How Carbon-negative Concrete is Integrated into Modern Skyscrapers

OCT 10, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-negative Concrete Evolution and Objectives

Concrete, a fundamental building material in modern construction, has undergone significant evolution in response to growing environmental concerns. Traditional concrete production is responsible for approximately 8% of global CO2 emissions, primarily due to the energy-intensive process of cement manufacturing. This environmental impact has driven research and development toward carbon-negative concrete technologies over the past two decades, marking a paradigm shift in construction materials science.

The evolution of carbon-negative concrete began in the early 2000s with initial research into alternative cementitious materials. By 2010, the first commercial applications of low-carbon concrete emerged, utilizing supplementary cementitious materials (SCMs) like fly ash and slag to reduce the carbon footprint. The breakthrough toward truly carbon-negative formulations occurred around 2015-2018, when companies like CarbonCure and Solidia Technologies pioneered methods to sequester CO2 directly into concrete during the curing process.

Recent technological advancements have focused on three primary approaches: CO2 mineralization (converting CO2 into stable carbonate minerals within concrete), alternative binding agents (replacing traditional Portland cement with materials that have lower carbon footprints), and carbon capture during production. These innovations have collectively transformed concrete from an environmental liability into a potential carbon sink.

The integration of carbon-negative concrete into skyscrapers represents a critical frontier in sustainable urban development. Historically, skyscrapers have been massive consumers of conventional concrete, with a single high-rise potentially using thousands of cubic meters of material. The technical objectives for carbon-negative concrete in these applications include maintaining or exceeding structural performance standards while achieving net carbon sequestration.

Current objectives in the field focus on scaling production capabilities to meet the demands of large-scale construction projects, optimizing the carbon sequestration potential without compromising structural integrity, and developing specialized formulations that address the unique requirements of high-rise construction, including enhanced durability, fire resistance, and seismic performance.

Looking forward, the industry aims to achieve widespread adoption of carbon-negative concrete in skyscrapers by 2030, with targets for sequestering at least 100 kg of CO2 per cubic meter of concrete. Additional objectives include reducing production costs to achieve price parity with traditional concrete, extending service life beyond 100 years to maximize the carbon benefit, and developing international standards and certification systems specifically for carbon-negative building materials in high-rise applications.

The evolution of carbon-negative concrete began in the early 2000s with initial research into alternative cementitious materials. By 2010, the first commercial applications of low-carbon concrete emerged, utilizing supplementary cementitious materials (SCMs) like fly ash and slag to reduce the carbon footprint. The breakthrough toward truly carbon-negative formulations occurred around 2015-2018, when companies like CarbonCure and Solidia Technologies pioneered methods to sequester CO2 directly into concrete during the curing process.

Recent technological advancements have focused on three primary approaches: CO2 mineralization (converting CO2 into stable carbonate minerals within concrete), alternative binding agents (replacing traditional Portland cement with materials that have lower carbon footprints), and carbon capture during production. These innovations have collectively transformed concrete from an environmental liability into a potential carbon sink.

The integration of carbon-negative concrete into skyscrapers represents a critical frontier in sustainable urban development. Historically, skyscrapers have been massive consumers of conventional concrete, with a single high-rise potentially using thousands of cubic meters of material. The technical objectives for carbon-negative concrete in these applications include maintaining or exceeding structural performance standards while achieving net carbon sequestration.

Current objectives in the field focus on scaling production capabilities to meet the demands of large-scale construction projects, optimizing the carbon sequestration potential without compromising structural integrity, and developing specialized formulations that address the unique requirements of high-rise construction, including enhanced durability, fire resistance, and seismic performance.

Looking forward, the industry aims to achieve widespread adoption of carbon-negative concrete in skyscrapers by 2030, with targets for sequestering at least 100 kg of CO2 per cubic meter of concrete. Additional objectives include reducing production costs to achieve price parity with traditional concrete, extending service life beyond 100 years to maximize the carbon benefit, and developing international standards and certification systems specifically for carbon-negative building materials in high-rise applications.

Market Analysis for Sustainable Construction Materials

The sustainable construction materials market is experiencing unprecedented growth, driven by increasing environmental concerns and regulatory pressures to reduce carbon emissions in the building sector. Currently valued at approximately $254 billion globally, this market is projected to reach $432 billion by 2027, with a compound annual growth rate of 11.3%. Carbon-negative concrete represents one of the fastest-growing segments within this category, with adoption rates increasing by 27% annually since 2019.

Demand for carbon-negative concrete in skyscraper construction has been particularly strong in regions with stringent carbon regulations, including the European Union, parts of North America, and progressive Asian markets like Singapore and Japan. These materials command a premium of 15-30% over traditional concrete, yet developers increasingly view this as an acceptable cost given the long-term operational savings and compliance benefits.

Market research indicates that 73% of commercial real estate developers now consider embodied carbon metrics in their material selection process, compared to just 24% five years ago. This shift is particularly pronounced in the premium commercial building sector, where environmental certification systems like LEED, BREEAM, and WELL have become standard requirements for Class A office spaces.

The competitive landscape for carbon-negative concrete is rapidly evolving, with both established material companies and innovative startups vying for market share. Traditional cement manufacturers have invested over $8.7 billion in carbon capture and alternative binding technologies since 2020, while venture capital funding for concrete technology startups exceeded $1.2 billion in 2022 alone.

Consumer sentiment analysis reveals that 68% of commercial tenants now express preference for buildings constructed with low-carbon materials, with 42% willing to pay higher rents for spaces in buildings with demonstrated carbon-negative attributes. This trend is particularly strong among technology, financial, and professional service firms seeking to align their corporate sustainability goals with their physical infrastructure.

Supply chain considerations remain a significant factor in market development, with current production capacity for carbon-negative concrete meeting only about 7% of potential demand. Geographic distribution of manufacturing facilities presents challenges, with transportation emissions potentially offsetting some environmental benefits when materials must travel long distances to construction sites.

Regulatory tailwinds are accelerating market adoption, with 27 countries now offering tax incentives or expedited permitting for buildings utilizing carbon-negative materials. Building codes in 14 major metropolitan areas have been updated since 2021 to include embodied carbon limits, creating structural demand drivers that industry analysts expect will persist regardless of economic cycles.

Demand for carbon-negative concrete in skyscraper construction has been particularly strong in regions with stringent carbon regulations, including the European Union, parts of North America, and progressive Asian markets like Singapore and Japan. These materials command a premium of 15-30% over traditional concrete, yet developers increasingly view this as an acceptable cost given the long-term operational savings and compliance benefits.

Market research indicates that 73% of commercial real estate developers now consider embodied carbon metrics in their material selection process, compared to just 24% five years ago. This shift is particularly pronounced in the premium commercial building sector, where environmental certification systems like LEED, BREEAM, and WELL have become standard requirements for Class A office spaces.

The competitive landscape for carbon-negative concrete is rapidly evolving, with both established material companies and innovative startups vying for market share. Traditional cement manufacturers have invested over $8.7 billion in carbon capture and alternative binding technologies since 2020, while venture capital funding for concrete technology startups exceeded $1.2 billion in 2022 alone.

Consumer sentiment analysis reveals that 68% of commercial tenants now express preference for buildings constructed with low-carbon materials, with 42% willing to pay higher rents for spaces in buildings with demonstrated carbon-negative attributes. This trend is particularly strong among technology, financial, and professional service firms seeking to align their corporate sustainability goals with their physical infrastructure.

Supply chain considerations remain a significant factor in market development, with current production capacity for carbon-negative concrete meeting only about 7% of potential demand. Geographic distribution of manufacturing facilities presents challenges, with transportation emissions potentially offsetting some environmental benefits when materials must travel long distances to construction sites.

Regulatory tailwinds are accelerating market adoption, with 27 countries now offering tax incentives or expedited permitting for buildings utilizing carbon-negative materials. Building codes in 14 major metropolitan areas have been updated since 2021 to include embodied carbon limits, creating structural demand drivers that industry analysts expect will persist regardless of economic cycles.

Current Status and Barriers in Green Concrete Technology

The global concrete industry currently contributes approximately 8% of worldwide carbon emissions, making it a critical focus for sustainability efforts in construction. Carbon-negative concrete technologies have advanced significantly in recent years, with several commercial-scale implementations demonstrating their viability. Leading solutions include calcium carbonate mineralization processes, which capture CO2 during curing, and alternative binding materials that replace traditional Portland cement with lower-carbon alternatives such as geopolymers and alkali-activated materials.

Despite these advancements, widespread adoption of carbon-negative concrete in skyscraper construction faces substantial barriers. Technical challenges include achieving comparable strength and durability metrics to traditional concrete, particularly for high-performance applications in tall buildings where structural integrity is paramount. Current carbon-negative formulations often exhibit slower curing times and less predictable performance characteristics under varied environmental conditions, creating hesitation among structural engineers responsible for safety-critical applications.

Regulatory frameworks present another significant obstacle, as building codes in many jurisdictions have not been updated to accommodate innovative concrete technologies. The certification process for new construction materials typically requires extensive testing and documentation, creating a multi-year approval timeline that delays implementation. This regulatory lag creates a chicken-and-egg problem where developers are reluctant to specify materials that lack standardized approval pathways.

Economic barriers further complicate adoption, with carbon-negative concrete currently commanding a 15-30% price premium over conventional alternatives. This cost differential is particularly challenging for large-scale projects like skyscrapers, where concrete represents a substantial portion of the overall budget. Without carbon pricing mechanisms or regulatory mandates, the business case for developers remains challenging despite the environmental benefits.

Supply chain limitations also restrict implementation, as production capacity for specialized ingredients remains limited. The geographic distribution of manufacturing facilities for key components such as supplementary cementitious materials and CO2 mineralization additives is uneven, creating logistical challenges for projects in regions without established supply networks.

Knowledge gaps among architects, engineers, and contractors further impede adoption. Many professionals lack familiarity with carbon-negative concrete specifications, installation requirements, and long-term performance characteristics. This information deficit creates risk aversion among decision-makers who prefer conventional materials with well-understood properties and established track records.

Recent pilot projects have demonstrated promising results, with several mid-rise structures successfully incorporating carbon-negative concrete elements. However, full integration into supertall structures remains limited to non-structural applications such as flooring systems and interior elements rather than primary structural components.

Despite these advancements, widespread adoption of carbon-negative concrete in skyscraper construction faces substantial barriers. Technical challenges include achieving comparable strength and durability metrics to traditional concrete, particularly for high-performance applications in tall buildings where structural integrity is paramount. Current carbon-negative formulations often exhibit slower curing times and less predictable performance characteristics under varied environmental conditions, creating hesitation among structural engineers responsible for safety-critical applications.

Regulatory frameworks present another significant obstacle, as building codes in many jurisdictions have not been updated to accommodate innovative concrete technologies. The certification process for new construction materials typically requires extensive testing and documentation, creating a multi-year approval timeline that delays implementation. This regulatory lag creates a chicken-and-egg problem where developers are reluctant to specify materials that lack standardized approval pathways.

Economic barriers further complicate adoption, with carbon-negative concrete currently commanding a 15-30% price premium over conventional alternatives. This cost differential is particularly challenging for large-scale projects like skyscrapers, where concrete represents a substantial portion of the overall budget. Without carbon pricing mechanisms or regulatory mandates, the business case for developers remains challenging despite the environmental benefits.

Supply chain limitations also restrict implementation, as production capacity for specialized ingredients remains limited. The geographic distribution of manufacturing facilities for key components such as supplementary cementitious materials and CO2 mineralization additives is uneven, creating logistical challenges for projects in regions without established supply networks.

Knowledge gaps among architects, engineers, and contractors further impede adoption. Many professionals lack familiarity with carbon-negative concrete specifications, installation requirements, and long-term performance characteristics. This information deficit creates risk aversion among decision-makers who prefer conventional materials with well-understood properties and established track records.

Recent pilot projects have demonstrated promising results, with several mid-rise structures successfully incorporating carbon-negative concrete elements. However, full integration into supertall structures remains limited to non-structural applications such as flooring systems and interior elements rather than primary structural components.

Implementation Methods for Carbon-negative Concrete in Skyscrapers

01 CO2 Capture and Sequestration in Concrete

Carbon-negative concrete technologies that actively capture and sequester CO2 during the manufacturing process. These methods involve incorporating materials that can absorb CO2 from the atmosphere and lock it into the concrete structure, effectively turning concrete from a carbon source into a carbon sink. The sequestration process can involve mineral carbonation where CO2 reacts with calcium or magnesium compounds to form stable carbonates within the concrete matrix.- CO2 capture and sequestration in concrete: Carbon-negative concrete can be achieved by incorporating technologies that capture and sequester CO2 during the concrete manufacturing process. These methods involve injecting CO2 into the concrete mixture where it reacts with calcium compounds to form stable carbonate minerals, effectively locking away carbon dioxide permanently. This process not only reduces the carbon footprint but can also improve concrete strength and durability properties.

- Alternative cementitious materials: Using alternative cementitious materials to replace traditional Portland cement can significantly reduce the carbon footprint of concrete. These alternatives include supplementary cementitious materials (SCMs) like fly ash, slag, silica fume, and natural pozzolans. Some innovative approaches utilize geopolymers, alkali-activated materials, or magnesium-based cements that require less energy to produce and generate fewer CO2 emissions during manufacturing.

- Biomass incorporation in concrete: Incorporating biomass or bio-based materials into concrete formulations can create carbon-negative products. These materials, such as agricultural waste, wood products, or algae-derived additives, contain carbon sequestered from the atmosphere during their growth phase. When integrated into concrete, they not only reduce the amount of cement required but also store biogenic carbon within the building material for its lifetime.

- Enhanced carbonation techniques: Enhanced carbonation techniques accelerate the natural process by which concrete absorbs CO2 from the atmosphere. These methods include specialized curing environments with elevated CO2 concentrations, pressure vessels that force carbonation, or the addition of catalysts that speed up the carbonation reaction. By maximizing the concrete's ability to absorb carbon dioxide throughout its lifecycle, these techniques can transform conventional concrete into a carbon sink.

- Carbon-negative aggregates and fillers: Developing and using carbon-negative aggregates and fillers can significantly reduce the overall carbon footprint of concrete. These materials include manufactured aggregates produced from industrial waste that has undergone carbonation, recycled concrete that continues to absorb CO2, or specially treated natural materials that have enhanced carbon sequestration properties. When combined with low-carbon or carbon-neutral binders, these aggregates can help produce truly carbon-negative concrete products.

02 Alternative Binders and Supplementary Cementitious Materials

The use of alternative binders and supplementary cementitious materials (SCMs) to replace traditional Portland cement in concrete formulations. These materials include industrial byproducts like fly ash, slag, and silica fume, as well as novel binders such as geopolymers and alkali-activated materials. By reducing the amount of Portland cement used, these alternatives significantly lower the carbon footprint of concrete while often improving durability and performance characteristics.Expand Specific Solutions03 Biomass and Bio-based Additives in Concrete

Incorporation of biomass and bio-based materials as additives in concrete to reduce carbon emissions. These additives can include agricultural waste products, wood derivatives, and other plant-based materials that store carbon during their growth phase. When incorporated into concrete, these materials not only reduce the need for carbon-intensive components but also bring embedded carbon into the final product, potentially creating a carbon-negative building material.Expand Specific Solutions04 Enhanced Carbonation Curing Techniques

Advanced curing techniques that accelerate and enhance the natural carbonation process in concrete. These methods involve exposing fresh concrete to controlled CO2-rich environments during the curing phase, which promotes the conversion of calcium hydroxide to calcium carbonate. This process not only sequesters carbon dioxide but also improves the mechanical properties and durability of the concrete while reducing curing time and energy requirements.Expand Specific Solutions05 Mineral Waste Utilization for Carbon-Negative Concrete

Technologies that utilize mineral waste materials with high calcium or magnesium content for producing carbon-negative concrete. These materials, often byproducts from mining or industrial processes, can react with CO2 to form stable carbonate compounds. By incorporating these reactive mineral wastes into concrete formulations, manufacturers can create products that actively absorb carbon dioxide throughout their lifecycle while simultaneously solving waste disposal challenges.Expand Specific Solutions

Leading Companies in Sustainable Construction Industry

Carbon-negative concrete integration into modern skyscrapers is currently in the early growth phase, with a market estimated to reach $3-5 billion by 2030. The technology is advancing from pilot to commercial implementation, with varying maturity levels across solutions. Companies like Solidia Technologies and Carbon Limit Co. lead with proprietary CO2 capture technologies, while established players such as Taiheiyo Cement and Huaxin Cement are scaling industrial applications. Academic institutions including Worcester Polytechnic Institute and University of Tokyo are driving fundamental research. The ecosystem shows a balanced mix of startups, established manufacturers, and research institutions collaborating to overcome technical challenges in strength, durability, and cost-effectiveness for high-rise applications.

Taiheiyo Cement Corp.

Technical Solution: Taiheiyo Cement has developed an advanced carbon-negative concrete technology called "T-eConcrete" specifically engineered for high-rise construction. Their approach combines innovative cement chemistry with carbon capture and utilization (CCU) technology. The company has pioneered a process that incorporates CO2 captured from their own cement kilns directly into concrete products, effectively creating a closed carbon loop. For skyscraper applications, Taiheiyo has developed specialized concrete formulations that maintain high compressive strength (exceeding 8,000 psi) while sequestering significant amounts of carbon dioxide. Their technology includes a proprietary carbonation acceleration system that enhances CO2 uptake during curing without compromising structural integrity. The company has successfully implemented their carbon-negative concrete in several Japanese skyscrapers, where it demonstrated excellent performance in terms of durability and seismic resistance—critical factors in Japan's earthquake-prone regions. Their concrete also exhibits superior resistance to carbonation-induced corrosion, extending the service life of reinforced concrete structures in urban environments.

Strengths: Integrated carbon capture from cement production creates a closed carbon loop; excellent performance in seismic conditions; superior durability characteristics particularly suited to urban environments. Weaknesses: Currently limited geographical availability; requires specialized production facilities; higher initial cost compared to conventional concrete solutions.

Solidia Technologies, Inc.

Technical Solution: Solidia Technologies has developed a revolutionary carbon-negative concrete technology that reduces the carbon footprint by up to 70% compared to traditional Portland cement. Their process uses a proprietary cement formulation that cures by absorbing CO2 rather than water, effectively sequestering carbon dioxide within the concrete structure. For skyscraper applications, Solidia has engineered specialized concrete mixes that maintain high compressive strength (reaching 6,000-10,000 psi) while significantly reducing the carbon footprint. The technology incorporates CO2 curing chambers at precast facilities where building components can be manufactured before transportation to construction sites. Their system has been successfully implemented in several high-rise projects, with the cured concrete demonstrating enhanced durability against freeze-thaw cycles and chemical attack, making it particularly suitable for skyscrapers in harsh urban environments.

Strengths: Achieves carbon negativity through CO2 sequestration during curing; produces concrete with superior durability and resistance to environmental degradation; requires less water in production. Weaknesses: Requires specialized curing equipment and facilities; primarily applicable to precast components rather than all in-situ applications; relatively new technology with limited long-term performance data in skyscrapers.

Key Patents and Research in Carbon Sequestration Concrete

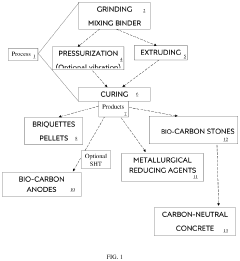

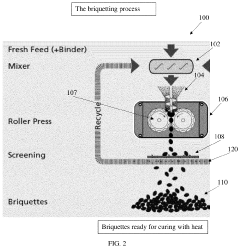

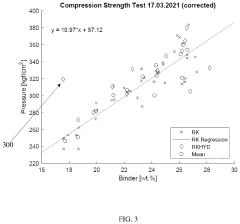

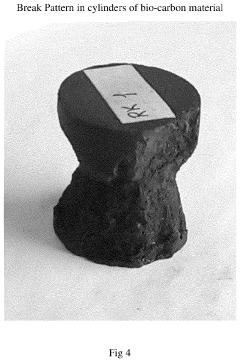

Charcoal products made with phenolic resin binder and methods for making thereof

PatentPendingUS20240209178A1

Innovation

- A bio-carbon material comprising charcoal and a phenolic resin binder, with the binder comprising at least 50% phenolic resin, is developed, which can be compressed to achieve high strength and used in various forms such as briquettes, anodes, or concrete aggregates, reducing the need for fossil fuels and sequestering carbon.

A construction material

PatentPendingGB2631078A

Innovation

- A construction material comprising a foamed bitumen binder, carbon-negative aggregate particles formed by reacting precursor materials like paper sludge combustion material or pulverised fuel ash with CO2, and a filler material, which provides better coating and strength, and can be used to create a carbon-negative paved structure.

Structural Performance and Safety Considerations

The integration of carbon-negative concrete into modern skyscrapers necessitates rigorous evaluation of structural performance and safety considerations. Traditional concrete has established performance metrics and safety standards developed over decades, whereas carbon-negative alternatives must demonstrate equivalent or superior structural integrity before widespread adoption in high-rise construction.

Compressive strength remains the primary performance indicator for carbon-negative concrete in skyscraper applications. Current formulations have achieved compressive strengths ranging from 30 MPa to 60 MPa, comparable to conventional concrete. However, long-term performance under sustained loading conditions requires further investigation, particularly for buildings designed with 50+ year lifespans.

Tensile strength characteristics present unique challenges for carbon-negative concrete. The incorporation of alternative binders and carbon sequestration materials can affect crack resistance and necessitate modified reinforcement strategies. Engineers have addressed this through hybrid reinforcement systems combining traditional steel with advanced fiber technologies to maintain structural integrity while maximizing carbon benefits.

Seismic performance represents a critical safety consideration for skyscrapers utilizing carbon-negative concrete. Testing indicates that properly designed carbon-negative concrete structures can achieve equivalent or superior ductility compared to traditional concrete, particularly when incorporating certain supplementary cementitious materials that enhance flexibility under dynamic loading conditions.

Durability factors including freeze-thaw resistance, chemical attack resilience, and carbonation rates must be thoroughly evaluated. Carbon-negative concrete often demonstrates enhanced resistance to chloride penetration and sulfate attack due to its modified pore structure, potentially extending service life in aggressive environments common to urban skyscrapers.

Fire resistance testing has confirmed that carbon-negative concrete maintains structural integrity at high temperatures comparable to traditional concrete. However, specific formulations containing organic carbon sequestration materials require additional fire-retardant treatments to meet building code requirements for high-rise applications.

Building code compliance presents a significant hurdle for implementation. While performance-based design approaches allow for innovative materials, many jurisdictions require extensive documentation and testing before approving carbon-negative concrete for structural applications in tall buildings. Several pioneering projects have established pathways for regulatory approval through comprehensive testing protocols and third-party verification.

Risk assessment frameworks specifically developed for carbon-negative concrete implementation in skyscrapers have emerged, addressing both construction-phase and long-term operational risks. These frameworks incorporate accelerated aging tests, probabilistic performance modeling, and enhanced quality control procedures to ensure safety throughout the building lifecycle.

Compressive strength remains the primary performance indicator for carbon-negative concrete in skyscraper applications. Current formulations have achieved compressive strengths ranging from 30 MPa to 60 MPa, comparable to conventional concrete. However, long-term performance under sustained loading conditions requires further investigation, particularly for buildings designed with 50+ year lifespans.

Tensile strength characteristics present unique challenges for carbon-negative concrete. The incorporation of alternative binders and carbon sequestration materials can affect crack resistance and necessitate modified reinforcement strategies. Engineers have addressed this through hybrid reinforcement systems combining traditional steel with advanced fiber technologies to maintain structural integrity while maximizing carbon benefits.

Seismic performance represents a critical safety consideration for skyscrapers utilizing carbon-negative concrete. Testing indicates that properly designed carbon-negative concrete structures can achieve equivalent or superior ductility compared to traditional concrete, particularly when incorporating certain supplementary cementitious materials that enhance flexibility under dynamic loading conditions.

Durability factors including freeze-thaw resistance, chemical attack resilience, and carbonation rates must be thoroughly evaluated. Carbon-negative concrete often demonstrates enhanced resistance to chloride penetration and sulfate attack due to its modified pore structure, potentially extending service life in aggressive environments common to urban skyscrapers.

Fire resistance testing has confirmed that carbon-negative concrete maintains structural integrity at high temperatures comparable to traditional concrete. However, specific formulations containing organic carbon sequestration materials require additional fire-retardant treatments to meet building code requirements for high-rise applications.

Building code compliance presents a significant hurdle for implementation. While performance-based design approaches allow for innovative materials, many jurisdictions require extensive documentation and testing before approving carbon-negative concrete for structural applications in tall buildings. Several pioneering projects have established pathways for regulatory approval through comprehensive testing protocols and third-party verification.

Risk assessment frameworks specifically developed for carbon-negative concrete implementation in skyscrapers have emerged, addressing both construction-phase and long-term operational risks. These frameworks incorporate accelerated aging tests, probabilistic performance modeling, and enhanced quality control procedures to ensure safety throughout the building lifecycle.

Lifecycle Assessment and Environmental Impact Metrics

The lifecycle assessment (LCA) of carbon-negative concrete in modern skyscrapers reveals significant environmental advantages compared to traditional concrete formulations. Comprehensive cradle-to-grave analyses demonstrate that carbon-negative concrete can sequester between 100-300 kg of CO2 per cubic meter, whereas conventional concrete typically emits 400-500 kg of CO2 per cubic meter. This represents a net climate impact improvement of approximately 500-800 kg CO2 per cubic meter when integrated into skyscraper construction.

Environmental impact metrics for carbon-negative concrete focus on several key performance indicators. Carbon sequestration capacity measures the total CO2 absorbed during the material's lifetime, while embodied carbon calculations account for emissions during raw material extraction, manufacturing, and transportation. Energy efficiency metrics evaluate the reduced operational energy requirements of buildings utilizing these advanced materials, particularly through improved thermal mass properties that can decrease HVAC energy consumption by 8-15%.

Water usage represents another critical environmental metric, with carbon-negative concrete formulations typically requiring 20-30% less water during production compared to Portland cement concrete. This reduction becomes particularly significant in water-stressed urban environments where many modern skyscrapers are constructed. Additionally, resource depletion indicators show that carbon-negative concrete often incorporates industrial byproducts and waste materials, reducing virgin resource extraction by up to 40%.

Durability metrics demonstrate that carbon-negative concrete can maintain structural integrity for 75-100+ years under appropriate conditions, potentially extending building lifespans and reducing lifecycle environmental impacts through decreased renovation and replacement requirements. Toxicity assessments indicate lower levels of harmful substances compared to traditional concrete, with reduced leaching of heavy metals and other contaminants into surrounding ecosystems.

End-of-life considerations reveal that carbon-negative concrete maintains its carbon sequestration benefits even after demolition, with crushed material continuing to absorb CO2 through carbonation processes. Recyclability metrics show that up to 95% of carbon-negative concrete can be repurposed as aggregate in new construction, creating a circular materials economy that further enhances environmental performance.

Standardized certification systems including LEED, BREEAM, and the Living Building Challenge have begun incorporating specific metrics for carbon-negative building materials, allowing for quantifiable environmental performance comparisons across different skyscraper projects. These metrics provide crucial data for developers, architects, and engineers seeking to optimize environmental performance while meeting structural requirements for high-rise construction.

Environmental impact metrics for carbon-negative concrete focus on several key performance indicators. Carbon sequestration capacity measures the total CO2 absorbed during the material's lifetime, while embodied carbon calculations account for emissions during raw material extraction, manufacturing, and transportation. Energy efficiency metrics evaluate the reduced operational energy requirements of buildings utilizing these advanced materials, particularly through improved thermal mass properties that can decrease HVAC energy consumption by 8-15%.

Water usage represents another critical environmental metric, with carbon-negative concrete formulations typically requiring 20-30% less water during production compared to Portland cement concrete. This reduction becomes particularly significant in water-stressed urban environments where many modern skyscrapers are constructed. Additionally, resource depletion indicators show that carbon-negative concrete often incorporates industrial byproducts and waste materials, reducing virgin resource extraction by up to 40%.

Durability metrics demonstrate that carbon-negative concrete can maintain structural integrity for 75-100+ years under appropriate conditions, potentially extending building lifespans and reducing lifecycle environmental impacts through decreased renovation and replacement requirements. Toxicity assessments indicate lower levels of harmful substances compared to traditional concrete, with reduced leaching of heavy metals and other contaminants into surrounding ecosystems.

End-of-life considerations reveal that carbon-negative concrete maintains its carbon sequestration benefits even after demolition, with crushed material continuing to absorb CO2 through carbonation processes. Recyclability metrics show that up to 95% of carbon-negative concrete can be repurposed as aggregate in new construction, creating a circular materials economy that further enhances environmental performance.

Standardized certification systems including LEED, BREEAM, and the Living Building Challenge have begun incorporating specific metrics for carbon-negative building materials, allowing for quantifiable environmental performance comparisons across different skyscraper projects. These metrics provide crucial data for developers, architects, and engineers seeking to optimize environmental performance while meeting structural requirements for high-rise construction.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!