Optimizing GDI Engine Intake Valve Timing for Results

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI Engine Intake Valve Timing Background and Objectives

Gasoline Direct Injection (GDI) engine technology has evolved significantly since its commercial introduction in the late 1990s. This evolution represents a paradigm shift from traditional port fuel injection systems, offering improved fuel efficiency, reduced emissions, and enhanced engine performance. The historical development of GDI technology can be traced back to the early 20th century, with significant advancements occurring in the 1970s during the oil crisis, though widespread adoption only materialized in the past two decades with advancements in electronic control systems and manufacturing capabilities.

The technological trajectory of GDI engines has been characterized by continuous refinement in fuel delivery precision, combustion efficiency, and emissions control. Recent trends indicate a growing focus on variable valve timing systems that can dynamically adjust intake valve operation based on engine load, speed, and environmental conditions. This adaptive capability represents the frontier of internal combustion engine optimization in an increasingly stringent regulatory environment.

The primary objective of optimizing GDI engine intake valve timing is to achieve an optimal balance between performance metrics, fuel economy, and emissions compliance. Specifically, this involves developing algorithms and mechanical systems that can precisely control valve opening duration, timing, and lift characteristics across the entire operating range of the engine. The goal is to maximize volumetric efficiency while minimizing pumping losses and optimizing the air-fuel mixture for complete combustion.

Current technical challenges include the need for more sophisticated control strategies that can account for transient operating conditions, cold-start requirements, and varying fuel qualities. Additionally, there is growing interest in integrating valve timing optimization with other engine subsystems, such as turbocharging, exhaust gas recirculation, and variable compression ratio technologies, to create holistic engine management solutions.

The expected outcomes of this technical research include developing advanced control algorithms that can predict optimal valve timing settings based on real-time sensor data and driver inputs. These algorithms must be robust enough to maintain optimal performance across the vehicle's lifespan while adapting to component wear and environmental variations. Furthermore, the research aims to establish design guidelines for future GDI engine development that incorporate these optimized valve timing strategies from the conceptual stage.

In the broader context of automotive engineering, this optimization represents a critical pathway to meeting increasingly stringent global emissions standards while satisfying consumer expectations for performance and drivability. As the industry transitions toward electrification, maximizing the efficiency of internal combustion engines remains a vital intermediate step in reducing the environmental impact of transportation systems worldwide.

The technological trajectory of GDI engines has been characterized by continuous refinement in fuel delivery precision, combustion efficiency, and emissions control. Recent trends indicate a growing focus on variable valve timing systems that can dynamically adjust intake valve operation based on engine load, speed, and environmental conditions. This adaptive capability represents the frontier of internal combustion engine optimization in an increasingly stringent regulatory environment.

The primary objective of optimizing GDI engine intake valve timing is to achieve an optimal balance between performance metrics, fuel economy, and emissions compliance. Specifically, this involves developing algorithms and mechanical systems that can precisely control valve opening duration, timing, and lift characteristics across the entire operating range of the engine. The goal is to maximize volumetric efficiency while minimizing pumping losses and optimizing the air-fuel mixture for complete combustion.

Current technical challenges include the need for more sophisticated control strategies that can account for transient operating conditions, cold-start requirements, and varying fuel qualities. Additionally, there is growing interest in integrating valve timing optimization with other engine subsystems, such as turbocharging, exhaust gas recirculation, and variable compression ratio technologies, to create holistic engine management solutions.

The expected outcomes of this technical research include developing advanced control algorithms that can predict optimal valve timing settings based on real-time sensor data and driver inputs. These algorithms must be robust enough to maintain optimal performance across the vehicle's lifespan while adapting to component wear and environmental variations. Furthermore, the research aims to establish design guidelines for future GDI engine development that incorporate these optimized valve timing strategies from the conceptual stage.

In the broader context of automotive engineering, this optimization represents a critical pathway to meeting increasingly stringent global emissions standards while satisfying consumer expectations for performance and drivability. As the industry transitions toward electrification, maximizing the efficiency of internal combustion engines remains a vital intermediate step in reducing the environmental impact of transportation systems worldwide.

Market Demand Analysis for Advanced Valve Timing Systems

The global market for advanced valve timing systems has experienced significant growth over the past decade, driven primarily by increasingly stringent emission regulations and consumer demand for improved fuel efficiency. The market size for variable valve timing systems reached approximately $40 billion in 2022, with projections indicating a compound annual growth rate of 6.8% through 2028. This growth trajectory underscores the critical importance of optimizing GDI (Gasoline Direct Injection) engine intake valve timing technologies.

Automotive manufacturers worldwide are facing mounting pressure to meet CO2 emission targets, with European standards requiring fleet averages below 95g/km and similar regulations being implemented across North America and Asia. Advanced valve timing systems represent a cost-effective solution to meet these requirements without sacrificing performance, creating substantial market pull for innovation in this space.

Consumer preferences have shifted notably toward vehicles offering improved fuel economy without compromising performance. Market research indicates that 78% of new vehicle buyers consider fuel efficiency among their top five purchasing factors, up from 62% just five years ago. This consumer trend has accelerated demand for technologies that optimize engine efficiency, with valve timing optimization being a key enabler.

The commercial vehicle segment presents a particularly promising growth opportunity, with fleet operators increasingly focused on total cost of ownership calculations where fuel consumption plays a dominant role. The potential fuel savings of 4-7% achievable through optimized valve timing systems translate to significant operational cost reductions over vehicle lifespans, creating compelling value propositions for fleet purchasers.

Regional market analysis reveals varying adoption rates, with mature markets like North America, Europe, and Japan showing strong penetration of advanced valve timing technologies, while emerging markets present substantial growth potential. China, now the world's largest automotive market, has implemented China VI emission standards that effectively mandate advanced engine technologies including sophisticated valve timing systems.

Aftermarket demand is also emerging as vehicle owners seek performance upgrades, with the performance parts industry reporting 15% year-over-year growth in advanced valve timing components. This trend indicates expanding market opportunities beyond original equipment manufacturers.

The competitive landscape features both established tier-one suppliers and emerging technology companies developing next-generation solutions. Market research indicates that manufacturers capable of delivering integrated systems that optimize valve timing in coordination with other engine parameters (fuel injection timing, ignition timing, etc.) are capturing premium market positions and commanding higher margins.

Automotive manufacturers worldwide are facing mounting pressure to meet CO2 emission targets, with European standards requiring fleet averages below 95g/km and similar regulations being implemented across North America and Asia. Advanced valve timing systems represent a cost-effective solution to meet these requirements without sacrificing performance, creating substantial market pull for innovation in this space.

Consumer preferences have shifted notably toward vehicles offering improved fuel economy without compromising performance. Market research indicates that 78% of new vehicle buyers consider fuel efficiency among their top five purchasing factors, up from 62% just five years ago. This consumer trend has accelerated demand for technologies that optimize engine efficiency, with valve timing optimization being a key enabler.

The commercial vehicle segment presents a particularly promising growth opportunity, with fleet operators increasingly focused on total cost of ownership calculations where fuel consumption plays a dominant role. The potential fuel savings of 4-7% achievable through optimized valve timing systems translate to significant operational cost reductions over vehicle lifespans, creating compelling value propositions for fleet purchasers.

Regional market analysis reveals varying adoption rates, with mature markets like North America, Europe, and Japan showing strong penetration of advanced valve timing technologies, while emerging markets present substantial growth potential. China, now the world's largest automotive market, has implemented China VI emission standards that effectively mandate advanced engine technologies including sophisticated valve timing systems.

Aftermarket demand is also emerging as vehicle owners seek performance upgrades, with the performance parts industry reporting 15% year-over-year growth in advanced valve timing components. This trend indicates expanding market opportunities beyond original equipment manufacturers.

The competitive landscape features both established tier-one suppliers and emerging technology companies developing next-generation solutions. Market research indicates that manufacturers capable of delivering integrated systems that optimize valve timing in coordination with other engine parameters (fuel injection timing, ignition timing, etc.) are capturing premium market positions and commanding higher margins.

Current State and Challenges in GDI Valve Timing Technology

Gasoline Direct Injection (GDI) valve timing technology has evolved significantly over the past decade, yet continues to face substantial challenges in optimization. Currently, most production GDI engines employ variable valve timing (VVT) systems that allow for adjustment of valve opening and closing events relative to crankshaft position. The predominant technologies include cam-phasing mechanisms, which can advance or retard valve timing events while maintaining fixed valve duration.

The state-of-the-art in production vehicles includes dual independent cam phasing systems that allow separate control of intake and exhaust valve timing. More advanced systems incorporate variable valve lift and duration capabilities, such as BMW's Valvetronic, Toyota's VVT-iE, and Honda's VTEC systems. These technologies have demonstrated fuel economy improvements of 5-8% and torque enhancements of up to 10% across various engine operating conditions.

Despite these advancements, significant technical challenges persist. The primary limitation involves the trade-off between optimizing valve timing for different engine operating conditions. Valve timing settings that maximize power output typically compromise fuel efficiency and emissions performance. This fundamental conflict creates a complex optimization problem that current systems address through compromise rather than ideal solutions.

Another critical challenge is the response time of mechanical VVT systems, which typically range from 300-500 milliseconds. This latency limits the engine's ability to rapidly adapt to transient operating conditions, such as during aggressive acceleration or load changes. The mechanical complexity of current systems also presents reliability concerns and increases manufacturing costs, with advanced VVT systems adding approximately $200-400 to engine production costs.

Control algorithm sophistication represents another significant hurdle. Current engine control units (ECUs) must balance multiple competing objectives including fuel economy, emissions compliance, performance, and durability. The computational demands of real-time valve timing optimization across all operating conditions exceed the capabilities of many production ECUs, necessitating simplified control strategies.

Emissions regulations present perhaps the most pressing challenge. Meeting Euro 7 and upcoming CARB standards requires precise combustion control that current valve timing systems struggle to deliver consistently across all operating conditions. Cold-start emissions particularly benefit from specific valve timing strategies that may not be optimal for other performance metrics.

Integration with other engine technologies, such as turbocharging, exhaust gas recirculation (EGR), and cylinder deactivation, further complicates valve timing optimization. These technologies create interdependencies that exponentially increase the complexity of the control strategy development and calibration process, requiring sophisticated modeling approaches and extensive validation testing.

The state-of-the-art in production vehicles includes dual independent cam phasing systems that allow separate control of intake and exhaust valve timing. More advanced systems incorporate variable valve lift and duration capabilities, such as BMW's Valvetronic, Toyota's VVT-iE, and Honda's VTEC systems. These technologies have demonstrated fuel economy improvements of 5-8% and torque enhancements of up to 10% across various engine operating conditions.

Despite these advancements, significant technical challenges persist. The primary limitation involves the trade-off between optimizing valve timing for different engine operating conditions. Valve timing settings that maximize power output typically compromise fuel efficiency and emissions performance. This fundamental conflict creates a complex optimization problem that current systems address through compromise rather than ideal solutions.

Another critical challenge is the response time of mechanical VVT systems, which typically range from 300-500 milliseconds. This latency limits the engine's ability to rapidly adapt to transient operating conditions, such as during aggressive acceleration or load changes. The mechanical complexity of current systems also presents reliability concerns and increases manufacturing costs, with advanced VVT systems adding approximately $200-400 to engine production costs.

Control algorithm sophistication represents another significant hurdle. Current engine control units (ECUs) must balance multiple competing objectives including fuel economy, emissions compliance, performance, and durability. The computational demands of real-time valve timing optimization across all operating conditions exceed the capabilities of many production ECUs, necessitating simplified control strategies.

Emissions regulations present perhaps the most pressing challenge. Meeting Euro 7 and upcoming CARB standards requires precise combustion control that current valve timing systems struggle to deliver consistently across all operating conditions. Cold-start emissions particularly benefit from specific valve timing strategies that may not be optimal for other performance metrics.

Integration with other engine technologies, such as turbocharging, exhaust gas recirculation (EGR), and cylinder deactivation, further complicates valve timing optimization. These technologies create interdependencies that exponentially increase the complexity of the control strategy development and calibration process, requiring sophisticated modeling approaches and extensive validation testing.

Current Valve Timing Optimization Solutions

01 Variable valve timing control for GDI engines

Variable valve timing control systems for gasoline direct injection (GDI) engines optimize engine performance by adjusting intake valve timing based on operating conditions. These systems can improve fuel efficiency, reduce emissions, and enhance power output by controlling the overlap between intake and exhaust valve operations. Advanced electronic control units monitor engine parameters to determine optimal valve timing for different driving conditions.- Variable valve timing optimization for GDI engines: Variable valve timing systems in gasoline direct injection (GDI) engines can be optimized to improve fuel efficiency and reduce emissions. By adjusting the intake valve timing based on engine load and speed, the combustion process can be enhanced. Advanced control algorithms determine the optimal valve timing for different operating conditions, resulting in improved engine performance and reduced fuel consumption.

- Intake valve timing strategies for reducing carbon deposits: Specific intake valve timing strategies can be implemented in GDI engines to reduce carbon deposits on intake valves. By controlling the valve overlap and timing, the flow of fuel and air can be managed to minimize fuel impingement on valve surfaces. These strategies help maintain clean intake valves over extended periods of operation, preventing performance degradation and maintaining efficient combustion.

- Dual independent valve timing for GDI performance enhancement: Dual independent valve timing systems allow for separate control of intake and exhaust valve timing in GDI engines. This technology enables precise optimization of valve events based on engine operating conditions. The independent control of intake valve timing can be used to enhance charge motion, improve fuel-air mixing, and optimize combustion phasing, resulting in better performance, fuel economy, and emissions control.

- Integration of intake valve timing with direct injection strategies: Coordinated control of intake valve timing and fuel injection timing in GDI engines can optimize engine performance across various operating conditions. By synchronizing valve events with injection events, the air-fuel mixture formation can be enhanced. This integration allows for multiple injection strategies, improved charge stratification, and better combustion stability, particularly during cold starts and transient operations.

- Intake valve timing control for emissions reduction: Specific intake valve timing strategies can be implemented to reduce emissions in GDI engines. By optimizing the valve timing during different operating conditions, the formation of NOx, CO, and hydrocarbon emissions can be minimized. Advanced control systems can adjust valve timing to enable internal EGR, optimize combustion temperature, and improve catalyst efficiency, resulting in cleaner exhaust emissions while maintaining performance.

02 Intake valve timing strategies for combustion optimization

Specific intake valve timing strategies are employed in GDI engines to optimize the combustion process. These strategies include early intake valve closing for improved volumetric efficiency, late intake valve closing for internal EGR, and variable intake valve lift for better air-fuel mixture formation. By precisely controlling the intake valve timing, engineers can achieve better combustion stability, reduced knock tendency, and improved thermal efficiency across various engine loads.Expand Specific Solutions03 Dual independent valve timing systems for GDI applications

Dual independent valve timing systems allow separate control of both intake and exhaust valve timing in GDI engines. This technology enables more precise control over the combustion process by independently optimizing intake air flow and exhaust gas recirculation. The system typically uses oil pressure-actuated cam phasers or electric actuators to adjust camshaft timing, providing benefits such as improved low-end torque, better high-speed performance, and reduced pumping losses.Expand Specific Solutions04 Integration of valve timing with direct injection parameters

The coordination between intake valve timing and fuel injection parameters is crucial in GDI engines. This integration involves synchronizing valve events with injection timing, duration, and pressure to create optimal air-fuel mixtures. Advanced engine management systems adjust both valve timing and injection parameters simultaneously based on engine speed, load, temperature, and other factors to achieve the desired stratified or homogeneous combustion modes, resulting in improved efficiency and reduced emissions.Expand Specific Solutions05 Diagnostic and feedback systems for valve timing performance

Diagnostic and feedback systems monitor and verify the actual performance of intake valve timing mechanisms in GDI engines. These systems use camshaft position sensors, pressure sensors, and other monitoring devices to detect deviations from target timing values. When discrepancies are detected, the engine control module can make compensatory adjustments or alert the driver to potential issues. This real-time monitoring ensures optimal engine performance and helps prevent damage from valve timing malfunctions.Expand Specific Solutions

Key Industry Players in GDI Engine Technology

The GDI engine intake valve timing optimization market is in a growth phase, with increasing demand driven by stringent emission regulations and fuel efficiency requirements. Major automotive manufacturers including Ford, Toyota, Hyundai, and Nissan are leading technological advancements in this space, with significant investments in variable valve timing systems. The market is characterized by moderate technological maturity, with established players like BorgWarner and Delphi providing specialized components. Emerging innovations are coming from research collaborations between companies like AVL List and academic institutions such as Tianjin University. Asian manufacturers, particularly Geely and Mitsubishi, are rapidly closing the technology gap with traditional Western automotive powerhouses, creating a more competitive global landscape.

Ford Global Technologies LLC

Technical Solution: Ford's GDI engine intake valve timing optimization employs a dual independent variable cam timing (Ti-VCT) system that allows for precise control of both intake and exhaust valve timing. Their EcoBoost technology integrates this with direct injection and turbocharging to create a comprehensive solution. Ford's system utilizes advanced electronic control modules that continuously adjust valve timing based on multiple parameters including engine load, speed, temperature, and driver demand. The system can advance or retard valve timing by up to 60 degrees of crankshaft rotation, allowing for significant flexibility in optimizing combustion efficiency. Ford has also implemented a patented cold-start strategy that specifically addresses emissions during engine warm-up phases by temporarily adjusting valve overlap to increase exhaust gas temperature.

Strengths: Exceptional fuel economy improvements (up to 20% compared to conventional engines) while maintaining performance; robust integration with other engine technologies; proven reliability across multiple vehicle platforms. Weaknesses: Higher system complexity increases manufacturing costs; requires more sophisticated maintenance procedures; potential for increased carbon buildup on intake valves due to GDI configuration.

Toyota Motor Corp.

Technical Solution: Toyota's VVT-iE (Variable Valve Timing-intelligent by Electric motor) system represents their advanced approach to GDI engine intake valve timing optimization. Unlike conventional hydraulic systems, Toyota employs an electric motor to control the intake camshaft position, enabling more precise timing adjustments even at low engine speeds and temperatures. This system works in conjunction with their D-4S dual injection technology, which combines direct and port fuel injection. Toyota's implementation includes a sophisticated ECU that utilizes adaptive learning algorithms to continuously optimize valve timing based on driving conditions and fuel quality. Their latest iteration incorporates a wider adjustment range of up to 70 degrees of crankshaft rotation and faster response times (under 0.1 seconds for full adjustment). Toyota has also developed specialized valve timing maps for different driving modes (Eco, Normal, Sport) to balance efficiency and performance requirements.

Strengths: Superior cold-start performance and emissions control; excellent reliability with reduced maintenance requirements; precise control across all engine operating conditions including extreme temperatures. Weaknesses: Higher initial system cost compared to hydraulic-only systems; increased electrical system complexity; slightly heavier than purely mechanical systems.

Core Patents and Innovations in Intake Valve Timing

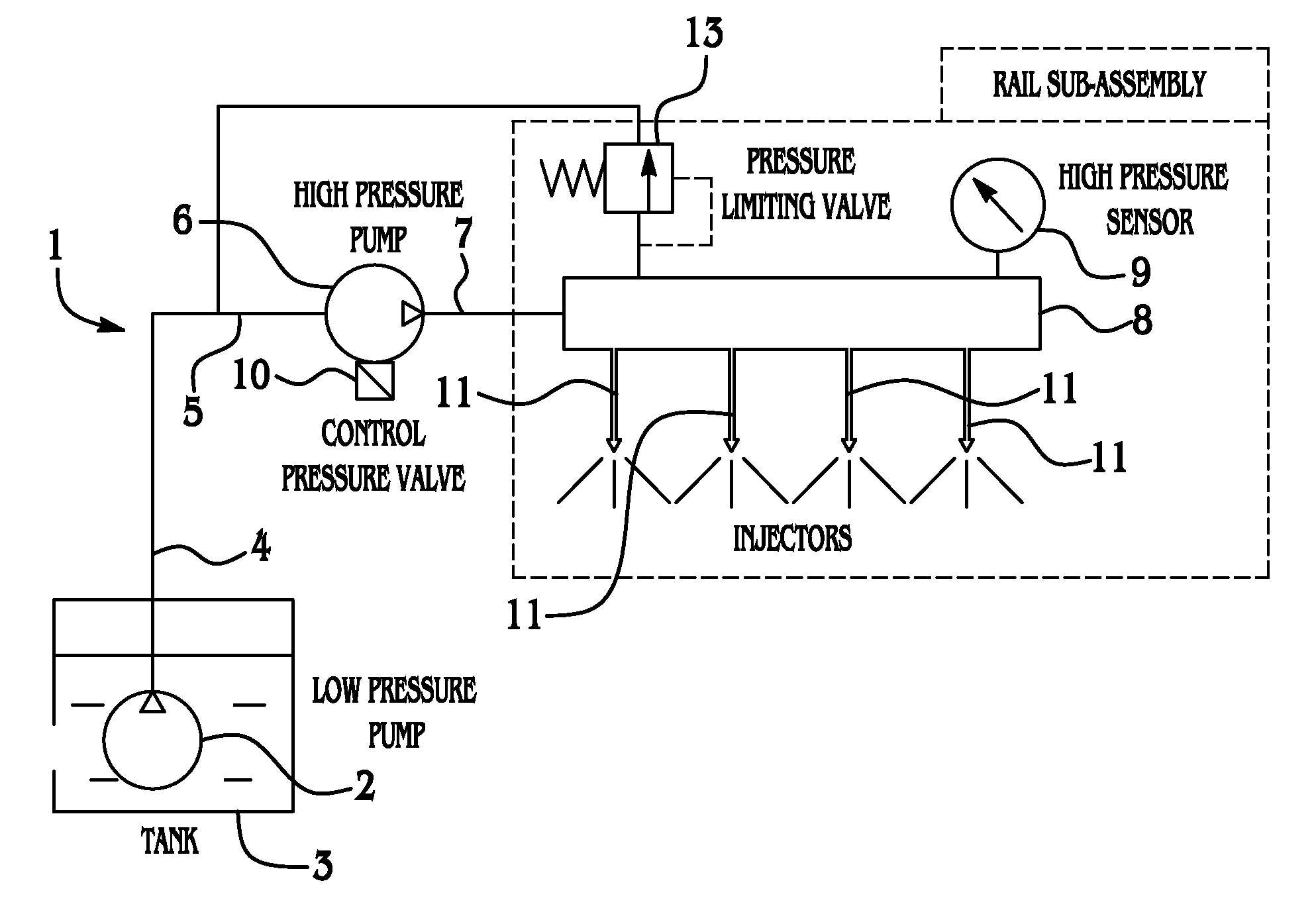

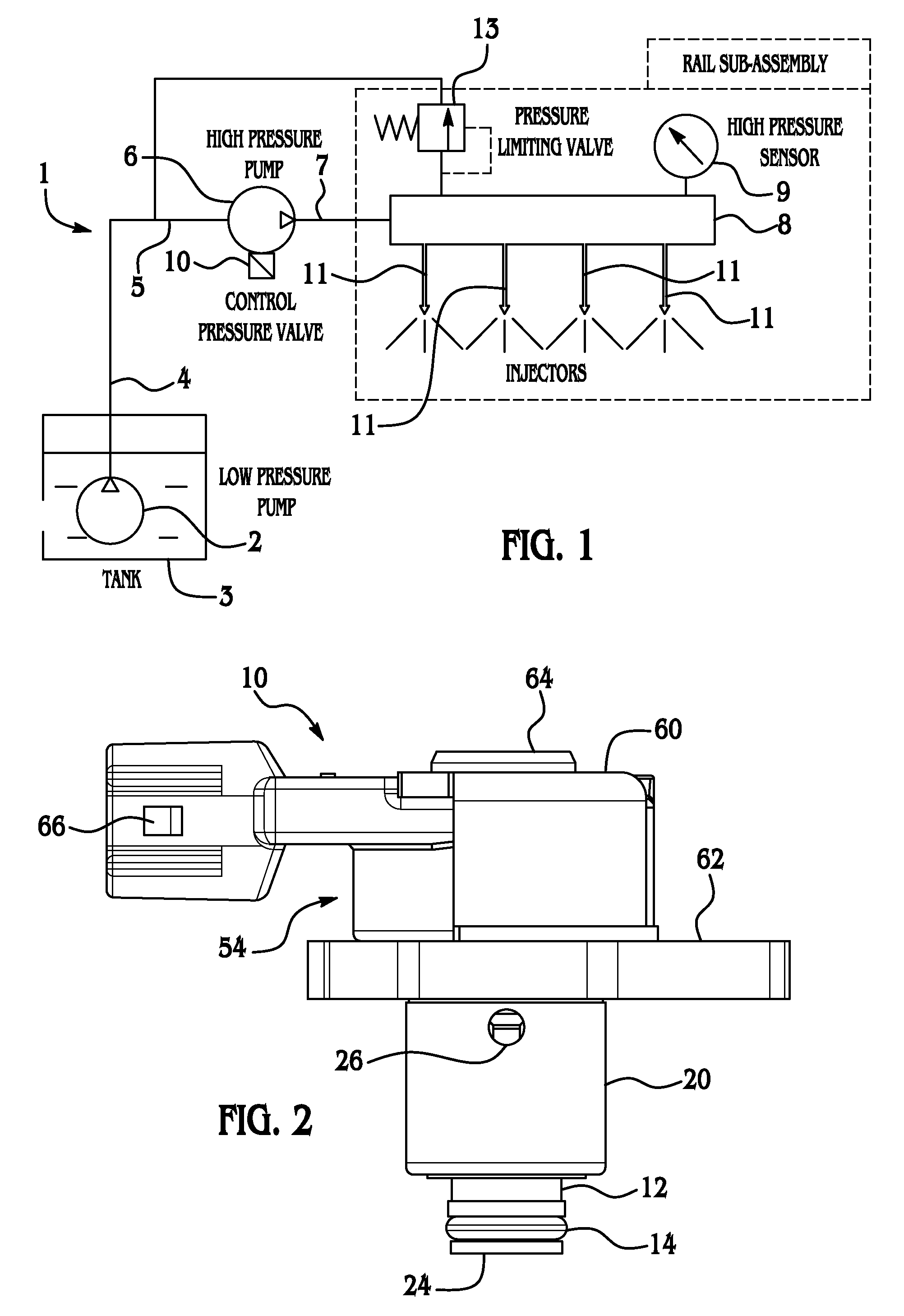

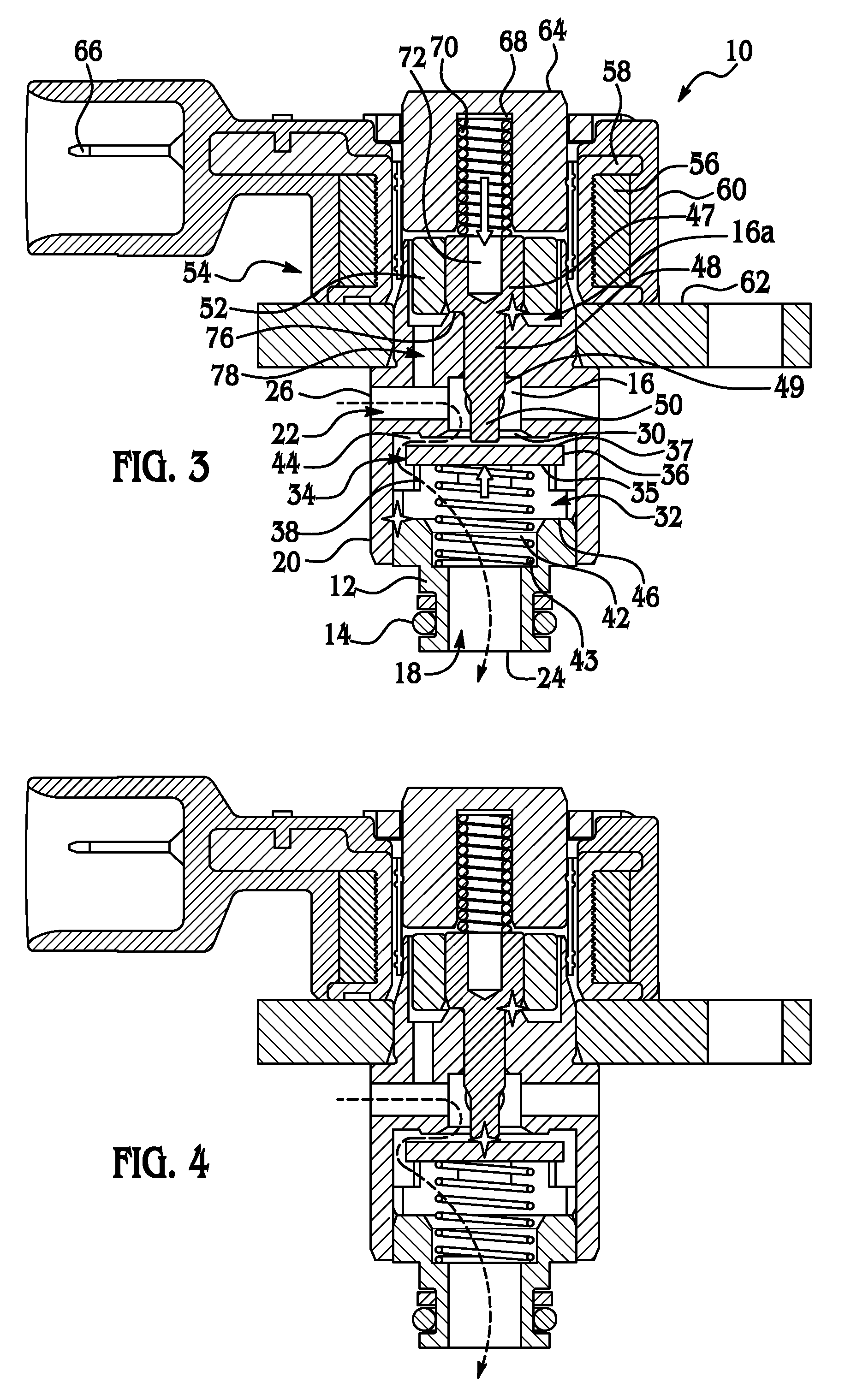

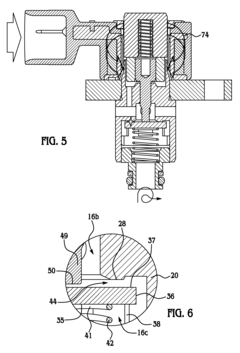

Control valve for a gas direct injection fuel system

PatentInactiveUS20080203347A1

Innovation

- A control valve design featuring a poppet mechanism and actuator system that regulates fluid communication between fluid paths, utilizing dual springs and an electrical actuator to manage pressure and flow rates, allowing for precise control of fuel injection by transitioning between open and closed states rapidly in response to engine conditions.

Gasoline direct injection engine

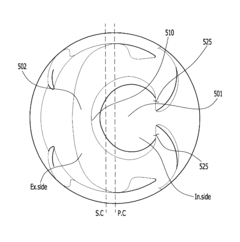

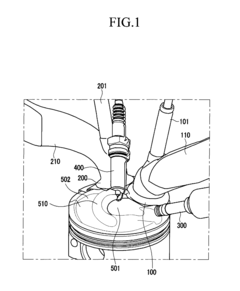

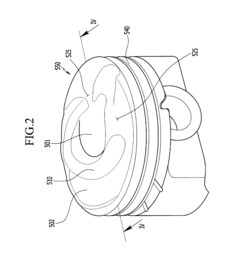

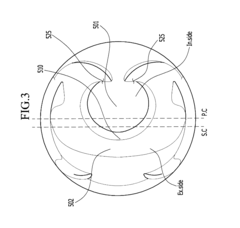

PatentInactiveUS8251040B2

Innovation

- The engine design includes a piston head with a first cavity for fuel return to the spark plug and a protrusion offset towards the exhaust valve, featuring a second cavity of a smaller height, allowing for differential control of intake and exhaust valve volumes to optimize the combustion chamber's volume ratio.

Emissions Regulations Impact on Valve Timing Development

Emissions regulations have become increasingly stringent worldwide, fundamentally reshaping the development trajectory of valve timing technologies in GDI (Gasoline Direct Injection) engines. Since the introduction of Euro 6 standards in Europe and Tier 3 regulations in the United States, manufacturers have been compelled to recalibrate their approach to intake valve timing optimization. These regulations have established unprecedented limits on NOx, particulate matter, and CO2 emissions, directly influencing the parameters within which valve timing must operate.

The California Air Resources Board (CARB) and the Environmental Protection Agency (EPA) have progressively tightened their requirements, with the latest standards demanding a reduction of fleet-average greenhouse gas emissions by approximately 5% annually through 2026. This regulatory pressure has accelerated research into variable valve timing systems that can dynamically adjust to different operating conditions while maintaining compliance with emissions standards.

Real Driving Emissions (RDE) testing, introduced in Europe in 2017, has particularly impacted valve timing development by requiring engines to perform efficiently across a broader range of operating conditions than traditional laboratory tests. This has necessitated more sophisticated control algorithms for valve timing that can optimize combustion efficiency while simultaneously managing emissions in real-world driving scenarios.

China's implementation of China 6 standards, equivalent to or stricter than Euro 6, has created a global convergence in emissions requirements, compelling engine designers to develop valve timing solutions with universal applicability. This global harmonization of standards has intensified competition among automotive manufacturers to develop proprietary valve timing technologies that deliver both performance and compliance.

The regulatory focus on cold-start emissions has specifically influenced intake valve timing strategies, as this phase accounts for a disproportionate percentage of total trip emissions. Engineers have responded by developing valve timing profiles that rapidly bring catalytic converters to operating temperature while minimizing raw emissions during the warm-up phase.

Looking forward, the announced phase-out of internal combustion engines in various markets by 2030-2040 has created a finite development window for GDI technology. This has paradoxically increased investment in advanced valve timing systems as manufacturers seek to maximize the efficiency and emissions performance of their combustion engines during this transition period to electrification.

The regulatory landscape has thus transformed valve timing from a performance-oriented feature to a critical emissions compliance technology, fundamentally altering development priorities and accelerating innovation in areas such as cam phasing speed, timing precision, and integration with other engine subsystems.

The California Air Resources Board (CARB) and the Environmental Protection Agency (EPA) have progressively tightened their requirements, with the latest standards demanding a reduction of fleet-average greenhouse gas emissions by approximately 5% annually through 2026. This regulatory pressure has accelerated research into variable valve timing systems that can dynamically adjust to different operating conditions while maintaining compliance with emissions standards.

Real Driving Emissions (RDE) testing, introduced in Europe in 2017, has particularly impacted valve timing development by requiring engines to perform efficiently across a broader range of operating conditions than traditional laboratory tests. This has necessitated more sophisticated control algorithms for valve timing that can optimize combustion efficiency while simultaneously managing emissions in real-world driving scenarios.

China's implementation of China 6 standards, equivalent to or stricter than Euro 6, has created a global convergence in emissions requirements, compelling engine designers to develop valve timing solutions with universal applicability. This global harmonization of standards has intensified competition among automotive manufacturers to develop proprietary valve timing technologies that deliver both performance and compliance.

The regulatory focus on cold-start emissions has specifically influenced intake valve timing strategies, as this phase accounts for a disproportionate percentage of total trip emissions. Engineers have responded by developing valve timing profiles that rapidly bring catalytic converters to operating temperature while minimizing raw emissions during the warm-up phase.

Looking forward, the announced phase-out of internal combustion engines in various markets by 2030-2040 has created a finite development window for GDI technology. This has paradoxically increased investment in advanced valve timing systems as manufacturers seek to maximize the efficiency and emissions performance of their combustion engines during this transition period to electrification.

The regulatory landscape has thus transformed valve timing from a performance-oriented feature to a critical emissions compliance technology, fundamentally altering development priorities and accelerating innovation in areas such as cam phasing speed, timing precision, and integration with other engine subsystems.

Fuel Economy and Performance Trade-offs

The optimization of intake valve timing in GDI (Gasoline Direct Injection) engines presents a classic engineering challenge that revolves around balancing fuel economy with performance metrics. This balance is not static but varies significantly across different operating conditions, creating a complex optimization landscape.

At lower engine speeds and partial load conditions, prioritizing fuel economy typically involves advancing intake valve closure timing to reduce pumping losses. This strategy effectively shortens the intake stroke, decreasing the work required during the compression phase. Studies have shown fuel consumption improvements of 3-7% through optimized valve timing in these conditions, particularly beneficial for urban driving cycles where engines frequently operate at partial loads.

Conversely, at higher engine speeds and loads, performance considerations often dominate. Delaying intake valve closure allows for improved cylinder filling due to the inertial effects of incoming air, enhancing volumetric efficiency. This translates to increased torque output and power, with potential gains of 5-10% in peak power output compared to fixed valve timing systems.

The trade-off becomes particularly evident in transient operations. Rapid acceleration scenarios demand responsive power delivery, requiring valve timing that maximizes airflow and combustion efficiency. However, this typically comes at the expense of increased fuel consumption, with studies indicating penalties of 8-15% compared to economy-optimized settings.

Temperature considerations further complicate this balance. Cold-start conditions necessitate different valve timing strategies to ensure proper combustion stability and emissions control, often at the expense of both performance and economy until operating temperature is reached.

Modern variable valve timing systems attempt to navigate these trade-offs through continuous adjustment based on operating conditions. Advanced systems can modify both timing and lift profiles, approaching the theoretical optimum for each condition. However, mechanical constraints, control system limitations, and production costs often necessitate compromises in the implementation of these systems.

The emergence of model-based control algorithms has enabled more sophisticated approaches to this optimization problem. These systems can predict the optimal valve timing based on multiple parameters including engine speed, load, temperature, and even driving behavior patterns, achieving a more dynamic balance between economy and performance objectives.

At lower engine speeds and partial load conditions, prioritizing fuel economy typically involves advancing intake valve closure timing to reduce pumping losses. This strategy effectively shortens the intake stroke, decreasing the work required during the compression phase. Studies have shown fuel consumption improvements of 3-7% through optimized valve timing in these conditions, particularly beneficial for urban driving cycles where engines frequently operate at partial loads.

Conversely, at higher engine speeds and loads, performance considerations often dominate. Delaying intake valve closure allows for improved cylinder filling due to the inertial effects of incoming air, enhancing volumetric efficiency. This translates to increased torque output and power, with potential gains of 5-10% in peak power output compared to fixed valve timing systems.

The trade-off becomes particularly evident in transient operations. Rapid acceleration scenarios demand responsive power delivery, requiring valve timing that maximizes airflow and combustion efficiency. However, this typically comes at the expense of increased fuel consumption, with studies indicating penalties of 8-15% compared to economy-optimized settings.

Temperature considerations further complicate this balance. Cold-start conditions necessitate different valve timing strategies to ensure proper combustion stability and emissions control, often at the expense of both performance and economy until operating temperature is reached.

Modern variable valve timing systems attempt to navigate these trade-offs through continuous adjustment based on operating conditions. Advanced systems can modify both timing and lift profiles, approaching the theoretical optimum for each condition. However, mechanical constraints, control system limitations, and production costs often necessitate compromises in the implementation of these systems.

The emergence of model-based control algorithms has enabled more sophisticated approaches to this optimization problem. These systems can predict the optimal valve timing based on multiple parameters including engine speed, load, temperature, and even driving behavior patterns, achieving a more dynamic balance between economy and performance objectives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!