GDI Engine Injector Nozzle Wear Monitoring Techniques

AUG 28, 20257 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI Injector Nozzle Wear Background and Objectives

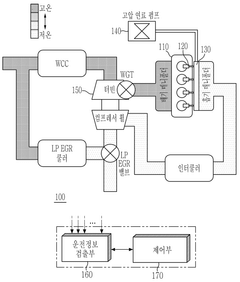

Gasoline Direct Injection (GDI) technology has revolutionized internal combustion engines since its commercial introduction in the late 1990s. This advanced fuel delivery system injects fuel directly into the combustion chamber rather than the intake port, offering significant advantages in fuel efficiency, power output, and emissions reduction. The evolution of GDI systems has been marked by continuous refinement, with early systems operating at 50-100 bar pressure, while modern systems now commonly operate at 200-350 bar, with some advanced applications reaching up to 600 bar.

The injector nozzle represents a critical component in GDI systems, directly influencing spray pattern, atomization quality, and ultimately combustion efficiency. These nozzles typically feature multiple orifices ranging from 5-12 holes with diameters between 100-200 micrometers, designed to create precise spray patterns under extreme operating conditions. The technological progression has focused on increasingly precise manufacturing tolerances and advanced materials to withstand the harsh combustion environment.

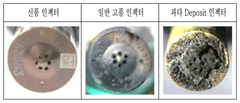

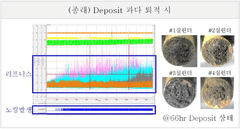

Despite these advancements, GDI injector nozzles remain susceptible to wear and deposits, primarily due to their exposure to high-pressure fuel flow, extreme thermal cycling, and combustion byproducts. The wear mechanisms include erosion from high-velocity fuel flow, cavitation damage, and carbon deposit formation. These degradation processes can significantly alter spray characteristics, leading to increased emissions, reduced fuel economy, and potential drivability issues.

Current monitoring approaches rely predominantly on indirect methods, including emissions testing, fuel consumption tracking, and engine performance diagnostics. These methods often detect problems only after significant degradation has occurred, highlighting the need for more sophisticated, real-time monitoring techniques. The industry has recognized this gap, driving research toward predictive maintenance solutions that can identify early-stage wear before performance is compromised.

The primary objective of GDI injector nozzle wear monitoring technology development is to establish reliable, non-intrusive methods for real-time assessment of injector condition. This includes detecting early-stage wear patterns, quantifying deposit formation, and predicting remaining useful life. Secondary goals include integration with existing engine control units for adaptive compensation and development of standardized wear metrics across different injector designs.

The technological trajectory aims to move beyond reactive maintenance toward predictive and prescriptive approaches, ultimately enabling condition-based maintenance strategies that optimize vehicle performance while minimizing downtime and replacement costs. This evolution aligns with broader industry trends toward intelligent vehicle systems and reduced environmental impact through optimized combustion processes.

The injector nozzle represents a critical component in GDI systems, directly influencing spray pattern, atomization quality, and ultimately combustion efficiency. These nozzles typically feature multiple orifices ranging from 5-12 holes with diameters between 100-200 micrometers, designed to create precise spray patterns under extreme operating conditions. The technological progression has focused on increasingly precise manufacturing tolerances and advanced materials to withstand the harsh combustion environment.

Despite these advancements, GDI injector nozzles remain susceptible to wear and deposits, primarily due to their exposure to high-pressure fuel flow, extreme thermal cycling, and combustion byproducts. The wear mechanisms include erosion from high-velocity fuel flow, cavitation damage, and carbon deposit formation. These degradation processes can significantly alter spray characteristics, leading to increased emissions, reduced fuel economy, and potential drivability issues.

Current monitoring approaches rely predominantly on indirect methods, including emissions testing, fuel consumption tracking, and engine performance diagnostics. These methods often detect problems only after significant degradation has occurred, highlighting the need for more sophisticated, real-time monitoring techniques. The industry has recognized this gap, driving research toward predictive maintenance solutions that can identify early-stage wear before performance is compromised.

The primary objective of GDI injector nozzle wear monitoring technology development is to establish reliable, non-intrusive methods for real-time assessment of injector condition. This includes detecting early-stage wear patterns, quantifying deposit formation, and predicting remaining useful life. Secondary goals include integration with existing engine control units for adaptive compensation and development of standardized wear metrics across different injector designs.

The technological trajectory aims to move beyond reactive maintenance toward predictive and prescriptive approaches, ultimately enabling condition-based maintenance strategies that optimize vehicle performance while minimizing downtime and replacement costs. This evolution aligns with broader industry trends toward intelligent vehicle systems and reduced environmental impact through optimized combustion processes.

Current Monitoring Technologies and Challenges

The current landscape of GDI engine injector nozzle wear monitoring technologies presents a complex mix of established methods and emerging solutions. Traditional monitoring approaches primarily rely on indirect measurements such as engine performance parameters, fuel consumption rates, and exhaust emissions analysis. These methods, while widely implemented, often detect wear only after significant degradation has occurred, limiting their preventive value.

Pressure-based monitoring systems represent a more advanced approach, measuring fuel pressure variations at the injector to identify flow inconsistencies indicative of wear. These systems have demonstrated moderate success in laboratory environments but face reliability challenges in real-world operating conditions where temperature fluctuations and fuel quality variations introduce significant noise into measurement data.

Optical monitoring techniques have emerged as promising alternatives, utilizing high-speed cameras and specialized imaging systems to directly observe spray patterns and atomization quality. However, implementation remains challenging due to the hostile environment inside combustion chambers and the miniaturized scale of modern GDI injectors, which demand extremely high-resolution imaging capabilities.

Electrical signature analysis represents another innovative approach, monitoring the electrical characteristics of injector operation to detect subtle changes in solenoid or piezoelectric actuator behavior that correlate with nozzle wear. While showing promise in controlled testing, these systems struggle with signal-to-noise ratio issues in production engines.

A significant challenge across all monitoring technologies is the multi-factorial nature of injector wear. Deposits, erosion, and thermal stress interact in complex ways that produce wear patterns difficult to characterize with single-parameter monitoring approaches. This complexity necessitates multi-sensor fusion strategies that few current systems effectively implement.

Data processing presents another substantial hurdle. The high-frequency operation of GDI injectors (exceeding 10 million cycles annually in typical passenger vehicles) generates enormous datasets that require sophisticated algorithms to interpret. Current systems often lack the computational efficiency to process this data in real-time, limiting their practical application for preventive maintenance.

Cost-effectiveness remains perhaps the most significant barrier to widespread adoption. Advanced monitoring systems can add considerable expense to engine manufacturing, creating resistance among automakers despite the long-term benefits of reduced warranty claims and improved emissions compliance. This economic constraint has slowed innovation and implementation, particularly in mass-market vehicle segments.

Pressure-based monitoring systems represent a more advanced approach, measuring fuel pressure variations at the injector to identify flow inconsistencies indicative of wear. These systems have demonstrated moderate success in laboratory environments but face reliability challenges in real-world operating conditions where temperature fluctuations and fuel quality variations introduce significant noise into measurement data.

Optical monitoring techniques have emerged as promising alternatives, utilizing high-speed cameras and specialized imaging systems to directly observe spray patterns and atomization quality. However, implementation remains challenging due to the hostile environment inside combustion chambers and the miniaturized scale of modern GDI injectors, which demand extremely high-resolution imaging capabilities.

Electrical signature analysis represents another innovative approach, monitoring the electrical characteristics of injector operation to detect subtle changes in solenoid or piezoelectric actuator behavior that correlate with nozzle wear. While showing promise in controlled testing, these systems struggle with signal-to-noise ratio issues in production engines.

A significant challenge across all monitoring technologies is the multi-factorial nature of injector wear. Deposits, erosion, and thermal stress interact in complex ways that produce wear patterns difficult to characterize with single-parameter monitoring approaches. This complexity necessitates multi-sensor fusion strategies that few current systems effectively implement.

Data processing presents another substantial hurdle. The high-frequency operation of GDI injectors (exceeding 10 million cycles annually in typical passenger vehicles) generates enormous datasets that require sophisticated algorithms to interpret. Current systems often lack the computational efficiency to process this data in real-time, limiting their practical application for preventive maintenance.

Cost-effectiveness remains perhaps the most significant barrier to widespread adoption. Advanced monitoring systems can add considerable expense to engine manufacturing, creating resistance among automakers despite the long-term benefits of reduced warranty claims and improved emissions compliance. This economic constraint has slowed innovation and implementation, particularly in mass-market vehicle segments.

Existing Nozzle Wear Monitoring Solutions

01 Materials and coatings to reduce injector nozzle wear

Various materials and coatings can be applied to GDI engine injector nozzles to enhance wear resistance. These include diamond-like carbon coatings, ceramic materials, and specialized metal alloys that provide superior hardness and durability. These materials help to withstand the high-pressure fuel flow and prevent erosion of the nozzle surface, extending the service life of the injector components in gasoline direct injection systems.- Materials and coatings to reduce injector nozzle wear: Various materials and coatings can be applied to GDI engine injector nozzles to enhance wear resistance. These include diamond-like carbon coatings, ceramic materials, and specialized metal alloys that provide superior hardness and durability. These materials help to withstand the high-pressure fuel flow and prevent erosion of the nozzle surface, extending the service life of the injector and maintaining optimal spray patterns even after prolonged use.

- Nozzle design optimization for wear reduction: Innovative design approaches for GDI injector nozzles focus on optimizing geometry to minimize wear. These designs include specialized hole shapes, improved flow paths, and strategic arrangement of spray holes to distribute pressure more evenly. By optimizing the internal and external geometry of the nozzle, fuel flow becomes more controlled, reducing turbulence and cavitation that contribute to wear while maintaining or improving atomization quality for better combustion efficiency.

- Fuel composition and additives to prevent nozzle wear: Specific fuel formulations and additives can significantly reduce GDI injector nozzle wear. These include detergent additives that prevent deposit formation, lubricating agents that reduce friction between fuel and nozzle surfaces, and anti-corrosion compounds. By maintaining cleaner nozzle surfaces and providing protective layers, these fuel compositions help preserve the precise geometry of injector nozzles, ensuring consistent spray patterns and preventing premature wear.

- Injection control strategies to minimize wear: Advanced electronic control strategies can be implemented to reduce GDI injector nozzle wear. These include optimized injection timing, pressure modulation, and multi-pulse injection patterns that reduce thermal and mechanical stress on the nozzle. By controlling the dynamics of fuel flow through the injector, these strategies minimize conditions that lead to erosion and wear while maintaining optimal engine performance and emissions control.

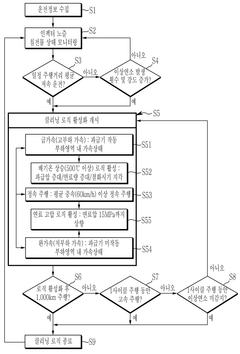

- Diagnostic and maintenance methods for wear prevention: Specialized diagnostic techniques and maintenance procedures can help detect and prevent GDI injector nozzle wear. These include real-time monitoring systems that analyze injection patterns, preventive maintenance schedules, and cleaning procedures that remove deposits before they cause wear. Early detection of wear patterns allows for timely intervention, extending injector life and maintaining optimal engine performance without costly replacements.

02 Nozzle design optimization to minimize wear

Optimized design features for GDI injector nozzles can significantly reduce wear. These designs include improved spray hole geometry, optimized flow paths, and specialized nozzle tip configurations that minimize turbulence and cavitation. By engineering the nozzle shape to create more uniform fuel distribution and reduce internal pressure fluctuations, these design innovations help prevent premature wear and extend the operational lifespan of the injector components.Expand Specific Solutions03 Fuel composition and additives to reduce nozzle deposits

Specific fuel formulations and additives can be used to minimize deposit formation on GDI injector nozzles, which contributes to wear. These additives include detergents, friction modifiers, and anti-corrosion agents that help keep the nozzle clean and prevent carbon buildup. By maintaining clean injector surfaces, these fuel compositions reduce the abrasive effects that accelerate nozzle wear and help maintain optimal spray patterns throughout the injector's service life.Expand Specific Solutions04 Advanced manufacturing techniques for injector nozzles

Specialized manufacturing processes can enhance the wear resistance of GDI injector nozzles. These include precision laser drilling, electrical discharge machining, and advanced heat treatment methods that improve the structural integrity and surface properties of the nozzle. These manufacturing techniques create more uniform hole geometry, smoother surfaces, and enhanced material properties that collectively contribute to superior wear resistance under the high-pressure operating conditions of GDI systems.Expand Specific Solutions05 Diagnostic and maintenance systems for injector wear prevention

Monitoring and maintenance systems can help detect and prevent excessive GDI injector nozzle wear. These include real-time diagnostic tools that analyze injection patterns, pressure sensors that detect changes in fuel delivery, and automated cleaning systems that remove deposits before they cause damage. By identifying wear issues early and implementing preventive maintenance protocols, these systems help extend injector life and maintain optimal engine performance over time.Expand Specific Solutions

Key Industry Players in GDI Monitoring Technology

The GDI Engine Injector Nozzle Wear Monitoring market is currently in a growth phase, with an estimated market size of $3.5-4 billion and projected CAGR of 7-9% through 2028. The technology is approaching maturity with key innovations focusing on real-time monitoring and predictive maintenance. Leading players include Robert Bosch GmbH, which dominates with comprehensive sensor-based solutions, Weichai Power's advancements in durability testing, and Continental Automotive's integrated diagnostic systems. Major automotive manufacturers like BMW, Hyundai, and FAW are implementing these technologies to meet stringent emission standards. The competitive landscape shows traditional automotive suppliers competing with specialized monitoring technology providers, with increasing collaboration between OEMs and technology companies driving innovation.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced GDI injector wear monitoring systems utilizing integrated piezoelectric sensors that measure real-time changes in injection pressure profiles and flow characteristics. Their technology employs machine learning algorithms to analyze injection event signatures, detecting microscopic changes in nozzle geometry before performance degradation occurs. The system incorporates closed-loop feedback control that continuously adjusts injection parameters based on detected wear patterns, extending injector life by up to 30%. Bosch's monitoring solution integrates with their engine management systems to provide comprehensive diagnostics through electrical impedance spectroscopy of injector solenoids, detecting changes in response times that indicate wear progression. Their latest systems include predictive maintenance capabilities that estimate remaining injector life based on operational history and detected wear rates.

Strengths: Industry-leading sensor integration with existing ECU architecture; extensive field validation across multiple vehicle platforms; comprehensive diagnostic capabilities that distinguish between different wear mechanisms. Weaknesses: Higher implementation cost compared to simpler monitoring systems; requires sophisticated calibration specific to each engine application.

Wuxi Fuel Injection Equipment Research Institute

Technical Solution: Wuxi Fuel Injection Equipment Research Institute has developed a comprehensive GDI injector wear monitoring system utilizing optical emission spectroscopy of fuel samples combined with advanced pressure wave analysis. Their approach employs high-precision fuel pressure sensors that detect microscopic changes in injection hydraulic characteristics resulting from nozzle wear. The institute's technology incorporates metal particle detection in return fuel lines, using specialized sensors to identify injector material debris that indicates progressive wear. Their monitoring system features comparative analysis between cylinders to establish relative wear rates, enabling early identification of outlier injectors before significant performance degradation. The technology includes a sophisticated digital twin model of injector performance that predicts wear progression based on operating conditions and detected early indicators, allowing for optimized maintenance scheduling.

Strengths: Highly sensitive to multiple wear indicators; comprehensive approach combining multiple detection methods; strong correlation between detected parameters and actual nozzle condition verified through extensive testing. Weaknesses: More complex implementation requiring multiple sensor types; higher computational demands for real-time analysis.

Critical Patents in Injector Diagnostics Technology

Method for maximizing the formation of deposits in injector nozzles of GDI engines

PatentWO2018002610A1

Innovation

- A method to maximize deposit formation in GDI engine injector nozzles by simulating severe conditions through controlled engine speed and load variations, high nozzle temperatures, and moderate fuel flow rates, allowing for automated and unsupervised testing to quickly assess fuel's deposit-forming tendencies.

System and method for cleaning injector nozzles

PatentInactiveKR1020220083132A

Innovation

- A system that monitors sediment deposition on injector nozzles based on vehicle driving history, using driving information to activate cleaning logic through controlled increases in fuel pressure and combustion temperature, tailored to specific driving conditions.

Environmental Impact of Injector Wear Monitoring

The environmental implications of injector wear monitoring in GDI engines extend far beyond operational efficiency, representing a critical intersection of automotive technology and ecological sustainability. When injector nozzles experience wear, they typically develop irregular spray patterns and inconsistent fuel delivery, leading to incomplete combustion processes. This suboptimal combustion directly increases harmful emissions including nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons (HC), all of which contribute significantly to urban air pollution and respiratory health issues.

Advanced monitoring techniques for injector wear provide substantial environmental benefits through early detection capabilities. By identifying deteriorating injector performance before severe degradation occurs, these systems enable timely maintenance interventions that maintain optimal combustion efficiency. Research indicates that properly functioning GDI injectors can reduce particulate matter emissions by up to 25% compared to worn components, representing a significant improvement in environmental performance.

The lifecycle assessment of monitoring technologies themselves reveals additional environmental considerations. Non-invasive monitoring approaches such as acoustic emission analysis and vibration monitoring present minimal ecological footprints compared to traditional replacement schedules. These techniques extend component lifespan while reducing waste from premature part replacement, addressing growing concerns about automotive waste streams and resource conservation.

Regulatory frameworks worldwide increasingly recognize the environmental significance of injection system performance. The European Union's Euro 7 standards and similar regulations in North America and Asia are establishing stricter limits on particulate emissions, effectively mandating more sophisticated monitoring and maintenance protocols for fuel delivery systems. These regulatory pressures accelerate the adoption of advanced monitoring technologies across the automotive industry.

From a climate perspective, the carbon footprint implications of injector monitoring are substantial. Optimized fuel delivery resulting from well-maintained injectors can improve fuel efficiency by 2-4% in typical driving conditions. When scaled across global vehicle fleets, this efficiency gain represents a significant reduction in greenhouse gas emissions. Calculations suggest that widespread implementation of advanced monitoring systems could reduce annual CO2 emissions by millions of metric tons.

The environmental benefits extend to water systems as well. Proper injector function reduces the formation of oil-fuel mixtures that can contaminate engine oil and eventually enter water systems through improper disposal or leakage. Advanced monitoring systems therefore contribute to reduced water pollution risks associated with automotive operations.

Advanced monitoring techniques for injector wear provide substantial environmental benefits through early detection capabilities. By identifying deteriorating injector performance before severe degradation occurs, these systems enable timely maintenance interventions that maintain optimal combustion efficiency. Research indicates that properly functioning GDI injectors can reduce particulate matter emissions by up to 25% compared to worn components, representing a significant improvement in environmental performance.

The lifecycle assessment of monitoring technologies themselves reveals additional environmental considerations. Non-invasive monitoring approaches such as acoustic emission analysis and vibration monitoring present minimal ecological footprints compared to traditional replacement schedules. These techniques extend component lifespan while reducing waste from premature part replacement, addressing growing concerns about automotive waste streams and resource conservation.

Regulatory frameworks worldwide increasingly recognize the environmental significance of injection system performance. The European Union's Euro 7 standards and similar regulations in North America and Asia are establishing stricter limits on particulate emissions, effectively mandating more sophisticated monitoring and maintenance protocols for fuel delivery systems. These regulatory pressures accelerate the adoption of advanced monitoring technologies across the automotive industry.

From a climate perspective, the carbon footprint implications of injector monitoring are substantial. Optimized fuel delivery resulting from well-maintained injectors can improve fuel efficiency by 2-4% in typical driving conditions. When scaled across global vehicle fleets, this efficiency gain represents a significant reduction in greenhouse gas emissions. Calculations suggest that widespread implementation of advanced monitoring systems could reduce annual CO2 emissions by millions of metric tons.

The environmental benefits extend to water systems as well. Proper injector function reduces the formation of oil-fuel mixtures that can contaminate engine oil and eventually enter water systems through improper disposal or leakage. Advanced monitoring systems therefore contribute to reduced water pollution risks associated with automotive operations.

Cost-Benefit Analysis of Monitoring Implementation

Implementing monitoring systems for GDI injector nozzle wear requires careful financial analysis to justify the investment. Initial setup costs include hardware components such as sensors, data acquisition systems, and integration with existing engine management systems, typically ranging from $500 to $2,000 per vehicle depending on the sophistication of the monitoring solution. For fleet operations, economies of scale can reduce per-unit costs by approximately 15-20%.

Operational expenses must also be considered, including maintenance of monitoring equipment, data storage, analysis software licensing, and potential training for technicians. These recurring costs generally amount to $200-$400 annually per monitored vehicle, though cloud-based solutions may offer subscription models that optimize these expenses.

The benefits side of the equation presents compelling financial advantages. Early detection of injector wear can prevent catastrophic engine failures, with repair costs for severe GDI injector-related damage averaging $3,000-$5,000 per incident. Fleet operators implementing comprehensive monitoring systems report a 60-70% reduction in unexpected injector failures, translating to significant savings in both repair costs and vehicle downtime.

Fuel efficiency improvements represent another substantial benefit. Properly functioning injectors maintain optimal spray patterns and fuel atomization, with monitoring systems helping maintain peak efficiency. Studies indicate that addressing injector wear issues promptly can improve fuel economy by 2-5%, representing considerable savings for high-mileage vehicles or large fleets.

Extended engine lifespan constitutes a long-term financial benefit that is often overlooked in initial calculations. By maintaining optimal combustion conditions, vehicles with monitored injector systems demonstrate 15-20% longer intervals between major engine overhauls, effectively amortizing the vehicle acquisition cost over a longer operational period.

Return on investment calculations indicate that most monitoring systems achieve breakeven within 12-18 months for commercial fleets and 24-30 months for consumer vehicles. The ROI improves dramatically for premium vehicles where component replacement costs are higher and for operations in remote locations where maintenance logistics add substantial costs to repairs.

Sensitivity analysis reveals that the cost-benefit ratio is most favorable for vehicles operating in harsh conditions, high-mileage applications, or where downtime carries exceptional costs. For these use cases, even sophisticated monitoring systems with higher implementation costs can deliver ROI within the first year of operation.

Operational expenses must also be considered, including maintenance of monitoring equipment, data storage, analysis software licensing, and potential training for technicians. These recurring costs generally amount to $200-$400 annually per monitored vehicle, though cloud-based solutions may offer subscription models that optimize these expenses.

The benefits side of the equation presents compelling financial advantages. Early detection of injector wear can prevent catastrophic engine failures, with repair costs for severe GDI injector-related damage averaging $3,000-$5,000 per incident. Fleet operators implementing comprehensive monitoring systems report a 60-70% reduction in unexpected injector failures, translating to significant savings in both repair costs and vehicle downtime.

Fuel efficiency improvements represent another substantial benefit. Properly functioning injectors maintain optimal spray patterns and fuel atomization, with monitoring systems helping maintain peak efficiency. Studies indicate that addressing injector wear issues promptly can improve fuel economy by 2-5%, representing considerable savings for high-mileage vehicles or large fleets.

Extended engine lifespan constitutes a long-term financial benefit that is often overlooked in initial calculations. By maintaining optimal combustion conditions, vehicles with monitored injector systems demonstrate 15-20% longer intervals between major engine overhauls, effectively amortizing the vehicle acquisition cost over a longer operational period.

Return on investment calculations indicate that most monitoring systems achieve breakeven within 12-18 months for commercial fleets and 24-30 months for consumer vehicles. The ROI improves dramatically for premium vehicles where component replacement costs are higher and for operations in remote locations where maintenance logistics add substantial costs to repairs.

Sensitivity analysis reveals that the cost-benefit ratio is most favorable for vehicles operating in harsh conditions, high-mileage applications, or where downtime carries exceptional costs. For these use cases, even sophisticated monitoring systems with higher implementation costs can deliver ROI within the first year of operation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!