Analyzing GDI Engine Idle Smoothness with Data

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI Engine Idle Smoothness Background and Objectives

Gasoline Direct Injection (GDI) engine technology has evolved significantly over the past three decades, revolutionizing internal combustion engine efficiency and performance. The technology first emerged in the late 1990s as a commercial solution but has seen accelerated adoption since 2010 due to increasingly stringent emissions regulations and fuel economy standards worldwide. GDI engines inject fuel directly into the combustion chamber rather than the intake port, allowing for precise control of the fuel-air mixture and combustion timing.

Idle smoothness represents a critical quality metric for modern engines, directly impacting customer satisfaction and perceived vehicle quality. During idle, when engine speeds are low (typically 600-900 RPM), even minor combustion irregularities become noticeable to occupants as vibration or sound disturbances. The technical challenge lies in maintaining consistent cylinder-to-cylinder combustion events at these low speeds, particularly with GDI systems where fuel atomization and mixing dynamics are more complex than in traditional port fuel injection.

The evolution of GDI technology has introduced specific challenges to idle smoothness, including cycle-to-cycle combustion variations, cylinder-to-cylinder imbalances, and cold-start instabilities. These challenges stem from the fundamental physics of direct injection, where wall wetting, spray pattern variations, and charge stratification can significantly impact combustion stability at idle conditions.

Data-driven analysis has emerged as an essential approach to understanding and optimizing GDI engine idle performance. Modern engines generate vast amounts of data through numerous sensors monitoring parameters such as crankshaft speed fluctuations, cylinder pressure, exhaust gas composition, and vibration characteristics. Advanced analytics techniques now enable engineers to extract meaningful patterns from this complex data landscape.

The primary objective of this technical research is to establish a comprehensive framework for analyzing GDI engine idle smoothness using data-driven methodologies. This includes developing robust metrics for quantifying idle quality, identifying key contributing factors to idle roughness, and creating predictive models that can guide engineering decisions during engine development and calibration phases.

Secondary objectives include mapping the correlation between subjective human perception of idle quality and objective measurable parameters, establishing benchmark standards across different vehicle segments and markets, and exploring how emerging technologies like artificial intelligence and machine learning can enhance idle smoothness analysis and optimization processes.

This research aims to bridge the gap between theoretical combustion physics and practical engineering solutions by leveraging the power of data analytics to decode the complex, multivariable nature of GDI engine idle behavior. The ultimate goal is to enable more efficient development cycles and superior idle quality in next-generation GDI powertrains.

Idle smoothness represents a critical quality metric for modern engines, directly impacting customer satisfaction and perceived vehicle quality. During idle, when engine speeds are low (typically 600-900 RPM), even minor combustion irregularities become noticeable to occupants as vibration or sound disturbances. The technical challenge lies in maintaining consistent cylinder-to-cylinder combustion events at these low speeds, particularly with GDI systems where fuel atomization and mixing dynamics are more complex than in traditional port fuel injection.

The evolution of GDI technology has introduced specific challenges to idle smoothness, including cycle-to-cycle combustion variations, cylinder-to-cylinder imbalances, and cold-start instabilities. These challenges stem from the fundamental physics of direct injection, where wall wetting, spray pattern variations, and charge stratification can significantly impact combustion stability at idle conditions.

Data-driven analysis has emerged as an essential approach to understanding and optimizing GDI engine idle performance. Modern engines generate vast amounts of data through numerous sensors monitoring parameters such as crankshaft speed fluctuations, cylinder pressure, exhaust gas composition, and vibration characteristics. Advanced analytics techniques now enable engineers to extract meaningful patterns from this complex data landscape.

The primary objective of this technical research is to establish a comprehensive framework for analyzing GDI engine idle smoothness using data-driven methodologies. This includes developing robust metrics for quantifying idle quality, identifying key contributing factors to idle roughness, and creating predictive models that can guide engineering decisions during engine development and calibration phases.

Secondary objectives include mapping the correlation between subjective human perception of idle quality and objective measurable parameters, establishing benchmark standards across different vehicle segments and markets, and exploring how emerging technologies like artificial intelligence and machine learning can enhance idle smoothness analysis and optimization processes.

This research aims to bridge the gap between theoretical combustion physics and practical engineering solutions by leveraging the power of data analytics to decode the complex, multivariable nature of GDI engine idle behavior. The ultimate goal is to enable more efficient development cycles and superior idle quality in next-generation GDI powertrains.

Market Requirements for Engine Idle Quality

Engine idle quality has emerged as a critical differentiator in the automotive market, with consumers increasingly demanding refined driving experiences across all vehicle segments. Market research indicates that idle smoothness ranks among the top five factors influencing customer satisfaction and brand perception in mature markets. Premium segment customers expect near-imperceptible idle vibrations, while even economy segment buyers now consider smooth idle operation a baseline requirement rather than a luxury feature.

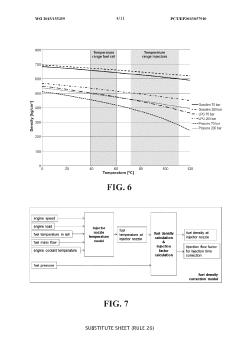

Vehicle manufacturers face mounting pressure to deliver consistent idle quality across diverse operating conditions. Temperature variations, from extreme cold starts to high-temperature operation, must not compromise idle stability. Additionally, accessory loads such as air conditioning, power steering, and electrical systems should minimally impact idle smoothness. This requirement presents significant engineering challenges, particularly for downsized GDI engines that inherently produce more vibration than their larger counterparts.

Regional market differences significantly impact idle quality requirements. European consumers typically prioritize refinement and are willing to pay premium prices for smoother idle characteristics. North American buyers expect consistent idle performance across a wider range of ambient conditions, while emerging markets increasingly demand idle quality comparable to established markets despite cost constraints. These regional variations necessitate tailored calibration strategies for global platforms.

Regulatory frameworks indirectly influence idle quality requirements through emissions standards. Low-emission calibrations often result in leaner combustion and more aggressive fuel cut-off strategies, which can adversely affect idle stability. The industry trend toward start-stop systems further complicates idle quality management, as the frequent engine restarts must occur seamlessly without perceptible vibration or hesitation.

Competitive benchmarking reveals that Japanese manufacturers have historically led in idle refinement, with European premium brands closing the gap in recent years. Chinese domestic manufacturers have made remarkable progress in idle quality, challenging established global players. This competitive landscape has established de facto market standards that all manufacturers must meet to remain competitive.

The economic impact of idle quality issues extends beyond customer satisfaction to warranty costs and brand reputation. Industry data suggests that idle-related complaints account for approximately 15% of powertrain-related dealer visits, with significant associated warranty expenses. Furthermore, social media and online reviews have amplified the visibility of idle quality issues, making them increasingly influential in purchase decisions.

Vehicle manufacturers face mounting pressure to deliver consistent idle quality across diverse operating conditions. Temperature variations, from extreme cold starts to high-temperature operation, must not compromise idle stability. Additionally, accessory loads such as air conditioning, power steering, and electrical systems should minimally impact idle smoothness. This requirement presents significant engineering challenges, particularly for downsized GDI engines that inherently produce more vibration than their larger counterparts.

Regional market differences significantly impact idle quality requirements. European consumers typically prioritize refinement and are willing to pay premium prices for smoother idle characteristics. North American buyers expect consistent idle performance across a wider range of ambient conditions, while emerging markets increasingly demand idle quality comparable to established markets despite cost constraints. These regional variations necessitate tailored calibration strategies for global platforms.

Regulatory frameworks indirectly influence idle quality requirements through emissions standards. Low-emission calibrations often result in leaner combustion and more aggressive fuel cut-off strategies, which can adversely affect idle stability. The industry trend toward start-stop systems further complicates idle quality management, as the frequent engine restarts must occur seamlessly without perceptible vibration or hesitation.

Competitive benchmarking reveals that Japanese manufacturers have historically led in idle refinement, with European premium brands closing the gap in recent years. Chinese domestic manufacturers have made remarkable progress in idle quality, challenging established global players. This competitive landscape has established de facto market standards that all manufacturers must meet to remain competitive.

The economic impact of idle quality issues extends beyond customer satisfaction to warranty costs and brand reputation. Industry data suggests that idle-related complaints account for approximately 15% of powertrain-related dealer visits, with significant associated warranty expenses. Furthermore, social media and online reviews have amplified the visibility of idle quality issues, making them increasingly influential in purchase decisions.

Current GDI Engine Idle Smoothness Challenges

Gasoline Direct Injection (GDI) engines, despite their advantages in fuel efficiency and performance, continue to face significant challenges in maintaining optimal idle smoothness. Current data analysis reveals that combustion instability during idle conditions remains a persistent issue across various GDI engine platforms. This instability manifests as fluctuations in engine speed, increased vibration, and audible noise that negatively impacts perceived vehicle quality and customer satisfaction.

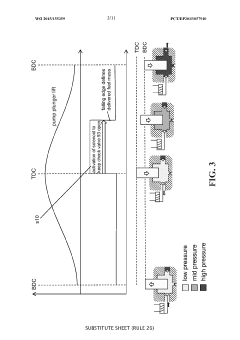

The primary technical challenge stems from the fundamental operating principles of GDI systems. Unlike port fuel injection, where fuel is pre-mixed with air, GDI engines inject fuel directly into the combustion chamber under varying pressure conditions. During idle operation, the reduced air flow and lower cylinder temperatures create suboptimal conditions for fuel atomization and mixture formation, leading to cycle-to-cycle combustion variations.

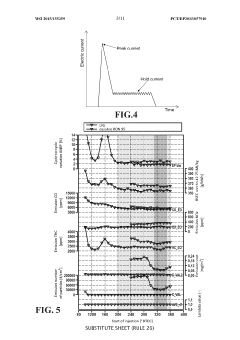

Data-driven analysis has identified several critical factors contributing to idle roughness. Injection timing variability shows a strong correlation with combustion stability metrics, with deviations as small as 0.5 degrees crank angle significantly impacting idle quality. Similarly, fuel pressure fluctuations exceeding 2% of nominal values demonstrate measurable effects on combustion consistency, particularly at cold start conditions when fuel viscosity is higher.

Cylinder-to-cylinder variations present another substantial challenge. Current data indicates that air-fuel ratio imbalances between cylinders can reach up to 5% in some production engines, creating torque imbalances that translate directly to perceptible vibration. These imbalances are often exacerbated by carbon deposit formation on intake valves, a known issue specific to GDI technology that worsens over vehicle lifetime.

Cold-start operation represents perhaps the most challenging condition for idle smoothness. Data analysis shows that hydrocarbon emissions during this phase can be 2-3 times higher than during warmed-up operation, indicating incomplete combustion that directly correlates with increased idle roughness. The limited effectiveness of three-way catalysts during cold operation compounds this issue from both emissions and performance perspectives.

Modern control strategies attempt to mitigate these challenges through adaptive learning algorithms and feedback control, but data suggests their effectiveness varies significantly across operating conditions. Temperature-dependent compensation maps show limited resolution in addressing the complex, non-linear relationships between environmental conditions and combustion stability parameters.

The increasing stringency of emissions regulations further complicates idle smoothness optimization, as strategies that might improve combustion stability (such as enrichment or spark retard) often conflict with emissions targets. Data analysis of production vehicles indicates that this trade-off becomes particularly pronounced when meeting SULEV30 and Euro 7 standards, creating a technical dilemma that requires innovative solutions beyond conventional calibration approaches.

The primary technical challenge stems from the fundamental operating principles of GDI systems. Unlike port fuel injection, where fuel is pre-mixed with air, GDI engines inject fuel directly into the combustion chamber under varying pressure conditions. During idle operation, the reduced air flow and lower cylinder temperatures create suboptimal conditions for fuel atomization and mixture formation, leading to cycle-to-cycle combustion variations.

Data-driven analysis has identified several critical factors contributing to idle roughness. Injection timing variability shows a strong correlation with combustion stability metrics, with deviations as small as 0.5 degrees crank angle significantly impacting idle quality. Similarly, fuel pressure fluctuations exceeding 2% of nominal values demonstrate measurable effects on combustion consistency, particularly at cold start conditions when fuel viscosity is higher.

Cylinder-to-cylinder variations present another substantial challenge. Current data indicates that air-fuel ratio imbalances between cylinders can reach up to 5% in some production engines, creating torque imbalances that translate directly to perceptible vibration. These imbalances are often exacerbated by carbon deposit formation on intake valves, a known issue specific to GDI technology that worsens over vehicle lifetime.

Cold-start operation represents perhaps the most challenging condition for idle smoothness. Data analysis shows that hydrocarbon emissions during this phase can be 2-3 times higher than during warmed-up operation, indicating incomplete combustion that directly correlates with increased idle roughness. The limited effectiveness of three-way catalysts during cold operation compounds this issue from both emissions and performance perspectives.

Modern control strategies attempt to mitigate these challenges through adaptive learning algorithms and feedback control, but data suggests their effectiveness varies significantly across operating conditions. Temperature-dependent compensation maps show limited resolution in addressing the complex, non-linear relationships between environmental conditions and combustion stability parameters.

The increasing stringency of emissions regulations further complicates idle smoothness optimization, as strategies that might improve combustion stability (such as enrichment or spark retard) often conflict with emissions targets. Data analysis of production vehicles indicates that this trade-off becomes particularly pronounced when meeting SULEV30 and Euro 7 standards, creating a technical dilemma that requires innovative solutions beyond conventional calibration approaches.

Data-Driven Approaches for Idle Smoothness Optimization

01 Fuel injection control strategies for idle smoothness

Various fuel injection control strategies can be implemented in GDI engines to improve idle smoothness. These include optimizing injection timing, adjusting fuel quantity based on engine conditions, implementing multiple injection events per cycle, and adapting injection parameters based on feedback from engine sensors. These strategies help to ensure consistent combustion, reduce fluctuations in engine speed, and minimize vibrations during idle operation.- Fuel injection control strategies for idle smoothness: Various fuel injection control strategies can be implemented in GDI engines to improve idle smoothness. These include optimizing injection timing, adjusting fuel quantity based on engine conditions, implementing multiple injection events per cycle, and adapting injection parameters based on feedback from engine sensors. These strategies help to ensure consistent combustion, reduce fluctuations in engine speed, and minimize vibrations during idle operation.

- Engine control systems for idle stability: Advanced engine control systems can significantly improve idle smoothness in GDI engines. These systems utilize various sensors to monitor engine parameters such as crankshaft position, intake air temperature, coolant temperature, and oxygen levels. Based on these inputs, the engine control unit adjusts ignition timing, air-fuel ratio, and other parameters to maintain stable idle operation under varying conditions including cold starts and different load requirements.

- Combustion chamber design for improved idle performance: The design of the combustion chamber plays a crucial role in achieving smooth idle operation in GDI engines. Optimized piston crown geometry, strategic placement of the fuel injector, and carefully designed intake ports can enhance fuel atomization and air-fuel mixing. These design elements promote more complete combustion, reduce cycle-to-cycle variations, and minimize combustion instabilities that can cause rough idling.

- Idle air control mechanisms: Idle air control mechanisms are essential for maintaining consistent engine speed during idle operation. These systems regulate the amount of air bypassing the throttle valve to compensate for varying engine loads from accessories and environmental conditions. Advanced idle air control systems can make rapid adjustments to airflow based on real-time feedback, helping to prevent engine stalling and reduce speed fluctuations that cause noticeable vibrations.

- Vibration reduction techniques for GDI engines at idle: Various vibration reduction techniques can be employed to improve the perceived smoothness of GDI engines at idle. These include optimized engine mounting systems, balance shaft mechanisms, active noise cancellation, and software-based torque management strategies. By minimizing the transmission of vibrations to the vehicle structure and implementing precise torque control during combustion events, these techniques can significantly enhance idle quality and driver comfort.

02 Engine control systems for idle stability

Advanced engine control systems can significantly improve idle smoothness in GDI engines. These systems utilize various sensors to monitor engine parameters such as crankshaft position, intake air temperature, coolant temperature, and throttle position. Based on these inputs, the engine control unit adjusts various parameters to maintain stable idle operation. Adaptive learning algorithms can also be implemented to continuously optimize idle performance under varying conditions.Expand Specific Solutions03 Combustion chamber design for improved idle performance

The design of the combustion chamber plays a crucial role in achieving smooth idle operation in GDI engines. Features such as optimized piston crown geometry, strategic placement of the fuel injector, and carefully designed intake ports can enhance fuel-air mixing and combustion stability at idle conditions. These design elements help to reduce cycle-to-cycle variations in combustion, which is a major contributor to idle roughness.Expand Specific Solutions04 Ignition timing control for idle smoothness

Precise control of ignition timing is essential for maintaining smooth idle operation in GDI engines. Advanced ignition systems can adjust spark timing based on various engine parameters to optimize combustion stability at idle. Techniques such as cylinder-specific timing adjustments, adaptive spark advance control, and misfire detection algorithms help to minimize torque fluctuations and improve idle quality under various operating conditions.Expand Specific Solutions05 Idle air control mechanisms

Idle air control mechanisms regulate the amount of air bypassing the throttle plate during idle operation, which directly affects idle stability in GDI engines. These systems can include electronic idle air control valves, throttle body designs with integrated bypass channels, or variable valve timing systems that adjust valve overlap at idle. By precisely controlling the air supply during idle, these mechanisms help maintain consistent engine speed and reduce vibrations for improved idle smoothness.Expand Specific Solutions

Key Industry Players in Engine Control Systems

The GDI Engine Idle Smoothness technology market is currently in a growth phase, with increasing demand for enhanced engine performance and fuel efficiency. The global market size is estimated to reach several billion dollars by 2025, driven by stringent emission regulations and consumer preference for smoother driving experiences. Major automotive manufacturers like GM, Toyota, Hyundai, and Volkswagen (through International Engine Intellectual Property) are leading technological innovation in this space, with significant R&D investments in data-driven approaches to engine optimization. Chinese manufacturers including SAIC, Great Wall, and Dongfeng are rapidly catching up, while component specialists like Bosch and DENSO provide critical supporting technologies. The technology is approaching maturity in premium segments but remains in development for mass-market applications, with data analytics becoming increasingly central to advancement.

GM Global Technology Operations LLC

Technical Solution: GM has developed an advanced data-driven approach to analyze GDI (Gasoline Direct Injection) engine idle smoothness using multi-sensor data fusion techniques. Their system employs accelerometers, crankshaft position sensors, and combustion pressure sensors to collect comprehensive vibration and performance data during idle conditions. The collected data undergoes real-time signal processing through proprietary algorithms that identify frequency patterns associated with combustion irregularities. GM's approach incorporates machine learning models trained on extensive fleet data to establish baseline smoothness parameters across different engine families and operating conditions. Their system can detect subtle changes in idle quality before they become perceptible to drivers, enabling predictive maintenance interventions. GM has integrated this technology into their OnStar diagnostic systems, allowing for remote monitoring and analysis of engine idle performance across their vehicle fleet.

Strengths: Comprehensive sensor integration provides holistic view of engine performance; machine learning capabilities enable adaptive baseline comparisons across different vehicle models and operating conditions. Weaknesses: System complexity requires significant computational resources; high implementation cost across vehicle lineup; potential privacy concerns with continuous data collection.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered a sophisticated idle smoothness analysis system for their GDI engines that combines high-precision data acquisition with advanced statistical analysis. Their approach utilizes a network of strategically placed micro-vibration sensors that capture engine block oscillations at multiple points, providing three-dimensional vibration mapping during idle operation. Toyota's system incorporates their proprietary "Idle Quality Index" (IQI) which quantifies smoothness through a composite score derived from vibration amplitude, frequency distribution, and combustion stability metrics. The technology employs adaptive filtering algorithms to isolate engine-specific vibrations from environmental noise and vehicle system interactions. Toyota has integrated this analysis capability with their engine control modules, enabling real-time combustion adjustments to maintain optimal idle smoothness under varying conditions including cold starts, different fuel qualities, and component aging. The system stores historical performance data to establish personalized baseline parameters for each vehicle, allowing for more accurate detection of degradation trends.

Strengths: High-precision vibration mapping provides detailed insight into specific sources of idle roughness; adaptive filtering effectively isolates engine-specific issues from external factors; integration with ECU enables real-time adjustments. Weaknesses: Requires extensive calibration for each engine variant; sensitive to sensor degradation over vehicle lifetime; higher component cost compared to traditional monitoring systems.

Critical Patents and Research in GDI Idle Control

Method for controlling deposit formation in gasoline direct injection engine by use of a fuel having particular compositional characteristics

PatentInactiveUS6746495B2

Innovation

- The use of gasoline with an aromatics content of 12-65 vol%, primarily sourced from reformate and light fluid catalytic cracker streams, helps control injector deposit formation by optimizing the fuel composition, including specific ranges for T90, olefins, sulfur, and aromatics content, to improve engine performance.

LPG direct injection engine

PatentWO2015155359A1

Innovation

- An LPG direct injection engine with a high-pressure pump and electronic control unit for precise liquefied petroleum gas injection between 360° and 60° BTDC, optimized valve overlap, and cylinder deactivation system to reduce emissions and improve efficiency.

NVH Analysis Methodologies for GDI Engines

Noise, Vibration, and Harshness (NVH) analysis methodologies for Gasoline Direct Injection (GDI) engines have evolved significantly over the past decade, incorporating advanced signal processing techniques and multi-domain analysis approaches. These methodologies are crucial for evaluating idle smoothness, which remains a key quality indicator for modern GDI engines.

Traditional NVH analysis typically relied on time-domain measurements such as acceleration and displacement. However, contemporary methodologies have expanded to include frequency-domain analysis, order tracking, and wavelet transforms that provide deeper insights into the complex vibration patterns characteristic of GDI engines during idle operation.

Cylinder pressure analysis has emerged as a fundamental methodology for GDI engine idle smoothness evaluation. By measuring in-cylinder pressure fluctuations with high-resolution transducers, engineers can identify combustion irregularities that manifest as vibration issues. This approach allows for direct correlation between combustion events and resulting NVH phenomena, enabling more targeted refinement strategies.

Modal analysis techniques have been adapted specifically for GDI applications, focusing on identifying structural resonances that may amplify combustion-induced vibrations. These methodologies typically involve experimental modal analysis (EMA) and operational modal analysis (OMA) to characterize the dynamic behavior of engine components under actual operating conditions.

Transfer path analysis (TPA) represents another critical methodology in the NVH toolkit. This approach maps the propagation routes of vibration energy from source (combustion chamber) to receiver (driver perception points), allowing engineers to identify and modify critical paths that contribute significantly to perceived roughness during idle.

Data-driven methodologies have gained prominence with the advancement of machine learning techniques. These approaches leverage large datasets collected from engine dynamometer tests and vehicle measurements to develop predictive models for idle quality. Pattern recognition algorithms can identify subtle signatures in vibration data that correlate with specific GDI system malfunctions or calibration issues.

Psychoacoustic analysis methodologies complement traditional vibration measurements by incorporating human perception factors. Metrics such as articulation index, loudness, and roughness provide quantitative measures that correlate well with subjective assessments of idle quality, bridging the gap between objective measurements and customer satisfaction.

Integration of these methodologies within a comprehensive development framework enables systematic improvement of GDI engine idle smoothness, addressing both technical performance requirements and increasingly stringent customer expectations for refined vehicle operation.

Traditional NVH analysis typically relied on time-domain measurements such as acceleration and displacement. However, contemporary methodologies have expanded to include frequency-domain analysis, order tracking, and wavelet transforms that provide deeper insights into the complex vibration patterns characteristic of GDI engines during idle operation.

Cylinder pressure analysis has emerged as a fundamental methodology for GDI engine idle smoothness evaluation. By measuring in-cylinder pressure fluctuations with high-resolution transducers, engineers can identify combustion irregularities that manifest as vibration issues. This approach allows for direct correlation between combustion events and resulting NVH phenomena, enabling more targeted refinement strategies.

Modal analysis techniques have been adapted specifically for GDI applications, focusing on identifying structural resonances that may amplify combustion-induced vibrations. These methodologies typically involve experimental modal analysis (EMA) and operational modal analysis (OMA) to characterize the dynamic behavior of engine components under actual operating conditions.

Transfer path analysis (TPA) represents another critical methodology in the NVH toolkit. This approach maps the propagation routes of vibration energy from source (combustion chamber) to receiver (driver perception points), allowing engineers to identify and modify critical paths that contribute significantly to perceived roughness during idle.

Data-driven methodologies have gained prominence with the advancement of machine learning techniques. These approaches leverage large datasets collected from engine dynamometer tests and vehicle measurements to develop predictive models for idle quality. Pattern recognition algorithms can identify subtle signatures in vibration data that correlate with specific GDI system malfunctions or calibration issues.

Psychoacoustic analysis methodologies complement traditional vibration measurements by incorporating human perception factors. Metrics such as articulation index, loudness, and roughness provide quantitative measures that correlate well with subjective assessments of idle quality, bridging the gap between objective measurements and customer satisfaction.

Integration of these methodologies within a comprehensive development framework enables systematic improvement of GDI engine idle smoothness, addressing both technical performance requirements and increasingly stringent customer expectations for refined vehicle operation.

Emissions Impact of Idle Smoothness Optimization

The optimization of idle smoothness in GDI (Gasoline Direct Injection) engines has significant implications for emissions control and environmental impact. Engine idle quality directly correlates with combustion efficiency, which in turn affects the production of harmful pollutants. Poor idle smoothness typically results in incomplete combustion cycles, leading to increased hydrocarbon (HC) and carbon monoxide (CO) emissions. Studies have shown that engines with irregular idle patterns can produce up to 15-20% higher HC emissions during cold start conditions compared to engines with optimized idle characteristics.

Particulate matter (PM) emissions, a particular concern with GDI technology, are also heavily influenced by idle quality. During unstable idle conditions, the air-fuel mixture distribution becomes less homogeneous, creating localized rich zones that promote soot formation. Recent EPA data indicates that improving idle smoothness can reduce PM emissions by 8-12% under urban driving cycles where idle periods constitute a significant portion of operation time.

Nitrogen oxide (NOx) emissions present a more complex relationship with idle smoothness. While smoother idle generally reduces NOx through more consistent combustion temperatures, the calibration methods used to achieve smoothness may sometimes increase thermal efficiency to a point where NOx production is inadvertently enhanced. This creates an engineering trade-off that must be carefully managed through advanced control strategies.

Carbon dioxide (CO2) emissions, while not classified as pollutants in the traditional sense, represent a critical greenhouse gas concern. Idle smoothness optimization typically improves fuel efficiency by 2-5% during idle and low-load operation, directly translating to proportional CO2 reductions. This becomes especially significant in urban environments where vehicles spend substantial time idling at traffic signals and in congestion.

From a regulatory perspective, idle smoothness optimization contributes to meeting increasingly stringent emissions standards worldwide. The European Euro 7 standards and China 6b regulations specifically address cold-start and low-load emissions where idle quality plays a crucial role. Manufacturers implementing advanced idle smoothness control technologies can achieve compliance margins that provide competitive advantages in global markets.

Real-world emissions testing protocols like RDE (Real Driving Emissions) have further emphasized the importance of idle quality, as these tests include extended idle periods that significantly impact overall compliance results. Data analytics applied to idle smoothness can therefore serve as a predictive tool for emissions performance under various regulatory test cycles.

Particulate matter (PM) emissions, a particular concern with GDI technology, are also heavily influenced by idle quality. During unstable idle conditions, the air-fuel mixture distribution becomes less homogeneous, creating localized rich zones that promote soot formation. Recent EPA data indicates that improving idle smoothness can reduce PM emissions by 8-12% under urban driving cycles where idle periods constitute a significant portion of operation time.

Nitrogen oxide (NOx) emissions present a more complex relationship with idle smoothness. While smoother idle generally reduces NOx through more consistent combustion temperatures, the calibration methods used to achieve smoothness may sometimes increase thermal efficiency to a point where NOx production is inadvertently enhanced. This creates an engineering trade-off that must be carefully managed through advanced control strategies.

Carbon dioxide (CO2) emissions, while not classified as pollutants in the traditional sense, represent a critical greenhouse gas concern. Idle smoothness optimization typically improves fuel efficiency by 2-5% during idle and low-load operation, directly translating to proportional CO2 reductions. This becomes especially significant in urban environments where vehicles spend substantial time idling at traffic signals and in congestion.

From a regulatory perspective, idle smoothness optimization contributes to meeting increasingly stringent emissions standards worldwide. The European Euro 7 standards and China 6b regulations specifically address cold-start and low-load emissions where idle quality plays a crucial role. Manufacturers implementing advanced idle smoothness control technologies can achieve compliance margins that provide competitive advantages in global markets.

Real-world emissions testing protocols like RDE (Real Driving Emissions) have further emphasized the importance of idle quality, as these tests include extended idle periods that significantly impact overall compliance results. Data analytics applied to idle smoothness can therefore serve as a predictive tool for emissions performance under various regulatory test cycles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!