GDI Engine Knock Reduction Techniques Explored

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI Engine Knock Background and Objectives

Gasoline Direct Injection (GDI) technology has evolved significantly since its commercial introduction in the late 1990s, revolutionizing internal combustion engine efficiency and performance. This advanced fuel delivery system injects fuel directly into the combustion chamber rather than the intake port, allowing for precise control over the fuel-air mixture and combustion timing. Despite its advantages, GDI engines face a persistent challenge in the form of engine knock, a phenomenon characterized by uncontrolled combustion that can severely impact engine performance and longevity.

The historical development of GDI technology can be traced back to the early 20th century, with significant advancements occurring in the 1970s during the oil crisis. However, it wasn't until the late 1990s that manufacturers like Mitsubishi and Toyota successfully commercialized GDI systems. The technology has since become mainstream, with global adoption accelerating in response to increasingly stringent emissions regulations and fuel economy standards.

Engine knock in GDI systems presents unique challenges compared to traditional port fuel injection systems. The direct injection process creates localized rich fuel zones and temperature gradients within the combustion chamber, potentially leading to pre-ignition and knock events. These events are particularly problematic in GDI engines operating under high load conditions, where the combination of increased cylinder pressures and temperatures creates an environment conducive to abnormal combustion.

Current technological trends in knock reduction focus on several key areas: advanced ignition systems, improved fuel injection strategies, optimized combustion chamber designs, and sophisticated engine control algorithms. The integration of these approaches with emerging technologies such as artificial intelligence and machine learning represents the cutting edge of knock mitigation research.

The primary objectives of this technical research report are threefold. First, to comprehensively analyze the fundamental mechanisms of knock formation in GDI engines, establishing a clear understanding of the physical and chemical processes involved. Second, to evaluate existing knock reduction techniques across the industry, identifying their relative strengths, limitations, and implementation challenges. Third, to explore emerging technologies and methodologies that show promise for future knock reduction strategies, with particular emphasis on those that maintain or enhance the efficiency and performance benefits inherent to GDI systems.

This research aims to provide actionable insights for engine designers and calibration engineers working to optimize GDI systems, ultimately contributing to the development of more efficient, powerful, and reliable internal combustion engines in an increasingly electrified automotive landscape.

The historical development of GDI technology can be traced back to the early 20th century, with significant advancements occurring in the 1970s during the oil crisis. However, it wasn't until the late 1990s that manufacturers like Mitsubishi and Toyota successfully commercialized GDI systems. The technology has since become mainstream, with global adoption accelerating in response to increasingly stringent emissions regulations and fuel economy standards.

Engine knock in GDI systems presents unique challenges compared to traditional port fuel injection systems. The direct injection process creates localized rich fuel zones and temperature gradients within the combustion chamber, potentially leading to pre-ignition and knock events. These events are particularly problematic in GDI engines operating under high load conditions, where the combination of increased cylinder pressures and temperatures creates an environment conducive to abnormal combustion.

Current technological trends in knock reduction focus on several key areas: advanced ignition systems, improved fuel injection strategies, optimized combustion chamber designs, and sophisticated engine control algorithms. The integration of these approaches with emerging technologies such as artificial intelligence and machine learning represents the cutting edge of knock mitigation research.

The primary objectives of this technical research report are threefold. First, to comprehensively analyze the fundamental mechanisms of knock formation in GDI engines, establishing a clear understanding of the physical and chemical processes involved. Second, to evaluate existing knock reduction techniques across the industry, identifying their relative strengths, limitations, and implementation challenges. Third, to explore emerging technologies and methodologies that show promise for future knock reduction strategies, with particular emphasis on those that maintain or enhance the efficiency and performance benefits inherent to GDI systems.

This research aims to provide actionable insights for engine designers and calibration engineers working to optimize GDI systems, ultimately contributing to the development of more efficient, powerful, and reliable internal combustion engines in an increasingly electrified automotive landscape.

Market Demand for Knock-Free GDI Engines

The global automotive industry is witnessing a significant shift towards more efficient and environmentally friendly propulsion systems, with Gasoline Direct Injection (GDI) engines at the forefront of this transformation. Market analysis indicates that GDI technology has experienced substantial growth, with its market share increasing from approximately 5% in 2010 to over 50% in recent years across major automotive markets including North America, Europe, and Asia.

This rapid adoption is primarily driven by stringent emission regulations worldwide, particularly Euro 7 in Europe, China 6 in Asia, and Tier 3 in the United States. These regulations have established increasingly demanding limits on particulate matter and NOx emissions, compelling manufacturers to implement advanced combustion technologies like GDI.

However, engine knock remains a critical challenge that limits the full potential of GDI systems. Industry surveys reveal that over 70% of automotive manufacturers identify knock reduction as a priority area for research and development investment. This focus stems from the direct correlation between knock mitigation and the ability to achieve higher compression ratios, which translates to improved thermal efficiency and reduced fuel consumption.

Consumer demand patterns further reinforce the market need for knock-free GDI engines. Recent market research indicates that fuel economy ranks among the top three purchase considerations for new vehicle buyers across all major markets. Additionally, the premium vehicle segment demonstrates willingness to pay for technologies that deliver smoother engine operation and enhanced performance characteristics.

Fleet operators and commercial vehicle markets represent another significant demand segment, where even marginal improvements in fuel efficiency can translate to substantial operational cost savings. Analysis of total cost of ownership models suggests that a 3-5% improvement in fuel economy through advanced knock reduction techniques could justify technology implementation costs within typical vehicle ownership cycles.

The aftermarket sector also shows growing interest in knock reduction solutions, particularly for performance tuning applications where operating engines at the threshold of knock limits can maximize power output. This niche but profitable segment values technologies that can reliably detect and mitigate knock events in real-time.

Looking forward, market projections indicate that the demand for knock-free GDI engines will continue to grow as hybridization increases across vehicle platforms. In hybrid powertrains, the ability to operate combustion engines at optimal efficiency points becomes even more critical, further emphasizing the need for effective knock reduction techniques that can enable higher compression operation under varying load conditions.

This rapid adoption is primarily driven by stringent emission regulations worldwide, particularly Euro 7 in Europe, China 6 in Asia, and Tier 3 in the United States. These regulations have established increasingly demanding limits on particulate matter and NOx emissions, compelling manufacturers to implement advanced combustion technologies like GDI.

However, engine knock remains a critical challenge that limits the full potential of GDI systems. Industry surveys reveal that over 70% of automotive manufacturers identify knock reduction as a priority area for research and development investment. This focus stems from the direct correlation between knock mitigation and the ability to achieve higher compression ratios, which translates to improved thermal efficiency and reduced fuel consumption.

Consumer demand patterns further reinforce the market need for knock-free GDI engines. Recent market research indicates that fuel economy ranks among the top three purchase considerations for new vehicle buyers across all major markets. Additionally, the premium vehicle segment demonstrates willingness to pay for technologies that deliver smoother engine operation and enhanced performance characteristics.

Fleet operators and commercial vehicle markets represent another significant demand segment, where even marginal improvements in fuel efficiency can translate to substantial operational cost savings. Analysis of total cost of ownership models suggests that a 3-5% improvement in fuel economy through advanced knock reduction techniques could justify technology implementation costs within typical vehicle ownership cycles.

The aftermarket sector also shows growing interest in knock reduction solutions, particularly for performance tuning applications where operating engines at the threshold of knock limits can maximize power output. This niche but profitable segment values technologies that can reliably detect and mitigate knock events in real-time.

Looking forward, market projections indicate that the demand for knock-free GDI engines will continue to grow as hybridization increases across vehicle platforms. In hybrid powertrains, the ability to operate combustion engines at optimal efficiency points becomes even more critical, further emphasizing the need for effective knock reduction techniques that can enable higher compression operation under varying load conditions.

Current Challenges in GDI Knock Reduction

Despite significant advancements in Gasoline Direct Injection (GDI) technology, engine knock remains a persistent challenge that limits performance optimization and efficiency gains. Current GDI systems face several interconnected technical hurdles that require innovative solutions to overcome.

The primary challenge lies in the precise control of combustion timing and propagation under varying operating conditions. Unlike port fuel injection systems, GDI engines experience greater cylinder-to-cylinder and cycle-to-cycle variations in air-fuel mixture distribution, creating localized rich zones that can promote knock. This variability becomes particularly problematic during transient operations and cold starts.

Fuel spray pattern optimization presents another significant obstacle. Current injector designs struggle to achieve the ideal balance between atomization quality, penetration depth, and spray pattern consistency across different engine loads and speeds. The interaction between the fuel spray and in-cylinder air flow remains difficult to predict and control, especially as injector deposits accumulate over time, altering the spray characteristics.

Thermal management challenges further complicate knock reduction efforts. GDI engines typically run hotter than port-injected engines due to reduced charge cooling effects and higher compression ratios. The resulting thermal gradients create hot spots on combustion chamber surfaces that can serve as knock initiation sites. Current cooling systems and thermal barrier coatings have not fully addressed this issue, particularly under high-load conditions.

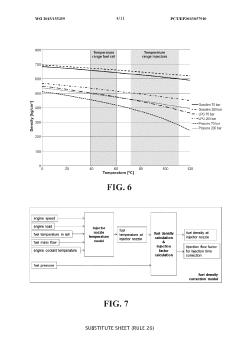

Advanced control algorithms represent another frontier in knock reduction. While modern engine control units employ sophisticated knock detection and mitigation strategies, they still rely heavily on conservative calibration approaches that sacrifice performance to ensure knock-free operation. Real-time adaptation capabilities remain limited by processing constraints and sensor technology limitations.

Fuel quality variations pose an additional challenge that current systems struggle to accommodate. GDI engines are particularly sensitive to fuel composition changes, with varying octane ratings, ethanol content, and aromatic compounds affecting knock propensity. The inability to rapidly detect and adapt to these variations forces calibration engineers to design for worst-case scenarios.

Finally, the integration of knock reduction strategies with increasingly stringent emissions requirements creates competing design priorities. Technologies that effectively reduce knock, such as exhaust gas recirculation, often increase particulate matter emissions—a particular concern for GDI engines that already face challenges meeting particulate number regulations without filtration systems.

These interconnected challenges highlight the need for holistic approaches to knock reduction that address multiple aspects of GDI engine design and operation simultaneously.

The primary challenge lies in the precise control of combustion timing and propagation under varying operating conditions. Unlike port fuel injection systems, GDI engines experience greater cylinder-to-cylinder and cycle-to-cycle variations in air-fuel mixture distribution, creating localized rich zones that can promote knock. This variability becomes particularly problematic during transient operations and cold starts.

Fuel spray pattern optimization presents another significant obstacle. Current injector designs struggle to achieve the ideal balance between atomization quality, penetration depth, and spray pattern consistency across different engine loads and speeds. The interaction between the fuel spray and in-cylinder air flow remains difficult to predict and control, especially as injector deposits accumulate over time, altering the spray characteristics.

Thermal management challenges further complicate knock reduction efforts. GDI engines typically run hotter than port-injected engines due to reduced charge cooling effects and higher compression ratios. The resulting thermal gradients create hot spots on combustion chamber surfaces that can serve as knock initiation sites. Current cooling systems and thermal barrier coatings have not fully addressed this issue, particularly under high-load conditions.

Advanced control algorithms represent another frontier in knock reduction. While modern engine control units employ sophisticated knock detection and mitigation strategies, they still rely heavily on conservative calibration approaches that sacrifice performance to ensure knock-free operation. Real-time adaptation capabilities remain limited by processing constraints and sensor technology limitations.

Fuel quality variations pose an additional challenge that current systems struggle to accommodate. GDI engines are particularly sensitive to fuel composition changes, with varying octane ratings, ethanol content, and aromatic compounds affecting knock propensity. The inability to rapidly detect and adapt to these variations forces calibration engineers to design for worst-case scenarios.

Finally, the integration of knock reduction strategies with increasingly stringent emissions requirements creates competing design priorities. Technologies that effectively reduce knock, such as exhaust gas recirculation, often increase particulate matter emissions—a particular concern for GDI engines that already face challenges meeting particulate number regulations without filtration systems.

These interconnected challenges highlight the need for holistic approaches to knock reduction that address multiple aspects of GDI engine design and operation simultaneously.

Current GDI Knock Reduction Solutions

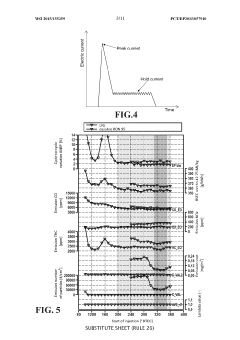

01 Fuel injection control strategies

Various fuel injection control strategies can be implemented to reduce engine knock in GDI engines. These include optimizing injection timing, adjusting fuel pressure, implementing multiple injection events per cycle, and controlling the air-fuel ratio. By precisely controlling when and how fuel is delivered to the combustion chamber, the likelihood of knock can be significantly reduced while maintaining performance and efficiency.- Fuel injection control strategies: Various fuel injection control strategies can be implemented to reduce engine knock in GDI engines. These include adjusting injection timing, optimizing fuel-air mixture formation, implementing split or multiple injections, and controlling the fuel spray pattern. By precisely controlling when and how fuel is injected into the combustion chamber, the likelihood of knock can be significantly reduced while maintaining engine performance and efficiency.

- Knock detection and monitoring systems: Advanced knock detection systems use sensors and signal processing algorithms to identify knock events in GDI engines. These systems can detect the characteristic vibration or pressure signatures of knock and provide real-time feedback to the engine control unit. Early detection allows for immediate adjustments to engine parameters to mitigate knock before it causes damage, improving both engine longevity and performance.

- Combustion chamber design optimization: The design of the combustion chamber significantly impacts knock tendency in GDI engines. Optimized piston crown shapes, cylinder head designs, and intake port configurations can improve air-fuel mixing and combustion efficiency. These design elements help create more uniform temperature distribution and controlled flame propagation, reducing hot spots that can lead to knock while enhancing overall combustion stability.

- Ignition timing and spark control: Precise control of ignition timing is crucial for knock reduction in GDI engines. Advanced ignition systems can dynamically adjust spark timing based on operating conditions to prevent knock while maximizing power and efficiency. Techniques such as cylinder-specific timing adjustments, multi-spark ignition, and adaptive spark control algorithms help maintain optimal combustion phasing under varying load and speed conditions.

- Cooling and thermal management: Effective thermal management strategies help reduce knock in GDI engines by controlling combustion chamber temperatures. Enhanced cooling systems, optimized coolant flow paths, and targeted cooling of critical components can prevent the formation of hot spots that lead to knock. Some systems also implement variable cooling strategies that adjust based on engine load and operating conditions to maintain ideal temperatures for knock-free operation.

02 Knock detection and monitoring systems

Advanced knock detection systems use sensors and signal processing algorithms to identify knock events in real-time. These systems can detect the characteristic vibration or pressure signatures of knock and provide feedback to the engine control unit. Early detection allows for immediate adjustments to operating parameters, preventing damage and optimizing performance in GDI engines.Expand Specific Solutions03 Combustion chamber design optimization

The design of the combustion chamber significantly impacts knock tendency in GDI engines. Optimized piston crown shapes, cylinder head designs, and intake port configurations can improve air-fuel mixing and combustion efficiency. These design elements help create more uniform temperature distribution and controlled flame propagation, reducing hot spots that can lead to knock.Expand Specific Solutions04 Ignition timing and spark control

Precise control of ignition timing is crucial for knock reduction in GDI engines. Advanced spark management systems can dynamically adjust timing based on operating conditions, retarding spark when knock is detected or anticipated. Some systems implement cylinder-specific timing control to address variations between cylinders, optimizing performance while preventing knock.Expand Specific Solutions05 Cooling and thermal management

Effective thermal management strategies help prevent engine knock by controlling combustion chamber temperatures. These include optimized coolant flow paths, targeted cooling of critical components, and advanced cooling system control algorithms. By maintaining appropriate temperature profiles throughout the engine, especially in high-load conditions, knock tendency can be significantly reduced in GDI engines.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The GDI Engine Knock Reduction market is currently in a growth phase, with an expanding market driven by stringent emission regulations and fuel efficiency demands. Major automotive manufacturers like Ford, GM, Toyota, and Hyundai are competing alongside specialized powertrain technology providers such as Robert Bosch, BorgWarner, and Cummins. The market exhibits moderate technological maturity with established players like Ford Global Technologies and Robert Bosch leading innovation through advanced electronic control systems. Chinese manufacturers including Weichai Power and Dongfeng are rapidly gaining ground by leveraging partnerships with academic institutions like Tsinghua University. The competitive landscape is increasingly globalized with significant R&D investments focused on integrating knock reduction with broader engine management systems.

Ford Global Technologies LLC

Technical Solution: Ford has developed a comprehensive GDI knock reduction system that combines multiple strategies. Their approach integrates advanced fuel injection timing control with variable valve timing to optimize combustion phasing. The system employs cylinder-specific knock detection algorithms that can identify individual cylinder knock events and apply targeted countermeasures. Ford's technology utilizes dual-injection strategies (combining port and direct injection) to create optimal fuel distribution under varying load conditions. Their system also incorporates predictive models that anticipate knock conditions based on environmental factors, engine load, and speed parameters, allowing for preemptive adjustments before audible knock occurs. Additionally, Ford has implemented closed-loop combustion control that continuously monitors and adjusts injection parameters to maintain optimal combustion stability while avoiding knock conditions.

Strengths: Highly integrated approach combining multiple technologies; excellent cylinder-specific control; adaptive learning capabilities that improve over time. Weaknesses: System complexity requires sophisticated sensors and processing power; potential higher manufacturing costs; calibration complexity across diverse operating conditions.

Robert Bosch GmbH

Technical Solution: Bosch has pioneered advanced GDI knock reduction technology centered around their precision-engineered high-pressure injection systems. Their solution features multi-hole injectors with optimized spray patterns that ensure homogeneous fuel distribution, significantly reducing hot spots that trigger knock. Bosch's system incorporates sophisticated pressure sensors that can detect pressure oscillations indicative of pre-knock conditions with millisecond precision. Their technology includes adaptive injection timing control that adjusts based on real-time combustion analysis, allowing for operation closer to optimal efficiency without crossing knock thresholds. Bosch has also developed specialized knock control modules that integrate with their engine management systems, using proprietary algorithms to distinguish between normal combustion noise and actual knock events, reducing false positives that would otherwise compromise performance. The system features multi-stage injection capabilities that can deliver precisely timed pilot injections to condition the combustion chamber before main injection events.

Strengths: Industry-leading injection precision; exceptional integration with broader engine management systems; robust detection algorithms with minimal false positives. Weaknesses: Premium components contribute to higher system costs; requires precise calibration for each engine application; higher dependency on fuel quality for optimal performance.

Key Patents in Knock Control Technology

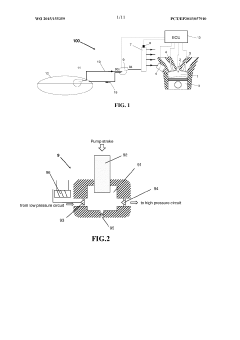

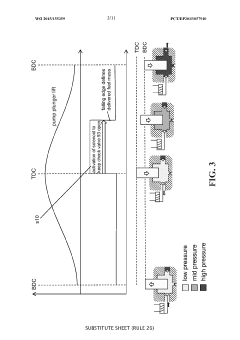

LPG direct injection engine

PatentWO2015155359A1

Innovation

- An LPG direct injection engine with a high-pressure pump and electronic control unit for precise liquefied petroleum gas injection between 360° and 60° BTDC, optimized valve overlap, and cylinder deactivation system to reduce emissions and improve efficiency.

Method for maximizing the formation of deposits in injector nozzles of GDI engines

PatentWO2018002610A1

Innovation

- A method to maximize deposit formation in GDI engine injector nozzles by simulating severe conditions through controlled engine speed and load variations, high nozzle temperatures, and moderate fuel flow rates, allowing for automated and unsupervised testing to quickly assess fuel's deposit-forming tendencies.

Emissions Regulations Impact on Knock Control

The evolution of emissions regulations has significantly shaped the development of knock control strategies in GDI (Gasoline Direct Injection) engines. Since the early 2000s, increasingly stringent emissions standards worldwide have forced manufacturers to optimize combustion processes while simultaneously reducing harmful exhaust components. This regulatory pressure has created a complex engineering challenge where knock reduction techniques must be balanced against emissions compliance.

Euro 6 and EPA Tier 3 standards have particularly influenced knock control development by requiring substantial reductions in NOx and particulate matter emissions. These regulations have effectively narrowed the operational window for GDI engines, as traditional knock mitigation strategies often conflict with emissions targets. For instance, retarding ignition timing to reduce knock tendency typically increases exhaust temperatures and can negatively impact catalyst efficiency and emissions performance.

The California Air Resources Board (CARB) and similar regulatory bodies have further accelerated this trend by implementing even stricter regional standards. These regulations have driven the development of more sophisticated knock control systems that can maintain optimal combustion characteristics while meeting emissions requirements. Real Driving Emissions (RDE) testing introduced in Europe has added another layer of complexity, requiring knock control systems to perform effectively across a wider range of operating conditions than laboratory testing alone.

China's rapidly evolving emissions standards have created a significant market for advanced knock control technologies, particularly as their regulations increasingly align with European standards. This global regulatory convergence has encouraged manufacturers to develop universal knock control solutions that can be deployed across multiple markets with minimal modification.

The regulatory focus on CO2 reduction has indirectly influenced knock control development by promoting higher compression ratios and downsized turbocharged engines, both of which increase knock tendency. This has necessitated more advanced detection and mitigation strategies to maintain performance while meeting efficiency targets.

Looking forward, upcoming regulations like Euro 7 will likely further constrain knock control strategies by imposing even lower emissions limits and expanding the conditions under which vehicles must comply. This regulatory trajectory suggests that future knock control systems will need to incorporate predictive capabilities and integrate more closely with other engine subsystems to optimize the emissions-performance balance across all operating conditions.

The regulatory impact extends beyond technical considerations to influence market dynamics, with regions implementing the most stringent standards often becoming proving grounds for cutting-edge knock control technologies before wider deployment. This regulatory-driven innovation cycle has accelerated the development and adoption of advanced knock detection sensors, closed-loop control systems, and adaptive algorithms that can precisely manage combustion parameters to simultaneously address knock concerns and emissions compliance.

Euro 6 and EPA Tier 3 standards have particularly influenced knock control development by requiring substantial reductions in NOx and particulate matter emissions. These regulations have effectively narrowed the operational window for GDI engines, as traditional knock mitigation strategies often conflict with emissions targets. For instance, retarding ignition timing to reduce knock tendency typically increases exhaust temperatures and can negatively impact catalyst efficiency and emissions performance.

The California Air Resources Board (CARB) and similar regulatory bodies have further accelerated this trend by implementing even stricter regional standards. These regulations have driven the development of more sophisticated knock control systems that can maintain optimal combustion characteristics while meeting emissions requirements. Real Driving Emissions (RDE) testing introduced in Europe has added another layer of complexity, requiring knock control systems to perform effectively across a wider range of operating conditions than laboratory testing alone.

China's rapidly evolving emissions standards have created a significant market for advanced knock control technologies, particularly as their regulations increasingly align with European standards. This global regulatory convergence has encouraged manufacturers to develop universal knock control solutions that can be deployed across multiple markets with minimal modification.

The regulatory focus on CO2 reduction has indirectly influenced knock control development by promoting higher compression ratios and downsized turbocharged engines, both of which increase knock tendency. This has necessitated more advanced detection and mitigation strategies to maintain performance while meeting efficiency targets.

Looking forward, upcoming regulations like Euro 7 will likely further constrain knock control strategies by imposing even lower emissions limits and expanding the conditions under which vehicles must comply. This regulatory trajectory suggests that future knock control systems will need to incorporate predictive capabilities and integrate more closely with other engine subsystems to optimize the emissions-performance balance across all operating conditions.

The regulatory impact extends beyond technical considerations to influence market dynamics, with regions implementing the most stringent standards often becoming proving grounds for cutting-edge knock control technologies before wider deployment. This regulatory-driven innovation cycle has accelerated the development and adoption of advanced knock detection sensors, closed-loop control systems, and adaptive algorithms that can precisely manage combustion parameters to simultaneously address knock concerns and emissions compliance.

Cost-Benefit Analysis of Knock Reduction Methods

The implementation of knock reduction techniques in GDI engines presents varying cost implications that must be carefully evaluated against their effectiveness. Advanced electronic control systems, while offering precise knock detection and mitigation capabilities, require significant initial investment in high-quality sensors, sophisticated ECU programming, and calibration expertise. These systems typically add $300-500 per vehicle in component costs, with additional development expenses of $1-2 million for calibration and validation across engine families.

Mechanical solutions such as piston design optimization and cylinder head modifications present a different cost profile. While redesigned pistons with optimized crown geometry may increase component costs by $15-30 per unit, they offer long-term benefits through reduced warranty claims. Similarly, cylinder head modifications that improve combustion chamber cooling can add $50-100 in manufacturing costs but significantly extend engine lifespan.

Fuel management strategies represent a middle-ground approach from a cost perspective. Dual injection systems combining port and direct injection capabilities add approximately $150-250 in hardware costs per engine but deliver substantial knock reduction benefits without requiring major mechanical redesigns. Advanced fuel formulations with higher octane ratings increase operational costs by 5-10% but require minimal hardware modifications.

When analyzing return on investment, electronic solutions typically show payback periods of 2-3 years through improved fuel economy (2-5%) and reduced warranty claims. Mechanical solutions demonstrate longer payback periods of 3-5 years but offer more consistent performance across varying operating conditions. The most cost-effective approach appears to be a strategic combination of basic electronic controls with targeted mechanical improvements, achieving approximately 80% of knock reduction benefits at 60% of the cost of implementing all available technologies.

Environmental regulations increasingly influence cost-benefit calculations, as penalties for exceeding emissions targets can reach $100-150 per vehicle. Solutions that simultaneously address knock and emissions concerns, such as EGR systems with advanced cooling, demonstrate superior long-term value despite higher initial implementation costs of $200-300 per unit.

Manufacturing scalability also impacts cost-effectiveness, with electronic solutions showing better economies of scale compared to mechanical modifications that may require significant retooling expenses. For high-volume manufacturers, the amortized development costs of electronic solutions become increasingly attractive, while low-volume specialty producers may find targeted mechanical solutions more economically viable.

Mechanical solutions such as piston design optimization and cylinder head modifications present a different cost profile. While redesigned pistons with optimized crown geometry may increase component costs by $15-30 per unit, they offer long-term benefits through reduced warranty claims. Similarly, cylinder head modifications that improve combustion chamber cooling can add $50-100 in manufacturing costs but significantly extend engine lifespan.

Fuel management strategies represent a middle-ground approach from a cost perspective. Dual injection systems combining port and direct injection capabilities add approximately $150-250 in hardware costs per engine but deliver substantial knock reduction benefits without requiring major mechanical redesigns. Advanced fuel formulations with higher octane ratings increase operational costs by 5-10% but require minimal hardware modifications.

When analyzing return on investment, electronic solutions typically show payback periods of 2-3 years through improved fuel economy (2-5%) and reduced warranty claims. Mechanical solutions demonstrate longer payback periods of 3-5 years but offer more consistent performance across varying operating conditions. The most cost-effective approach appears to be a strategic combination of basic electronic controls with targeted mechanical improvements, achieving approximately 80% of knock reduction benefits at 60% of the cost of implementing all available technologies.

Environmental regulations increasingly influence cost-benefit calculations, as penalties for exceeding emissions targets can reach $100-150 per vehicle. Solutions that simultaneously address knock and emissions concerns, such as EGR systems with advanced cooling, demonstrate superior long-term value despite higher initial implementation costs of $200-300 per unit.

Manufacturing scalability also impacts cost-effectiveness, with electronic solutions showing better economies of scale compared to mechanical modifications that may require significant retooling expenses. For high-volume manufacturers, the amortized development costs of electronic solutions become increasingly attractive, while low-volume specialty producers may find targeted mechanical solutions more economically viable.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!