Quantify GDI Engine's Fuel Economy with Specific Tests

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI Engine Technology Background and Objectives

Gasoline Direct Injection (GDI) technology represents a significant evolution in internal combustion engine design, emerging as a response to increasingly stringent emissions regulations and consumer demand for improved fuel efficiency. First conceptualized in the early 20th century, GDI technology only became commercially viable in the 1990s when electronic control systems advanced sufficiently to manage the precise fuel delivery required. Unlike traditional port fuel injection systems, GDI injects fuel directly into the combustion chamber at high pressure, allowing for more precise control over the combustion process.

The evolution of GDI technology has been characterized by continuous refinement in injector design, spray pattern optimization, and integration with other engine technologies such as turbocharging and variable valve timing. This technological progression has enabled manufacturers to extract greater efficiency from smaller displacement engines while maintaining or improving performance characteristics—a concept known as "downsizing."

Current market trends indicate a growing adoption of GDI engines across various vehicle segments, from economy cars to high-performance vehicles. This widespread implementation underscores the technology's versatility and effectiveness in addressing both regulatory requirements and market demands. Industry forecasts suggest that by 2025, GDI systems will be present in over 50% of new gasoline-powered vehicles globally.

The primary technical objective in quantifying GDI engine fuel economy is to establish standardized testing methodologies that accurately reflect real-world operating conditions. This includes developing test cycles that incorporate various driving scenarios, ambient conditions, and engine loads to provide comprehensive performance data. Additionally, there is a need to isolate the specific contribution of GDI technology from other efficiency-enhancing features in modern engines.

Secondary objectives include identifying the optimal operating parameters for maximum fuel efficiency, understanding the relationship between injection timing, pressure, and fuel atomization on combustion efficiency, and evaluating the long-term durability and maintenance requirements of GDI systems compared to conventional fuel injection technologies.

The broader goal of this technical research extends beyond mere quantification to establishing a framework for continuous improvement in GDI technology. By developing robust testing methodologies, engineers can more effectively target areas for enhancement, such as reducing particulate emissions—a known challenge with GDI engines—while maintaining their superior fuel economy advantages.

As automotive manufacturers continue to face pressure to reduce fleet emissions and improve fuel economy, the refinement of GDI technology remains a critical pathway to meeting these objectives. Quantifying the precise benefits through specific, standardized tests will provide valuable data to guide future development efforts and regulatory frameworks.

The evolution of GDI technology has been characterized by continuous refinement in injector design, spray pattern optimization, and integration with other engine technologies such as turbocharging and variable valve timing. This technological progression has enabled manufacturers to extract greater efficiency from smaller displacement engines while maintaining or improving performance characteristics—a concept known as "downsizing."

Current market trends indicate a growing adoption of GDI engines across various vehicle segments, from economy cars to high-performance vehicles. This widespread implementation underscores the technology's versatility and effectiveness in addressing both regulatory requirements and market demands. Industry forecasts suggest that by 2025, GDI systems will be present in over 50% of new gasoline-powered vehicles globally.

The primary technical objective in quantifying GDI engine fuel economy is to establish standardized testing methodologies that accurately reflect real-world operating conditions. This includes developing test cycles that incorporate various driving scenarios, ambient conditions, and engine loads to provide comprehensive performance data. Additionally, there is a need to isolate the specific contribution of GDI technology from other efficiency-enhancing features in modern engines.

Secondary objectives include identifying the optimal operating parameters for maximum fuel efficiency, understanding the relationship between injection timing, pressure, and fuel atomization on combustion efficiency, and evaluating the long-term durability and maintenance requirements of GDI systems compared to conventional fuel injection technologies.

The broader goal of this technical research extends beyond mere quantification to establishing a framework for continuous improvement in GDI technology. By developing robust testing methodologies, engineers can more effectively target areas for enhancement, such as reducing particulate emissions—a known challenge with GDI engines—while maintaining their superior fuel economy advantages.

As automotive manufacturers continue to face pressure to reduce fleet emissions and improve fuel economy, the refinement of GDI technology remains a critical pathway to meeting these objectives. Quantifying the precise benefits through specific, standardized tests will provide valuable data to guide future development efforts and regulatory frameworks.

Market Demand Analysis for Fuel-Efficient Engines

The global automotive industry is witnessing a significant shift towards fuel-efficient technologies, with Gasoline Direct Injection (GDI) engines emerging as a key solution. Market analysis indicates that the demand for fuel-efficient engines has grown at an annual rate of 5.7% over the past five years, driven primarily by stringent emission regulations and consumer preference for economical vehicles.

Consumer surveys across major markets reveal that fuel economy ranks among the top three purchasing considerations for 78% of new vehicle buyers. This trend is particularly pronounced in regions with high fuel prices such as Europe and parts of Asia, where consumers demonstrate willingness to pay premium prices for vehicles offering superior fuel efficiency.

Regulatory frameworks worldwide continue to tighten emission standards, with the European Union's Euro 7 standards, the United States' CAFE regulations, and China's dual-credit policy all pushing manufacturers towards more efficient powertrain solutions. These regulations have created a projected market opportunity of $47.9 billion for fuel-efficient engine technologies by 2028.

The GDI engine segment specifically has shown remarkable growth, capturing 43% of the global gasoline engine market in 2022, up from 27% in 2017. Industry forecasts suggest this share will reach 58% by 2027, representing a compound annual growth rate of 6.3%.

Fleet operators and commercial vehicle segments demonstrate particularly strong demand for quantifiable fuel economy improvements, with purchasing decisions increasingly based on total cost of ownership calculations where fuel consumption is a dominant factor. Studies indicate that a 5% improvement in fuel efficiency can translate to savings of approximately $3,000 per vehicle annually for commercial fleets.

Market segmentation analysis reveals varying demand patterns across vehicle categories. The compact and mid-size segments show the highest adoption rates for GDI technology at 52%, followed by SUVs at 47% and luxury vehicles at 39%. The commercial vehicle segment, while currently at 28% adoption, is projected to be the fastest-growing segment with a 9.2% annual growth rate.

Regional market analysis indicates that North America and Europe currently lead in GDI engine demand, accounting for 37% and 33% of the global market respectively. However, the Asia-Pacific region, particularly China and India, is expected to demonstrate the highest growth rate at 8.4% annually through 2027, driven by rapid vehicle market expansion and increasingly stringent emission standards.

Consumer willingness to pay for fuel efficiency improvements varies by market segment, with premium vehicle buyers accepting a 3-5% price premium for 10% better fuel economy, while mass-market consumers expect a return on investment within 2-3 years of ownership.

Consumer surveys across major markets reveal that fuel economy ranks among the top three purchasing considerations for 78% of new vehicle buyers. This trend is particularly pronounced in regions with high fuel prices such as Europe and parts of Asia, where consumers demonstrate willingness to pay premium prices for vehicles offering superior fuel efficiency.

Regulatory frameworks worldwide continue to tighten emission standards, with the European Union's Euro 7 standards, the United States' CAFE regulations, and China's dual-credit policy all pushing manufacturers towards more efficient powertrain solutions. These regulations have created a projected market opportunity of $47.9 billion for fuel-efficient engine technologies by 2028.

The GDI engine segment specifically has shown remarkable growth, capturing 43% of the global gasoline engine market in 2022, up from 27% in 2017. Industry forecasts suggest this share will reach 58% by 2027, representing a compound annual growth rate of 6.3%.

Fleet operators and commercial vehicle segments demonstrate particularly strong demand for quantifiable fuel economy improvements, with purchasing decisions increasingly based on total cost of ownership calculations where fuel consumption is a dominant factor. Studies indicate that a 5% improvement in fuel efficiency can translate to savings of approximately $3,000 per vehicle annually for commercial fleets.

Market segmentation analysis reveals varying demand patterns across vehicle categories. The compact and mid-size segments show the highest adoption rates for GDI technology at 52%, followed by SUVs at 47% and luxury vehicles at 39%. The commercial vehicle segment, while currently at 28% adoption, is projected to be the fastest-growing segment with a 9.2% annual growth rate.

Regional market analysis indicates that North America and Europe currently lead in GDI engine demand, accounting for 37% and 33% of the global market respectively. However, the Asia-Pacific region, particularly China and India, is expected to demonstrate the highest growth rate at 8.4% annually through 2027, driven by rapid vehicle market expansion and increasingly stringent emission standards.

Consumer willingness to pay for fuel efficiency improvements varies by market segment, with premium vehicle buyers accepting a 3-5% price premium for 10% better fuel economy, while mass-market consumers expect a return on investment within 2-3 years of ownership.

Current State and Challenges in GDI Fuel Economy Testing

Gasoline Direct Injection (GDI) technology has become a cornerstone of modern internal combustion engine design, offering significant potential for improved fuel economy. However, quantifying these benefits presents substantial challenges in the current testing landscape. Standard testing protocols established by regulatory bodies such as the EPA, CARB, and European Commission often fail to fully capture the real-world performance advantages of GDI systems, particularly under dynamic driving conditions where direct injection provides its most significant benefits.

Current laboratory testing methodologies predominantly utilize steady-state conditions that inadequately represent the transient operation where GDI excels. The New European Driving Cycle (NEDC) and Federal Test Procedure (FTP) cycles, while standardized, have been criticized for their limited ability to reflect actual driving behaviors and the resulting fuel economy benefits of advanced injection technologies. This disconnect between laboratory results and real-world performance creates significant challenges for manufacturers seeking to demonstrate GDI advantages.

Technical limitations in measurement precision also impede accurate quantification of GDI benefits. The complex interaction between injection timing, spray pattern, and combustion dynamics requires sophisticated instrumentation that can capture microsecond-level events. Current industry-standard equipment often lacks the temporal resolution necessary to fully characterize these rapid processes, leading to incomplete data collection and analysis.

Another significant challenge lies in isolating GDI-specific benefits from other engine technologies. Modern engines typically implement multiple efficiency-enhancing features simultaneously, including variable valve timing, turbocharging, and advanced thermal management. Determining the specific contribution of the GDI system requires carefully controlled testing environments and sophisticated statistical methods that are not yet standardized across the industry.

Environmental factors further complicate testing procedures. GDI systems demonstrate varying performance characteristics across different ambient temperatures, altitudes, and humidity levels. Current standardized tests typically occur under narrowly defined environmental conditions that may not represent the diverse operating environments vehicles encounter. This limitation creates uncertainty when extrapolating laboratory results to predict real-world fuel economy benefits.

Fuel quality variations present additional challenges, as GDI systems can be particularly sensitive to fuel composition differences. Regional and seasonal variations in fuel formulations can significantly impact performance metrics, yet standardized testing protocols rarely account for these variables. The lack of globally harmonized fuel standards further complicates cross-market comparisons of GDI efficiency benefits.

Emerging technologies like real-driving emissions (RDE) testing and portable emissions measurement systems (PEMS) offer promising approaches to address some of these challenges, but methodological standardization remains incomplete. Without consistent testing protocols specifically designed to evaluate GDI performance under representative conditions, quantifying the true fuel economy benefits of this technology will continue to present significant technical and regulatory challenges.

Current laboratory testing methodologies predominantly utilize steady-state conditions that inadequately represent the transient operation where GDI excels. The New European Driving Cycle (NEDC) and Federal Test Procedure (FTP) cycles, while standardized, have been criticized for their limited ability to reflect actual driving behaviors and the resulting fuel economy benefits of advanced injection technologies. This disconnect between laboratory results and real-world performance creates significant challenges for manufacturers seeking to demonstrate GDI advantages.

Technical limitations in measurement precision also impede accurate quantification of GDI benefits. The complex interaction between injection timing, spray pattern, and combustion dynamics requires sophisticated instrumentation that can capture microsecond-level events. Current industry-standard equipment often lacks the temporal resolution necessary to fully characterize these rapid processes, leading to incomplete data collection and analysis.

Another significant challenge lies in isolating GDI-specific benefits from other engine technologies. Modern engines typically implement multiple efficiency-enhancing features simultaneously, including variable valve timing, turbocharging, and advanced thermal management. Determining the specific contribution of the GDI system requires carefully controlled testing environments and sophisticated statistical methods that are not yet standardized across the industry.

Environmental factors further complicate testing procedures. GDI systems demonstrate varying performance characteristics across different ambient temperatures, altitudes, and humidity levels. Current standardized tests typically occur under narrowly defined environmental conditions that may not represent the diverse operating environments vehicles encounter. This limitation creates uncertainty when extrapolating laboratory results to predict real-world fuel economy benefits.

Fuel quality variations present additional challenges, as GDI systems can be particularly sensitive to fuel composition differences. Regional and seasonal variations in fuel formulations can significantly impact performance metrics, yet standardized testing protocols rarely account for these variables. The lack of globally harmonized fuel standards further complicates cross-market comparisons of GDI efficiency benefits.

Emerging technologies like real-driving emissions (RDE) testing and portable emissions measurement systems (PEMS) offer promising approaches to address some of these challenges, but methodological standardization remains incomplete. Without consistent testing protocols specifically designed to evaluate GDI performance under representative conditions, quantifying the true fuel economy benefits of this technology will continue to present significant technical and regulatory challenges.

Current Methodologies for GDI Fuel Economy Quantification

01 Fuel injection system optimization

Optimizing the fuel injection system in GDI engines can significantly improve fuel economy. This includes precise control of injection timing, pressure, and spray pattern to ensure optimal combustion. Advanced injector designs that provide better atomization of fuel and reduce wall wetting can minimize fuel waste and improve combustion efficiency, leading to better fuel economy in gasoline direct injection engines.- Fuel injection system optimization: Optimizing the fuel injection system in GDI engines can significantly improve fuel economy. This includes precise control of injection timing, pressure, and spray pattern to ensure optimal fuel atomization and combustion efficiency. Advanced injection strategies such as multiple injections per cycle and variable injection pressure systems help reduce fuel consumption while maintaining performance. These optimizations ensure better air-fuel mixture formation and more complete combustion.

- Engine control and management systems: Sophisticated engine control and management systems play a crucial role in improving GDI engine fuel economy. These systems utilize various sensors and algorithms to monitor engine parameters and adjust operating conditions in real-time. Advanced electronic control units (ECUs) can implement strategies such as lean burn operation, cylinder deactivation, and adaptive fuel mapping to optimize fuel consumption based on driving conditions and load requirements.

- Combustion chamber design improvements: Innovations in combustion chamber design contribute to enhanced fuel economy in GDI engines. Optimized piston crown shapes, intake port configurations, and valve arrangements promote better air-fuel mixing and more efficient combustion. Designs that create controlled turbulence or swirl patterns help distribute fuel evenly throughout the combustion chamber, reducing wall wetting and improving combustion efficiency, which directly translates to better fuel economy.

- Friction reduction technologies: Reducing mechanical friction within GDI engines is an effective approach to improving fuel economy. This includes the use of low-friction coatings on engine components, optimized piston ring designs, advanced lubricants, and improved bearing surfaces. Lightweight components and materials also contribute to reduced friction and inertial losses. These technologies collectively minimize parasitic power losses, allowing more of the fuel energy to be converted into useful work.

- Thermal management and efficiency: Effective thermal management systems improve GDI engine fuel economy by optimizing operating temperatures. Advanced cooling systems, exhaust heat recovery mechanisms, and thermal barrier coatings help maintain ideal combustion temperatures and reduce heat losses. Strategic cooling of specific engine components and rapid warm-up technologies ensure the engine reaches and maintains its most efficient operating temperature range quickly, reducing fuel consumption particularly during cold starts and low-load operation.

02 Combustion chamber design improvements

Modifications to the combustion chamber design can enhance the fuel economy of GDI engines. This includes optimizing the piston crown shape, cylinder head design, and valve configuration to promote better air-fuel mixing and more complete combustion. Improved combustion chamber designs can reduce knocking tendencies, allowing for higher compression ratios which directly contribute to better thermal efficiency and fuel economy.Expand Specific Solutions03 Engine control strategies

Advanced control strategies for GDI engines can optimize fuel economy under various operating conditions. These include lean burn operation, stratified charge combustion, variable valve timing, and cylinder deactivation. Electronic control units can be programmed to adjust fuel delivery, ignition timing, and air intake based on real-time engine parameters to maximize efficiency while maintaining performance and emissions compliance.Expand Specific Solutions04 Turbocharging and downsizing

Combining GDI technology with turbocharging allows for engine downsizing while maintaining power output, which improves fuel economy. Smaller displacement engines with turbochargers have reduced pumping losses and friction, leading to better efficiency. The precise fuel control of GDI systems works synergistically with turbocharging to optimize the air-fuel mixture under boost conditions, further enhancing fuel economy.Expand Specific Solutions05 Fuel formulation and additives

Specialized fuel formulations and additives can improve the fuel economy of GDI engines. These formulations can reduce deposit formation on injectors and intake valves, which is a common issue in GDI engines that can degrade performance over time. Detergent additives that keep fuel system components clean and lubricating additives that reduce friction can contribute to maintaining optimal fuel economy throughout the engine's service life.Expand Specific Solutions

Major Players in GDI Engine Development

The GDI (Gasoline Direct Injection) engine fuel economy technology market is in a growth phase, with increasing adoption across global automotive manufacturers. The market size is expanding rapidly as stringent emission regulations drive demand for more efficient combustion technologies. Leading players like Hyundai Motor, Kia, Ford Global Technologies, and GM Global Technology Operations are at the forefront of GDI technology advancement, with significant patent portfolios and commercial implementations. Oil companies including ExxonMobil, Shell, and Chevron are developing specialized fuels and lubricants for GDI systems. The technology is reaching maturity in developed markets, with companies like Delphi Technology, Tula Technology, and Southwest Research Institute focusing on next-generation innovations to address carbon deposit challenges and further improve efficiency through advanced control algorithms and hybrid integration.

Ford Global Technologies LLC

Technical Solution: Ford has developed a comprehensive GDI engine fuel economy testing methodology that combines laboratory dynamometer testing with real-world driving cycles. Their approach utilizes direct injection pressure mapping across various engine loads and speeds to optimize fuel atomization and combustion efficiency. Ford's testing protocol incorporates both the EPA standard cycles and proprietary drive patterns that simulate real-world conditions more accurately. Their methodology includes high-precision fuel flow measurement systems capable of detecting differences as small as 0.1% in fuel consumption[1]. Ford also employs advanced thermal management techniques during testing to account for cold-start inefficiencies, which can significantly impact GDI engine performance in real-world scenarios[3]. Their test procedures specifically address particulate emissions alongside fuel economy, recognizing the inherent trade-off between these factors in GDI systems.

Strengths: Extensive real-world validation data across multiple vehicle platforms and comprehensive integration with vehicle control systems. Their testing methodology effectively balances laboratory precision with real-world applicability. Weaknesses: Testing protocols may be overly optimized for regulatory compliance rather than capturing all real-world driving scenarios, and their approach requires expensive specialized equipment.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed a sophisticated fuel economy testing methodology specifically for GDI engines that focuses on the interaction between fuel formulation and engine performance. Their approach combines standardized engine dynamometer testing with specialized fuel property analysis to quantify the impact of different fuel components on GDI efficiency. ExxonMobil's testing protocol incorporates detailed combustion analysis using pressure transducers and heat release calculations to characterize combustion efficiency across different operating conditions[9]. Their methodology includes specialized procedures for evaluating deposit formation in GDI injectors and its impact on spray patterns and fuel economy over time. ExxonMobil employs advanced statistical design of experiments to efficiently map the relationship between fuel properties, engine operating parameters, and fuel economy outcomes. Their testing approach also incorporates specialized cold-start and warm-up evaluations, recognizing that GDI engines have unique thermal characteristics that significantly impact real-world fuel economy[10]. Additionally, ExxonMobil's methodology includes accelerated durability testing to project long-term fuel economy trends as GDI components age.

Strengths: Unparalleled expertise in fuel chemistry effects on GDI performance, with excellent capabilities for isolating and quantifying specific fuel property impacts. Their methodology effectively bridges fundamental research and practical application. Weaknesses: Testing approach may overemphasize fuel formulation effects relative to other factors affecting GDI fuel economy, and their proprietary test methods may limit comparability with industry-standard results.

Key Technical Innovations in GDI Fuel Economy Testing

Low viscosity lubricating oil composition

PatentInactiveUS20180258365A1

Innovation

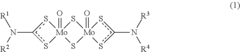

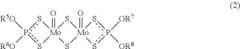

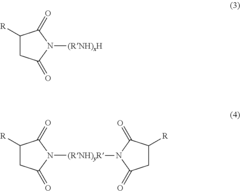

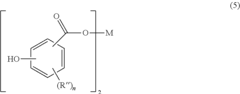

- A lubricating oil composition with a High Temperature High Shear (HTHS) viscosity of 1.3 to 2.3 cP, comprising a major amount of lubricating viscosity oil, an organomolybdenum compound providing 200-1500 ppm molybdenum, a calcium-containing detergent, a magnesium-containing detergent, and a viscosity modifier with a Permanent Shear Stability Index (PSSI) of 30 or less, is developed to address these challenges.

Method for maximizing the formation of deposits in injector nozzles of GDI engines

PatentWO2018002610A1

Innovation

- A method to maximize deposit formation in GDI engine injector nozzles by simulating severe conditions through controlled engine speed and load variations, high nozzle temperatures, and moderate fuel flow rates, allowing for automated and unsupervised testing to quickly assess fuel's deposit-forming tendencies.

Emissions Regulations Impact on GDI Development

The evolution of emissions regulations has been a primary driver for Gasoline Direct Injection (GDI) technology development over the past two decades. Initially, GDI engines emerged as a response to increasingly stringent CO2 emission standards in Europe and fuel economy requirements in North America. These regulatory frameworks created a technological imperative that accelerated GDI adoption across global markets.

The Euro 6 standards and the US EPA Tier 3 regulations have particularly influenced GDI development by imposing strict limits on particulate matter (PM) emissions. This regulatory pressure has necessitated the integration of Gasoline Particulate Filters (GPFs) in many GDI systems, adding complexity to engine design but enabling compliance with emission targets while maintaining fuel economy advantages.

China's implementation of China 6 standards, which closely align with Euro 6 requirements but include additional testing conditions, has further expanded the global regulatory landscape affecting GDI technology. These regulations have created a unified direction for automotive manufacturers, pushing them toward similar technological solutions despite regional market differences.

The regulatory focus on real-world driving emissions (RDE) testing has significantly impacted GDI development strategies. Traditional laboratory-based testing cycles have been supplemented with on-road testing requirements, forcing engineers to optimize GDI systems for a broader range of operating conditions. This shift has influenced fuel injection strategies, combustion chamber designs, and control algorithms to maintain optimal fuel economy across diverse driving scenarios.

Upcoming regulations are increasingly targeting particulate number (PN) emissions alongside traditional pollutants, creating new challenges for GDI technology. The trade-off between NOx reduction and fuel economy has become more complex, requiring sophisticated calibration approaches when quantifying GDI engine performance. Test procedures must now account for cold-start emissions, which represent a disproportionate share of total emissions but significantly impact overall compliance.

The regulatory timeline for emissions standards implementation has created a technology roadmap for GDI development. Manufacturers must balance immediate compliance requirements with long-term technology investments, influencing how fuel economy tests are designed and interpreted. This regulatory-driven innovation cycle has accelerated the development of advanced fuel injection systems, improved atomization technologies, and more precise engine control strategies.

When quantifying GDI engine fuel economy, these regulatory contexts must be considered as boundary conditions that define the operational envelope within which efficiency improvements can be pursued. The most meaningful fuel economy tests now incorporate regulatory driving cycles alongside supplementary assessments that capture real-world performance variations.

The Euro 6 standards and the US EPA Tier 3 regulations have particularly influenced GDI development by imposing strict limits on particulate matter (PM) emissions. This regulatory pressure has necessitated the integration of Gasoline Particulate Filters (GPFs) in many GDI systems, adding complexity to engine design but enabling compliance with emission targets while maintaining fuel economy advantages.

China's implementation of China 6 standards, which closely align with Euro 6 requirements but include additional testing conditions, has further expanded the global regulatory landscape affecting GDI technology. These regulations have created a unified direction for automotive manufacturers, pushing them toward similar technological solutions despite regional market differences.

The regulatory focus on real-world driving emissions (RDE) testing has significantly impacted GDI development strategies. Traditional laboratory-based testing cycles have been supplemented with on-road testing requirements, forcing engineers to optimize GDI systems for a broader range of operating conditions. This shift has influenced fuel injection strategies, combustion chamber designs, and control algorithms to maintain optimal fuel economy across diverse driving scenarios.

Upcoming regulations are increasingly targeting particulate number (PN) emissions alongside traditional pollutants, creating new challenges for GDI technology. The trade-off between NOx reduction and fuel economy has become more complex, requiring sophisticated calibration approaches when quantifying GDI engine performance. Test procedures must now account for cold-start emissions, which represent a disproportionate share of total emissions but significantly impact overall compliance.

The regulatory timeline for emissions standards implementation has created a technology roadmap for GDI development. Manufacturers must balance immediate compliance requirements with long-term technology investments, influencing how fuel economy tests are designed and interpreted. This regulatory-driven innovation cycle has accelerated the development of advanced fuel injection systems, improved atomization technologies, and more precise engine control strategies.

When quantifying GDI engine fuel economy, these regulatory contexts must be considered as boundary conditions that define the operational envelope within which efficiency improvements can be pursued. The most meaningful fuel economy tests now incorporate regulatory driving cycles alongside supplementary assessments that capture real-world performance variations.

Cost-Benefit Analysis of GDI Implementation

The implementation of Gasoline Direct Injection (GDI) technology represents a significant investment for automotive manufacturers, necessitating a comprehensive cost-benefit analysis to justify adoption. Initial manufacturing costs for GDI systems typically exceed those of traditional port fuel injection (PFI) systems by approximately 15-20%, primarily due to higher-precision components and more complex electronic control systems.

Material costs constitute a substantial portion of this differential, with high-pressure fuel pumps, precision injectors, and reinforced fuel lines accounting for approximately 60% of the additional expense. Engineering and development costs further contribute to the investment, particularly for manufacturers transitioning their product lines from conventional systems.

However, these upfront costs must be evaluated against the quantifiable benefits that GDI technology delivers. Fuel economy improvements, as demonstrated through standardized testing protocols, typically range from 3-6% compared to equivalent PFI engines. When translated to lifetime vehicle operation, this represents significant cost savings for consumers and contributes to manufacturer compliance with increasingly stringent corporate average fuel economy (CAFE) standards.

Emissions performance provides another critical dimension to the cost-benefit equation. GDI engines generally produce lower CO2 emissions, directly proportional to their improved fuel efficiency. However, particulate matter emissions may increase without additional mitigation technologies, potentially requiring supplementary systems like gasoline particulate filters that add approximately 5-8% to the system cost.

Manufacturing scalability also influences the cost-benefit ratio. Production volume analysis indicates that per-unit costs decrease approximately 7-10% when production volumes exceed 500,000 units annually, making GDI more economically viable for high-volume vehicle platforms.

Consumer value perception must additionally be factored into the analysis. Market research indicates that consumers typically value improved performance characteristics of GDI engines—particularly enhanced torque and responsiveness—and are willing to accept a 2-3% price premium for vehicles featuring this technology.

The long-term maintenance considerations present a mixed picture in the cost-benefit analysis. While GDI systems may require more specialized maintenance procedures, their potential for extended engine life through reduced carbon buildup in combustion chambers can offset these costs when properly maintained.

Material costs constitute a substantial portion of this differential, with high-pressure fuel pumps, precision injectors, and reinforced fuel lines accounting for approximately 60% of the additional expense. Engineering and development costs further contribute to the investment, particularly for manufacturers transitioning their product lines from conventional systems.

However, these upfront costs must be evaluated against the quantifiable benefits that GDI technology delivers. Fuel economy improvements, as demonstrated through standardized testing protocols, typically range from 3-6% compared to equivalent PFI engines. When translated to lifetime vehicle operation, this represents significant cost savings for consumers and contributes to manufacturer compliance with increasingly stringent corporate average fuel economy (CAFE) standards.

Emissions performance provides another critical dimension to the cost-benefit equation. GDI engines generally produce lower CO2 emissions, directly proportional to their improved fuel efficiency. However, particulate matter emissions may increase without additional mitigation technologies, potentially requiring supplementary systems like gasoline particulate filters that add approximately 5-8% to the system cost.

Manufacturing scalability also influences the cost-benefit ratio. Production volume analysis indicates that per-unit costs decrease approximately 7-10% when production volumes exceed 500,000 units annually, making GDI more economically viable for high-volume vehicle platforms.

Consumer value perception must additionally be factored into the analysis. Market research indicates that consumers typically value improved performance characteristics of GDI engines—particularly enhanced torque and responsiveness—and are willing to accept a 2-3% price premium for vehicles featuring this technology.

The long-term maintenance considerations present a mixed picture in the cost-benefit analysis. While GDI systems may require more specialized maintenance procedures, their potential for extended engine life through reduced carbon buildup in combustion chambers can offset these costs when properly maintained.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!