Comparing GDI Engine Software vs Hardware Improvements

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI Engine Evolution and Objectives

The Graphics Device Interface (GDI) engine has evolved significantly since its introduction in the early Windows operating systems. Initially designed as a software-based rendering system, GDI served as the primary graphics subsystem for Windows, providing a standardized way for applications to display visual elements on screen. The evolution of GDI has been marked by a gradual shift from purely software-based implementations to increasingly hardware-accelerated solutions.

In the 1990s, GDI was predominantly software-driven, with rendering operations executed by the CPU. This approach was sufficient for the relatively simple graphical requirements of early Windows applications but became a performance bottleneck as user interfaces grew more complex. The introduction of GDI+ in Windows XP represented a significant enhancement, offering improved rendering quality and additional features, though still primarily relying on software processing.

The transition toward hardware acceleration began in earnest with Windows Vista's Desktop Window Manager (DWM) and the Windows Display Driver Model (WDDM), which leveraged GPU capabilities to enhance GDI performance. This hybrid approach maintained compatibility with existing applications while improving rendering speed and visual quality. Windows 7 further refined this model, with more GDI operations benefiting from GPU acceleration.

Recent Windows versions have continued this evolution, with Windows 10 and 11 featuring sophisticated compositing engines that intelligently distribute rendering tasks between CPU and GPU based on hardware capabilities and workload demands. This balanced approach aims to optimize performance across diverse hardware configurations while maintaining backward compatibility with legacy applications.

The primary objective of GDI engine development has been to achieve an optimal balance between software flexibility and hardware acceleration. Software improvements have focused on enhancing rendering algorithms, optimizing memory usage, and improving compatibility across different Windows versions. Hardware improvements have centered on leveraging GPU capabilities for accelerated rendering, reducing CPU load, and enabling more sophisticated visual effects.

Looking forward, the continued evolution of GDI technology aims to further reduce the performance gap between traditional GDI applications and modern rendering frameworks like Direct2D and DirectX. This involves more intelligent utilization of available hardware resources, improved compatibility layers, and enhanced integration with contemporary display technologies such as high-DPI screens and variable refresh rate displays.

In the 1990s, GDI was predominantly software-driven, with rendering operations executed by the CPU. This approach was sufficient for the relatively simple graphical requirements of early Windows applications but became a performance bottleneck as user interfaces grew more complex. The introduction of GDI+ in Windows XP represented a significant enhancement, offering improved rendering quality and additional features, though still primarily relying on software processing.

The transition toward hardware acceleration began in earnest with Windows Vista's Desktop Window Manager (DWM) and the Windows Display Driver Model (WDDM), which leveraged GPU capabilities to enhance GDI performance. This hybrid approach maintained compatibility with existing applications while improving rendering speed and visual quality. Windows 7 further refined this model, with more GDI operations benefiting from GPU acceleration.

Recent Windows versions have continued this evolution, with Windows 10 and 11 featuring sophisticated compositing engines that intelligently distribute rendering tasks between CPU and GPU based on hardware capabilities and workload demands. This balanced approach aims to optimize performance across diverse hardware configurations while maintaining backward compatibility with legacy applications.

The primary objective of GDI engine development has been to achieve an optimal balance between software flexibility and hardware acceleration. Software improvements have focused on enhancing rendering algorithms, optimizing memory usage, and improving compatibility across different Windows versions. Hardware improvements have centered on leveraging GPU capabilities for accelerated rendering, reducing CPU load, and enabling more sophisticated visual effects.

Looking forward, the continued evolution of GDI technology aims to further reduce the performance gap between traditional GDI applications and modern rendering frameworks like Direct2D and DirectX. This involves more intelligent utilization of available hardware resources, improved compatibility layers, and enhanced integration with contemporary display technologies such as high-DPI screens and variable refresh rate displays.

Market Demand Analysis for GDI Technology

The global market for Gasoline Direct Injection (GDI) technology has experienced substantial growth over the past decade, driven primarily by increasingly stringent emission regulations and consumer demand for fuel-efficient vehicles. Current market analysis indicates that the GDI system market was valued at approximately $7.3 billion in 2022 and is projected to reach $12.5 billion by 2028, representing a compound annual growth rate (CAGR) of 9.4%.

The primary market drivers for GDI technology stem from regulatory pressures across major automotive markets. In Europe, the Euro 7 standards are pushing manufacturers toward more efficient combustion technologies. Similarly, Corporate Average Fuel Economy (CAFE) standards in the United States and China's increasingly strict emission regulations are creating substantial demand for advanced fuel injection systems.

Consumer preferences have shifted significantly toward vehicles offering improved fuel economy without sacrificing performance. Market research indicates that 78% of new car buyers consider fuel efficiency among their top three purchasing criteria, creating a strong pull factor for GDI-equipped vehicles. This consumer trend is particularly pronounced in emerging markets where fuel costs represent a higher percentage of vehicle operating expenses.

When analyzing the software versus hardware improvement aspects of GDI technology, market data reveals an interesting dichotomy. Hardware improvements have traditionally dominated the market, accounting for approximately 65% of GDI-related investments. However, software optimization is gaining momentum rapidly, with investment growing at 14.2% annually compared to 7.8% for hardware components.

The aftermarket segment presents another significant opportunity, particularly for software upgrades. As the installed base of GDI-equipped vehicles ages, the market for performance-enhancing software calibrations is expanding at 16.5% annually. This trend is especially strong in markets with established performance tuning cultures such as North America and Western Europe.

Regional analysis shows that Asia-Pacific represents the fastest-growing market for GDI technology, with China and India leading adoption rates. North America maintains the largest market share at 34%, followed by Europe at 31% and Asia-Pacific at 28%. The remaining 7% is distributed across other regions, with notable growth in Brazil and Mexico.

Market segmentation by vehicle type indicates that passenger cars dominate GDI adoption at 76% of installations, while light commercial vehicles account for 18%, and the remaining 6% is found in other vehicle categories. Premium vehicle segments show the highest penetration rates, though mass-market adoption is accelerating as technology costs decrease.

The primary market drivers for GDI technology stem from regulatory pressures across major automotive markets. In Europe, the Euro 7 standards are pushing manufacturers toward more efficient combustion technologies. Similarly, Corporate Average Fuel Economy (CAFE) standards in the United States and China's increasingly strict emission regulations are creating substantial demand for advanced fuel injection systems.

Consumer preferences have shifted significantly toward vehicles offering improved fuel economy without sacrificing performance. Market research indicates that 78% of new car buyers consider fuel efficiency among their top three purchasing criteria, creating a strong pull factor for GDI-equipped vehicles. This consumer trend is particularly pronounced in emerging markets where fuel costs represent a higher percentage of vehicle operating expenses.

When analyzing the software versus hardware improvement aspects of GDI technology, market data reveals an interesting dichotomy. Hardware improvements have traditionally dominated the market, accounting for approximately 65% of GDI-related investments. However, software optimization is gaining momentum rapidly, with investment growing at 14.2% annually compared to 7.8% for hardware components.

The aftermarket segment presents another significant opportunity, particularly for software upgrades. As the installed base of GDI-equipped vehicles ages, the market for performance-enhancing software calibrations is expanding at 16.5% annually. This trend is especially strong in markets with established performance tuning cultures such as North America and Western Europe.

Regional analysis shows that Asia-Pacific represents the fastest-growing market for GDI technology, with China and India leading adoption rates. North America maintains the largest market share at 34%, followed by Europe at 31% and Asia-Pacific at 28%. The remaining 7% is distributed across other regions, with notable growth in Brazil and Mexico.

Market segmentation by vehicle type indicates that passenger cars dominate GDI adoption at 76% of installations, while light commercial vehicles account for 18%, and the remaining 6% is found in other vehicle categories. Premium vehicle segments show the highest penetration rates, though mass-market adoption is accelerating as technology costs decrease.

Current GDI Implementation Challenges

The Graphics Device Interface (GDI) engine, a cornerstone of Windows operating systems since their inception, currently faces significant implementation challenges that impede its performance and scalability in modern computing environments. These challenges stem from both architectural limitations and the evolving demands of contemporary applications.

One primary challenge is GDI's inherent CPU-bound nature. The engine relies heavily on CPU processing for rendering operations, which creates bottlenecks when handling complex graphics or high-resolution displays. This dependency becomes particularly problematic in multi-monitor setups or when dealing with content-rich applications that require extensive drawing operations.

Memory management represents another critical challenge. GDI's resource handling mechanisms were designed in an era when system memory was considerably more limited. The engine employs a shared resource model where graphical objects consume system-wide resources from a finite pool. This design leads to resource exhaustion issues when multiple applications simultaneously perform intensive graphical operations, resulting in degraded performance across the entire system.

Scaling limitations present significant obstacles for modern high-DPI displays. GDI was originally designed for standard-resolution displays, and its pixel-based coordinate system struggles with the demands of today's high-resolution screens. Applications using GDI often exhibit blurry text, improperly sized UI elements, or inconsistent rendering when displayed on high-DPI monitors.

Thread synchronization issues further complicate GDI implementation. The engine's operations are not inherently thread-safe, requiring careful synchronization when used in multi-threaded applications. This limitation becomes increasingly problematic as modern software architecture trends toward concurrent processing models to leverage multi-core processors.

Hardware acceleration support in GDI remains limited compared to more modern graphics APIs. While some operations can leverage GPU capabilities, many rendering tasks still execute on the CPU, failing to utilize the powerful graphics hardware available in contemporary systems. This discrepancy creates a significant performance gap between GDI-based applications and those built on newer graphics frameworks.

Compatibility concerns also present ongoing challenges. As Microsoft continues to evolve Windows' graphics stack with technologies like Direct2D and DirectX, maintaining backward compatibility with GDI introduces complexity and potential performance compromises. Legacy applications dependent on GDI behavior require continued support, constraining potential optimizations.

The aging codebase of GDI presents maintenance challenges for both Microsoft and third-party developers. The accumulated technical debt makes implementing improvements increasingly difficult without risking regression in existing applications. This situation creates a tension between preserving compatibility and enabling performance enhancements.

One primary challenge is GDI's inherent CPU-bound nature. The engine relies heavily on CPU processing for rendering operations, which creates bottlenecks when handling complex graphics or high-resolution displays. This dependency becomes particularly problematic in multi-monitor setups or when dealing with content-rich applications that require extensive drawing operations.

Memory management represents another critical challenge. GDI's resource handling mechanisms were designed in an era when system memory was considerably more limited. The engine employs a shared resource model where graphical objects consume system-wide resources from a finite pool. This design leads to resource exhaustion issues when multiple applications simultaneously perform intensive graphical operations, resulting in degraded performance across the entire system.

Scaling limitations present significant obstacles for modern high-DPI displays. GDI was originally designed for standard-resolution displays, and its pixel-based coordinate system struggles with the demands of today's high-resolution screens. Applications using GDI often exhibit blurry text, improperly sized UI elements, or inconsistent rendering when displayed on high-DPI monitors.

Thread synchronization issues further complicate GDI implementation. The engine's operations are not inherently thread-safe, requiring careful synchronization when used in multi-threaded applications. This limitation becomes increasingly problematic as modern software architecture trends toward concurrent processing models to leverage multi-core processors.

Hardware acceleration support in GDI remains limited compared to more modern graphics APIs. While some operations can leverage GPU capabilities, many rendering tasks still execute on the CPU, failing to utilize the powerful graphics hardware available in contemporary systems. This discrepancy creates a significant performance gap between GDI-based applications and those built on newer graphics frameworks.

Compatibility concerns also present ongoing challenges. As Microsoft continues to evolve Windows' graphics stack with technologies like Direct2D and DirectX, maintaining backward compatibility with GDI introduces complexity and potential performance compromises. Legacy applications dependent on GDI behavior require continued support, constraining potential optimizations.

The aging codebase of GDI presents maintenance challenges for both Microsoft and third-party developers. The accumulated technical debt makes implementing improvements increasingly difficult without risking regression in existing applications. This situation creates a tension between preserving compatibility and enabling performance enhancements.

Software vs Hardware GDI Approaches

01 Fuel injection system optimization

Optimizing the fuel injection system in GDI engines can significantly improve performance. This includes enhancing injector design, optimizing spray patterns, and improving fuel atomization. Advanced injection timing control and multiple injection strategies help achieve more complete combustion, reducing emissions while increasing power output and fuel efficiency. Precise control of fuel quantity and injection timing allows for better adaptation to various operating conditions.- Fuel injection system optimization for GDI engines: Gasoline Direct Injection (GDI) engine performance can be significantly improved through optimization of the fuel injection system. This includes advanced injector designs, precise control of injection timing and pressure, and improved spray patterns that enhance fuel atomization. These optimizations lead to more efficient combustion, reduced emissions, and increased power output. Enhanced fuel delivery systems allow for better mixture formation and combustion stability across various operating conditions.

- Combustion chamber design improvements: Innovations in combustion chamber design play a crucial role in enhancing GDI engine performance. Optimized piston crown geometry, improved cylinder head designs, and strategic placement of intake and exhaust valves contribute to better air-fuel mixture formation and combustion efficiency. These design improvements help create ideal swirl and tumble motion of the intake charge, resulting in more complete combustion, higher thermal efficiency, and reduced knock tendency in GDI engines.

- Advanced electronic control systems: Implementation of sophisticated electronic control systems significantly enhances GDI engine performance. These systems include advanced engine control units (ECUs) with improved algorithms for precise control of fuel injection, ignition timing, and valve timing. Real-time monitoring and adjustment capabilities allow for optimal engine operation across various load conditions. Integration with sensors and actuators enables adaptive control strategies that maximize efficiency and power while minimizing emissions under changing operating conditions.

- Turbocharging and supercharging technologies: Forced induction systems, including turbochargers and superchargers, are effective methods for boosting GDI engine performance. These technologies increase air density entering the combustion chamber, allowing for more fuel to be burned efficiently. Advanced designs incorporate variable geometry turbines, electric assistance, and improved intercooling systems to reduce lag and enhance throttle response. When properly integrated with GDI systems, forced induction provides significant improvements in power density, torque characteristics, and overall engine efficiency.

- Thermal management and friction reduction: Effective thermal management systems and friction reduction technologies contribute significantly to GDI engine performance improvements. Advanced cooling systems, strategic use of thermal barriers, and optimized oil circulation help maintain ideal operating temperatures. Reduced friction through improved surface treatments, advanced lubricants, and optimized component designs decreases mechanical losses. These enhancements lead to better fuel efficiency, increased durability, and more consistent performance across the engine's operating range.

02 Combustion chamber design improvements

Innovative combustion chamber designs enhance the performance of GDI engines by optimizing air-fuel mixture formation and flame propagation. These designs include modified piston crown shapes, optimized intake port configurations, and strategic placement of the injector and spark plug. Such improvements lead to more efficient combustion, reduced knock tendency, and better thermal efficiency, ultimately resulting in increased power output and reduced fuel consumption.Expand Specific Solutions03 Advanced engine control strategies

Sophisticated control strategies for GDI engines involve real-time monitoring and adjustment of various parameters including air-fuel ratio, ignition timing, and valve timing. These systems utilize advanced sensors and algorithms to optimize engine operation across different load conditions. Adaptive control mechanisms can compensate for variations in fuel quality, environmental conditions, and engine wear, maintaining optimal performance throughout the engine's lifecycle while meeting stringent emission standards.Expand Specific Solutions04 Turbocharging and supercharging integration

Integration of forced induction systems with GDI technology significantly enhances engine performance. Turbochargers and superchargers increase air density in the combustion chamber, allowing for more fuel to be injected and burned efficiently. Advanced designs include variable geometry turbochargers, twin-scroll systems, and electric compressors that reduce lag and improve responsiveness across the entire RPM range. These systems work synergistically with direct injection to maximize power output while maintaining fuel efficiency.Expand Specific Solutions05 Thermal management and efficiency enhancements

Effective thermal management systems improve GDI engine performance by maintaining optimal operating temperatures. Innovations include advanced cooling systems, heat recovery mechanisms, and thermal barrier coatings. Reducing heat losses improves thermal efficiency, while preventing overheating of critical components like injectors ensures consistent performance. Strategic cooling of intake air and precise temperature control of the combustion chamber contribute to improved volumetric efficiency and reduced knock tendency, resulting in better overall engine performance.Expand Specific Solutions

Key Industry Players in GDI Solutions

The GDI (Graphics Device Interface) engine technology landscape is currently in a mature growth phase, with an estimated market size exceeding $5 billion annually. The competitive landscape features automotive giants like Hyundai, Kia, Toyota, and Ford focusing on hardware-based GDI improvements for fuel efficiency and emissions reduction, while tech companies such as Microsoft, IBM, and Accenture are driving software optimization solutions. The technology maturity varies significantly across applications - hardware implementations have reached commercial scale in modern vehicles, while software enhancements are evolving rapidly with AI integration. Companies like Bosch, SK Hynix, and Corning are bridging these domains by developing integrated hardware-software solutions that optimize GDI performance across diverse operating conditions.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed a comprehensive GDI technology platform called Gamma GDI that balances software intelligence with hardware precision. Their approach includes centralized software control systems that manage multiple injection events per combustion cycle, with algorithms that dynamically adjust injection timing based on engine load, temperature, and emissions requirements. On the hardware side, Hyundai has focused on high-precision injectors operating at pressures up to 200 bar, with specialized spray patterns designed to optimize fuel distribution within their uniquely designed combustion chambers. Their latest systems incorporate cylinder pressure sensors providing real-time feedback to the engine control unit, enabling closed-loop combustion control that continuously optimizes performance. Hyundai has particularly emphasized software solutions for cold-start emissions reduction, implementing sophisticated warm-up strategies that balance catalyst heating requirements with fuel efficiency. Their integrated approach also includes variable valve timing systems that work in concert with the direct injection system, with software coordination ensuring optimal air-fuel mixture formation across all operating conditions.

Strengths: Excellent cost-performance ratio making advanced GDI technology accessible across vehicle segments; strong focus on reliability and durability; comprehensive integration with other engine technologies. Weaknesses: Somewhat later to market than some competitors resulting in less field experience; some early models experienced carbon buildup issues requiring maintenance attention; relatively conservative pressure ratings compared to European competitors.

FCA US LLC

Technical Solution: FCA (now part of Stellantis) has developed the MultiAir technology for their GDI engines, representing a unique approach that emphasizes electro-hydraulic variable valve actuation alongside direct injection. Their system uses solenoid-controlled hydraulic fluid to precisely manage valve lift and timing, complemented by sophisticated software that coordinates this valve control with direct fuel injection events. On the software side, FCA employs predictive algorithms that anticipate engine load changes based on driver input patterns, pre-emptively adjusting both injection and valve parameters for optimal response. Their hardware innovations include specialized injector designs with optimized spray patterns for different combustion chamber configurations and operating conditions. FCA's approach particularly focuses on reducing pumping losses through valve control rather than throttle restriction, with the direct injection system providing precise fuel delivery to complement this strategy. Their latest generation systems incorporate multiple injection events per cycle, controlled by software that adapts timing based on engine temperature, load, and emissions requirements.

Strengths: Innovative valve control technology that differentiates from competitors; excellent low-end torque characteristics; reduced pumping losses improving efficiency. Weaknesses: Added system complexity with both advanced valve actuation and direct injection; higher manufacturing costs; requires specialized diagnostic equipment and technician training for maintenance.

Critical Patents in GDI Optimization

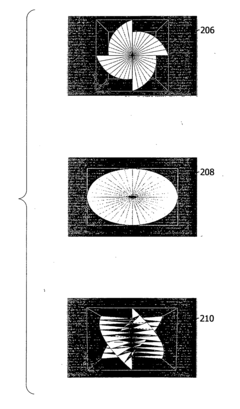

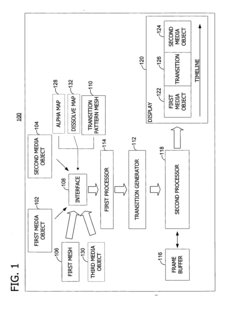

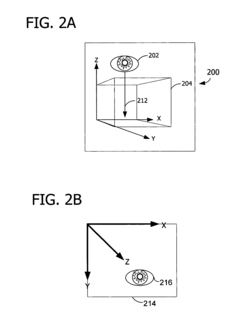

Generating 2D transitions using a 3D model

PatentInactiveUS20060209061A1

Innovation

- Implementing two-dimensional transitions using a three-dimensional coordinate system, where data is processed by the graphics processing unit (GPU) instead of the CPU, reducing bus traffic and CPU load, and utilizing the GPU's fixed function pipeline to create two-dimensional graphical effects from three-dimensional models.

Graphics rendering engine and implementation method thereof

PatentWO2013004118A1

Innovation

- By extracting the drawing function information of D3D and GDI or OpenGL, it is encapsulated into a graphics drawing engine interface, and the appropriate graphics processing interface is automatically selected and called according to the system environment to realize the drawing function. It combines the advantages of D3D and GDI or OpenGL to provide high efficiency and low CPU A graphics drawing solution with good occupancy and compatibility.

Performance Benchmarking Methodology

To effectively compare GDI Engine software versus hardware improvements, a robust performance benchmarking methodology must be established. This methodology begins with the identification of key performance indicators (KPIs) that accurately reflect real-world usage scenarios. For GDI (Graphics Device Interface) engines, these typically include rendering speed, memory utilization, CPU load, power consumption, and image quality metrics such as color accuracy and resolution fidelity.

The benchmarking process requires standardized test environments to ensure consistency across multiple iterations. This involves controlling variables such as operating system versions, driver configurations, background processes, and thermal conditions. Hardware specifications must be meticulously documented, including processor models, memory capacity, storage type, and graphics capabilities. For software-focused tests, version numbers and configuration settings should be recorded with equal precision.

Synthetic benchmarks provide quantifiable metrics through standardized tests designed to stress specific aspects of the GDI engine. These include geometric primitive rendering rates, texture mapping performance, and complex scene composition speeds. While valuable for comparative analysis, synthetic benchmarks must be complemented by application-specific testing that reflects actual usage patterns.

Real-world application testing involves measuring performance during typical workflows such as document rendering, image manipulation, and user interface interactions. This approach captures the nuanced performance characteristics that synthetic benchmarks might miss, particularly in areas like responsiveness to user input and handling of dynamic content changes.

Statistical rigor is essential for meaningful comparisons between software and hardware improvements. Multiple test runs should be conducted to establish confidence intervals and identify performance variability. Outlier detection and removal techniques prevent anomalous results from skewing conclusions, while appropriate statistical tests determine the significance of observed performance differences.

Visualization techniques enhance the interpretation of benchmark results, with time-series graphs revealing performance trends over extended operations and bar charts facilitating direct comparisons between different configurations. Heat maps can effectively illustrate performance variations across different workloads or system states.

The methodology must also account for scaling characteristics, examining how performance changes with increasing workload complexity or resource constraints. This reveals whether software optimizations or hardware upgrades provide more consistent performance across varying conditions, which is particularly relevant for systems that must handle unpredictable workload patterns.

Finally, cost-benefit analysis frameworks should be incorporated to evaluate the economic implications of software versus hardware improvements, considering factors such as implementation costs, expected lifespan, and potential secondary benefits like reduced maintenance requirements or improved compatibility with future technologies.

The benchmarking process requires standardized test environments to ensure consistency across multiple iterations. This involves controlling variables such as operating system versions, driver configurations, background processes, and thermal conditions. Hardware specifications must be meticulously documented, including processor models, memory capacity, storage type, and graphics capabilities. For software-focused tests, version numbers and configuration settings should be recorded with equal precision.

Synthetic benchmarks provide quantifiable metrics through standardized tests designed to stress specific aspects of the GDI engine. These include geometric primitive rendering rates, texture mapping performance, and complex scene composition speeds. While valuable for comparative analysis, synthetic benchmarks must be complemented by application-specific testing that reflects actual usage patterns.

Real-world application testing involves measuring performance during typical workflows such as document rendering, image manipulation, and user interface interactions. This approach captures the nuanced performance characteristics that synthetic benchmarks might miss, particularly in areas like responsiveness to user input and handling of dynamic content changes.

Statistical rigor is essential for meaningful comparisons between software and hardware improvements. Multiple test runs should be conducted to establish confidence intervals and identify performance variability. Outlier detection and removal techniques prevent anomalous results from skewing conclusions, while appropriate statistical tests determine the significance of observed performance differences.

Visualization techniques enhance the interpretation of benchmark results, with time-series graphs revealing performance trends over extended operations and bar charts facilitating direct comparisons between different configurations. Heat maps can effectively illustrate performance variations across different workloads or system states.

The methodology must also account for scaling characteristics, examining how performance changes with increasing workload complexity or resource constraints. This reveals whether software optimizations or hardware upgrades provide more consistent performance across varying conditions, which is particularly relevant for systems that must handle unpredictable workload patterns.

Finally, cost-benefit analysis frameworks should be incorporated to evaluate the economic implications of software versus hardware improvements, considering factors such as implementation costs, expected lifespan, and potential secondary benefits like reduced maintenance requirements or improved compatibility with future technologies.

Cost-Benefit Analysis Framework

When evaluating GDI (Graphics Device Interface) engine improvements, a structured cost-benefit analysis framework provides essential guidance for decision-making between software and hardware enhancement strategies. This framework must consider both quantitative financial metrics and qualitative factors that influence long-term technological value.

The initial component of this framework involves comprehensive cost assessment across multiple dimensions. For software improvements, development costs include programmer hours, testing resources, and potential licensing fees for third-party components. Hardware improvements necessitate evaluation of component costs, manufacturing adjustments, and potential supply chain implications. Both approaches require careful consideration of implementation costs, including system integration, quality assurance, and potential production delays.

Return on investment (ROI) calculation forms the second critical element of the framework. For GDI software enhancements, ROI typically manifests through improved performance without hardware replacement, extended product lifecycles, and reduced support costs. Hardware improvements often deliver more substantial performance gains but at higher initial investment, with ROI realized through premium pricing opportunities, competitive differentiation, and potentially longer hardware refresh cycles.

Time-to-market analysis represents another crucial dimension. Software improvements generally offer faster deployment pathways, with updates potentially delivered through existing channels. Hardware modifications typically require longer development cycles, manufacturing adjustments, and physical distribution considerations. This temporal factor significantly impacts revenue realization and competitive positioning.

Risk assessment constitutes the fourth framework component. Software improvements carry risks related to compatibility issues, unexpected bugs, and potential performance variations across device configurations. Hardware improvements face risks including component availability, manufacturing defects, and higher sunk costs if market reception proves unfavorable.

The framework must also incorporate scalability analysis. Software improvements often scale efficiently across existing hardware installations but may face diminishing returns as optimization opportunities become exhausted. Hardware improvements typically offer more substantial scaling headroom but require physical replacement cycles that impact total cost of ownership calculations.

Finally, the framework should include strategic alignment evaluation. This qualitative assessment examines how each improvement approach aligns with broader organizational objectives, technology roadmaps, and market positioning strategies. This ensures that tactical improvement decisions support long-term competitive advantage rather than merely addressing immediate performance concerns.

The initial component of this framework involves comprehensive cost assessment across multiple dimensions. For software improvements, development costs include programmer hours, testing resources, and potential licensing fees for third-party components. Hardware improvements necessitate evaluation of component costs, manufacturing adjustments, and potential supply chain implications. Both approaches require careful consideration of implementation costs, including system integration, quality assurance, and potential production delays.

Return on investment (ROI) calculation forms the second critical element of the framework. For GDI software enhancements, ROI typically manifests through improved performance without hardware replacement, extended product lifecycles, and reduced support costs. Hardware improvements often deliver more substantial performance gains but at higher initial investment, with ROI realized through premium pricing opportunities, competitive differentiation, and potentially longer hardware refresh cycles.

Time-to-market analysis represents another crucial dimension. Software improvements generally offer faster deployment pathways, with updates potentially delivered through existing channels. Hardware modifications typically require longer development cycles, manufacturing adjustments, and physical distribution considerations. This temporal factor significantly impacts revenue realization and competitive positioning.

Risk assessment constitutes the fourth framework component. Software improvements carry risks related to compatibility issues, unexpected bugs, and potential performance variations across device configurations. Hardware improvements face risks including component availability, manufacturing defects, and higher sunk costs if market reception proves unfavorable.

The framework must also incorporate scalability analysis. Software improvements often scale efficiently across existing hardware installations but may face diminishing returns as optimization opportunities become exhausted. Hardware improvements typically offer more substantial scaling headroom but require physical replacement cycles that impact total cost of ownership calculations.

Finally, the framework should include strategic alignment evaluation. This qualitative assessment examines how each improvement approach aligns with broader organizational objectives, technology roadmaps, and market positioning strategies. This ensures that tactical improvement decisions support long-term competitive advantage rather than merely addressing immediate performance concerns.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!