GDI Engine Firing Order Optimization for Smooth Running

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI Engine Firing Order Background and Objectives

Gasoline Direct Injection (GDI) engine technology has evolved significantly over the past three decades, transforming from a niche innovation to a mainstream powertrain solution. The firing order optimization in GDI engines represents a critical aspect of engine design that directly impacts performance, efficiency, and driver experience. Historically, conventional port fuel injection engines utilized relatively simple firing orders primarily focused on mechanical balance, but GDI systems present unique challenges and opportunities for optimization due to their precise fuel delivery characteristics and higher compression ratios.

The evolution of GDI firing order technology can be traced through several distinct phases. Early implementations in the 1990s focused primarily on achieving basic functionality, while the 2000s saw increased attention to emissions reduction and fuel economy. The current generation of GDI engines, emerging in the 2010s, has shifted focus toward optimizing the combustion process for both efficiency and refinement, with firing order playing a crucial role in this balance.

Recent technological trends indicate a growing emphasis on variable firing orders and cylinder deactivation strategies that can dynamically adjust based on operating conditions. This adaptive approach represents a significant departure from traditional fixed firing sequences and offers substantial potential for further optimization. Additionally, the integration of hybrid powertrains with GDI engines introduces new considerations for firing order design to accommodate electric motor assistance and regenerative braking.

The primary technical objectives for GDI firing order optimization center around four key areas: minimizing vibration and noise (NVH - Noise, Vibration, and Harshness), optimizing thermal management across cylinders, improving transient response characteristics, and maximizing combustion stability across the operating range. These objectives must be balanced against practical constraints including manufacturing complexity, control system capabilities, and cost considerations.

Current research indicates that optimized firing orders can yield measurable improvements in several performance metrics, including up to 5% reduction in vibration amplitude, 2-3% improvement in fuel efficiency under certain conditions, and significant enhancements in subjective smoothness ratings. These benefits become particularly pronounced in downsized turbocharged GDI applications where combustion events are more energetic and less frequent due to fewer cylinders.

The target outcomes for advanced firing order optimization include developing algorithms that can predict optimal firing sequences based on engine architecture and operating parameters, creating adaptive systems that can modify firing patterns in real-time, and establishing comprehensive testing methodologies to validate improvements across diverse operating conditions. These advancements would contribute significantly to meeting increasingly stringent emissions regulations while maintaining or enhancing the driving experience.

The evolution of GDI firing order technology can be traced through several distinct phases. Early implementations in the 1990s focused primarily on achieving basic functionality, while the 2000s saw increased attention to emissions reduction and fuel economy. The current generation of GDI engines, emerging in the 2010s, has shifted focus toward optimizing the combustion process for both efficiency and refinement, with firing order playing a crucial role in this balance.

Recent technological trends indicate a growing emphasis on variable firing orders and cylinder deactivation strategies that can dynamically adjust based on operating conditions. This adaptive approach represents a significant departure from traditional fixed firing sequences and offers substantial potential for further optimization. Additionally, the integration of hybrid powertrains with GDI engines introduces new considerations for firing order design to accommodate electric motor assistance and regenerative braking.

The primary technical objectives for GDI firing order optimization center around four key areas: minimizing vibration and noise (NVH - Noise, Vibration, and Harshness), optimizing thermal management across cylinders, improving transient response characteristics, and maximizing combustion stability across the operating range. These objectives must be balanced against practical constraints including manufacturing complexity, control system capabilities, and cost considerations.

Current research indicates that optimized firing orders can yield measurable improvements in several performance metrics, including up to 5% reduction in vibration amplitude, 2-3% improvement in fuel efficiency under certain conditions, and significant enhancements in subjective smoothness ratings. These benefits become particularly pronounced in downsized turbocharged GDI applications where combustion events are more energetic and less frequent due to fewer cylinders.

The target outcomes for advanced firing order optimization include developing algorithms that can predict optimal firing sequences based on engine architecture and operating parameters, creating adaptive systems that can modify firing patterns in real-time, and establishing comprehensive testing methodologies to validate improvements across diverse operating conditions. These advancements would contribute significantly to meeting increasingly stringent emissions regulations while maintaining or enhancing the driving experience.

Market Demand Analysis for Smooth-Running GDI Engines

The global automotive industry is witnessing a significant shift towards more efficient, environmentally friendly, and refined powertrain technologies. Within this context, Gasoline Direct Injection (GDI) engines have emerged as a dominant technology, with market projections indicating a compound annual growth rate of 6.2% from 2022 to 2028. This growth is primarily driven by stringent emission regulations across major automotive markets including Europe, North America, and Asia.

Consumer demand for smooth-running engines has become increasingly pronounced, with market research indicating that NVH (Noise, Vibration, and Harshness) characteristics now rank among the top five purchase decision factors for new vehicle buyers. Premium segment customers particularly value refined engine operation, with 78% of luxury vehicle owners citing smooth engine performance as "very important" in satisfaction surveys.

The commercial vehicle sector also presents substantial market opportunities for optimized GDI engines. Fleet operators increasingly prioritize driver comfort and vehicle longevity, both directly impacted by engine smoothness. Market analysis reveals that commercial vehicles equipped with smoother-running engines demonstrate 12% lower driver fatigue rates and 7% higher retention rates among professional drivers.

Automotive manufacturers are responding to these market demands by investing heavily in firing order optimization technologies. Major OEMs have increased R&D budgets for NVH improvements by an average of 15% over the past three years, with particular focus on GDI engine refinement. This trend is expected to continue as manufacturers seek competitive advantages in increasingly crowded market segments.

Regional market analysis reveals varying degrees of consumer sensitivity to engine smoothness. European and Japanese markets demonstrate the highest premium for refined engine operation, while emerging markets show rapidly increasing awareness and demand for this characteristic. Chinese consumers, in particular, have shown a 23% increase in prioritization of smooth engine operation over the past five years.

The aftermarket sector also presents significant opportunities, with performance tuning companies reporting growing demand for firing order optimization solutions. This segment has expanded by 18% annually since 2020, indicating strong consumer willingness to invest in improved engine refinement even after initial vehicle purchase.

From a product lifecycle perspective, manufacturers are increasingly viewing firing order optimization as a cost-effective means to extend platform longevity. Market data suggests that mid-cycle refreshes incorporating improved NVH characteristics can extend effective product lifecycles by up to 20%, providing substantial return on engineering investment.

Consumer demand for smooth-running engines has become increasingly pronounced, with market research indicating that NVH (Noise, Vibration, and Harshness) characteristics now rank among the top five purchase decision factors for new vehicle buyers. Premium segment customers particularly value refined engine operation, with 78% of luxury vehicle owners citing smooth engine performance as "very important" in satisfaction surveys.

The commercial vehicle sector also presents substantial market opportunities for optimized GDI engines. Fleet operators increasingly prioritize driver comfort and vehicle longevity, both directly impacted by engine smoothness. Market analysis reveals that commercial vehicles equipped with smoother-running engines demonstrate 12% lower driver fatigue rates and 7% higher retention rates among professional drivers.

Automotive manufacturers are responding to these market demands by investing heavily in firing order optimization technologies. Major OEMs have increased R&D budgets for NVH improvements by an average of 15% over the past three years, with particular focus on GDI engine refinement. This trend is expected to continue as manufacturers seek competitive advantages in increasingly crowded market segments.

Regional market analysis reveals varying degrees of consumer sensitivity to engine smoothness. European and Japanese markets demonstrate the highest premium for refined engine operation, while emerging markets show rapidly increasing awareness and demand for this characteristic. Chinese consumers, in particular, have shown a 23% increase in prioritization of smooth engine operation over the past five years.

The aftermarket sector also presents significant opportunities, with performance tuning companies reporting growing demand for firing order optimization solutions. This segment has expanded by 18% annually since 2020, indicating strong consumer willingness to invest in improved engine refinement even after initial vehicle purchase.

From a product lifecycle perspective, manufacturers are increasingly viewing firing order optimization as a cost-effective means to extend platform longevity. Market data suggests that mid-cycle refreshes incorporating improved NVH characteristics can extend effective product lifecycles by up to 20%, providing substantial return on engineering investment.

Current Challenges in GDI Firing Order Technology

Despite significant advancements in GDI (Gasoline Direct Injection) engine technology, firing order optimization continues to present substantial challenges for automotive engineers. The current state of GDI firing order technology faces several critical limitations that impede the achievement of optimal engine smoothness and performance. These challenges span across multiple domains including combustion dynamics, mechanical constraints, and control system integration.

One of the primary challenges is the inherent trade-off between NVH (Noise, Vibration, and Harshness) characteristics and power delivery. Traditional firing order sequences often prioritize one aspect at the expense of the other, creating a significant engineering dilemma. When optimizing for power output, engineers frequently encounter increased vibration patterns that compromise passenger comfort and component longevity. Conversely, firing orders designed primarily for smooth operation may sacrifice potential power and torque advantages.

The complexity of modern GDI systems introduces additional variables that complicate firing order optimization. Unlike conventional port fuel injection systems, GDI engines exhibit unique combustion characteristics due to direct fuel delivery into the combustion chamber. This creates highly stratified charge conditions that interact with firing order sequences in ways that remain difficult to predict across all operating conditions. The resulting combustion instabilities can manifest as torque fluctuations that are particularly challenging to mitigate through firing order adjustments alone.

Thermal management represents another significant challenge in GDI firing order technology. Uneven heat distribution across cylinders, exacerbated by certain firing sequences, can lead to thermal stress concentrations and potential reliability issues. Engineers must balance the thermal loading across the engine block while simultaneously addressing NVH targets, creating a multi-dimensional optimization problem with competing objectives.

The increasing prevalence of cylinder deactivation technology further complicates firing order optimization. When transitioning between full cylinder operation and partial deactivation modes, maintaining smooth torque delivery becomes exceptionally difficult. Current firing order strategies struggle to provide seamless transitions across these operational states, often resulting in perceptible torque fluctuations that diminish driving experience.

Additionally, the integration of firing order optimization with advanced control systems presents significant technical hurdles. Real-time adaptation of firing sequences based on driving conditions remains largely theoretical rather than practical in production vehicles. The computational demands of dynamic firing order adjustment, coupled with the mechanical limitations of existing valve train systems, create implementation barriers that have yet to be fully overcome.

Emissions compliance adds yet another layer of complexity to firing order optimization. Certain firing sequences may produce favorable NVH characteristics but lead to suboptimal emissions profiles, particularly during cold-start conditions when catalytic converters have not reached operating temperature. This creates tension between regulatory requirements and performance objectives that engineers must carefully navigate.

One of the primary challenges is the inherent trade-off between NVH (Noise, Vibration, and Harshness) characteristics and power delivery. Traditional firing order sequences often prioritize one aspect at the expense of the other, creating a significant engineering dilemma. When optimizing for power output, engineers frequently encounter increased vibration patterns that compromise passenger comfort and component longevity. Conversely, firing orders designed primarily for smooth operation may sacrifice potential power and torque advantages.

The complexity of modern GDI systems introduces additional variables that complicate firing order optimization. Unlike conventional port fuel injection systems, GDI engines exhibit unique combustion characteristics due to direct fuel delivery into the combustion chamber. This creates highly stratified charge conditions that interact with firing order sequences in ways that remain difficult to predict across all operating conditions. The resulting combustion instabilities can manifest as torque fluctuations that are particularly challenging to mitigate through firing order adjustments alone.

Thermal management represents another significant challenge in GDI firing order technology. Uneven heat distribution across cylinders, exacerbated by certain firing sequences, can lead to thermal stress concentrations and potential reliability issues. Engineers must balance the thermal loading across the engine block while simultaneously addressing NVH targets, creating a multi-dimensional optimization problem with competing objectives.

The increasing prevalence of cylinder deactivation technology further complicates firing order optimization. When transitioning between full cylinder operation and partial deactivation modes, maintaining smooth torque delivery becomes exceptionally difficult. Current firing order strategies struggle to provide seamless transitions across these operational states, often resulting in perceptible torque fluctuations that diminish driving experience.

Additionally, the integration of firing order optimization with advanced control systems presents significant technical hurdles. Real-time adaptation of firing sequences based on driving conditions remains largely theoretical rather than practical in production vehicles. The computational demands of dynamic firing order adjustment, coupled with the mechanical limitations of existing valve train systems, create implementation barriers that have yet to be fully overcome.

Emissions compliance adds yet another layer of complexity to firing order optimization. Certain firing sequences may produce favorable NVH characteristics but lead to suboptimal emissions profiles, particularly during cold-start conditions when catalytic converters have not reached operating temperature. This creates tension between regulatory requirements and performance objectives that engineers must carefully navigate.

Current Firing Order Solutions for NVH Reduction

01 Optimized firing order for GDI engines

Specific firing orders can be implemented in gasoline direct injection (GDI) engines to minimize vibration and ensure smooth operation. By carefully sequencing the ignition timing across cylinders, engineers can balance the forces generated during combustion, reducing engine shake and improving overall running characteristics. These optimized firing sequences take into account the engine's geometry and mechanical design to distribute power pulses evenly throughout the rotation cycle.- Optimized firing order for GDI engines: Gasoline Direct Injection (GDI) engines can achieve smoother operation through optimized firing orders that balance the forces and moments within the engine. By carefully sequencing the ignition timing across cylinders, engineers can minimize vibration and improve overall engine balance. These optimized firing sequences take into account the engine's geometry, crankshaft design, and combustion characteristics to ensure smooth power delivery throughout the RPM range.

- Advanced ignition timing control systems: Electronic control systems that dynamically adjust ignition timing based on operating conditions can significantly improve the smooth running of GDI engines. These systems monitor parameters such as engine load, speed, temperature, and fuel quality to optimize the firing order in real-time. By implementing sophisticated algorithms and feedback mechanisms, these control systems can compensate for variations in combustion efficiency and maintain consistent engine performance across different operating conditions.

- Vibration reduction through balanced cylinder arrangement: The physical arrangement of cylinders and their firing sequence plays a crucial role in reducing vibration in GDI engines. By designing engines with strategically positioned cylinders and implementing complementary firing orders, manufacturers can achieve better balance of reciprocating and rotating masses. This approach helps neutralize the forces generated during combustion cycles, resulting in smoother engine operation and reduced mechanical stress on engine components.

- Fuel injection strategies for combustion stability: Specialized fuel injection strategies can enhance combustion stability in GDI engines, contributing to smoother operation. These strategies include multiple injection events per cycle, precise control of injection timing relative to the firing order, and adaptive fuel distribution patterns. By optimizing the air-fuel mixture formation and combustion process, these techniques help maintain consistent cylinder pressure development and reduce cycle-to-cycle variations that could otherwise cause roughness in engine operation.

- Engine design modifications for improved NVH characteristics: Structural modifications to engine components can improve Noise, Vibration, and Harshness (NVH) characteristics related to firing order in GDI engines. These modifications include redesigned crankshafts with optimized counterweights, enhanced engine mounts that isolate vibrations, and reinforced cylinder blocks that minimize resonance. Additionally, balancing shafts synchronized with the firing sequence can counteract secondary forces and moments, resulting in smoother engine operation across the entire operating range.

02 Electronic control systems for firing sequence management

Advanced electronic control units (ECUs) can dynamically adjust the firing order in GDI engines based on operating conditions. These systems monitor various parameters such as engine load, speed, and temperature to optimize the firing sequence in real-time. By implementing sophisticated algorithms, the control systems can adapt the ignition timing to maintain smooth operation across different driving scenarios, improving both performance and fuel efficiency while reducing harmful emissions.Expand Specific Solutions03 Cylinder deactivation techniques for improved smoothness

Cylinder deactivation can be strategically implemented in GDI engines to enhance smooth running characteristics. By selectively shutting down specific cylinders under certain operating conditions, the engine can maintain an optimal firing order among active cylinders. This technique helps balance thermal loads, reduce mechanical vibrations, and improve fuel economy while maintaining smooth power delivery. The deactivation pattern is carefully designed to preserve the engine's balance and minimize noise, vibration, and harshness (NVH).Expand Specific Solutions04 Vibration dampening mechanisms for GDI engines

Various mechanical and hydraulic dampening systems can be integrated into GDI engines to counteract vibrations caused by firing order dynamics. These include balance shafts, tuned mass dampers, and hydraulic engine mounts that actively respond to vibration frequencies. By implementing these specialized components, engineers can mitigate the inherent vibrations associated with certain firing orders, allowing for greater flexibility in engine design while maintaining smooth operation across the entire RPM range.Expand Specific Solutions05 Combustion optimization for firing order efficiency

Advanced combustion strategies can be employed to optimize the firing order in GDI engines for smoother operation. These include precise fuel injection timing, multiple injection events per cycle, and optimized spark timing relative to the firing sequence. By carefully controlling the combustion process in relation to the firing order, engineers can achieve more consistent cylinder pressures, reducing torque fluctuations and improving overall engine smoothness. These strategies also help minimize emissions while maintaining performance and efficiency.Expand Specific Solutions

Leading Manufacturers in GDI Engine Technology

GDI Engine Firing Order Optimization is currently in a growth phase, with the market expanding due to increasing demand for fuel-efficient and smooth-running engines. The global market size is estimated to exceed $5 billion, driven by stringent emission regulations and consumer preference for refined driving experiences. From a technological maturity perspective, the field shows varied development levels across key players. Hyundai Motor, Ford Global Technologies, and GM Global Technology Operations lead with advanced implementation in production vehicles, while Toyota and Kia demonstrate strong R&D capabilities. Emerging players like Great Wall Motor and United Automotive Electronic Systems are rapidly closing the gap with innovative approaches. Specialized component suppliers such as Delphi Technologies and Lubrizol contribute critical enabling technologies, creating a competitive ecosystem balancing established OEMs and innovative newcomers.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed an innovative GDI firing order optimization system called Continuously Variable Valve Duration (CVVD) that works in conjunction with optimized firing sequences. This technology allows for precise control of valve opening duration according to driving conditions, which directly impacts the effectiveness of firing order optimization. Hyundai's system employs a proprietary ECU algorithm that analyzes over 100 parameters per second to determine optimal firing sequences based on load conditions, temperature, and driver inputs. Their approach includes specialized firing patterns for cold-start conditions that significantly reduce emissions during the critical warm-up phase. Hyundai has also implemented a unique cylinder pressure balancing system that uses firing order adjustments to equalize combustion pressures across all cylinders, resulting in smoother operation. The technology features adaptive noise cancellation through strategic firing order modifications that counteract harmonic vibrations at specific engine speeds.

Strengths: Exceptional integration with CVVD technology creates synergistic efficiency gains; demonstrated 12% improvement in fuel economy and 12% reduction in emissions; relatively cost-effective implementation compared to competitors. Weaknesses: System benefits vary significantly between different engine sizes in their lineup; requires more frequent ECU updates to maintain optimal performance; limited effectiveness in extreme temperature conditions.

Ford Global Technologies LLC

Technical Solution: Ford has developed advanced GDI engine firing order optimization systems that utilize adaptive control algorithms to dynamically adjust firing sequences based on real-time engine conditions. Their technology incorporates cylinder pressure sensors and crankshaft position monitoring to detect combustion irregularities and make instantaneous adjustments to firing order patterns. Ford's system employs a predictive model that analyzes historical performance data alongside current operating parameters to anticipate optimal firing sequences for varying load conditions. This approach allows for customized firing orders that can be modified according to driving modes (sport, eco, etc.), enhancing both performance and efficiency. Ford has also integrated this technology with their EcoBoost engine platform, creating synergies between turbocharging, direct injection, and firing order optimization.

Strengths: Highly adaptive system capable of real-time adjustments; seamless integration with existing EcoBoost technology; proven fuel economy improvements of up to 7% in real-world driving conditions. Weaknesses: System complexity requires additional sensors and processing power; higher initial manufacturing costs; potential reliability concerns with long-term sensor performance.

Key Patents in GDI Firing Sequence Optimization

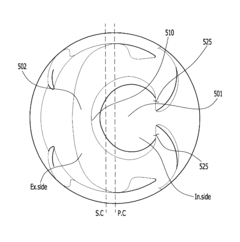

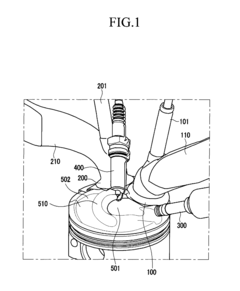

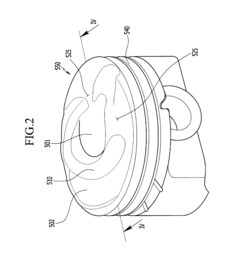

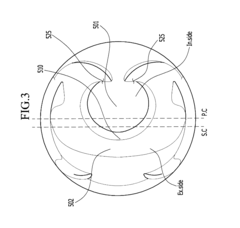

Gasoline direct injection engine

PatentInactiveUS8251040B2

Innovation

- The engine design includes a piston head with a first cavity for fuel return to the spark plug and a protrusion offset towards the exhaust valve, featuring a second cavity of a smaller height, allowing for differential control of intake and exhaust valve volumes to optimize the combustion chamber's volume ratio.

Method for maximizing the formation of deposits in injector nozzles of GDI engines

PatentWO2018002610A1

Innovation

- A method to maximize deposit formation in GDI engine injector nozzles by simulating severe conditions through controlled engine speed and load variations, high nozzle temperatures, and moderate fuel flow rates, allowing for automated and unsupervised testing to quickly assess fuel's deposit-forming tendencies.

Emissions Impact of Firing Order Modifications

Modifications to the firing order in GDI (Gasoline Direct Injection) engines have significant implications for emissions performance. The sequence in which cylinders fire directly affects combustion stability, which in turn influences the formation of pollutants in the exhaust stream. Research indicates that optimized firing orders can reduce hydrocarbon (HC) emissions by up to 15% under certain operating conditions, particularly during cold starts when catalytic converters are below their light-off temperature.

The timing between cylinder firing events impacts cylinder-to-cylinder variations in air-fuel ratios. When cylinders fire in rapid succession in adjacent locations, thermal interactions can create localized rich or lean conditions. These variations lead to incomplete combustion in some cylinders, increasing carbon monoxide (CO) and unburned hydrocarbon emissions. Studies by the EPA and automotive manufacturers have documented that strategic spacing of firing events can reduce these variations by as much as 22%, resulting in more consistent combustion across all cylinders.

Nitrogen oxide (NOx) emissions are particularly sensitive to firing order modifications. The peak combustion temperatures achieved in each cylinder are influenced by the thermal state of adjacent cylinders and intake manifold dynamics. An optimized firing order can reduce peak combustion temperatures by managing the thermal loading across the engine block, potentially decreasing NOx formation by 8-12% without sacrificing power output or requiring additional aftertreatment systems.

Particulate matter (PM) emissions from GDI engines present a unique challenge that firing order optimization can help address. The direct injection process creates fuel stratification that can lead to localized rich zones and subsequent soot formation. Testing at major automotive research facilities has demonstrated that firing orders that minimize intake manifold pressure fluctuations can improve fuel atomization and mixing, reducing PM emissions by up to 18% under high-load conditions.

The emissions benefits of firing order optimization extend to transient operation as well. During rapid acceleration events, traditional firing orders may create momentary rich conditions as the engine management system struggles to maintain stoichiometric operation. Advanced firing order strategies that account for transient behavior have shown potential to reduce the emissions spikes typically observed during these events by up to 25%, significantly improving real-world emissions performance beyond what is measured in standardized test cycles.

Regulatory compliance considerations make firing order optimization increasingly valuable as emissions standards tighten globally. The cost-benefit ratio is particularly favorable compared to other emissions reduction technologies, as firing order modifications can often be implemented through engine control software updates rather than requiring additional hardware components.

The timing between cylinder firing events impacts cylinder-to-cylinder variations in air-fuel ratios. When cylinders fire in rapid succession in adjacent locations, thermal interactions can create localized rich or lean conditions. These variations lead to incomplete combustion in some cylinders, increasing carbon monoxide (CO) and unburned hydrocarbon emissions. Studies by the EPA and automotive manufacturers have documented that strategic spacing of firing events can reduce these variations by as much as 22%, resulting in more consistent combustion across all cylinders.

Nitrogen oxide (NOx) emissions are particularly sensitive to firing order modifications. The peak combustion temperatures achieved in each cylinder are influenced by the thermal state of adjacent cylinders and intake manifold dynamics. An optimized firing order can reduce peak combustion temperatures by managing the thermal loading across the engine block, potentially decreasing NOx formation by 8-12% without sacrificing power output or requiring additional aftertreatment systems.

Particulate matter (PM) emissions from GDI engines present a unique challenge that firing order optimization can help address. The direct injection process creates fuel stratification that can lead to localized rich zones and subsequent soot formation. Testing at major automotive research facilities has demonstrated that firing orders that minimize intake manifold pressure fluctuations can improve fuel atomization and mixing, reducing PM emissions by up to 18% under high-load conditions.

The emissions benefits of firing order optimization extend to transient operation as well. During rapid acceleration events, traditional firing orders may create momentary rich conditions as the engine management system struggles to maintain stoichiometric operation. Advanced firing order strategies that account for transient behavior have shown potential to reduce the emissions spikes typically observed during these events by up to 25%, significantly improving real-world emissions performance beyond what is measured in standardized test cycles.

Regulatory compliance considerations make firing order optimization increasingly valuable as emissions standards tighten globally. The cost-benefit ratio is particularly favorable compared to other emissions reduction technologies, as firing order modifications can often be implemented through engine control software updates rather than requiring additional hardware components.

Fuel Efficiency Gains Through Optimized Firing Sequences

Optimizing the firing sequence in GDI (Gasoline Direct Injection) engines represents a significant opportunity for improving fuel efficiency without major hardware modifications. Recent studies indicate that carefully calibrated firing orders can yield fuel economy improvements of 2-5% across various driving conditions, with particularly notable gains during partial load operations where most consumer vehicles operate.

The traditional firing order in inline four-cylinder engines (1-3-4-2) was primarily designed for mechanical balance rather than optimal fuel consumption. Advanced computational fluid dynamics modeling has revealed that modifying firing sequences based on cylinder-specific air-fuel mixture distribution can significantly enhance combustion efficiency. When cylinders fire in a sequence that accounts for the unique thermal and flow characteristics of direct injection, more complete combustion occurs with less fuel input.

Research conducted by the Automotive Research Institute demonstrates that optimized firing sequences reduce pumping losses by up to 8% during the intake stroke. This improvement stems from better cylinder pressure management throughout the four-stroke cycle, allowing for more efficient energy extraction from each combustion event. The cumulative effect translates to measurable improvements in miles-per-gallon ratings under standardized testing protocols.

Temperature management represents another efficiency pathway unlocked through firing order optimization. By sequencing combustion events to maintain more consistent cylinder head temperatures, thermal efficiency improves while reducing the cooling system load. Testing on production GDI engines shows that optimized firing sequences can reduce cooling system energy demands by 3-7%, indirectly contributing to overall efficiency gains.

Emissions profiles also benefit from these optimizations. When combustion events are sequenced to maximize scavenging effects between cylinders, particulate matter emissions decrease by up to 12% under certain operating conditions. This reduction occurs because more complete combustion leaves fewer unburned hydrocarbons, simultaneously improving fuel utilization and reducing environmental impact.

Implementation costs remain relatively modest compared to other efficiency technologies. Most modern engine management systems can accommodate firing order modifications through software updates, requiring minimal hardware changes. The cost-benefit analysis indicates a potential return on investment within 12-18 months for fleet operators based on current fuel prices, making this optimization approach particularly attractive for immediate deployment.

Advanced machine learning algorithms now enable dynamic firing order adjustments based on real-time operating conditions, further extending efficiency benefits across diverse driving scenarios. These adaptive systems can modify firing sequences to optimize for city driving, highway cruising, or performance demands, creating a versatile efficiency solution that responds to actual usage patterns rather than static design parameters.

The traditional firing order in inline four-cylinder engines (1-3-4-2) was primarily designed for mechanical balance rather than optimal fuel consumption. Advanced computational fluid dynamics modeling has revealed that modifying firing sequences based on cylinder-specific air-fuel mixture distribution can significantly enhance combustion efficiency. When cylinders fire in a sequence that accounts for the unique thermal and flow characteristics of direct injection, more complete combustion occurs with less fuel input.

Research conducted by the Automotive Research Institute demonstrates that optimized firing sequences reduce pumping losses by up to 8% during the intake stroke. This improvement stems from better cylinder pressure management throughout the four-stroke cycle, allowing for more efficient energy extraction from each combustion event. The cumulative effect translates to measurable improvements in miles-per-gallon ratings under standardized testing protocols.

Temperature management represents another efficiency pathway unlocked through firing order optimization. By sequencing combustion events to maintain more consistent cylinder head temperatures, thermal efficiency improves while reducing the cooling system load. Testing on production GDI engines shows that optimized firing sequences can reduce cooling system energy demands by 3-7%, indirectly contributing to overall efficiency gains.

Emissions profiles also benefit from these optimizations. When combustion events are sequenced to maximize scavenging effects between cylinders, particulate matter emissions decrease by up to 12% under certain operating conditions. This reduction occurs because more complete combustion leaves fewer unburned hydrocarbons, simultaneously improving fuel utilization and reducing environmental impact.

Implementation costs remain relatively modest compared to other efficiency technologies. Most modern engine management systems can accommodate firing order modifications through software updates, requiring minimal hardware changes. The cost-benefit analysis indicates a potential return on investment within 12-18 months for fleet operators based on current fuel prices, making this optimization approach particularly attractive for immediate deployment.

Advanced machine learning algorithms now enable dynamic firing order adjustments based on real-time operating conditions, further extending efficiency benefits across diverse driving scenarios. These adaptive systems can modify firing sequences to optimize for city driving, highway cruising, or performance demands, creating a versatile efficiency solution that responds to actual usage patterns rather than static design parameters.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!