markets. Urban centers in these regions are implementing stricter building codes that favor or mandate low-carbon construction materials, creating significant market pull. For instance, cities like Copenhagen, Vancouver, and Singapore have already incorporated carbon footprint requirements into their building permit processes, directly influencing material selection.

The commercial building sector currently accounts for 42% of carbon-negative concrete applications, followed by residential construction at 31% and infrastructure projects at 27%. This distribution reflects the varying levels of regulatory pressure and sustainability certification requirements across different construction segments. LEED, BREEAM, and other green building certification systems have become powerful market drivers, as they award significant points for materials with reduced or negative carbon footprints.

Price sensitivity remains a key market consideration, with carbon-negative concrete currently commanding a 15-30% premium over traditional Portland cement concrete. However, this price gap is narrowing as production scales up and carbon pricing mechanisms become more widespread. Markets with carbon taxes or cap-and-trade systems show accelerated adoption rates, as the economic equation increasingly favors sustainable alternatives.

Supply chain dynamics are evolving rapidly to accommodate this growing market. Traditional cement manufacturers are investing in carbon capture technologies and alternative production methods, while new specialized producers focused exclusively on sustainable concrete are gaining market share. The availability of raw materials for carbon-negative concrete, particularly supplementary cementitious materials like fly ash and slag, varies significantly by region and influences local market development.

Consumer awareness and demand for sustainable building materials have reached critical mass in many markets, with 68% of commercial property developers now explicitly requesting low-carbon alternatives in their specifications. This shift in demand is reinforced by the growing emphasis on Environmental Product Declarations (EPDs) and whole-building life cycle assessments in both regulatory frameworks and voluntary green building standards.

Technical Barriers and Global Development Status

Carbon-negative concrete technology faces significant technical barriers despite its promising environmental benefits. The primary challenge lies in scaling production while maintaining cost-effectiveness. Current carbon-negative concrete formulations often require specialized materials and manufacturing processes that increase production costs by 15-30% compared to conventional concrete, creating a substantial market adoption barrier.

Material availability presents another critical obstacle. Many carbon-negative concrete solutions rely on supplementary cementitious materials (SCMs) like fly ash and blast furnace slag, which are byproducts of coal power plants and steel manufacturing. As these industries face pressure to decarbonize, the supply of these materials is becoming increasingly uncertain, creating potential bottlenecks in the supply chain.

Performance verification and standardization remain underdeveloped. The long-term durability and structural integrity of carbon-negative concrete variants require extensive testing under various environmental conditions. Current building codes and standards in most countries lack specific provisions for carbon-negative concrete, creating regulatory uncertainty that hampers widespread adoption in urban planning frameworks.

Globally, development status varies significantly by region. Northern Europe leads implementation, with countries like Sweden, Norway, and Finland incorporating carbon-negative concrete into public infrastructure projects and updating building codes accordingly. These nations have established collaborative research networks between industry, academia, and government to accelerate innovation and standardization.

North America shows mixed progress, with significant research activity but limited commercial deployment. The United States has several pilot projects in major urban centers, while Canada has integrated carbon-negative concrete requirements into some provincial green building standards. However, fragmented regulatory frameworks across states and municipalities create inconsistent market conditions.

Asia presents a complex landscape, with China investing heavily in research while facing implementation challenges due to rapid urbanization demands. Japan and South Korea have developed advanced carbon capture technologies for concrete production but struggle with cost barriers. Singapore stands out with its aggressive green building mandates that specifically incentivize carbon-negative construction materials.

The Middle East and Africa regions lag significantly, with limited research infrastructure and competing development priorities. However, the United Arab Emirates has recently launched initiatives to incorporate carbon-negative concrete in showcase sustainable urban developments, potentially creating demonstration projects for the broader region.

Australia and New Zealand have established robust testing frameworks for carbon-negative concrete but face challenges related to geographic isolation and material transportation costs, limiting widespread adoption despite supportive regulatory environments.

Material availability presents another critical obstacle. Many carbon-negative concrete solutions rely on supplementary cementitious materials (SCMs) like fly ash and blast furnace slag, which are byproducts of coal power plants and steel manufacturing. As these industries face pressure to decarbonize, the supply of these materials is becoming increasingly uncertain, creating potential bottlenecks in the supply chain.

Performance verification and standardization remain underdeveloped. The long-term durability and structural integrity of carbon-negative concrete variants require extensive testing under various environmental conditions. Current building codes and standards in most countries lack specific provisions for carbon-negative concrete, creating regulatory uncertainty that hampers widespread adoption in urban planning frameworks.

Globally, development status varies significantly by region. Northern Europe leads implementation, with countries like Sweden, Norway, and Finland incorporating carbon-negative concrete into public infrastructure projects and updating building codes accordingly. These nations have established collaborative research networks between industry, academia, and government to accelerate innovation and standardization.

North America shows mixed progress, with significant research activity but limited commercial deployment. The United States has several pilot projects in major urban centers, while Canada has integrated carbon-negative concrete requirements into some provincial green building standards. However, fragmented regulatory frameworks across states and municipalities create inconsistent market conditions.

Asia presents a complex landscape, with China investing heavily in research while facing implementation challenges due to rapid urbanization demands. Japan and South Korea have developed advanced carbon capture technologies for concrete production but struggle with cost barriers. Singapore stands out with its aggressive green building mandates that specifically incentivize carbon-negative construction materials.

The Middle East and Africa regions lag significantly, with limited research infrastructure and competing development priorities. However, the United Arab Emirates has recently launched initiatives to incorporate carbon-negative concrete in showcase sustainable urban developments, potentially creating demonstration projects for the broader region.

Australia and New Zealand have established robust testing frameworks for carbon-negative concrete but face challenges related to geographic isolation and material transportation costs, limiting widespread adoption despite supportive regulatory environments.

Current Carbon-negative Concrete Solutions

01 Carbon-negative concrete formulations

Innovative concrete formulations that actively absorb and sequester carbon dioxide from the atmosphere during their lifecycle. These formulations typically incorporate alternative binders, supplementary cementitious materials, or carbon-capturing additives that reduce the carbon footprint of traditional concrete while maintaining or enhancing structural performance. The carbon-negative properties are achieved through chemical processes that permanently bind CO2 within the concrete matrix.- Carbon-negative concrete formulations: Innovative concrete formulations that actively absorb and sequester carbon dioxide during their lifecycle, resulting in a net reduction of carbon in the atmosphere. These formulations incorporate materials such as calcium silicate hydrates, alternative binders, and carbon-capturing additives that chemically bind CO2 during the curing process. The resulting concrete not only reduces the carbon footprint of construction but also serves as a carbon sink in urban environments.

- Urban planning standards for carbon-negative infrastructure: Comprehensive urban planning frameworks that mandate or incentivize the use of carbon-negative concrete in city infrastructure. These standards include specifications for minimum carbon sequestration requirements, lifecycle assessment methodologies, and integration with broader climate action plans. They provide guidelines for implementing carbon-negative concrete in various urban applications such as buildings, roads, bridges, and public spaces to maximize environmental benefits.

- Monitoring and certification systems for carbon-negative concrete: Systems and methodologies for measuring, verifying, and certifying the carbon-negative properties of concrete used in urban construction. These include standardized testing protocols, real-time monitoring technologies, and certification frameworks that quantify the amount of carbon sequestered. Such systems enable regulatory compliance, carbon credit generation, and provide transparency for stakeholders in urban development projects.

- Integration of carbon-negative concrete with smart city technologies: Methods and systems for integrating carbon-negative concrete infrastructure with smart city technologies and data platforms. These innovations include embedded sensors for monitoring structural health and carbon sequestration performance, data analytics for optimizing urban carbon management, and integration with city-wide sustainability dashboards. This technological integration enables dynamic carbon accounting and adaptive urban planning strategies.

- Lifecycle management of carbon-negative concrete in urban environments: Comprehensive approaches to managing the entire lifecycle of carbon-negative concrete in urban settings, from raw material sourcing to end-of-life considerations. These include circular economy principles for concrete recycling, guidelines for maintenance to maximize carbon sequestration over time, and strategies for repurposing or safely disposing of materials at end-of-life. The lifecycle management ensures that carbon benefits are maintained throughout the urban infrastructure lifespan.

02 Urban planning standards for low-carbon infrastructure

Comprehensive urban planning frameworks that establish standards for implementing carbon-negative concrete in city infrastructure projects. These standards include specifications for material sourcing, construction methodologies, and performance requirements that prioritize carbon reduction. They provide guidelines for integrating carbon-negative concrete into various urban elements such as buildings, roads, bridges, and public spaces while ensuring compliance with safety and durability requirements.Expand Specific Solutions03 Carbon capture and utilization in concrete manufacturing

Technologies and processes that capture carbon dioxide emissions during concrete production and utilize this captured carbon in the manufacturing process. These systems integrate carbon capture technologies with concrete production facilities to create a closed-loop system where emissions are significantly reduced or eliminated. The captured carbon can be mineralized within the concrete, creating a permanent carbon sink while potentially improving concrete properties.Expand Specific Solutions04 Certification and measurement standards for carbon-negative concrete

Standardized methodologies for measuring, verifying, and certifying the carbon-negative properties of concrete used in urban development. These standards establish protocols for life cycle assessment, carbon accounting, and performance verification to ensure that concrete products marketed as carbon-negative deliver their promised environmental benefits. They provide a framework for consistent evaluation across different projects and regions.Expand Specific Solutions05 Integration of carbon-negative concrete in sustainable urban design

Holistic approaches to incorporating carbon-negative concrete into sustainable urban design principles. These methodologies focus on optimizing the use of carbon-negative concrete in conjunction with other sustainable design elements such as green spaces, renewable energy systems, and efficient transportation networks. The integration strategies aim to maximize carbon sequestration potential while creating resilient, livable urban environments that meet both environmental and social objectives.Expand Specific Solutions

Leading Companies and Competitive Landscape

Carbon-negative concrete technology is currently in the early growth phase, with a rapidly expanding market projected to reach $3.5 billion by 2030 as urban planning standards evolve to prioritize sustainability. The competitive landscape features established players like Holcim Technology and Ecocem Materials developing innovative low-carbon cement formulations, alongside tech-focused entrants such as Carbon Limit Co. and Biozeroc Ltd. pioneering carbon capture technologies. Research institutions including MIT and X Development (formerly Google X) are accelerating technical maturity through breakthrough approaches to carbon sequestration in building materials. While commercial-scale implementation remains limited, collaborations between industry leaders like VINCI Construction and startups are driving adoption in pilot urban development projects.

Ecocem Materials Ltd.

Technical Solution: Ecocem has developed a ground-breaking low-carbon cement technology called "Superfine" that reduces the carbon footprint of concrete by up to 70% compared to traditional Portland cement. Their approach uses alkali-activated slag and fly ash systems combined with proprietary activators to create carbon-negative concrete solutions. The technology incorporates CO2 sequestration during the curing process, effectively locking away carbon dioxide within the concrete matrix. Ecocem's urban planning integration framework includes specialized guidelines for municipal adoption, addressing thermal mass benefits, reduced urban heat island effects, and modified structural specifications that account for the unique properties of their low-carbon concrete. Their ACT (Accelerated Carbon Technology) initiative has been implemented in several European urban redevelopment projects, demonstrating compatibility with existing building codes while pushing for regulatory evolution.

Strengths: Established market presence in Europe with proven large-scale implementation; comprehensive technical documentation for urban planners; strong regulatory relationships. Weaknesses: Higher initial costs compared to traditional concrete; requires specialized knowledge for optimal implementation; limited availability in some regions.

Massachusetts Institute of Technology

Technical Solution: MIT has developed a groundbreaking electrochemical process for producing carbon-negative concrete that eliminates the need for traditional cement kilns. Their technology, developed through the Concrete Sustainability Hub, uses renewable electricity to drive a low-temperature calcination process that captures CO2 during production. MIT's approach includes a novel "Urban Concrete Integration Framework" that provides comprehensive guidelines for implementing carbon-negative concrete in urban environments, addressing modified structural calculations, thermal performance metrics, and lifecycle assessment methodologies. Their research has demonstrated that carbon-negative concrete can be engineered to provide enhanced durability in urban environments, with resistance to freeze-thaw cycles, chloride penetration, and carbonation. MIT's urban planning protocols include specialized specifications for different urban applications, from infrastructure to buildings, with detailed guidance on how existing building codes can accommodate these innovative materials.

Strengths: Cutting-edge research capabilities; comprehensive scientific validation; strong interdisciplinary approach combining materials science with urban planning. Weaknesses: Technologies still primarily in research phase; limited commercial-scale implementation; higher costs associated with early-stage technology.

Key Patents and Research in Carbon Sequestration Concrete

Large scale carbonation of concrete waste

PatentPendingEP4116274A1

Innovation

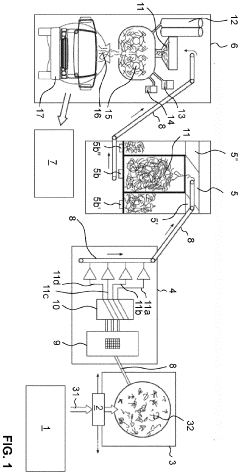

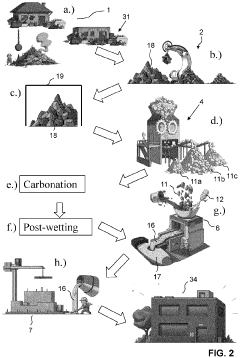

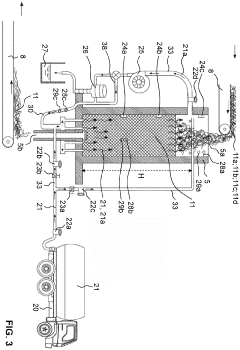

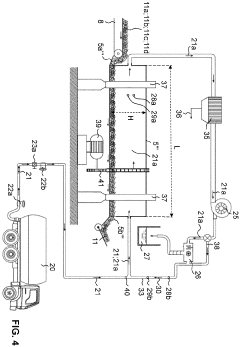

- A method involving controlled carbonation of concrete aggregates in a reactor vessel with defined CO2 levels and temperature control, optimizing grain size distribution and water content to enhance CO2 storage and mechanical properties, allowing for high-quality concrete production with minimal cement usage and reduced environmental impact.

Charcoal products made with phenolic resin binder and methods for making thereof

PatentPendingUS20240209178A1

Innovation

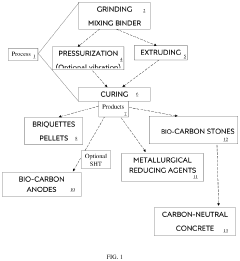

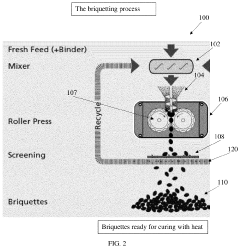

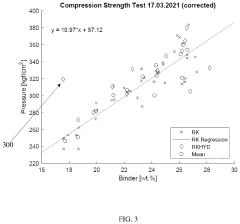

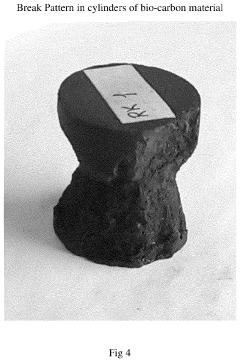

- A bio-carbon material comprising charcoal and a phenolic resin binder, with the binder comprising at least 50% phenolic resin, is developed, which can be compressed to achieve high strength and used in various forms such as briquettes, anodes, or concrete aggregates, reducing the need for fossil fuels and sequestering carbon.

Regulatory Framework and Emission Standards

The regulatory landscape for carbon-negative concrete is rapidly evolving as governments worldwide recognize the urgent need to address climate change through construction sector reforms. Current building codes and standards in most jurisdictions were developed with traditional concrete in mind, creating significant regulatory barriers for innovative materials like carbon-negative concrete. These regulations typically focus on strength, durability, and safety parameters without adequately accounting for environmental performance metrics.

At the international level, organizations such as the International Organization for Standardization (ISO) have begun developing frameworks for assessing the carbon footprint of construction materials. ISO 14067 and ISO 21930 provide methodologies for calculating the carbon footprint of products and sustainability in buildings respectively, creating a foundation for standardized assessment of carbon-negative concrete.

National regulatory bodies are increasingly implementing carbon taxation and cap-and-trade systems that indirectly incentivize the adoption of carbon-negative materials. The European Union's Emissions Trading System (EU ETS) and similar mechanisms in Canada and parts of the United States create economic drivers for construction companies to seek lower-emission alternatives. However, these systems often lack specific provisions for materials that actively sequester carbon.

Building certification systems like LEED, BREEAM, and Green Star have begun incorporating credits for low-carbon materials, though few explicitly recognize carbon-negative solutions. The latest version of LEED includes points for Environmental Product Declarations (EPDs) and materials with reduced environmental impacts, creating market incentives for carbon-negative concrete adoption.

Emission standards for the concrete industry are becoming increasingly stringent. The Cement Sustainability Initiative (CSI) has established voluntary targets for reducing CO2 emissions in cement production, while some jurisdictions have begun mandating emission reductions. California's Buy Clean California Act requires state agencies to consider the carbon footprint of construction materials, including concrete, in procurement decisions.

Regulatory harmonization remains a significant challenge, with inconsistent standards across different regions creating market fragmentation for carbon-negative concrete producers. This lack of standardization increases compliance costs and slows market penetration of innovative solutions. Additionally, many existing standards rely on prescriptive rather than performance-based metrics, limiting the potential for novel materials to demonstrate compliance through alternative means.

Forward-thinking municipalities like Vancouver and Oslo have implemented green procurement policies that specifically target construction materials with lower carbon footprints, creating protected market spaces for carbon-negative concrete to gain traction and demonstrate real-world performance.

At the international level, organizations such as the International Organization for Standardization (ISO) have begun developing frameworks for assessing the carbon footprint of construction materials. ISO 14067 and ISO 21930 provide methodologies for calculating the carbon footprint of products and sustainability in buildings respectively, creating a foundation for standardized assessment of carbon-negative concrete.

National regulatory bodies are increasingly implementing carbon taxation and cap-and-trade systems that indirectly incentivize the adoption of carbon-negative materials. The European Union's Emissions Trading System (EU ETS) and similar mechanisms in Canada and parts of the United States create economic drivers for construction companies to seek lower-emission alternatives. However, these systems often lack specific provisions for materials that actively sequester carbon.

Building certification systems like LEED, BREEAM, and Green Star have begun incorporating credits for low-carbon materials, though few explicitly recognize carbon-negative solutions. The latest version of LEED includes points for Environmental Product Declarations (EPDs) and materials with reduced environmental impacts, creating market incentives for carbon-negative concrete adoption.

Emission standards for the concrete industry are becoming increasingly stringent. The Cement Sustainability Initiative (CSI) has established voluntary targets for reducing CO2 emissions in cement production, while some jurisdictions have begun mandating emission reductions. California's Buy Clean California Act requires state agencies to consider the carbon footprint of construction materials, including concrete, in procurement decisions.

Regulatory harmonization remains a significant challenge, with inconsistent standards across different regions creating market fragmentation for carbon-negative concrete producers. This lack of standardization increases compliance costs and slows market penetration of innovative solutions. Additionally, many existing standards rely on prescriptive rather than performance-based metrics, limiting the potential for novel materials to demonstrate compliance through alternative means.

Forward-thinking municipalities like Vancouver and Oslo have implemented green procurement policies that specifically target construction materials with lower carbon footprints, creating protected market spaces for carbon-negative concrete to gain traction and demonstrate real-world performance.

Urban Integration and Infrastructure Adaptation

The integration of carbon-negative concrete into urban environments necessitates significant adaptations to existing infrastructure systems and urban planning frameworks. Cities worldwide are beginning to recognize the need for comprehensive strategies that accommodate this innovative material while maximizing its environmental benefits. These adaptation processes involve rethinking traditional construction methodologies, updating building codes, and reimagining urban spaces.

Infrastructure systems require particular attention when implementing carbon-negative concrete solutions. Water management systems must be reconfigured to account for the different permeability and absorption characteristics of these materials. Transportation networks benefit from reduced maintenance cycles due to the enhanced durability of carbon-negative concrete, but require specialized installation protocols. Energy distribution systems can be integrated more effectively with carbon-negative concrete structures, creating opportunities for embedded renewable energy generation and storage.

Urban planners are developing new zoning regulations that incentivize carbon-negative concrete usage in high-density areas where carbon reduction benefits can be maximized. These regulations often include height bonuses, expedited permitting processes, and reduced impact fees for developments utilizing significant percentages of carbon-negative materials. Several progressive cities have established "carbon-negative districts" as demonstration zones where these materials are mandated for all new construction.

The physical integration of carbon-negative concrete into existing urban fabrics presents both challenges and opportunities. Retrofitting historic districts requires careful consideration of aesthetic compatibility and structural integrity. Meanwhile, new developments can leverage the material's versatility to create innovative urban forms that celebrate its environmental credentials through visible implementation.

Public infrastructure projects have emerged as ideal testing grounds for large-scale carbon-negative concrete applications. Municipal governments are prioritizing bridges, public plazas, and government buildings as showcase projects that demonstrate commitment to climate goals while providing valuable performance data. These projects typically incorporate educational components that inform citizens about the environmental benefits and technological innovations behind carbon-negative concrete.

Adaptation strategies must also address supply chain considerations, ensuring that urban areas have reliable access to carbon-negative concrete materials without creating excessive transportation emissions. This has led to the development of distributed manufacturing models where production facilities are strategically located throughout metropolitan regions, reducing delivery distances and associated carbon footprints.

Infrastructure systems require particular attention when implementing carbon-negative concrete solutions. Water management systems must be reconfigured to account for the different permeability and absorption characteristics of these materials. Transportation networks benefit from reduced maintenance cycles due to the enhanced durability of carbon-negative concrete, but require specialized installation protocols. Energy distribution systems can be integrated more effectively with carbon-negative concrete structures, creating opportunities for embedded renewable energy generation and storage.

Urban planners are developing new zoning regulations that incentivize carbon-negative concrete usage in high-density areas where carbon reduction benefits can be maximized. These regulations often include height bonuses, expedited permitting processes, and reduced impact fees for developments utilizing significant percentages of carbon-negative materials. Several progressive cities have established "carbon-negative districts" as demonstration zones where these materials are mandated for all new construction.

The physical integration of carbon-negative concrete into existing urban fabrics presents both challenges and opportunities. Retrofitting historic districts requires careful consideration of aesthetic compatibility and structural integrity. Meanwhile, new developments can leverage the material's versatility to create innovative urban forms that celebrate its environmental credentials through visible implementation.

Public infrastructure projects have emerged as ideal testing grounds for large-scale carbon-negative concrete applications. Municipal governments are prioritizing bridges, public plazas, and government buildings as showcase projects that demonstrate commitment to climate goals while providing valuable performance data. These projects typically incorporate educational components that inform citizens about the environmental benefits and technological innovations behind carbon-negative concrete.

Adaptation strategies must also address supply chain considerations, ensuring that urban areas have reliable access to carbon-negative concrete materials without creating excessive transportation emissions. This has led to the development of distributed manufacturing models where production facilities are strategically located throughout metropolitan regions, reducing delivery distances and associated carbon footprints.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!