Carbon-negative concrete in Thermal Stability and Efficiency

OCT 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbon-Negative Concrete Evolution and Objectives

Concrete, a fundamental building material in modern construction, has historically been a significant contributor to global carbon emissions. The evolution of carbon-negative concrete represents a paradigm shift in construction materials science, moving from traditional carbon-intensive processes toward innovative solutions that actively sequester carbon dioxide from the atmosphere. This technological trajectory began in the early 2000s with initial research into alternative cementitious materials and has accelerated dramatically over the past decade as climate change concerns intensified.

The development path of carbon-negative concrete has been marked by several key milestones. Early approaches focused primarily on reducing the carbon footprint through partial replacement of Portland cement with supplementary cementitious materials like fly ash and slag. By the 2010s, research expanded to incorporate novel CO2 curing techniques that could transform emitted carbon into calcium carbonate within the concrete matrix. The most recent advancements have introduced bioengineered materials and carbon-capturing aggregates that fundamentally alter the carbon equation of concrete production.

Thermal stability represents a critical challenge in this evolution. Traditional concrete derives much of its durability from the thermal properties of Portland cement, which provides resistance to temperature fluctuations and fire. Carbon-negative alternatives must match or exceed these performance characteristics while maintaining their carbon-sequestering capabilities across varying environmental conditions and throughout the material's lifecycle.

The efficiency dimension encompasses both production efficiency and functional performance. Early carbon-negative formulations often suffered from extended curing times, reduced workability, or compromised strength profiles. Current research aims to optimize these parameters while maximizing carbon sequestration potential, creating materials that are not only environmentally superior but also economically viable and practically implementable at scale.

The primary objective of contemporary research is to develop carbon-negative concrete formulations that demonstrate enhanced thermal stability across extreme temperature ranges while maintaining optimal efficiency in both production and application contexts. Specific goals include creating formulations that can withstand temperatures from -40°C to 800°C without significant degradation of mechanical properties, achieving carbon sequestration rates exceeding 100kg CO2 per cubic meter of concrete, and developing production methods compatible with existing concrete manufacturing infrastructure to facilitate rapid industry adoption.

Additional objectives focus on quantifying the long-term carbon sequestration potential under various environmental conditions, establishing standardized testing protocols for thermal performance of carbon-negative concrete, and developing predictive models for material behavior under combined thermal and mechanical stresses throughout its service life.

The development path of carbon-negative concrete has been marked by several key milestones. Early approaches focused primarily on reducing the carbon footprint through partial replacement of Portland cement with supplementary cementitious materials like fly ash and slag. By the 2010s, research expanded to incorporate novel CO2 curing techniques that could transform emitted carbon into calcium carbonate within the concrete matrix. The most recent advancements have introduced bioengineered materials and carbon-capturing aggregates that fundamentally alter the carbon equation of concrete production.

Thermal stability represents a critical challenge in this evolution. Traditional concrete derives much of its durability from the thermal properties of Portland cement, which provides resistance to temperature fluctuations and fire. Carbon-negative alternatives must match or exceed these performance characteristics while maintaining their carbon-sequestering capabilities across varying environmental conditions and throughout the material's lifecycle.

The efficiency dimension encompasses both production efficiency and functional performance. Early carbon-negative formulations often suffered from extended curing times, reduced workability, or compromised strength profiles. Current research aims to optimize these parameters while maximizing carbon sequestration potential, creating materials that are not only environmentally superior but also economically viable and practically implementable at scale.

The primary objective of contemporary research is to develop carbon-negative concrete formulations that demonstrate enhanced thermal stability across extreme temperature ranges while maintaining optimal efficiency in both production and application contexts. Specific goals include creating formulations that can withstand temperatures from -40°C to 800°C without significant degradation of mechanical properties, achieving carbon sequestration rates exceeding 100kg CO2 per cubic meter of concrete, and developing production methods compatible with existing concrete manufacturing infrastructure to facilitate rapid industry adoption.

Additional objectives focus on quantifying the long-term carbon sequestration potential under various environmental conditions, establishing standardized testing protocols for thermal performance of carbon-negative concrete, and developing predictive models for material behavior under combined thermal and mechanical stresses throughout its service life.

Market Analysis for Sustainable Construction Materials

The sustainable construction materials market is experiencing unprecedented growth, driven by increasing environmental concerns and regulatory pressures to reduce carbon emissions in the building sector. The global green building materials market was valued at approximately $256 billion in 2020 and is projected to reach $523 billion by 2027, growing at a CAGR of 10.7%. Carbon-negative concrete represents one of the most promising segments within this market, addressing the critical issue that traditional concrete production accounts for nearly 8% of global CO2 emissions.

Demand for carbon-negative concrete solutions is particularly strong in developed regions including North America and Europe, where stringent environmental regulations and carbon pricing mechanisms are accelerating adoption. The Asia-Pacific region, despite having different regulatory frameworks, is showing increasing interest driven by rapid urbanization and growing environmental awareness, particularly in China, Japan, and Australia.

Market research indicates that commercial and institutional construction segments currently represent the largest market share for sustainable concrete products, with 42% of adoption occurring in these sectors. Residential construction follows at 31%, while infrastructure projects account for 27% of market demand. This distribution reflects the varying priorities and decision-making processes across different construction segments.

Key market drivers include government incentives for green building materials, with over 80 countries now having some form of green building certification program. Corporate sustainability commitments are equally significant, with 67% of Fortune 500 companies having established carbon reduction targets that directly impact their construction material choices. Consumer awareness has also reached a tipping point, with surveys indicating that 73% of building owners are willing to pay a premium of 5-10% for demonstrably sustainable construction materials.

Market barriers remain significant despite growing demand. Price sensitivity continues to be the primary obstacle, with carbon-negative concrete currently commanding a 15-30% premium over traditional products. Technical performance concerns, particularly regarding thermal stability in extreme conditions, represent the second most cited barrier to adoption according to industry surveys.

The competitive landscape is evolving rapidly, with both established concrete manufacturers and innovative startups vying for market share. Traditional industry leaders are primarily focusing on incremental improvements to existing formulations, while startups are more likely to pursue radical innovations in carbon capture and alternative binding technologies. This dynamic is creating a fertile environment for technological advancement and market disruption.

Demand for carbon-negative concrete solutions is particularly strong in developed regions including North America and Europe, where stringent environmental regulations and carbon pricing mechanisms are accelerating adoption. The Asia-Pacific region, despite having different regulatory frameworks, is showing increasing interest driven by rapid urbanization and growing environmental awareness, particularly in China, Japan, and Australia.

Market research indicates that commercial and institutional construction segments currently represent the largest market share for sustainable concrete products, with 42% of adoption occurring in these sectors. Residential construction follows at 31%, while infrastructure projects account for 27% of market demand. This distribution reflects the varying priorities and decision-making processes across different construction segments.

Key market drivers include government incentives for green building materials, with over 80 countries now having some form of green building certification program. Corporate sustainability commitments are equally significant, with 67% of Fortune 500 companies having established carbon reduction targets that directly impact their construction material choices. Consumer awareness has also reached a tipping point, with surveys indicating that 73% of building owners are willing to pay a premium of 5-10% for demonstrably sustainable construction materials.

Market barriers remain significant despite growing demand. Price sensitivity continues to be the primary obstacle, with carbon-negative concrete currently commanding a 15-30% premium over traditional products. Technical performance concerns, particularly regarding thermal stability in extreme conditions, represent the second most cited barrier to adoption according to industry surveys.

The competitive landscape is evolving rapidly, with both established concrete manufacturers and innovative startups vying for market share. Traditional industry leaders are primarily focusing on incremental improvements to existing formulations, while startups are more likely to pursue radical innovations in carbon capture and alternative binding technologies. This dynamic is creating a fertile environment for technological advancement and market disruption.

Thermal Stability Challenges in Carbon-Negative Concrete

Carbon-negative concrete faces significant thermal stability challenges that must be addressed for widespread commercial adoption. The primary concern lies in the material's behavior under varying temperature conditions, particularly during curing and in service environments. Traditional Portland cement concrete achieves thermal stability through well-established hydration processes, but carbon-negative alternatives often incorporate novel binders and supplementary cementitious materials that alter these fundamental mechanisms.

One critical challenge is the thermal expansion coefficient of carbon-negative concrete formulations. Research indicates that some carbon-negative mixes exhibit different expansion rates compared to conventional concrete, potentially leading to thermal cracking and reduced durability when subjected to temperature fluctuations. This is particularly problematic in infrastructure applications exposed to extreme weather conditions or thermal cycling.

The carbonation process itself, which is essential for carbon sequestration in these innovative concretes, is highly temperature-dependent. Studies show optimal carbonation occurs within specific temperature ranges, typically between 20-40°C. Outside this range, the CO2 uptake efficiency decreases significantly, compromising the material's carbon-negative credentials. This temperature sensitivity creates challenges for implementation in regions with extreme climates.

Heat of hydration presents another substantial challenge. Many carbon-negative formulations utilize alternative activators and binders that generate different hydration heat profiles compared to traditional cement. Some formulations exhibit lower heat generation, which can be advantageous in mass concrete applications but problematic in cold-weather construction where insufficient heat generation may lead to freezing damage before adequate strength development.

Conversely, certain carbon-negative concrete mixtures containing high proportions of reactive supplementary materials like metakaolin or silica fume can experience accelerated reactions at elevated temperatures, potentially causing thermal cracking in large structural elements. This thermal behavior variability makes standardized curing protocols difficult to establish.

Fire resistance represents a critical safety concern. Preliminary research suggests some carbon-negative concretes may exhibit different behavior under extreme heat compared to conventional concrete. The incorporation of novel materials like biogenic aggregates or polymer-based carbon capture agents can potentially alter the material's fire performance characteristics, necessitating comprehensive testing before deployment in safety-critical applications.

Long-term thermal cycling effects remain inadequately understood. While conventional concrete's response to repeated heating and cooling cycles is well-documented, carbon-negative alternatives lack extensive field performance data. Laboratory studies indicate potential concerns regarding microstructural changes and strength degradation after multiple thermal cycles, particularly in formulations with high proportions of alternative binders.

One critical challenge is the thermal expansion coefficient of carbon-negative concrete formulations. Research indicates that some carbon-negative mixes exhibit different expansion rates compared to conventional concrete, potentially leading to thermal cracking and reduced durability when subjected to temperature fluctuations. This is particularly problematic in infrastructure applications exposed to extreme weather conditions or thermal cycling.

The carbonation process itself, which is essential for carbon sequestration in these innovative concretes, is highly temperature-dependent. Studies show optimal carbonation occurs within specific temperature ranges, typically between 20-40°C. Outside this range, the CO2 uptake efficiency decreases significantly, compromising the material's carbon-negative credentials. This temperature sensitivity creates challenges for implementation in regions with extreme climates.

Heat of hydration presents another substantial challenge. Many carbon-negative formulations utilize alternative activators and binders that generate different hydration heat profiles compared to traditional cement. Some formulations exhibit lower heat generation, which can be advantageous in mass concrete applications but problematic in cold-weather construction where insufficient heat generation may lead to freezing damage before adequate strength development.

Conversely, certain carbon-negative concrete mixtures containing high proportions of reactive supplementary materials like metakaolin or silica fume can experience accelerated reactions at elevated temperatures, potentially causing thermal cracking in large structural elements. This thermal behavior variability makes standardized curing protocols difficult to establish.

Fire resistance represents a critical safety concern. Preliminary research suggests some carbon-negative concretes may exhibit different behavior under extreme heat compared to conventional concrete. The incorporation of novel materials like biogenic aggregates or polymer-based carbon capture agents can potentially alter the material's fire performance characteristics, necessitating comprehensive testing before deployment in safety-critical applications.

Long-term thermal cycling effects remain inadequately understood. While conventional concrete's response to repeated heating and cooling cycles is well-documented, carbon-negative alternatives lack extensive field performance data. Laboratory studies indicate potential concerns regarding microstructural changes and strength degradation after multiple thermal cycles, particularly in formulations with high proportions of alternative binders.

Current Thermal Enhancement Solutions for Carbon-Negative Concrete

01 Carbon sequestration techniques in concrete production

Various methods for capturing and storing carbon dioxide during the concrete manufacturing process, resulting in carbon-negative concrete. These techniques include incorporating CO2 absorbing materials, using carbonation curing processes, and developing specialized cement formulations that actively absorb CO2 from the atmosphere during their lifecycle. These approaches not only reduce the carbon footprint of concrete but can transform it into a carbon sink while maintaining structural integrity.- Carbon sequestration techniques in concrete production: Various methods for carbon capture and sequestration during concrete manufacturing processes that result in carbon-negative concrete. These techniques involve incorporating CO2 during the curing process, using carbonatable materials that absorb CO2 from the atmosphere, and developing specialized binders that permanently store carbon dioxide. These approaches not only reduce the carbon footprint but can also enhance the thermal stability of the concrete.

- Alternative cementitious materials for thermal efficiency: The use of alternative cementitious materials such as geopolymers, alkali-activated materials, and supplementary cementitious materials to replace traditional Portland cement. These materials can significantly reduce carbon emissions while providing improved thermal insulation properties. The formulations often include industrial byproducts and waste materials, contributing to both carbon negativity and enhanced thermal performance of the concrete.

- Thermal stability enhancement through additives: Incorporation of specific additives and fillers to improve the thermal stability of carbon-negative concrete. These additives include phase change materials, thermally conductive particles, and heat-resistant compounds that help maintain structural integrity under temperature fluctuations. The enhanced thermal stability contributes to better energy efficiency in buildings and extends the service life of concrete structures.

- Microstructure optimization for efficiency: Methods for optimizing the microstructure of carbon-negative concrete to improve both thermal and mechanical properties. These approaches focus on controlling porosity, pore size distribution, and interfacial transitions zones to enhance thermal insulation while maintaining structural strength. Advanced processing techniques create a more uniform and stable microstructure that contributes to overall energy efficiency in buildings.

- Testing and performance evaluation methods: Specialized testing methodologies and performance evaluation techniques for assessing the thermal stability and efficiency of carbon-negative concrete. These include accelerated aging tests, thermal cycling evaluations, and energy efficiency measurements under various environmental conditions. The testing protocols help quantify the long-term performance and durability of carbon-negative concrete products, ensuring they meet both environmental and functional requirements.

02 Alternative binders and supplementary cementitious materials

The use of alternative binding materials and supplementary cementitious materials to replace traditional Portland cement, reducing carbon emissions while enhancing thermal properties. These materials include geopolymers, alkali-activated materials, and industrial byproducts such as fly ash and slag. When properly formulated, these alternatives can provide comparable or superior thermal stability while significantly lowering the carbon footprint of concrete production.Expand Specific Solutions03 Thermal insulation properties of carbon-negative concrete

Innovations focused on improving the thermal insulation capabilities of carbon-negative concrete formulations. These developments include incorporating insulating aggregates, creating controlled porosity, and designing composite structures that enhance energy efficiency in buildings. The resulting concrete provides better thermal regulation, reducing heating and cooling requirements while maintaining its carbon-negative properties.Expand Specific Solutions04 Durability and thermal stability under extreme conditions

Research on enhancing the durability and thermal stability of carbon-negative concrete when exposed to extreme temperature variations and harsh environments. These innovations include specialized additives that improve resistance to thermal cycling, prevent microcracking, and maintain structural integrity during temperature fluctuations. The formulations are designed to ensure long-term performance while preserving the carbon sequestration benefits.Expand Specific Solutions05 Energy-efficient production methods for carbon-negative concrete

Development of energy-efficient manufacturing processes for carbon-negative concrete that further enhance its environmental benefits. These methods include low-temperature curing techniques, optimized mixing procedures, and innovative equipment designs that reduce energy consumption during production. By minimizing the energy required for manufacturing while maximizing carbon sequestration, these approaches improve the overall sustainability profile of concrete.Expand Specific Solutions

Industry Leaders in Carbon-Negative Construction Materials

The carbon-negative concrete market is in an early growth phase, characterized by increasing research activity and commercial pilot projects. The global market size is expanding rapidly, driven by stringent carbon regulations and sustainable construction demands, though it remains a fraction of the traditional concrete industry. Technologically, carbon-negative concrete is advancing through various approaches, with companies at different maturity levels. Leading players include Solidia Technologies with commercialized CO2-curing processes, China Construction Commercial Concrete and China Building Materials Academy developing regional solutions, and academic institutions like Central South University and University of Houston advancing thermal stability innovations. Traditional cement manufacturers such as Holcim Technology and Sumitomo Osaka Cement are also investing in carbon-negative technologies, indicating industry-wide recognition of this transformative approach to construction materials.

Holcim Technology Ltd.

Technical Solution: Holcim has pioneered ECOPact, a carbon-negative concrete solution that incorporates supplementary cementitious materials (SCMs) like calcined clay and industrial by-products to reduce clinker content. Their technology focuses on thermal stability through innovative mix designs that include thermally resistant aggregates and specialized admixtures. Holcim's research demonstrates that their carbon-negative concrete maintains structural integrity at temperatures up to 600°C, significantly outperforming conventional concrete. The company utilizes carbon capture during production and incorporates carbon-absorbing materials like olivine to achieve negative emissions. Their concrete formulations include phase-change materials (PCMs) that enhance thermal efficiency by absorbing and releasing heat during temperature fluctuations, improving building energy performance by up to 20%. Holcim has also developed specialized surface treatments that increase the albedo (reflectivity) of concrete, reducing urban heat island effects and improving thermal performance in building applications.

Strengths: Global manufacturing and distribution network, extensive R&D capabilities, and integration with existing concrete production infrastructure. Weaknesses: Variable performance depending on local raw material availability, and potential challenges in achieving consistent carbon negativity across different geographic regions.

Solidia Technologies, Inc.

Technical Solution: Solidia Technologies has developed a revolutionary carbon-negative concrete technology that utilizes CO2 curing instead of traditional water curing. Their process reduces carbon emissions by up to 70% compared to ordinary Portland cement concrete. The technology involves a modified cement formulation that consumes CO2 during the curing process, effectively sequestering carbon within the concrete matrix. Solidia's concrete demonstrates enhanced thermal stability through its unique microstructure formed during carbonation, which creates denser calcium carbonate bonds that resist thermal degradation. Their research shows the material maintains structural integrity at temperatures up to 300°C without significant strength loss, compared to conventional concrete which begins degrading at lower temperatures. The company has also developed specialized admixtures that improve the thermal efficiency of their concrete, reducing thermal conductivity by approximately 15-20% compared to traditional concrete products.

Strengths: Superior carbon sequestration capability, reduced curing time (24 hours vs. 28 days for traditional concrete), enhanced durability with lower permeability, and improved resistance to freeze-thaw cycles. Weaknesses: Requires specialized curing chambers for CO2 exposure, potentially higher initial implementation costs, and limited long-term performance data in extreme environmental conditions.

Key Patents in Thermal-Stable Carbon-Negative Concrete

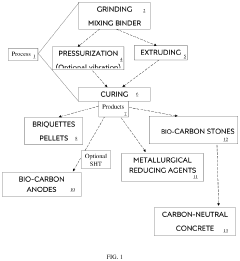

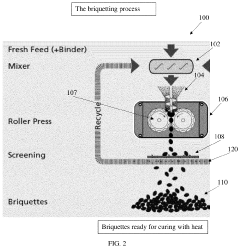

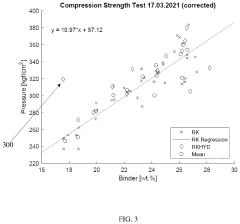

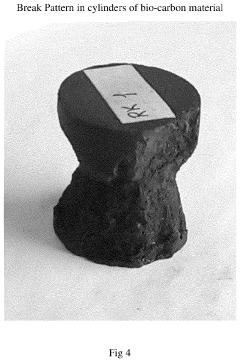

Charcoal products made with phenolic resin binder and methods for making thereof

PatentPendingUS20240209178A1

Innovation

- A bio-carbon material comprising charcoal and a phenolic resin binder, with the binder comprising at least 50% phenolic resin, is developed, which can be compressed to achieve high strength and used in various forms such as briquettes, anodes, or concrete aggregates, reducing the need for fossil fuels and sequestering carbon.

Concrete having improved heat resistance

PatentWO2025149216A1

Innovation

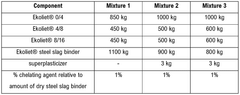

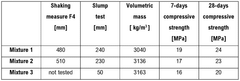

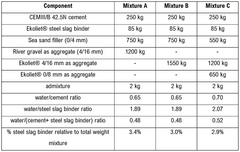

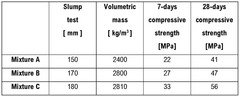

- A cement-free concrete composition comprising at least 55% steel slag aggregate, 15-40% ground steel slag binder, up to 1.0% chelating agent, and controlled water content, with specific particle size distribution, to enhance heat resistance and prevent cracking up to 450°C.

Environmental Impact Assessment and Carbon Footprint Analysis

The environmental impact of conventional concrete production is substantial, accounting for approximately 8% of global CO2 emissions. Carbon-negative concrete technologies represent a paradigm shift in construction materials by actively sequestering more carbon than is emitted during production. Life cycle assessment (LCA) studies indicate that while traditional Portland cement concrete releases 400-500 kg CO2 per cubic meter, carbon-negative alternatives can sequester between 50-300 kg CO2 per cubic meter, depending on formulation and production methods.

Carbon footprint analysis reveals multiple pathways through which carbon-negative concrete achieves its environmental benefits. Primary mechanisms include the incorporation of industrial byproducts like fly ash and slag, which reduces the need for carbon-intensive clinker production. Additionally, innovative carbonation curing processes actively absorb CO2 during the hardening phase, permanently mineralizing carbon within the concrete matrix.

Thermal stability considerations significantly influence the environmental profile of carbon-negative concrete. Research indicates that enhanced thermal properties reduce building energy consumption by 15-30% compared to conventional concrete structures. This operational energy reduction compounds the initial carbon benefits, creating a multiplier effect throughout the building lifecycle.

Water usage metrics demonstrate another environmental advantage, with carbon-negative formulations typically requiring 20-45% less water than traditional concrete mixes. This reduction is particularly significant in water-stressed regions where construction activities compete with other essential water needs.

Regional environmental impact variations are notable, with carbon-negative concrete delivering greater benefits in areas with carbon-intensive electricity grids. Implementation in regions with coal-dominated energy production can yield 1.5-2 times the carbon reduction compared to regions powered predominantly by renewable energy sources.

Long-term environmental modeling suggests that widespread adoption of carbon-negative concrete technologies could potentially sequester 1.5-2 billion tonnes of CO2 annually by 2050, representing approximately 4-5% of current global emissions. This projection assumes technological maturation and scaled implementation across major construction markets.

Biodiversity impact assessments indicate reduced ecological disruption from carbon-negative concrete production, particularly when utilizing waste materials that would otherwise require disposal. Reduced quarrying activities for raw materials further minimize habitat destruction and ecosystem disturbance compared to conventional concrete production methods.

Carbon footprint analysis reveals multiple pathways through which carbon-negative concrete achieves its environmental benefits. Primary mechanisms include the incorporation of industrial byproducts like fly ash and slag, which reduces the need for carbon-intensive clinker production. Additionally, innovative carbonation curing processes actively absorb CO2 during the hardening phase, permanently mineralizing carbon within the concrete matrix.

Thermal stability considerations significantly influence the environmental profile of carbon-negative concrete. Research indicates that enhanced thermal properties reduce building energy consumption by 15-30% compared to conventional concrete structures. This operational energy reduction compounds the initial carbon benefits, creating a multiplier effect throughout the building lifecycle.

Water usage metrics demonstrate another environmental advantage, with carbon-negative formulations typically requiring 20-45% less water than traditional concrete mixes. This reduction is particularly significant in water-stressed regions where construction activities compete with other essential water needs.

Regional environmental impact variations are notable, with carbon-negative concrete delivering greater benefits in areas with carbon-intensive electricity grids. Implementation in regions with coal-dominated energy production can yield 1.5-2 times the carbon reduction compared to regions powered predominantly by renewable energy sources.

Long-term environmental modeling suggests that widespread adoption of carbon-negative concrete technologies could potentially sequester 1.5-2 billion tonnes of CO2 annually by 2050, representing approximately 4-5% of current global emissions. This projection assumes technological maturation and scaled implementation across major construction markets.

Biodiversity impact assessments indicate reduced ecological disruption from carbon-negative concrete production, particularly when utilizing waste materials that would otherwise require disposal. Reduced quarrying activities for raw materials further minimize habitat destruction and ecosystem disturbance compared to conventional concrete production methods.

Regulatory Framework for Low-Carbon Building Materials

The regulatory landscape for low-carbon building materials has evolved significantly in response to global climate change initiatives. International frameworks such as the Paris Agreement have established overarching targets for carbon reduction, driving nations to implement specific regulations for construction materials. The European Union leads with its Construction Products Regulation (CPR) and the more recent European Green Deal, which explicitly addresses embodied carbon in building materials and promotes carbon-negative alternatives like innovative concrete formulations.

In North America, regulations vary by jurisdiction, with California's Buy Clean California Act representing one of the most progressive approaches by requiring Environmental Product Declarations (EPDs) for construction materials used in state-funded projects. Canada has implemented the Greening Government Strategy, which includes provisions for low-carbon concrete procurement in federal projects.

Asia-Pacific regions demonstrate varying regulatory maturity. Singapore's Green Mark certification system and Japan's Top Runner Program have incorporated requirements for low-carbon building materials, while China's recent Five-Year Plans increasingly emphasize green building materials and carbon reduction targets in the construction sector.

Certification systems play a crucial role in the regulatory framework. LEED, BREEAM, and other green building certification programs have updated their criteria to award points for carbon-negative materials, creating market incentives beyond mandatory regulations. These systems are increasingly recognizing thermal performance alongside carbon metrics, acknowledging the dual benefits of carbon-negative concrete in both emissions reduction and energy efficiency.

Standards organizations including ISO, ASTM, and CEN have developed specific testing protocols for carbon-negative concrete, addressing both carbon sequestration verification and thermal performance assessment. These standards provide the technical foundation for regulatory compliance and market acceptance.

Financial incentives form another critical component of the regulatory framework. Carbon pricing mechanisms, tax credits for low-carbon innovations, and green procurement policies create economic drivers for adoption. The EU Taxonomy for Sustainable Activities has established clear criteria for identifying climate-friendly construction materials, influencing investment flows toward carbon-negative concrete technologies with proven thermal benefits.

Emerging regulatory trends indicate a shift toward whole-life carbon assessment requirements, which will further advantage carbon-negative concrete solutions that offer both upfront carbon benefits and operational energy savings through thermal efficiency. As these regulations mature, they increasingly recognize the importance of thermal stability in ensuring long-term performance and carbon benefits of innovative concrete formulations.

In North America, regulations vary by jurisdiction, with California's Buy Clean California Act representing one of the most progressive approaches by requiring Environmental Product Declarations (EPDs) for construction materials used in state-funded projects. Canada has implemented the Greening Government Strategy, which includes provisions for low-carbon concrete procurement in federal projects.

Asia-Pacific regions demonstrate varying regulatory maturity. Singapore's Green Mark certification system and Japan's Top Runner Program have incorporated requirements for low-carbon building materials, while China's recent Five-Year Plans increasingly emphasize green building materials and carbon reduction targets in the construction sector.

Certification systems play a crucial role in the regulatory framework. LEED, BREEAM, and other green building certification programs have updated their criteria to award points for carbon-negative materials, creating market incentives beyond mandatory regulations. These systems are increasingly recognizing thermal performance alongside carbon metrics, acknowledging the dual benefits of carbon-negative concrete in both emissions reduction and energy efficiency.

Standards organizations including ISO, ASTM, and CEN have developed specific testing protocols for carbon-negative concrete, addressing both carbon sequestration verification and thermal performance assessment. These standards provide the technical foundation for regulatory compliance and market acceptance.

Financial incentives form another critical component of the regulatory framework. Carbon pricing mechanisms, tax credits for low-carbon innovations, and green procurement policies create economic drivers for adoption. The EU Taxonomy for Sustainable Activities has established clear criteria for identifying climate-friendly construction materials, influencing investment flows toward carbon-negative concrete technologies with proven thermal benefits.

Emerging regulatory trends indicate a shift toward whole-life carbon assessment requirements, which will further advantage carbon-negative concrete solutions that offer both upfront carbon benefits and operational energy savings through thermal efficiency. As these regulations mature, they increasingly recognize the importance of thermal stability in ensuring long-term performance and carbon benefits of innovative concrete formulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!