The Future of Smart Cities with Carbon-negative Concrete

OCT 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Technology Background and Objectives

Concrete, a fundamental building material in modern civilization, has undergone significant evolution since its widespread adoption in the 20th century. Traditional concrete production is responsible for approximately 8% of global CO2 emissions, primarily due to the energy-intensive process of cement manufacturing. This environmental impact has driven research into carbon-negative concrete technologies over the past two decades, with acceleration in development occurring since 2010.

Carbon-negative concrete represents a paradigm shift in construction materials, as it aims not only to reduce emissions but to actively sequester carbon dioxide throughout its lifecycle. The technology has evolved from early carbon-neutral formulations to truly carbon-negative solutions that can serve as carbon sinks in urban infrastructure. This evolution aligns with global sustainability goals and the increasing focus on circular economy principles in construction.

The primary objective of carbon-negative concrete technology is to transform urban construction from a carbon source to a carbon sink while maintaining or enhancing the structural performance characteristics required for modern building codes. Secondary objectives include reducing dependency on virgin raw materials, minimizing water usage, and creating economically viable alternatives to traditional concrete that can be adopted at scale in diverse geographic and economic contexts.

Current technological approaches include CO2 mineralization processes, alternative binding agents derived from industrial byproducts, biomass incorporation, and enhanced carbonation techniques. These methods aim to permanently sequester carbon within the concrete matrix while simultaneously reducing the carbon footprint of the manufacturing process itself.

The trajectory of this technology indicates potential for transformative impact on smart city development, as urban planners increasingly prioritize sustainability metrics alongside traditional performance indicators. Carbon-negative concrete could enable cities to utilize their built environment as a tool for climate mitigation rather than a contributor to climate change.

Research milestones in this field include the development of geopolymer cements with carbon-sequestering capabilities, successful commercial-scale demonstrations of CO2-cured concrete products, and the integration of carbon capture technologies directly into concrete manufacturing facilities. These advancements have progressively reduced implementation barriers and improved economic feasibility.

The ultimate technological goal is to develop carbon-negative concrete solutions that can be widely implemented across diverse construction applications, from residential buildings to critical infrastructure, while offering competitive pricing and superior performance compared to traditional concrete. This would position smart cities to leverage their construction activities as a mechanism for atmospheric carbon reduction rather than emission.

Carbon-negative concrete represents a paradigm shift in construction materials, as it aims not only to reduce emissions but to actively sequester carbon dioxide throughout its lifecycle. The technology has evolved from early carbon-neutral formulations to truly carbon-negative solutions that can serve as carbon sinks in urban infrastructure. This evolution aligns with global sustainability goals and the increasing focus on circular economy principles in construction.

The primary objective of carbon-negative concrete technology is to transform urban construction from a carbon source to a carbon sink while maintaining or enhancing the structural performance characteristics required for modern building codes. Secondary objectives include reducing dependency on virgin raw materials, minimizing water usage, and creating economically viable alternatives to traditional concrete that can be adopted at scale in diverse geographic and economic contexts.

Current technological approaches include CO2 mineralization processes, alternative binding agents derived from industrial byproducts, biomass incorporation, and enhanced carbonation techniques. These methods aim to permanently sequester carbon within the concrete matrix while simultaneously reducing the carbon footprint of the manufacturing process itself.

The trajectory of this technology indicates potential for transformative impact on smart city development, as urban planners increasingly prioritize sustainability metrics alongside traditional performance indicators. Carbon-negative concrete could enable cities to utilize their built environment as a tool for climate mitigation rather than a contributor to climate change.

Research milestones in this field include the development of geopolymer cements with carbon-sequestering capabilities, successful commercial-scale demonstrations of CO2-cured concrete products, and the integration of carbon capture technologies directly into concrete manufacturing facilities. These advancements have progressively reduced implementation barriers and improved economic feasibility.

The ultimate technological goal is to develop carbon-negative concrete solutions that can be widely implemented across diverse construction applications, from residential buildings to critical infrastructure, while offering competitive pricing and superior performance compared to traditional concrete. This would position smart cities to leverage their construction activities as a mechanism for atmospheric carbon reduction rather than emission.

Smart City Market Demand Analysis

The global smart city market is experiencing unprecedented growth, driven by rapid urbanization and the pressing need for sustainable urban development solutions. Current projections indicate the smart city market will reach $2.5 trillion by 2026, with a compound annual growth rate of approximately 18%. Within this expanding ecosystem, carbon-negative concrete represents a critical innovation addressing multiple market demands simultaneously.

Urban infrastructure development constitutes a significant portion of smart city investments, with construction materials accounting for nearly 40% of these expenditures. Traditional concrete production generates approximately 8% of global CO2 emissions, creating substantial demand for carbon-negative alternatives that align with smart cities' sustainability objectives. Market research indicates that 73% of urban development projects now include specific sustainability requirements, with carbon footprint reduction emerging as a top priority.

The convergence of environmental regulations and corporate sustainability commitments is accelerating market demand for carbon-negative building materials. Over 170 countries have established carbon reduction targets following the Paris Agreement, with many major urban centers implementing even more stringent local regulations. Cities like Copenhagen, Singapore, and Seattle have mandated carbon-neutral or carbon-negative construction materials for public infrastructure projects, creating immediate market opportunities.

Consumer preferences are similarly evolving, with surveys indicating 68% of urban residents consider environmental impact when evaluating residential options. This shift in consumer consciousness has prompted real estate developers to incorporate sustainable materials as a market differentiator, with premium pricing models emerging for carbon-negative developments.

The economic case for carbon-negative concrete continues to strengthen as carbon pricing mechanisms mature globally. With carbon taxes ranging from $25-$75 per ton in various jurisdictions, the financial incentives for adopting carbon-negative materials are becoming increasingly compelling. Market analysis suggests that by 2030, carbon pricing could add 15-30% to traditional concrete costs, while carbon-negative alternatives may qualify for substantial tax incentives and credits.

Smart city technology integration represents another significant market driver. The Internet of Things (IoT) sensor market for construction materials is growing at 22% annually, with particular emphasis on materials that can monitor structural health, air quality, and carbon sequestration performance. Carbon-negative concrete with embedded sensing capabilities addresses this emerging market segment, with potential applications in transportation infrastructure, commercial buildings, and public spaces.

Regional market analysis reveals varying adoption rates, with Northern Europe, North America, and parts of Asia-Pacific leading in carbon-negative concrete implementation. Developing urban centers in Africa and South Asia present substantial growth opportunities as they build new infrastructure while attempting to leapfrog carbon-intensive development patterns.

Urban infrastructure development constitutes a significant portion of smart city investments, with construction materials accounting for nearly 40% of these expenditures. Traditional concrete production generates approximately 8% of global CO2 emissions, creating substantial demand for carbon-negative alternatives that align with smart cities' sustainability objectives. Market research indicates that 73% of urban development projects now include specific sustainability requirements, with carbon footprint reduction emerging as a top priority.

The convergence of environmental regulations and corporate sustainability commitments is accelerating market demand for carbon-negative building materials. Over 170 countries have established carbon reduction targets following the Paris Agreement, with many major urban centers implementing even more stringent local regulations. Cities like Copenhagen, Singapore, and Seattle have mandated carbon-neutral or carbon-negative construction materials for public infrastructure projects, creating immediate market opportunities.

Consumer preferences are similarly evolving, with surveys indicating 68% of urban residents consider environmental impact when evaluating residential options. This shift in consumer consciousness has prompted real estate developers to incorporate sustainable materials as a market differentiator, with premium pricing models emerging for carbon-negative developments.

The economic case for carbon-negative concrete continues to strengthen as carbon pricing mechanisms mature globally. With carbon taxes ranging from $25-$75 per ton in various jurisdictions, the financial incentives for adopting carbon-negative materials are becoming increasingly compelling. Market analysis suggests that by 2030, carbon pricing could add 15-30% to traditional concrete costs, while carbon-negative alternatives may qualify for substantial tax incentives and credits.

Smart city technology integration represents another significant market driver. The Internet of Things (IoT) sensor market for construction materials is growing at 22% annually, with particular emphasis on materials that can monitor structural health, air quality, and carbon sequestration performance. Carbon-negative concrete with embedded sensing capabilities addresses this emerging market segment, with potential applications in transportation infrastructure, commercial buildings, and public spaces.

Regional market analysis reveals varying adoption rates, with Northern Europe, North America, and parts of Asia-Pacific leading in carbon-negative concrete implementation. Developing urban centers in Africa and South Asia present substantial growth opportunities as they build new infrastructure while attempting to leapfrog carbon-intensive development patterns.

Global Status and Challenges in Carbon-negative Concrete

Carbon-negative concrete technology has gained significant momentum globally, yet its implementation faces diverse challenges across different regions. Currently, several pioneering countries lead the development of carbon-negative concrete technologies, with notable advancements in North America, Europe, and parts of Asia. The United States, Canada, the United Kingdom, Germany, and Scandinavian countries have established robust research frameworks and pilot projects demonstrating the viability of carbon-negative concrete in urban infrastructure.

Despite these advancements, the global adoption of carbon-negative concrete remains limited, accounting for less than 5% of the worldwide concrete market. This low penetration rate stems from several interconnected challenges. The primary technical obstacle involves achieving consistent carbon sequestration performance across varying environmental conditions and concrete applications. Current carbon-negative formulations often demonstrate reduced early-stage strength compared to traditional concrete, creating hesitation among engineers and contractors.

Economic barriers present another significant challenge. The production cost of carbon-negative concrete typically exceeds conventional concrete by 15-30%, depending on regional factors and availability of alternative cementitious materials. This cost premium, although decreasing annually, continues to impede widespread adoption, particularly in developing economies where construction cost sensitivity is high.

Regulatory frameworks globally remain inconsistent, with few countries having established clear standards and certification processes for carbon-negative concrete. This regulatory uncertainty creates market hesitation and complicates international trade of these innovative materials. Additionally, building codes in many regions have not been updated to accommodate the unique properties and performance characteristics of carbon-negative concrete.

The supply chain for essential components of carbon-negative concrete presents another challenge. Materials such as supplementary cementitious materials (SCMs), carbon capture technologies, and specialized additives face distribution limitations and regional availability constraints. This supply chain fragmentation creates uneven access to necessary raw materials and technologies.

Knowledge gaps and technical expertise deficiencies further complicate global adoption. Many construction professionals lack familiarity with carbon-negative concrete properties, mixing requirements, and application techniques. This knowledge deficit extends to building officials and inspectors, creating potential barriers during project approval and inspection phases.

Despite these challenges, promising developments are emerging. International collaborations between research institutions, industry partners, and governmental bodies are accelerating knowledge sharing and standardization efforts. Several multinational construction firms have committed to carbon-negative concrete usage targets, creating market pull that stimulates further innovation and cost reduction.

Despite these advancements, the global adoption of carbon-negative concrete remains limited, accounting for less than 5% of the worldwide concrete market. This low penetration rate stems from several interconnected challenges. The primary technical obstacle involves achieving consistent carbon sequestration performance across varying environmental conditions and concrete applications. Current carbon-negative formulations often demonstrate reduced early-stage strength compared to traditional concrete, creating hesitation among engineers and contractors.

Economic barriers present another significant challenge. The production cost of carbon-negative concrete typically exceeds conventional concrete by 15-30%, depending on regional factors and availability of alternative cementitious materials. This cost premium, although decreasing annually, continues to impede widespread adoption, particularly in developing economies where construction cost sensitivity is high.

Regulatory frameworks globally remain inconsistent, with few countries having established clear standards and certification processes for carbon-negative concrete. This regulatory uncertainty creates market hesitation and complicates international trade of these innovative materials. Additionally, building codes in many regions have not been updated to accommodate the unique properties and performance characteristics of carbon-negative concrete.

The supply chain for essential components of carbon-negative concrete presents another challenge. Materials such as supplementary cementitious materials (SCMs), carbon capture technologies, and specialized additives face distribution limitations and regional availability constraints. This supply chain fragmentation creates uneven access to necessary raw materials and technologies.

Knowledge gaps and technical expertise deficiencies further complicate global adoption. Many construction professionals lack familiarity with carbon-negative concrete properties, mixing requirements, and application techniques. This knowledge deficit extends to building officials and inspectors, creating potential barriers during project approval and inspection phases.

Despite these challenges, promising developments are emerging. International collaborations between research institutions, industry partners, and governmental bodies are accelerating knowledge sharing and standardization efforts. Several multinational construction firms have committed to carbon-negative concrete usage targets, creating market pull that stimulates further innovation and cost reduction.

Current Carbon-negative Concrete Solutions for Smart Cities

01 Carbon capture and sequestration in concrete

Carbon-negative concrete technologies that actively capture and sequester CO2 during the manufacturing process. These methods involve incorporating materials that can absorb CO2 from the atmosphere and lock it into the concrete structure, effectively making the concrete a carbon sink. This approach not only reduces the carbon footprint of concrete production but can actually result in a net removal of carbon dioxide from the atmosphere.- CO2 capture and sequestration in concrete: Carbon-negative concrete technologies that actively capture and sequester CO2 during the manufacturing process. These methods involve incorporating materials that can absorb carbon dioxide from the atmosphere and permanently store it within the concrete structure, effectively turning concrete from a carbon source into a carbon sink. This approach not only reduces the carbon footprint of concrete production but can actually make the final product carbon-negative by sequestering more CO2 than is emitted during production.

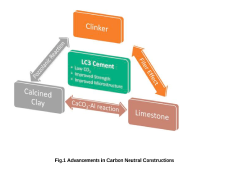

- Alternative binders and supplementary cementitious materials: The use of alternative binders and supplementary cementitious materials (SCMs) to replace traditional Portland cement in concrete formulations. These materials include industrial byproducts like fly ash, slag, and silica fume, as well as novel binders such as geopolymers and alkali-activated materials. By reducing the amount of Portland cement needed, these alternatives significantly lower the carbon emissions associated with concrete production while maintaining or even enhancing performance characteristics.

- Carbonation curing techniques: Innovative curing processes that expose fresh concrete to CO2-rich environments, promoting the carbonation reaction where carbon dioxide is chemically bound to the concrete matrix. This accelerated carbonation not only sequesters CO2 but also improves the mechanical properties and durability of the concrete. The process can be applied during manufacturing or as a post-production treatment, offering a pathway to create concrete products that have a negative carbon footprint over their lifecycle.

- Biomass and waste incorporation: Methods for incorporating biomass and waste materials into concrete formulations to reduce carbon emissions. These approaches include using agricultural waste ash, biochar, and other carbon-rich biomass as partial replacements for cement or as additives. The organic carbon contained in these materials is effectively sequestered in the concrete, while simultaneously reducing the need for virgin materials and diverting waste from landfills, creating a double environmental benefit.

- Enhanced carbonation through mineral additives: The use of specific mineral additives that enhance the concrete's ability to absorb and react with atmospheric CO2 throughout its lifetime. These minerals, such as magnesium oxides and calcium silicates, can continuously capture carbon dioxide through natural weathering processes. By engineering concrete with these reactive components, the material can progressively become more carbon-negative over time, potentially offsetting a significant portion of the emissions generated during its production.

02 Alternative cementitious materials

The use of alternative cementitious materials to replace traditional Portland cement in concrete formulations. These alternatives include supplementary cementitious materials (SCMs) like fly ash, slag, and natural pozzolans that require less energy to produce and generate fewer CO2 emissions. Some innovative materials can even absorb CO2 during their service life, contributing to the carbon-negative properties of the resulting concrete.Expand Specific Solutions03 CO2 curing and carbonation processes

Specialized curing processes that utilize CO2 to accelerate the hardening of concrete while simultaneously sequestering carbon. These carbonation techniques involve exposing fresh concrete to controlled amounts of carbon dioxide, which reacts with calcium hydroxide in the concrete to form calcium carbonate. This process not only improves the mechanical properties of concrete but also permanently stores CO2 within the material structure.Expand Specific Solutions04 Biomass and waste incorporation

The incorporation of biomass and industrial waste products into concrete formulations to reduce carbon emissions. These materials, which might include agricultural residues, wood waste, or industrial byproducts, can replace portions of traditional concrete ingredients. Some biomass-derived additives can enhance carbon sequestration properties while also improving certain performance characteristics of the concrete.Expand Specific Solutions05 Novel production methods and technologies

Innovative production methods and technologies designed specifically to create carbon-negative concrete. These approaches include new mixing techniques, advanced curing systems, and specialized equipment that minimize energy consumption during manufacturing. Some technologies focus on optimizing the concrete's microstructure to enhance CO2 absorption capacity throughout the material's lifecycle, while others implement renewable energy sources in the production process to further reduce the carbon footprint.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The carbon-negative concrete market is in an early growth phase, characterized by increasing research activity and commercial exploration. The global market potential is substantial, driven by construction industry's need to reduce its carbon footprint, with projections suggesting significant expansion over the next decade. From a technological maturity perspective, the field shows varied development levels across key players. Academic institutions like MIT, Centre National de la Recherche Scientifique, and Shenzhen University are advancing fundamental research, while companies such as Carbon Limit Co., Ecocem Materials, and China Construction Commercial Concrete are developing commercial applications. Government-affiliated entities like CCCC Second Harbor Engineering and research foundations are facilitating technology transfer. The ecosystem demonstrates a healthy balance of theoretical research and practical implementation, though widespread commercial adoption remains in early stages.

Ecocem Materials Ltd.

Technical Solution: Ecocem has developed a groundbreaking low-carbon cement technology called GGBS (Ground Granulated Blast-furnace Slag) that reduces carbon emissions by up to 95% compared to traditional Portland cement. Their innovative ACT (Accelerated Carbonation Technology) process actively absorbs CO2 during concrete curing, making their product carbon-negative. For smart cities, Ecocem has implemented IoT-enabled concrete monitoring systems that track carbon sequestration in real-time, allowing urban planners to quantify environmental benefits. Their SCM (Supplementary Cementitious Material) technology has been deployed in major European smart city initiatives, including the Paris Climate-Resilient Infrastructure Project where their concrete absorbed approximately 120kg of CO2 per cubic meter.

Strengths: Industry-leading carbon reduction capabilities; established commercial deployments in European smart cities; comprehensive monitoring technology for carbon metrics. Weaknesses: Higher initial production costs compared to traditional concrete; requires specialized equipment for optimal installation; limited production capacity for meeting global demand.

Massachusetts Institute of Technology

Technical Solution: MIT has developed a groundbreaking carbon-negative concrete technology called "Carbonatable Calcium Silicate" (CCS) specifically designed for smart city applications. Their approach replaces traditional Portland cement with alternative cementitious materials that can absorb CO2 during the curing process and throughout the concrete's lifetime. MIT's research team has integrated nanosensors within the concrete matrix that monitor carbon sequestration rates, structural integrity, and environmental performance in real-time. Their smart concrete system connects to urban data networks, allowing city managers to track carbon metrics across infrastructure projects. The technology incorporates a novel electrochemical process that accelerates carbonation, enabling their concrete to sequester approximately 0.5 tons of CO2 per ton of concrete produced. MIT has demonstrated this technology in pilot projects showing 40% greater strength development and significantly reduced cracking compared to conventional concrete, while maintaining carbon-negative properties.

Strengths: Cutting-edge research capabilities; integration of advanced sensing technologies; strong scientific validation through peer-reviewed research. Weaknesses: Technology still primarily in research/pilot phase; higher production costs than conventional concrete; requires specialized knowledge for implementation.

Core Patents and Innovations in Carbon-negative Concrete

Carbon-neutral concrete solutions for sustainable infrastructure

PatentPendingIN202441036149A

Innovation

- The use of supplementary cementitious materials like fly ash, slag, and calcined clays, combined with carbon capture technologies and recycled aggregates, along with lifecycle assessment and carbon offsetting initiatives, aims to minimize emissions and enhance the sustainability of concrete production.

Sustainability Impact Assessment and Carbon Metrics

The sustainability impact of carbon-negative concrete in smart cities extends far beyond simple carbon reduction metrics. Comprehensive assessment frameworks must evaluate the entire lifecycle of these innovative materials, from raw material extraction through manufacturing, transportation, installation, use phase, and end-of-life management. These assessments typically employ methodologies such as Life Cycle Assessment (LCA), Environmental Product Declarations (EPDs), and carbon footprinting to quantify environmental impacts.

Carbon metrics for these advanced concretes require standardized measurement protocols that account for both embodied carbon (emissions during production) and operational carbon (emissions during use). The development of ISO-compliant carbon accounting standards specifically for carbon-negative building materials represents a significant advancement in this field. These standards enable meaningful comparisons between traditional concrete and carbon-negative alternatives across different urban applications.

Smart cities implementing carbon-negative concrete can leverage digital monitoring systems that track real-time carbon performance through embedded sensors and IoT connectivity. These systems provide continuous data on carbon sequestration rates, structural performance, and environmental conditions, allowing for dynamic sustainability assessments throughout the material's lifetime. This integration with smart city infrastructure creates opportunities for carbon credit generation and verification through blockchain-based tracking systems.

The economic dimensions of sustainability impact assessment for carbon-negative concrete include cost-benefit analyses that consider both direct costs and externality valuation. Studies indicate that while initial implementation costs may exceed traditional concrete by 15-30%, the long-term economic benefits from carbon credits, reduced maintenance, and extended service life often yield positive returns within 7-12 years. These economic metrics are increasingly important as carbon pricing mechanisms expand globally.

Social impact metrics complement environmental and economic assessments by measuring health outcomes, job creation, and community resilience. Research demonstrates that widespread adoption of carbon-negative concrete in smart cities can reduce respiratory illnesses by decreasing airborne particulates during construction and throughout the material's lifecycle. Additionally, the specialized manufacturing processes create new green jobs that support local economies.

Regulatory frameworks are evolving to incorporate these comprehensive sustainability metrics into building codes and procurement policies. Leading smart cities have implemented performance-based standards that incentivize carbon-negative materials through expedited permitting, density bonuses, and tax incentives based on verified carbon performance metrics. These policy instruments accelerate adoption while ensuring rigorous verification of sustainability claims.

Carbon metrics for these advanced concretes require standardized measurement protocols that account for both embodied carbon (emissions during production) and operational carbon (emissions during use). The development of ISO-compliant carbon accounting standards specifically for carbon-negative building materials represents a significant advancement in this field. These standards enable meaningful comparisons between traditional concrete and carbon-negative alternatives across different urban applications.

Smart cities implementing carbon-negative concrete can leverage digital monitoring systems that track real-time carbon performance through embedded sensors and IoT connectivity. These systems provide continuous data on carbon sequestration rates, structural performance, and environmental conditions, allowing for dynamic sustainability assessments throughout the material's lifetime. This integration with smart city infrastructure creates opportunities for carbon credit generation and verification through blockchain-based tracking systems.

The economic dimensions of sustainability impact assessment for carbon-negative concrete include cost-benefit analyses that consider both direct costs and externality valuation. Studies indicate that while initial implementation costs may exceed traditional concrete by 15-30%, the long-term economic benefits from carbon credits, reduced maintenance, and extended service life often yield positive returns within 7-12 years. These economic metrics are increasingly important as carbon pricing mechanisms expand globally.

Social impact metrics complement environmental and economic assessments by measuring health outcomes, job creation, and community resilience. Research demonstrates that widespread adoption of carbon-negative concrete in smart cities can reduce respiratory illnesses by decreasing airborne particulates during construction and throughout the material's lifecycle. Additionally, the specialized manufacturing processes create new green jobs that support local economies.

Regulatory frameworks are evolving to incorporate these comprehensive sustainability metrics into building codes and procurement policies. Leading smart cities have implemented performance-based standards that incentivize carbon-negative materials through expedited permitting, density bonuses, and tax incentives based on verified carbon performance metrics. These policy instruments accelerate adoption while ensuring rigorous verification of sustainability claims.

Regulatory Framework and Green Building Standards

The regulatory landscape for carbon-negative concrete in smart cities is rapidly evolving as governments worldwide recognize the urgent need to address climate change through sustainable urban development. International frameworks such as the Paris Agreement have established foundational targets for carbon reduction, creating pressure for national and local governments to implement specific building codes that favor low-carbon construction materials.

In the European Union, the Construction Products Regulation (CPR) has been updated to include carbon footprint considerations, while the EU Taxonomy for Sustainable Activities specifically recognizes carbon-negative building materials as sustainable investments. These regulations create market incentives for the adoption of innovative concrete solutions that sequester carbon rather than emit it.

The United States has implemented a patchwork of state and municipal green building codes, with California's Title 24 Building Energy Efficiency Standards and New York City's Local Law 97 standing out as progressive frameworks that incentivize carbon-negative materials. The federal government has also introduced tax credits through the Inflation Reduction Act for construction projects utilizing carbon-negative technologies.

Green building certification systems play a crucial role in standardizing and promoting carbon-negative concrete adoption. LEED (Leadership in Energy and Environmental Design) has updated its Materials and Resources credits to award additional points for carbon-negative materials, while the Living Building Challenge requires net-positive carbon impact for its highest certification levels. Similarly, BREEAM has incorporated embodied carbon assessments that favor carbon-negative solutions.

Emerging standards specifically for concrete are gaining prominence, with the Concrete Sustainability Council (CSC) certification expanding its criteria to recognize carbon sequestration capabilities. The Carbon Leadership Forum's EC3 (Embodied Carbon in Construction Calculator) tool has become an industry standard for comparing the carbon footprint of different concrete formulations, providing transparency and accountability in material selection.

Procurement policies in public sector construction are increasingly incorporating carbon footprint requirements, with countries like Sweden, Finland, and the Netherlands implementing carbon budgets for infrastructure projects. These policies create significant market pull for carbon-negative concrete technologies by leveraging the purchasing power of government construction.

The harmonization of these various regulatory frameworks remains a challenge, with industry stakeholders calling for consistent global standards to facilitate wider adoption of carbon-negative concrete. International organizations such as the World Green Building Council are working to develop unified approaches to measuring and verifying carbon negativity claims, which will be essential for the technology's integration into smart city development worldwide.

In the European Union, the Construction Products Regulation (CPR) has been updated to include carbon footprint considerations, while the EU Taxonomy for Sustainable Activities specifically recognizes carbon-negative building materials as sustainable investments. These regulations create market incentives for the adoption of innovative concrete solutions that sequester carbon rather than emit it.

The United States has implemented a patchwork of state and municipal green building codes, with California's Title 24 Building Energy Efficiency Standards and New York City's Local Law 97 standing out as progressive frameworks that incentivize carbon-negative materials. The federal government has also introduced tax credits through the Inflation Reduction Act for construction projects utilizing carbon-negative technologies.

Green building certification systems play a crucial role in standardizing and promoting carbon-negative concrete adoption. LEED (Leadership in Energy and Environmental Design) has updated its Materials and Resources credits to award additional points for carbon-negative materials, while the Living Building Challenge requires net-positive carbon impact for its highest certification levels. Similarly, BREEAM has incorporated embodied carbon assessments that favor carbon-negative solutions.

Emerging standards specifically for concrete are gaining prominence, with the Concrete Sustainability Council (CSC) certification expanding its criteria to recognize carbon sequestration capabilities. The Carbon Leadership Forum's EC3 (Embodied Carbon in Construction Calculator) tool has become an industry standard for comparing the carbon footprint of different concrete formulations, providing transparency and accountability in material selection.

Procurement policies in public sector construction are increasingly incorporating carbon footprint requirements, with countries like Sweden, Finland, and the Netherlands implementing carbon budgets for infrastructure projects. These policies create significant market pull for carbon-negative concrete technologies by leveraging the purchasing power of government construction.

The harmonization of these various regulatory frameworks remains a challenge, with industry stakeholders calling for consistent global standards to facilitate wider adoption of carbon-negative concrete. International organizations such as the World Green Building Council are working to develop unified approaches to measuring and verifying carbon negativity claims, which will be essential for the technology's integration into smart city development worldwide.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!