GDI Engine Valve Spring Force Measurement Techniques

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI Engine Valve Spring Technology Evolution

Valve spring technology in GDI (Gasoline Direct Injection) engines has undergone significant evolution over the past decades, driven by increasing demands for engine performance, efficiency, and durability. The earliest valve springs were simple helical compression springs made from carbon steel, designed primarily for basic functionality rather than optimized performance.

In the 1970s and 1980s, as engine speeds increased, valve spring technology began to evolve with the introduction of chrome silicon and chrome vanadium alloys, offering improved fatigue resistance and durability. These materials allowed for higher spring rates while maintaining reasonable service life, enabling engines to operate at higher RPMs without valve float.

The 1990s marked a significant advancement with the introduction of beehive-shaped valve springs, featuring a progressive diameter reduction from bottom to top. This design reduced mass at the critical top end where acceleration forces are highest, allowing for faster valve train response and reduced valve bounce. The reduced mass also decreased the overall inertia of the valve train system, contributing to improved engine efficiency.

The early 2000s saw the emergence of GDI technology in mass-market vehicles, placing new demands on valve springs due to higher combustion pressures and temperatures. This period witnessed the development of multi-spring assemblies, where two or more concentric springs work together to provide increased force while distributing stress more evenly.

From 2010 onwards, advanced manufacturing techniques enabled the production of oval and non-circular wire springs, which offer improved space efficiency and more consistent performance under high-stress conditions. These designs provide better control of resonance frequencies and reduce the risk of surge, a critical factor in high-revving GDI engines.

Recent innovations include the use of titanium for valve springs, offering exceptional strength-to-weight ratios. Though expensive, titanium springs allow for even higher engine speeds and more aggressive cam profiles, pushing the performance envelope further. Additionally, composite materials incorporating carbon fiber have been explored for specialized applications, though they remain primarily in the experimental and racing domains.

The measurement techniques for valve spring force have evolved alongside the springs themselves, from simple static load testing to sophisticated dynamic analysis using high-speed cameras, laser vibrometers, and strain gauges capable of capturing real-time performance data during engine operation. These advanced measurement capabilities have been crucial in validating new spring designs and materials, ensuring they meet the demanding requirements of modern GDI engines.

In the 1970s and 1980s, as engine speeds increased, valve spring technology began to evolve with the introduction of chrome silicon and chrome vanadium alloys, offering improved fatigue resistance and durability. These materials allowed for higher spring rates while maintaining reasonable service life, enabling engines to operate at higher RPMs without valve float.

The 1990s marked a significant advancement with the introduction of beehive-shaped valve springs, featuring a progressive diameter reduction from bottom to top. This design reduced mass at the critical top end where acceleration forces are highest, allowing for faster valve train response and reduced valve bounce. The reduced mass also decreased the overall inertia of the valve train system, contributing to improved engine efficiency.

The early 2000s saw the emergence of GDI technology in mass-market vehicles, placing new demands on valve springs due to higher combustion pressures and temperatures. This period witnessed the development of multi-spring assemblies, where two or more concentric springs work together to provide increased force while distributing stress more evenly.

From 2010 onwards, advanced manufacturing techniques enabled the production of oval and non-circular wire springs, which offer improved space efficiency and more consistent performance under high-stress conditions. These designs provide better control of resonance frequencies and reduce the risk of surge, a critical factor in high-revving GDI engines.

Recent innovations include the use of titanium for valve springs, offering exceptional strength-to-weight ratios. Though expensive, titanium springs allow for even higher engine speeds and more aggressive cam profiles, pushing the performance envelope further. Additionally, composite materials incorporating carbon fiber have been explored for specialized applications, though they remain primarily in the experimental and racing domains.

The measurement techniques for valve spring force have evolved alongside the springs themselves, from simple static load testing to sophisticated dynamic analysis using high-speed cameras, laser vibrometers, and strain gauges capable of capturing real-time performance data during engine operation. These advanced measurement capabilities have been crucial in validating new spring designs and materials, ensuring they meet the demanding requirements of modern GDI engines.

Market Demand for Precise Valve Spring Force Measurement

The global market for precise valve spring force measurement technologies in GDI (Gasoline Direct Injection) engines has experienced significant growth over the past decade, driven primarily by stringent emission regulations and the automotive industry's pursuit of enhanced fuel efficiency. Market research indicates that the demand for high-precision measurement tools has increased by approximately 7% annually since 2018, reflecting the critical importance of accurate valve spring performance in modern engine designs.

Automotive manufacturers are increasingly recognizing that even minor variations in valve spring force can significantly impact engine performance, fuel consumption, and emissions. This awareness has created a substantial market for advanced measurement technologies that can detect force variations with precision down to 0.1 Newton. The premium automotive segment has been particularly aggressive in adopting these technologies, with luxury vehicle manufacturers implementing 100% quality inspection protocols for valve springs.

The aftermarket sector represents another significant demand driver, with performance tuning companies requiring precise measurement tools to optimize engine modifications. This segment has grown at double the rate of the OEM market, particularly in regions with strong automotive customization cultures such as North America, Germany, and Japan.

From a geographical perspective, Asia-Pacific currently dominates the market demand, accounting for over 40% of global consumption of valve spring force measurement equipment. This is largely attributed to the region's position as a manufacturing hub for automotive components and the rapid adoption of GDI technology in emerging markets like China and India.

Industry surveys reveal that automotive engineers and quality control specialists are specifically seeking measurement solutions that offer real-time data analysis, integration with existing production systems, and the capability to perform measurements under simulated operating conditions. The ability to measure dynamic spring behavior under various temperature conditions has emerged as a particularly valuable feature, with 78% of respondents in a recent industry survey identifying this as a critical requirement.

The economic value proposition for precise measurement technologies is compelling. Manufacturing facilities implementing advanced valve spring force measurement systems report defect rate reductions averaging 35%, translating to significant cost savings in warranty claims and recalls. One major European automotive manufacturer documented annual savings exceeding $3.2 million after implementing high-precision valve spring testing across their production facilities.

Looking forward, market analysts project continued growth in demand for these technologies, particularly as GDI engines become more prevalent in hybrid vehicle architectures. The integration of artificial intelligence and machine learning capabilities into measurement systems represents an emerging trend, with predictive analytics becoming increasingly valuable for quality control and production optimization.

Automotive manufacturers are increasingly recognizing that even minor variations in valve spring force can significantly impact engine performance, fuel consumption, and emissions. This awareness has created a substantial market for advanced measurement technologies that can detect force variations with precision down to 0.1 Newton. The premium automotive segment has been particularly aggressive in adopting these technologies, with luxury vehicle manufacturers implementing 100% quality inspection protocols for valve springs.

The aftermarket sector represents another significant demand driver, with performance tuning companies requiring precise measurement tools to optimize engine modifications. This segment has grown at double the rate of the OEM market, particularly in regions with strong automotive customization cultures such as North America, Germany, and Japan.

From a geographical perspective, Asia-Pacific currently dominates the market demand, accounting for over 40% of global consumption of valve spring force measurement equipment. This is largely attributed to the region's position as a manufacturing hub for automotive components and the rapid adoption of GDI technology in emerging markets like China and India.

Industry surveys reveal that automotive engineers and quality control specialists are specifically seeking measurement solutions that offer real-time data analysis, integration with existing production systems, and the capability to perform measurements under simulated operating conditions. The ability to measure dynamic spring behavior under various temperature conditions has emerged as a particularly valuable feature, with 78% of respondents in a recent industry survey identifying this as a critical requirement.

The economic value proposition for precise measurement technologies is compelling. Manufacturing facilities implementing advanced valve spring force measurement systems report defect rate reductions averaging 35%, translating to significant cost savings in warranty claims and recalls. One major European automotive manufacturer documented annual savings exceeding $3.2 million after implementing high-precision valve spring testing across their production facilities.

Looking forward, market analysts project continued growth in demand for these technologies, particularly as GDI engines become more prevalent in hybrid vehicle architectures. The integration of artificial intelligence and machine learning capabilities into measurement systems represents an emerging trend, with predictive analytics becoming increasingly valuable for quality control and production optimization.

Current Challenges in Valve Spring Force Measurement

Despite significant advancements in GDI engine technology, valve spring force measurement continues to present substantial challenges for engineers and researchers. The dynamic nature of valve springs operating at high engine speeds creates complex measurement scenarios that conventional static testing methods fail to adequately address. Current measurement techniques struggle to capture real-time force variations during actual engine operation, particularly at elevated RPMs where valve spring surge and harmonics become critical factors.

One primary challenge is the integration of sensors within the confined valve train environment without disrupting normal engine operation. The limited physical space between valve components restricts sensor placement options, while the high-temperature environment (often exceeding 150°C) compromises the reliability and accuracy of many sensing technologies. Additionally, the intense vibration present in operating engines introduces significant noise into measurement signals, requiring sophisticated filtering techniques that may inadvertently remove valuable data.

The temporal resolution of current measurement systems presents another significant hurdle. With modern high-performance engines operating at speeds where valve events occur within milliseconds, measurement systems must capture data at extremely high sampling rates to accurately characterize spring behavior. This generates enormous data volumes that require substantial computational resources to process and analyze effectively.

Calibration of measurement systems under dynamic conditions remains problematic. While static calibration in laboratory settings can be performed with relative ease, translating these calibrations to the dynamic environment of an operating engine introduces numerous variables that affect measurement accuracy. Temperature drift, mechanical wear, and system hysteresis all contribute to measurement uncertainty that is difficult to quantify and compensate for.

The non-linear behavior of valve springs under varying loads further complicates measurement efforts. As springs approach coil bind or experience surge conditions, their force response characteristics change dramatically, requiring measurement systems capable of adapting to these non-linearities. Current technologies often fail to accurately capture these transitional behaviors, particularly at the extremes of the operating range.

Cost considerations also present significant barriers to implementing comprehensive measurement solutions. High-precision sensors capable of withstanding the harsh engine environment come with substantial price tags, limiting their application primarily to research settings rather than production testing. This cost barrier has slowed the development and validation of new spring designs that might otherwise improve engine performance and efficiency.

One primary challenge is the integration of sensors within the confined valve train environment without disrupting normal engine operation. The limited physical space between valve components restricts sensor placement options, while the high-temperature environment (often exceeding 150°C) compromises the reliability and accuracy of many sensing technologies. Additionally, the intense vibration present in operating engines introduces significant noise into measurement signals, requiring sophisticated filtering techniques that may inadvertently remove valuable data.

The temporal resolution of current measurement systems presents another significant hurdle. With modern high-performance engines operating at speeds where valve events occur within milliseconds, measurement systems must capture data at extremely high sampling rates to accurately characterize spring behavior. This generates enormous data volumes that require substantial computational resources to process and analyze effectively.

Calibration of measurement systems under dynamic conditions remains problematic. While static calibration in laboratory settings can be performed with relative ease, translating these calibrations to the dynamic environment of an operating engine introduces numerous variables that affect measurement accuracy. Temperature drift, mechanical wear, and system hysteresis all contribute to measurement uncertainty that is difficult to quantify and compensate for.

The non-linear behavior of valve springs under varying loads further complicates measurement efforts. As springs approach coil bind or experience surge conditions, their force response characteristics change dramatically, requiring measurement systems capable of adapting to these non-linearities. Current technologies often fail to accurately capture these transitional behaviors, particularly at the extremes of the operating range.

Cost considerations also present significant barriers to implementing comprehensive measurement solutions. High-precision sensors capable of withstanding the harsh engine environment come with substantial price tags, limiting their application primarily to research settings rather than production testing. This cost barrier has slowed the development and validation of new spring designs that might otherwise improve engine performance and efficiency.

Current Measurement Solutions and Methodologies

01 Direct force measurement systems

Direct force measurement systems are used to accurately measure valve spring force. These systems typically involve sensors or load cells that directly contact the spring to measure the applied force. The measurements can be taken in real-time during engine operation or in static testing environments. These systems provide precise data on spring performance, including force variations at different compression levels, which is crucial for engine design and optimization.- Direct force measurement systems: Direct force measurement systems are used to measure valve spring force by applying a load directly to the spring and measuring the resulting force. These systems typically use load cells or force transducers that convert the mechanical force into an electrical signal. The measurement can be performed either in-situ while the spring is installed in the valve assembly or on a dedicated test bench. These systems provide accurate and real-time measurements of spring force under various compression states.

- Displacement-based measurement techniques: These techniques measure valve spring force indirectly by measuring the displacement or compression of the spring and calculating the force using Hooke's Law or calibrated force-displacement curves. Displacement sensors such as linear variable differential transformers (LVDTs), optical encoders, or laser displacement sensors are used to measure the spring compression. This approach allows for non-contact measurement and can be integrated into automated testing systems for high-throughput quality control applications.

- Dynamic force measurement during engine operation: These techniques focus on measuring valve spring force under actual operating conditions while the engine is running. They typically involve specialized sensors that can withstand the harsh environment and high frequencies of a running engine. Some systems use strain gauges attached to the valve train components or non-contact methods such as high-speed cameras combined with image processing algorithms. These measurements provide insights into dynamic behaviors such as spring surge, harmonics, and valve float that cannot be observed in static testing.

- Automated testing systems for production quality control: Automated systems designed for high-volume testing of valve springs in production environments. These systems typically include automated handling mechanisms, multiple measurement stations, and integrated data analysis capabilities. They can rapidly measure and sort springs based on force characteristics, ensuring consistency in manufacturing. Advanced systems incorporate machine learning algorithms to detect trends and potential quality issues before they become critical problems.

- Specialized measurement fixtures and calibration methods: This category includes specialized fixtures, jigs, and calibration methods specifically designed for accurate valve spring force measurement. These fixtures ensure proper alignment and consistent loading conditions during testing. Calibration methods include procedures for verifying the accuracy of measurement systems against known standards. Some advanced fixtures allow for simultaneous measurement of multiple parameters such as force, displacement, and spring rate at different compression levels.

02 Automated testing equipment for valve springs

Automated testing equipment has been developed specifically for measuring valve spring forces with high precision and repeatability. These systems often include motorized compression mechanisms, digital force sensors, and computerized data acquisition systems. The automation allows for rapid testing of multiple springs, ensuring consistent quality control in manufacturing processes. Some systems can also perform fatigue testing by repeatedly compressing and releasing the spring to simulate real-world operating conditions.Expand Specific Solutions03 Non-contact measurement techniques

Non-contact measurement techniques utilize advanced technologies such as optical sensors, laser systems, or magnetic field measurements to determine valve spring force without physically touching the spring. These methods are particularly valuable for measuring spring force during actual engine operation, as they don't interfere with the spring's movement. The non-contact approach also eliminates measurement errors that might occur due to friction or mechanical interference in traditional contact-based systems.Expand Specific Solutions04 In-engine measurement systems

In-engine measurement systems are designed to monitor valve spring force while the engine is running. These systems incorporate specialized sensors that can withstand the harsh environment of an operating engine, including high temperatures and vibrations. The data collected provides valuable insights into how valve springs perform under actual operating conditions, including dynamic effects that cannot be observed in static testing. This information is crucial for optimizing valve train design and preventing failures during operation.Expand Specific Solutions05 Calibration and validation methods

Calibration and validation methods ensure the accuracy and reliability of valve spring force measurements. These methods include comparison against reference standards, statistical analysis of measurement data, and cross-validation using different measurement techniques. Proper calibration procedures account for environmental factors such as temperature and humidity that might affect measurement accuracy. Regular validation helps identify and correct systematic errors in the measurement system, ensuring consistent and trustworthy results across different testing conditions.Expand Specific Solutions

Key Industry Players in Engine Testing Equipment

The GDI Engine Valve Spring Force Measurement Techniques market is currently in a growth phase, with increasing demand for precise measurement solutions to optimize engine performance and efficiency. The market size is expanding as automotive manufacturers focus on developing more efficient internal combustion engines. Leading automotive OEMs like Hyundai Motor, Kia, Ford, SAIC, Porsche, and BMW are investing significantly in this technology, while tier-one suppliers such as Bosch, Continental AG, and Vitesco Technologies provide specialized measurement solutions. The technology is reaching maturity with companies like FEV Motorentechnik and Liberty Technology developing advanced measurement techniques that combine traditional mechanical approaches with digital sensors and real-time analytics, creating a competitive landscape where precision and integration capabilities are key differentiators.

Ford Global Technologies LLC

Technical Solution: Ford has developed advanced GDI engine valve spring force measurement techniques utilizing piezoelectric sensors integrated directly into valve spring retainers. Their system employs high-frequency data acquisition (up to 100kHz) to capture dynamic spring behavior during engine operation. Ford's proprietary algorithm filters combustion noise while maintaining signal integrity, allowing real-time monitoring of valve spring performance. The technology incorporates wireless data transmission from the engine to analysis systems, enabling continuous monitoring without intrusive wiring. Ford has also pioneered temperature-compensated strain gauge applications specifically designed for high-temperature valve spring environments, providing accurate measurements across the full operating temperature range of modern GDI engines. This comprehensive approach allows engineers to validate simulation models and optimize valve train designs for improved durability and performance.

Strengths: Superior real-time data acquisition during actual engine operation; wireless monitoring capabilities reduce installation complexity; temperature compensation ensures accuracy across operating conditions. Weaknesses: System requires specialized installation expertise; higher implementation cost compared to bench testing methods; potential reliability concerns in extreme operating conditions.

Robert Bosch GmbH

Technical Solution: Bosch has pioneered non-invasive valve spring force measurement techniques specifically optimized for GDI engines. Their system utilizes laser vibrometry to measure valve spring oscillations without physical contact, preserving the natural dynamics of the valve train. This optical measurement system can detect displacements as small as 0.1 micrometers at frequencies up to 20kHz. Bosch's approach integrates multiple measurement points along the spring coil to create a comprehensive force distribution profile throughout the compression cycle. The data acquisition system synchronizes with engine position sensors to correlate measurements with specific engine events. Bosch has also developed specialized software that applies finite element analysis to convert displacement measurements into accurate force calculations, accounting for material properties and geometric variations. This technology enables engineers to identify potential resonance issues, coil clash events, and spring surge phenomena that could lead to premature failure or performance degradation in GDI engines operating under high-pressure fuel delivery conditions.

Strengths: Non-contact measurement preserves natural spring dynamics; high precision detection of micro-displacements; comprehensive force distribution profiling across the entire spring. Weaknesses: Optical access requirements limit application in fully assembled production engines; sensitive to environmental vibrations; higher initial equipment investment compared to conventional methods.

Critical Patents in Spring Force Measurement Technology

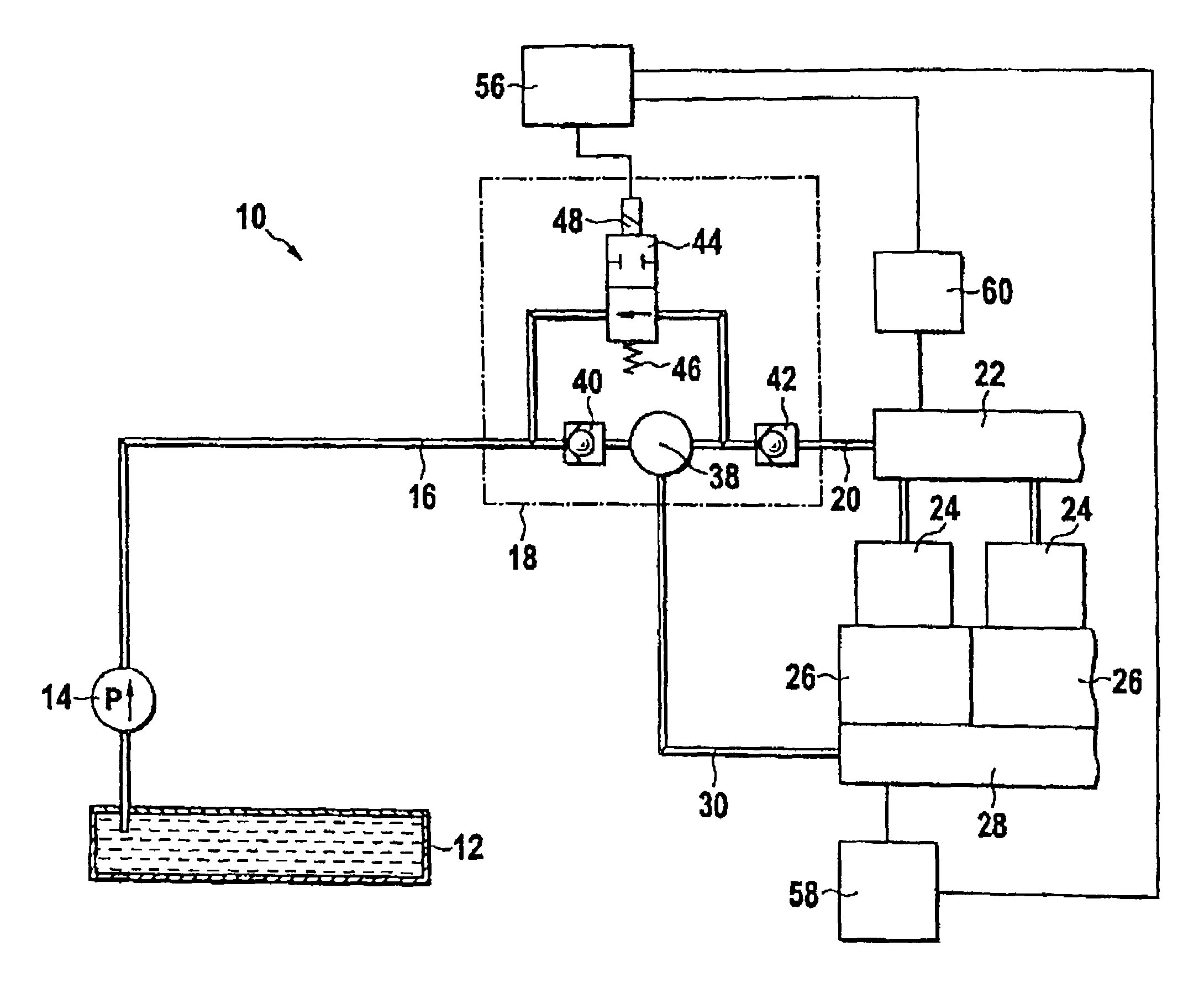

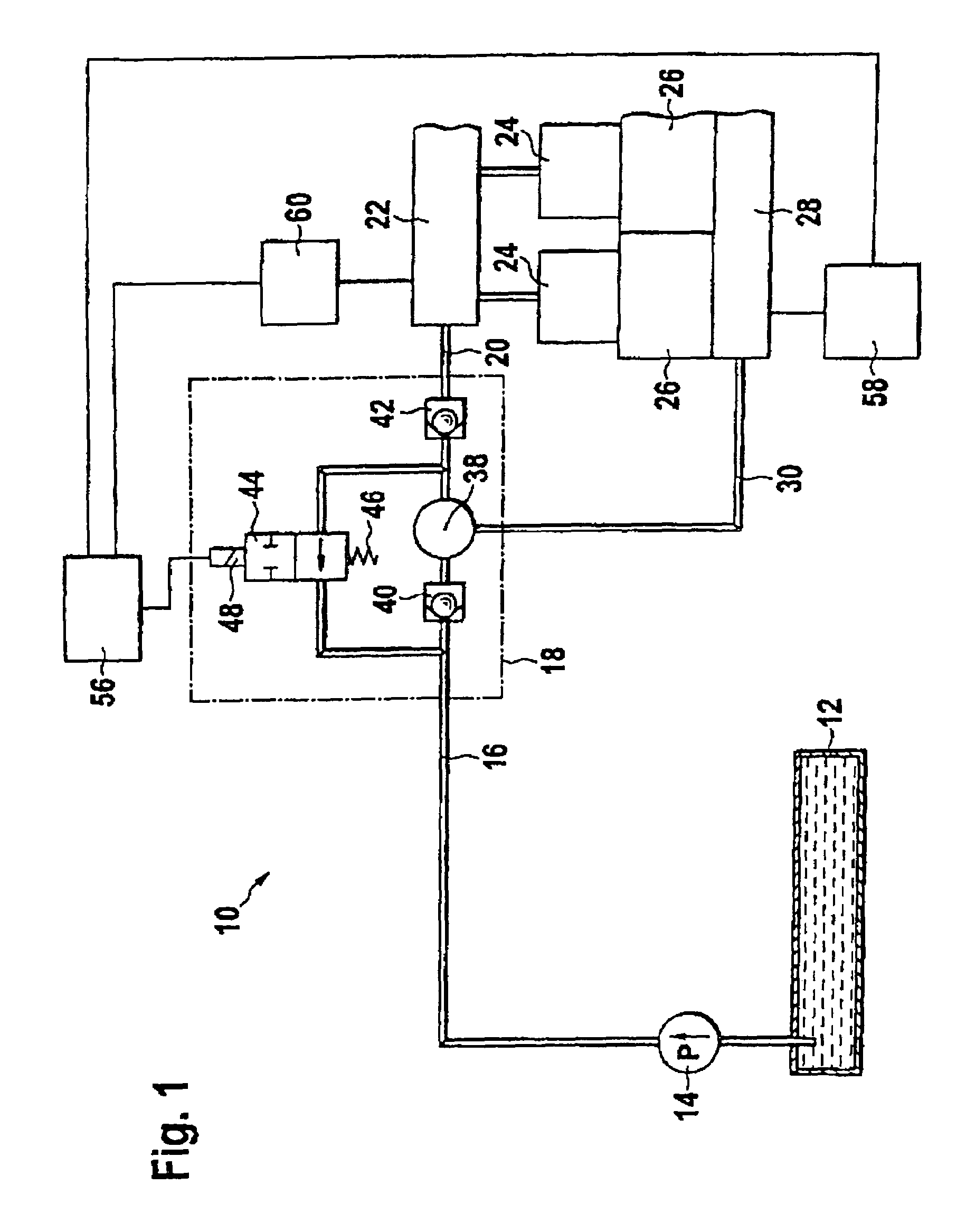

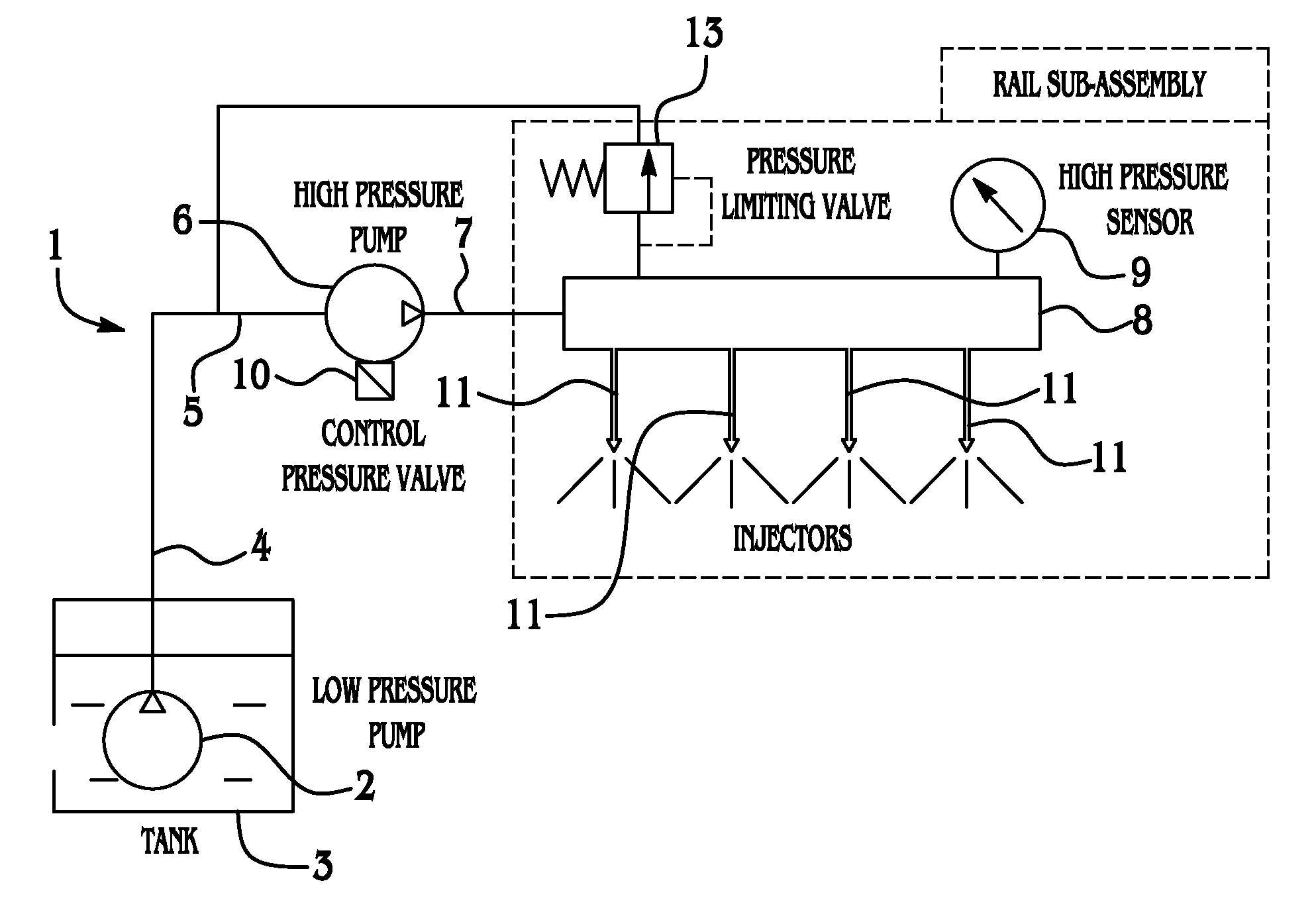

Two-point control of a high-pressure pump for direct-injecting gasoline engines

PatentInactiveUS7536997B2

Innovation

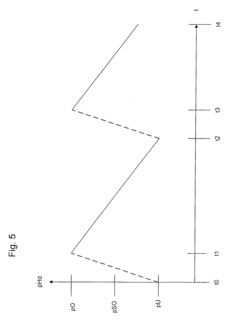

- Implementing a two-point operation method for the high-pressure pump, where it alternates between full delivery and idle delivery based on pressure thresholds, limiting the frequency of delivery to the maximum required amount, and switching to two-point control in idle mode to reduce noise.

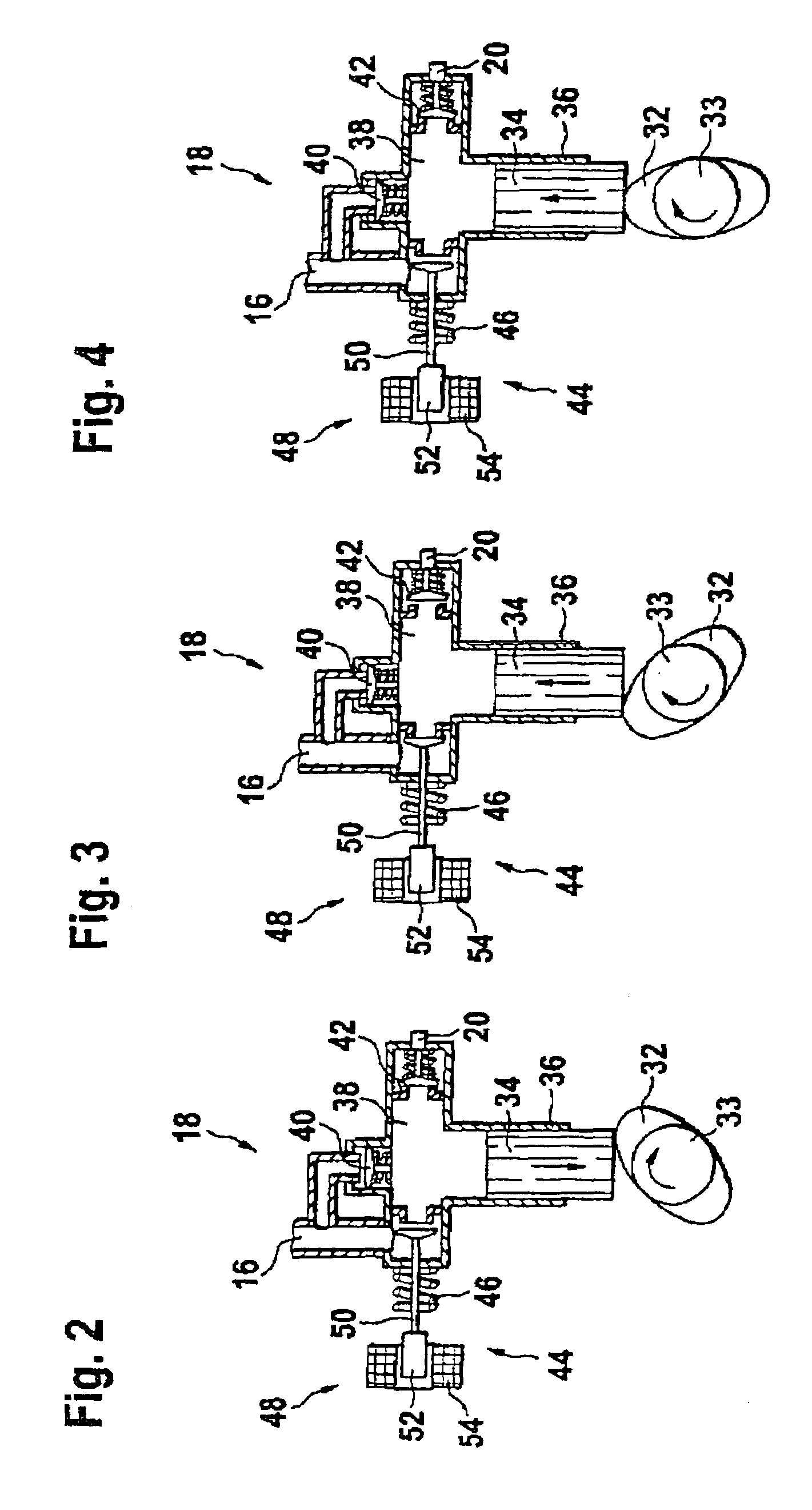

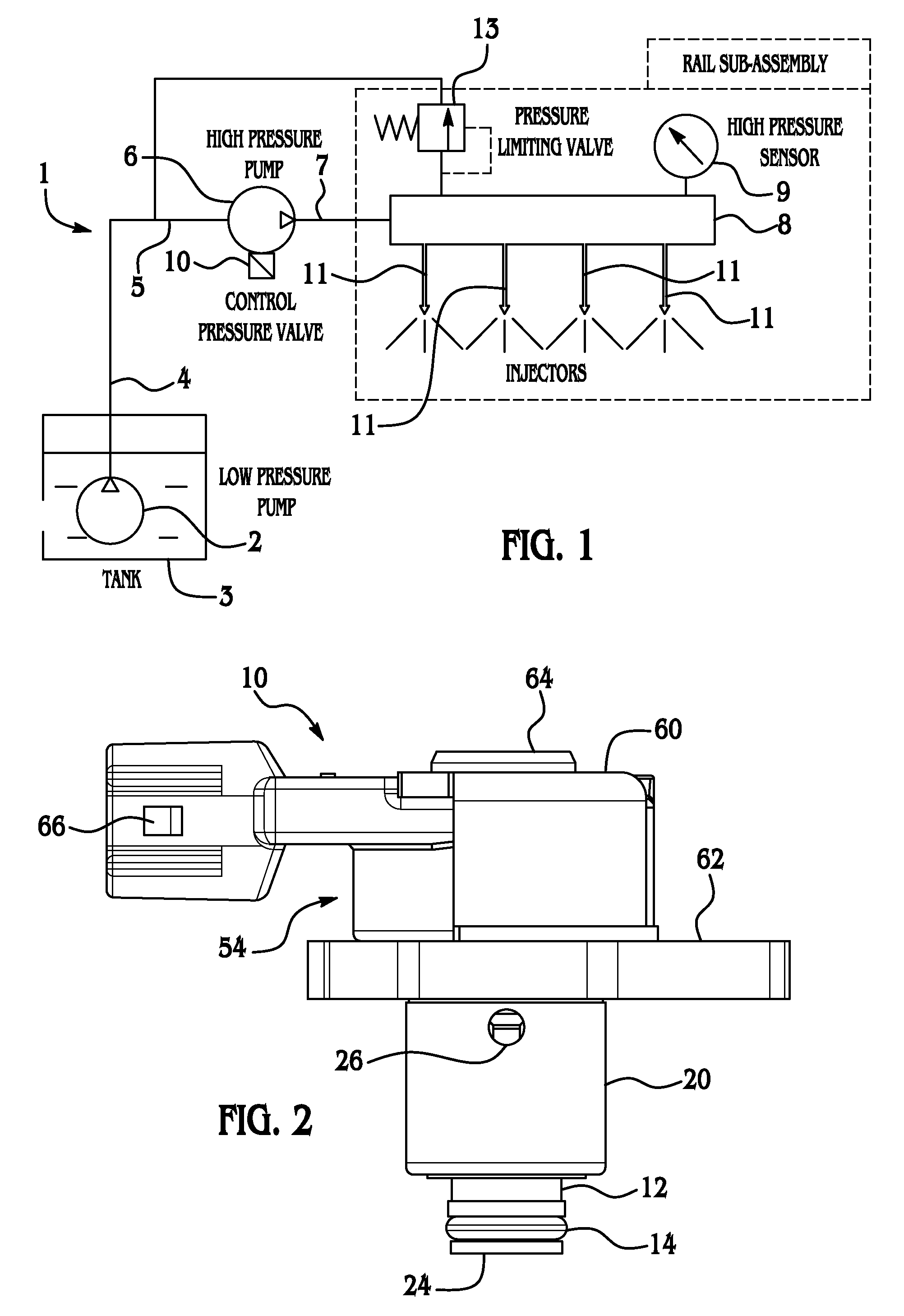

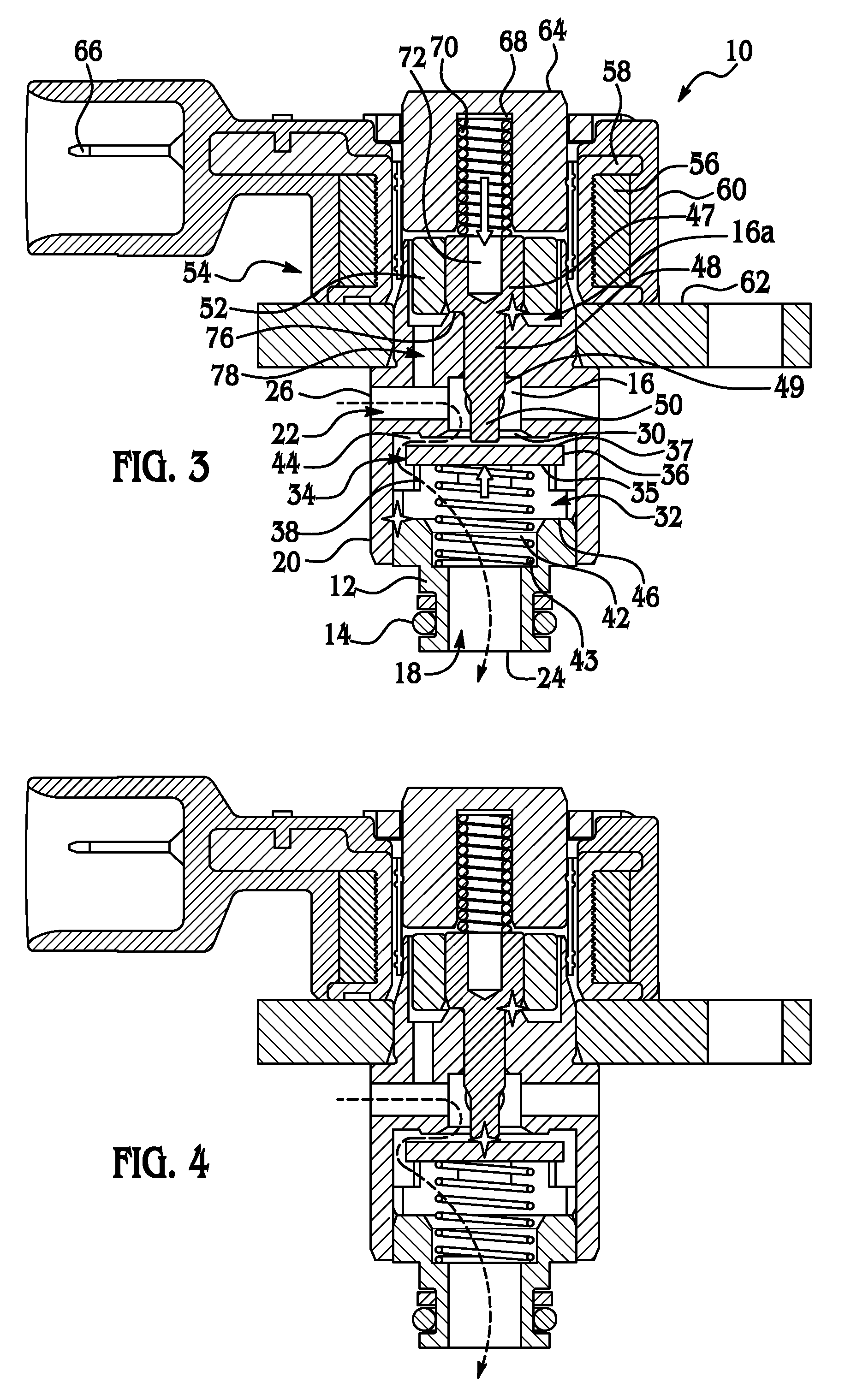

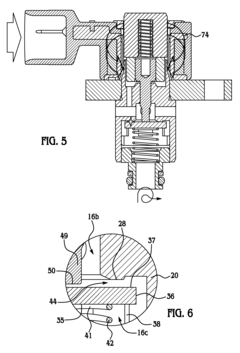

Control valve for a gas direct injection fuel system

PatentInactiveUS20080203347A1

Innovation

- A control valve design featuring a poppet mechanism and actuator system that regulates fluid communication between fluid paths, utilizing dual springs and an electrical actuator to manage pressure and flow rates, allowing for precise control of fuel injection by transitioning between open and closed states rapidly in response to engine conditions.

Calibration Standards and Quality Control

Accurate calibration standards and rigorous quality control protocols are essential components in the development and implementation of GDI engine valve spring force measurement techniques. The reliability and precision of these measurements directly impact engine performance, durability, and emissions control capabilities. Industry standards such as ISO 17025 and SAE J1349 provide foundational frameworks for calibration procedures specific to automotive testing equipment, including those used for valve spring force measurements.

Calibration of force measurement devices for valve springs requires traceable standards that link measurements to national or international reference standards. Primary calibration standards typically include precision dead weights, reference load cells, and certified material testing machines that can provide force references with uncertainties below 0.1% of the measured value. These standards must be regularly verified by accredited calibration laboratories to maintain their integrity and traceability.

Quality control in valve spring force measurement encompasses both pre-measurement verification and ongoing monitoring during testing operations. Pre-measurement verification includes zero-point calibration, linearity checks across the expected measurement range (typically 50-1000N for passenger vehicle GDI engines), and hysteresis evaluation. These procedures help identify potential measurement system anomalies before critical testing begins.

Statistical process control (SPC) methods play a crucial role in maintaining measurement quality over time. Implementation of control charts for key measurement parameters allows engineers to detect measurement drift and system degradation before they impact production decisions. Recommended practice includes establishing upper and lower control limits at ±2σ from the mean, with verification measurements conducted at frequencies determined by measurement stability history.

Environmental factors significantly influence force measurement accuracy and must be controlled as part of quality protocols. Temperature compensation algorithms are particularly important, as thermal expansion can introduce errors of up to 0.02% per degree Celsius in some measurement systems. Humidity and vibration isolation standards should also be specified in measurement protocols, with typical requirements limiting ambient vibration to less than 0.1g and maintaining relative humidity between 40-60%.

Measurement uncertainty analysis forms the cornerstone of quality control in valve spring force measurement. This analysis should account for contributions from calibration uncertainty, repeatability, reproducibility, resolution, and environmental effects. Modern GDI engine development typically requires expanded measurement uncertainties (k=2) below 1% of the measured value to support precise valve timing optimization and material selection decisions.

Calibration of force measurement devices for valve springs requires traceable standards that link measurements to national or international reference standards. Primary calibration standards typically include precision dead weights, reference load cells, and certified material testing machines that can provide force references with uncertainties below 0.1% of the measured value. These standards must be regularly verified by accredited calibration laboratories to maintain their integrity and traceability.

Quality control in valve spring force measurement encompasses both pre-measurement verification and ongoing monitoring during testing operations. Pre-measurement verification includes zero-point calibration, linearity checks across the expected measurement range (typically 50-1000N for passenger vehicle GDI engines), and hysteresis evaluation. These procedures help identify potential measurement system anomalies before critical testing begins.

Statistical process control (SPC) methods play a crucial role in maintaining measurement quality over time. Implementation of control charts for key measurement parameters allows engineers to detect measurement drift and system degradation before they impact production decisions. Recommended practice includes establishing upper and lower control limits at ±2σ from the mean, with verification measurements conducted at frequencies determined by measurement stability history.

Environmental factors significantly influence force measurement accuracy and must be controlled as part of quality protocols. Temperature compensation algorithms are particularly important, as thermal expansion can introduce errors of up to 0.02% per degree Celsius in some measurement systems. Humidity and vibration isolation standards should also be specified in measurement protocols, with typical requirements limiting ambient vibration to less than 0.1g and maintaining relative humidity between 40-60%.

Measurement uncertainty analysis forms the cornerstone of quality control in valve spring force measurement. This analysis should account for contributions from calibration uncertainty, repeatability, reproducibility, resolution, and environmental effects. Modern GDI engine development typically requires expanded measurement uncertainties (k=2) below 1% of the measured value to support precise valve timing optimization and material selection decisions.

Environmental Impact of Testing Procedures

The environmental impact of valve spring force measurement techniques in GDI engines represents a critical yet often overlooked aspect of automotive testing procedures. Traditional measurement methods typically involve significant energy consumption, particularly when utilizing dynamometers and specialized test benches that operate continuously for extended periods. These testing facilities often require controlled environmental conditions, necessitating substantial HVAC system usage that further increases the carbon footprint of the testing process.

Material waste constitutes another environmental concern in valve spring force measurement. Destructive testing methods, which remain common in certain validation protocols, result in components that cannot be reused or recycled effectively. Additionally, specialized lubricants and coolants used during testing procedures may contain environmentally harmful substances that require proper disposal protocols to prevent contamination of soil and water resources.

Noise pollution emerges as a significant environmental factor during valve spring testing. High-speed engine operation during measurement procedures can generate considerable noise levels, potentially affecting both laboratory personnel and surrounding communities if adequate sound insulation is not implemented. This aspect becomes particularly relevant when testing facilities are located near residential areas.

Recent advancements in measurement technologies have begun addressing these environmental concerns. Non-invasive measurement techniques utilizing optical sensors and digital imaging have reduced the need for destructive testing, thereby minimizing waste generation. Similarly, virtual testing environments and simulation software have enabled preliminary evaluations without physical prototypes, significantly reducing energy consumption and material usage during early development phases.

The implementation of ISO 14001 environmental management standards has become increasingly common in testing facilities, promoting systematic approaches to reducing environmental impacts. These standards encourage the adoption of more efficient testing schedules, optimization of resource usage, and proper waste management practices. Furthermore, some leading automotive research centers have implemented energy recovery systems that capture and repurpose heat generated during engine testing procedures.

Looking forward, the industry trend is moving toward more sustainable testing methodologies. This includes the development of biodegradable testing fluids, energy-efficient measurement equipment, and comprehensive lifecycle assessments of testing procedures. The integration of artificial intelligence in testing protocols also promises to optimize test durations and conditions, further reducing unnecessary environmental impacts while maintaining measurement accuracy and reliability.

Material waste constitutes another environmental concern in valve spring force measurement. Destructive testing methods, which remain common in certain validation protocols, result in components that cannot be reused or recycled effectively. Additionally, specialized lubricants and coolants used during testing procedures may contain environmentally harmful substances that require proper disposal protocols to prevent contamination of soil and water resources.

Noise pollution emerges as a significant environmental factor during valve spring testing. High-speed engine operation during measurement procedures can generate considerable noise levels, potentially affecting both laboratory personnel and surrounding communities if adequate sound insulation is not implemented. This aspect becomes particularly relevant when testing facilities are located near residential areas.

Recent advancements in measurement technologies have begun addressing these environmental concerns. Non-invasive measurement techniques utilizing optical sensors and digital imaging have reduced the need for destructive testing, thereby minimizing waste generation. Similarly, virtual testing environments and simulation software have enabled preliminary evaluations without physical prototypes, significantly reducing energy consumption and material usage during early development phases.

The implementation of ISO 14001 environmental management standards has become increasingly common in testing facilities, promoting systematic approaches to reducing environmental impacts. These standards encourage the adoption of more efficient testing schedules, optimization of resource usage, and proper waste management practices. Furthermore, some leading automotive research centers have implemented energy recovery systems that capture and repurpose heat generated during engine testing procedures.

Looking forward, the industry trend is moving toward more sustainable testing methodologies. This includes the development of biodegradable testing fluids, energy-efficient measurement equipment, and comprehensive lifecycle assessments of testing procedures. The integration of artificial intelligence in testing protocols also promises to optimize test durations and conditions, further reducing unnecessary environmental impacts while maintaining measurement accuracy and reliability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!