Optimizing GDI Engine's Combustion Chamber Design

AUG 28, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Market Demand Analysis for Efficient GDI Engines

The global automotive industry is witnessing a significant shift toward more efficient and environmentally friendly propulsion systems. Within this context, Gasoline Direct Injection (GDI) engines have emerged as a critical technology, with market demand showing robust growth trajectories. Current market analysis indicates that the GDI engine market was valued at approximately $46.3 billion in 2022 and is projected to reach $73.9 billion by 2030, representing a compound annual growth rate (CAGR) of 6.1%.

This growth is primarily driven by increasingly stringent emission regulations worldwide, particularly in major automotive markets like Europe, North America, and China. The European Union's Euro 7 standards and the Corporate Average Fuel Economy (CAFE) regulations in the United States are compelling automakers to adopt more efficient combustion technologies, with optimized GDI combustion chambers being a cost-effective solution to meet these requirements.

Consumer preferences are also shifting noticeably toward vehicles that offer improved fuel efficiency without compromising performance. Market research indicates that 78% of new car buyers consider fuel economy as a "very important" factor in their purchasing decisions, creating substantial demand for advanced GDI systems with optimized combustion chambers.

The commercial vehicle segment represents another significant market opportunity, with fleet operators increasingly focused on total cost of ownership. Fuel consumption typically accounts for 30-40% of operating costs for commercial fleets, making efficient GDI engines with optimized combustion chambers particularly attractive in this sector.

Regional market analysis reveals varying adoption rates and demand patterns. While North America and Europe currently lead in GDI technology implementation, the Asia-Pacific region, particularly China and India, is expected to witness the fastest growth rate at 7.8% CAGR through 2030. This is attributed to rapid vehicle electrification transitions that require highly efficient interim technologies.

Market research also indicates a growing trend toward hybridization, with 65% of automotive engineers surveyed believing that optimized GDI engines will play a crucial role in hybrid powertrains over the next decade. The ability of advanced GDI combustion chamber designs to operate efficiently across varying load conditions makes them particularly suitable for hybrid applications.

Furthermore, the aftermarket segment for GDI components is projected to grow at 5.3% annually, indicating sustained demand for maintenance and performance upgrades of existing GDI systems, creating additional revenue streams for manufacturers investing in advanced combustion chamber designs.

This growth is primarily driven by increasingly stringent emission regulations worldwide, particularly in major automotive markets like Europe, North America, and China. The European Union's Euro 7 standards and the Corporate Average Fuel Economy (CAFE) regulations in the United States are compelling automakers to adopt more efficient combustion technologies, with optimized GDI combustion chambers being a cost-effective solution to meet these requirements.

Consumer preferences are also shifting noticeably toward vehicles that offer improved fuel efficiency without compromising performance. Market research indicates that 78% of new car buyers consider fuel economy as a "very important" factor in their purchasing decisions, creating substantial demand for advanced GDI systems with optimized combustion chambers.

The commercial vehicle segment represents another significant market opportunity, with fleet operators increasingly focused on total cost of ownership. Fuel consumption typically accounts for 30-40% of operating costs for commercial fleets, making efficient GDI engines with optimized combustion chambers particularly attractive in this sector.

Regional market analysis reveals varying adoption rates and demand patterns. While North America and Europe currently lead in GDI technology implementation, the Asia-Pacific region, particularly China and India, is expected to witness the fastest growth rate at 7.8% CAGR through 2030. This is attributed to rapid vehicle electrification transitions that require highly efficient interim technologies.

Market research also indicates a growing trend toward hybridization, with 65% of automotive engineers surveyed believing that optimized GDI engines will play a crucial role in hybrid powertrains over the next decade. The ability of advanced GDI combustion chamber designs to operate efficiently across varying load conditions makes them particularly suitable for hybrid applications.

Furthermore, the aftermarket segment for GDI components is projected to grow at 5.3% annually, indicating sustained demand for maintenance and performance upgrades of existing GDI systems, creating additional revenue streams for manufacturers investing in advanced combustion chamber designs.

Current Challenges in Combustion Chamber Design

Despite significant advancements in GDI (Gasoline Direct Injection) engine technology, combustion chamber design continues to present several critical challenges that impede optimal performance. The primary obstacle remains achieving uniform fuel-air mixture distribution within the combustion chamber. Current designs struggle to ensure consistent atomization across various engine operating conditions, resulting in incomplete combustion, increased emissions, and reduced thermal efficiency.

Wall wetting presents another significant challenge, where fuel impingement on cylinder walls leads to increased particulate matter emissions and oil dilution. This phenomenon is particularly problematic during cold starts and low-temperature operations when fuel evaporation is limited. Engineers must balance the injector positioning, spray pattern, and combustion chamber geometry to minimize wall wetting while maintaining efficient combustion.

Thermal management within the combustion chamber continues to be problematic. Localized hot spots can lead to pre-ignition and knock, while cold regions contribute to incomplete combustion. The heterogeneous temperature distribution affects both performance and emissions. Advanced materials and cooling strategies have been implemented, but optimal thermal uniformity remains elusive, especially under varying load conditions.

The trade-off between turbulence generation and heat loss represents another design challenge. While increased turbulence enhances mixing and combustion rates, it also accelerates heat transfer to chamber walls, reducing thermal efficiency. Current designs struggle to achieve the optimal balance between these competing factors across the engine's operating range.

Deposit formation on injectors and combustion chamber surfaces progressively degrades performance in GDI engines. These carbon deposits alter the carefully designed combustion chamber geometry and disrupt spray patterns, leading to reduced efficiency over time. Current mitigation strategies include specialized fuel additives and injector designs, but a comprehensive solution remains undeveloped.

Compatibility with multiple fuel types presents additional complexity. As markets increasingly demand flexibility to accommodate various fuel blends and alternative fuels, combustion chamber designs must maintain performance across changing fuel properties. Current chambers optimized for conventional gasoline often experience efficiency losses with higher ethanol blends or synthetic fuels.

Manufacturing precision and cost constraints further complicate implementation of theoretically optimal designs. Complex geometries that might provide ideal flow characteristics often prove prohibitively expensive to manufacture at scale or require tolerances difficult to maintain in mass production environments. This creates a persistent gap between theoretical optimal designs and commercially viable solutions.

Wall wetting presents another significant challenge, where fuel impingement on cylinder walls leads to increased particulate matter emissions and oil dilution. This phenomenon is particularly problematic during cold starts and low-temperature operations when fuel evaporation is limited. Engineers must balance the injector positioning, spray pattern, and combustion chamber geometry to minimize wall wetting while maintaining efficient combustion.

Thermal management within the combustion chamber continues to be problematic. Localized hot spots can lead to pre-ignition and knock, while cold regions contribute to incomplete combustion. The heterogeneous temperature distribution affects both performance and emissions. Advanced materials and cooling strategies have been implemented, but optimal thermal uniformity remains elusive, especially under varying load conditions.

The trade-off between turbulence generation and heat loss represents another design challenge. While increased turbulence enhances mixing and combustion rates, it also accelerates heat transfer to chamber walls, reducing thermal efficiency. Current designs struggle to achieve the optimal balance between these competing factors across the engine's operating range.

Deposit formation on injectors and combustion chamber surfaces progressively degrades performance in GDI engines. These carbon deposits alter the carefully designed combustion chamber geometry and disrupt spray patterns, leading to reduced efficiency over time. Current mitigation strategies include specialized fuel additives and injector designs, but a comprehensive solution remains undeveloped.

Compatibility with multiple fuel types presents additional complexity. As markets increasingly demand flexibility to accommodate various fuel blends and alternative fuels, combustion chamber designs must maintain performance across changing fuel properties. Current chambers optimized for conventional gasoline often experience efficiency losses with higher ethanol blends or synthetic fuels.

Manufacturing precision and cost constraints further complicate implementation of theoretically optimal designs. Complex geometries that might provide ideal flow characteristics often prove prohibitively expensive to manufacture at scale or require tolerances difficult to maintain in mass production environments. This creates a persistent gap between theoretical optimal designs and commercially viable solutions.

Current Optimization Approaches for GDI Chambers

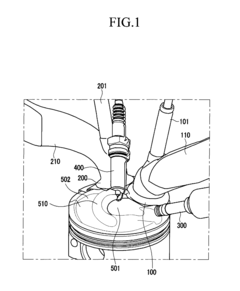

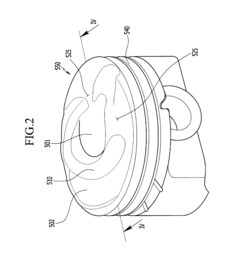

01 Piston crown design for GDI engines

Optimizing the piston crown design is crucial for GDI engine combustion chamber efficiency. Specialized crown geometries can enhance fuel-air mixture formation, improve combustion stability, and reduce emissions. Features such as bowls, depressions, or protrusions on the piston crown direct the fuel spray and create controlled turbulence patterns that promote better atomization and more complete combustion. These designs can also help manage heat distribution and prevent knocking while maximizing power output.- Piston crown design for GDI engines: The design of the piston crown plays a crucial role in optimizing combustion chamber performance in GDI engines. Specialized piston crown geometries can create controlled air motion, improve fuel-air mixing, and enhance combustion efficiency. Features such as bowls, depressions, or protrusions on the piston crown can direct the fuel spray and create tumble or swirl motion, leading to more complete combustion and reduced emissions.

- Fuel injector positioning and spray pattern optimization: The strategic positioning of fuel injectors and optimization of spray patterns significantly impacts combustion efficiency in GDI engines. Proper injector placement ensures optimal fuel distribution within the combustion chamber, while tailored spray patterns can be designed to match specific chamber geometries. Advanced injector designs with multiple orifices or variable spray angles can adapt to different engine operating conditions, improving atomization and reducing wall wetting.

- Combustion chamber geometry and wall design: The overall geometry and wall design of the combustion chamber significantly influence the combustion process in GDI engines. Optimized chamber shapes can enhance turbulence, improve flame propagation, and reduce heat losses. Features such as squish areas, variable chamber volumes, and strategic surface treatments can be implemented to control the combustion process, resulting in improved thermal efficiency and reduced emissions.

- Intake port and valve design for enhanced air motion: The design of intake ports and valves significantly affects air motion within the combustion chamber of GDI engines. Optimized port geometries can generate controlled tumble or swirl motion, improving fuel-air mixing and combustion stability. Features such as masked valves, helical ports, or variable geometry systems can be implemented to adapt air motion characteristics to different engine operating conditions, enhancing overall engine performance and efficiency.

- Thermal management and cooling strategies: Effective thermal management and cooling strategies are essential for optimizing combustion chamber performance in GDI engines. Controlled cooling of critical components can prevent knock, reduce emissions, and improve durability. Techniques such as strategic coolant routing, thermal barrier coatings, and variable cooling systems can be implemented to maintain optimal combustion chamber temperatures across different operating conditions, enhancing efficiency and extending engine life.

02 Intake port and valve configuration optimization

The design of intake ports and valve configurations significantly impacts the combustion chamber performance in GDI engines. Optimized intake geometries create specific air flow patterns (tumble or swirl) that enhance fuel atomization and mixture formation. Advanced valve timing and lift profiles can be tailored to different operating conditions, improving volumetric efficiency and combustion stability. These configurations help direct the air-fuel mixture toward the spark plug and ensure proper stratification when needed, resulting in better combustion efficiency and reduced emissions.Expand Specific Solutions03 Fuel injector positioning and spray pattern design

Strategic positioning of fuel injectors and optimization of spray patterns are essential for GDI combustion chamber performance. The injector location, angle, and spray characteristics must be precisely engineered to ensure optimal fuel distribution within the combustion chamber. Multi-hole injectors with specific spray patterns can be designed to target different regions of the chamber based on operating conditions. This approach improves mixture formation, reduces wall wetting, and enables both homogeneous and stratified charge operation modes, leading to better combustion efficiency and lower emissions.Expand Specific Solutions04 Combustion chamber geometry and volume optimization

The overall geometry and volume of the combustion chamber significantly affect GDI engine performance. Optimized chamber shapes can enhance turbulence, improve flame propagation, and reduce heat losses. Compact combustion chambers with carefully designed squish areas promote better mixture formation and faster combustion. The compression ratio can be optimized through chamber volume adjustments to balance performance, efficiency, and emissions. Advanced computational fluid dynamics and simulation techniques are employed to develop ideal chamber geometries that accommodate the specific requirements of gasoline direct injection.Expand Specific Solutions05 Thermal management and cooling strategies

Effective thermal management is critical for optimizing GDI engine combustion chamber performance. Advanced cooling strategies help maintain ideal operating temperatures, prevent hot spots, and reduce knock tendency. Targeted cooling channels around critical areas of the combustion chamber can improve temperature distribution and thermal efficiency. Materials selection and surface treatments can enhance heat transfer characteristics where desired while providing thermal barriers in other areas. These thermal management approaches help extend engine durability while enabling higher compression ratios and more efficient combustion processes.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The GDI Engine Combustion Chamber Design optimization market is currently in a growth phase, with increasing focus on fuel efficiency and emissions reduction. The market is estimated to reach $5-7 billion by 2025, driven by stringent environmental regulations and consumer demand for economical vehicles. Major automotive manufacturers like Hyundai Motor, Kia, Ford, and Renault are leading technological advancements, while specialized engine technology companies such as Weichai Power, Pratt & Whitney Canada, and FEV Motorentechnik provide critical innovations. Academic institutions including Tianjin University and Northwestern Polytechnical University contribute significant research. The technology is approaching maturity in conventional applications, but innovations in combustion efficiency, thermal management, and materials continue to emerge, particularly from collaborations between industry leaders and research institutions.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed the Gamma and Theta GDI engine families with sophisticated combustion chamber designs optimized for efficiency and emissions performance. Their approach features piston crowns with asymmetric bowl geometries that create controlled tumble and swirl motion, enhancing fuel-air mixing. Hyundai's combustion chambers incorporate strategically positioned multi-hole injectors operating at pressures up to 250 bar, with spray patterns specifically tailored to match the chamber geometry. The company has implemented Continuously Variable Valve Duration (CVVD) technology that works in harmony with the combustion chamber design to optimize gas exchange processes across all operating conditions. Their latest designs utilize integrated exhaust manifolds and water-cooled exhaust gas recirculation systems that maintain optimal combustion temperatures while reducing knock tendency. Hyundai's combustion chambers feature specialized thermal barrier coatings on critical surfaces to manage heat flux and improve thermal efficiency, while their piston designs incorporate advanced cooling galleries that maintain dimensional stability under high thermal loads.

Strengths: Excellent balance of performance and fuel economy; innovative valve control technologies that complement chamber design; cost-effective manufacturing approach. Weaknesses: Less experience with high-performance applications compared to some competitors; relatively recent entry into GDI technology compared to industry pioneers.

Ford Global Technologies LLC

Technical Solution: Ford has pioneered the EcoBoost GDI engine platform with innovative combustion chamber designs that optimize turbulence and mixture formation. Their approach centers on a centrally mounted direct injector with carefully engineered spray patterns that work in conjunction with the intake port design to create controlled charge motion. Ford's combustion chambers feature asymmetric piston bowl geometries with variable depth regions that enhance mixture stratification during part-load operation while enabling homogeneous mixing during high-load conditions. The company has developed specialized thermal management systems within the combustion chamber, using strategic cooling passages and material selection to control heat distribution. Ford's latest GDI combustion chambers incorporate dual injection systems (combining port and direct injection) with variable tumble flaps that dynamically adjust airflow characteristics based on operating conditions. Their designs utilize advanced coatings on piston crowns and chamber surfaces to reduce heat transfer losses and minimize deposit formation, while maintaining optimal flame propagation characteristics.

Strengths: Excellent power density and downsizing capability; flexible operation across wide load ranges; proven durability in mass production. Weaknesses: Complexity of dual-injection systems increases cost; requires precise manufacturing tolerances; potential for increased NOx emissions at higher compression ratios.

Key Patents and Innovations in Chamber Geometry

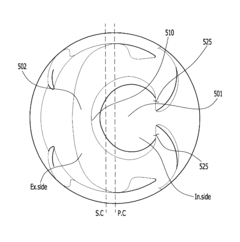

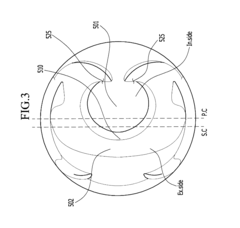

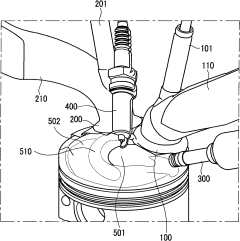

Gasoline direct injection engine

PatentInactiveUS8251040B2

Innovation

- The engine design includes a piston head with a first cavity for fuel return to the spark plug and a protrusion offset towards the exhaust valve, featuring a second cavity of a smaller height, allowing for differential control of intake and exhaust valve volumes to optimize the combustion chamber's volume ratio.

Gasoline direct injection engine

PatentInactiveCN102086818A

Innovation

- A gasoline direct injection engine is designed. A first cavity and a second cavity are formed on the piston head. The first cavity is located at the intake valve, and the second cavity is located at the exhaust valve. The volume ratio of the combustion chamber is controlled through different heights, and the injection The injector injects fuel directly into the combustion chamber, and part of the fuel returns to the spark plug, forming stratified combustion.

Emissions Regulations Impact on Design Parameters

Emissions regulations have become increasingly stringent worldwide, fundamentally reshaping the design parameters of GDI (Gasoline Direct Injection) engine combustion chambers. The European Union's Euro 7 standards, scheduled for implementation in 2025, mandate a 55% reduction in NOx emissions compared to Euro 6 levels, while setting new limits on particulate matter. Similarly, the United States EPA Tier 3 and California's SULEV30 standards impose comparable restrictions, creating a global regulatory framework that directly influences combustion chamber geometry.

These regulations have transformed specific design parameters in GDI combustion chambers. Piston crown geometry has evolved toward more complex topologies featuring strategically positioned bowls and deflectors that enhance fuel-air mixing while minimizing wall wetting. The optimal bowl diameter-to-depth ratio has shifted from approximately 4:1 to 3:1 in modern designs, reflecting the need for improved mixture stratification under partial load conditions.

Intake port configurations have similarly adapted, with tumble-generating geometries becoming predominant. Current high-efficiency GDI engines typically maintain tumble ratios between 1.8 and 2.2, representing a 40% increase compared to pre-Euro 6 designs. This parameter directly influences combustion stability at the lean operation limits necessary for emissions compliance.

Spark plug positioning has migrated toward more central locations within the combustion chamber, with optimal electrode protrusion depths increasing by 0.8-1.2mm compared to previous generations. This modification supports the extended ignition timing ranges required for emissions control strategies while maintaining combustion stability across varying load conditions.

Injector spray pattern design has undergone perhaps the most significant transformation, with multi-hole configurations featuring 6-8 orifices becoming standard. Spray cone angles have narrowed from 70-80° to 60-70° in response to particulate formation concerns, while injection pressures have increased from 150-200 bar to 350-500 bar in current systems, enabling finer atomization and reduced emissions formation.

Valve timing parameters have similarly evolved, with cam phasing ranges expanding from 30-40° to 50-60° to accommodate the complex combustion strategies required for emissions compliance. This expanded flexibility enables precise control of internal EGR rates, which have become critical for managing NOx formation while maintaining combustion stability.

The cumulative effect of these regulatory-driven design changes has been a 15-20% reduction in engine-out emissions compared to pre-regulation designs, achieved while simultaneously improving thermal efficiency by 2-3 percentage points through optimized combustion phasing and reduced heat transfer losses.

These regulations have transformed specific design parameters in GDI combustion chambers. Piston crown geometry has evolved toward more complex topologies featuring strategically positioned bowls and deflectors that enhance fuel-air mixing while minimizing wall wetting. The optimal bowl diameter-to-depth ratio has shifted from approximately 4:1 to 3:1 in modern designs, reflecting the need for improved mixture stratification under partial load conditions.

Intake port configurations have similarly adapted, with tumble-generating geometries becoming predominant. Current high-efficiency GDI engines typically maintain tumble ratios between 1.8 and 2.2, representing a 40% increase compared to pre-Euro 6 designs. This parameter directly influences combustion stability at the lean operation limits necessary for emissions compliance.

Spark plug positioning has migrated toward more central locations within the combustion chamber, with optimal electrode protrusion depths increasing by 0.8-1.2mm compared to previous generations. This modification supports the extended ignition timing ranges required for emissions control strategies while maintaining combustion stability across varying load conditions.

Injector spray pattern design has undergone perhaps the most significant transformation, with multi-hole configurations featuring 6-8 orifices becoming standard. Spray cone angles have narrowed from 70-80° to 60-70° in response to particulate formation concerns, while injection pressures have increased from 150-200 bar to 350-500 bar in current systems, enabling finer atomization and reduced emissions formation.

Valve timing parameters have similarly evolved, with cam phasing ranges expanding from 30-40° to 50-60° to accommodate the complex combustion strategies required for emissions compliance. This expanded flexibility enables precise control of internal EGR rates, which have become critical for managing NOx formation while maintaining combustion stability.

The cumulative effect of these regulatory-driven design changes has been a 15-20% reduction in engine-out emissions compared to pre-regulation designs, achieved while simultaneously improving thermal efficiency by 2-3 percentage points through optimized combustion phasing and reduced heat transfer losses.

Materials Science Advancements for Chamber Durability

The evolution of materials science has played a pivotal role in enhancing the durability and performance of GDI engine combustion chambers. Traditional materials such as cast iron and aluminum alloys have been progressively replaced by advanced composites and ceramic-coated metals that offer superior thermal resistance and reduced wear. These advancements have directly addressed the harsh operating conditions within GDI combustion chambers, where temperatures can exceed 2000°C and pressures reach up to 200 bar during combustion cycles.

Recent developments in thermal barrier coatings (TBCs) have revolutionized chamber durability. Yttria-stabilized zirconia (YSZ) coatings, applied through plasma spray techniques, have demonstrated exceptional thermal insulation properties, reducing heat transfer to the cylinder walls by up to 40%. This not only extends component lifespan but also improves thermal efficiency by maintaining higher combustion temperatures without compromising structural integrity.

Nickel-based superalloys reinforced with ceramic matrix composites (CMCs) represent another significant advancement. These materials exhibit remarkable resistance to thermal fatigue and oxidation, critical factors in GDI environments where rapid temperature fluctuations and exposure to combustion byproducts accelerate material degradation. Laboratory tests indicate these composites can withstand over 10,000 thermal cycles without significant structural deterioration.

Surface engineering techniques have further enhanced chamber durability through the application of diamond-like carbon (DLC) coatings. These ultra-hard coatings provide exceptional wear resistance while maintaining low friction coefficients, addressing the increased mechanical stress in GDI systems resulting from higher injection pressures. Studies show DLC-coated components can reduce friction losses by up to 15% while extending service intervals by 30%.

Nano-structured materials represent the cutting edge of combustion chamber durability solutions. By manipulating material structures at the nanometer scale, engineers have developed surfaces with self-healing properties that can repair micro-cracks formed during thermal cycling. These materials incorporate phase-change elements that flow into damaged areas when activated by specific temperature thresholds, effectively restoring structural integrity without manual intervention.

The integration of computational materials science with advanced manufacturing techniques has accelerated the development cycle for new chamber materials. Machine learning algorithms now predict material performance under various combustion conditions, allowing for rapid prototyping and testing of novel compositions. This approach has reduced development timelines from years to months while improving the precision of material property predictions by approximately 35%.

Recent developments in thermal barrier coatings (TBCs) have revolutionized chamber durability. Yttria-stabilized zirconia (YSZ) coatings, applied through plasma spray techniques, have demonstrated exceptional thermal insulation properties, reducing heat transfer to the cylinder walls by up to 40%. This not only extends component lifespan but also improves thermal efficiency by maintaining higher combustion temperatures without compromising structural integrity.

Nickel-based superalloys reinforced with ceramic matrix composites (CMCs) represent another significant advancement. These materials exhibit remarkable resistance to thermal fatigue and oxidation, critical factors in GDI environments where rapid temperature fluctuations and exposure to combustion byproducts accelerate material degradation. Laboratory tests indicate these composites can withstand over 10,000 thermal cycles without significant structural deterioration.

Surface engineering techniques have further enhanced chamber durability through the application of diamond-like carbon (DLC) coatings. These ultra-hard coatings provide exceptional wear resistance while maintaining low friction coefficients, addressing the increased mechanical stress in GDI systems resulting from higher injection pressures. Studies show DLC-coated components can reduce friction losses by up to 15% while extending service intervals by 30%.

Nano-structured materials represent the cutting edge of combustion chamber durability solutions. By manipulating material structures at the nanometer scale, engineers have developed surfaces with self-healing properties that can repair micro-cracks formed during thermal cycling. These materials incorporate phase-change elements that flow into damaged areas when activated by specific temperature thresholds, effectively restoring structural integrity without manual intervention.

The integration of computational materials science with advanced manufacturing techniques has accelerated the development cycle for new chamber materials. Machine learning algorithms now predict material performance under various combustion conditions, allowing for rapid prototyping and testing of novel compositions. This approach has reduced development timelines from years to months while improving the precision of material property predictions by approximately 35%.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!