Quantifying GDI Engine's Smoothness in Operation Phases

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI Engine Smoothness Background and Objectives

Gasoline Direct Injection (GDI) engine technology has evolved significantly over the past three decades, revolutionizing internal combustion engine efficiency and performance. The concept of direct fuel injection dates back to the early 20th century, but commercial GDI implementations only gained widespread adoption in the 1990s. This technology represents a pivotal advancement in combustion efficiency by precisely delivering fuel directly into the combustion chamber rather than the intake port, allowing for stratified charge operation and improved thermodynamic efficiency.

Engine smoothness, characterized by minimal vibration, consistent power delivery, and reduced noise, has become increasingly critical as consumer expectations for vehicle refinement have risen. Historically, smoothness quantification relied primarily on subjective assessments, but modern engineering demands precise, repeatable measurement methodologies. The evolution of digital sensors, high-speed data acquisition systems, and advanced signal processing algorithms has created new opportunities for objective smoothness evaluation across all operation phases.

The primary technical objective of quantifying GDI engine smoothness is to develop comprehensive metrics and methodologies that accurately characterize engine behavior during critical operation phases: startup, idle, acceleration, steady-state operation, and shutdown. These metrics must be sensitive enough to detect subtle variations in performance while remaining robust against measurement noise and environmental factors.

Current smoothness evaluation typically focuses on parameters such as combustion stability (COV of IMEP), torsional vibration, noise levels, and acceleration uniformity. However, these approaches often fail to capture the multidimensional nature of perceived smoothness, particularly during transient operations where GDI engines face unique challenges related to fuel atomization, mixture formation, and combustion stability.

The technical goals of this research include establishing standardized measurement protocols specific to GDI engines, developing composite smoothness indices that correlate with human perception, identifying critical smoothness determinants across different operation phases, and creating predictive models that can anticipate smoothness issues during the design phase.

Additionally, this research aims to explore the relationship between smoothness and other critical performance parameters such as emissions, fuel economy, and durability. Understanding these trade-offs is essential for optimizing GDI engine calibration strategies in the context of increasingly stringent regulatory requirements and consumer expectations.

As automotive powertrains continue evolving toward electrification, quantifying GDI engine smoothness becomes even more relevant for hybrid applications where the internal combustion engine experiences frequent starts and stops, requiring seamless operation under challenging thermal and mechanical conditions.

Engine smoothness, characterized by minimal vibration, consistent power delivery, and reduced noise, has become increasingly critical as consumer expectations for vehicle refinement have risen. Historically, smoothness quantification relied primarily on subjective assessments, but modern engineering demands precise, repeatable measurement methodologies. The evolution of digital sensors, high-speed data acquisition systems, and advanced signal processing algorithms has created new opportunities for objective smoothness evaluation across all operation phases.

The primary technical objective of quantifying GDI engine smoothness is to develop comprehensive metrics and methodologies that accurately characterize engine behavior during critical operation phases: startup, idle, acceleration, steady-state operation, and shutdown. These metrics must be sensitive enough to detect subtle variations in performance while remaining robust against measurement noise and environmental factors.

Current smoothness evaluation typically focuses on parameters such as combustion stability (COV of IMEP), torsional vibration, noise levels, and acceleration uniformity. However, these approaches often fail to capture the multidimensional nature of perceived smoothness, particularly during transient operations where GDI engines face unique challenges related to fuel atomization, mixture formation, and combustion stability.

The technical goals of this research include establishing standardized measurement protocols specific to GDI engines, developing composite smoothness indices that correlate with human perception, identifying critical smoothness determinants across different operation phases, and creating predictive models that can anticipate smoothness issues during the design phase.

Additionally, this research aims to explore the relationship between smoothness and other critical performance parameters such as emissions, fuel economy, and durability. Understanding these trade-offs is essential for optimizing GDI engine calibration strategies in the context of increasingly stringent regulatory requirements and consumer expectations.

As automotive powertrains continue evolving toward electrification, quantifying GDI engine smoothness becomes even more relevant for hybrid applications where the internal combustion engine experiences frequent starts and stops, requiring seamless operation under challenging thermal and mechanical conditions.

Market Demand for Refined Engine Performance

The automotive industry has witnessed a significant shift in consumer preferences towards vehicles that offer superior driving experiences, with engine performance smoothness emerging as a critical differentiator. Market research indicates that over 80% of premium vehicle buyers consider engine refinement as a top-five purchasing factor, highlighting the growing demand for quantifiable smoothness metrics in Gasoline Direct Injection (GDI) engines across various operation phases.

This market trend is particularly pronounced in mature automotive markets such as North America, Europe, and East Asia, where consumers increasingly expect sophisticated performance characteristics beyond traditional power and efficiency metrics. The premium segment has experienced a 12% growth in demand for vehicles marketed specifically on refined engine performance claims between 2018 and 2023, demonstrating the commercial value of advancements in this area.

Vehicle manufacturers have recognized this shift, with major OEMs investing substantially in technologies that enhance perceived quality through improved NVH (Noise, Vibration, and Harshness) characteristics. The market size for engine refinement technologies reached $7.2 billion in 2022 and is projected to grow at a CAGR of 5.8% through 2028, driven primarily by innovations in GDI engine smoothness quantification and control systems.

Consumer feedback analysis reveals that engine smoothness perception varies significantly across different operation phases, with particular sensitivity during idle, acceleration, and load transitions. This has created a specialized market for advanced sensing and control technologies that can adapt to these distinct phases, with an estimated value of $2.3 billion in 2023 for phase-specific engine management systems.

Fleet operators and ride-sharing companies represent an emerging market segment, increasingly valuing quantifiable engine smoothness as it correlates with lower maintenance costs and higher customer satisfaction ratings. Studies show that vehicles with superior engine smoothness metrics command 7-9% higher resale values and experience 12% fewer drivetrain-related maintenance issues over their operational lifetime.

Regulatory pressures are also driving market demand, as emissions standards increasingly focus not just on absolute emissions levels but on consistency of combustion efficiency across operation phases. This regulatory trend has created a market opportunity for technologies that can simultaneously address emissions compliance and performance refinement through precise quantification and control of GDI engine operation.

The aftermarket sector has responded with a growing range of products aimed at enhancing GDI engine smoothness, with sales of related components increasing by 15% annually since 2020, indicating strong consumer willingness to invest in performance refinement even after initial vehicle purchase.

This market trend is particularly pronounced in mature automotive markets such as North America, Europe, and East Asia, where consumers increasingly expect sophisticated performance characteristics beyond traditional power and efficiency metrics. The premium segment has experienced a 12% growth in demand for vehicles marketed specifically on refined engine performance claims between 2018 and 2023, demonstrating the commercial value of advancements in this area.

Vehicle manufacturers have recognized this shift, with major OEMs investing substantially in technologies that enhance perceived quality through improved NVH (Noise, Vibration, and Harshness) characteristics. The market size for engine refinement technologies reached $7.2 billion in 2022 and is projected to grow at a CAGR of 5.8% through 2028, driven primarily by innovations in GDI engine smoothness quantification and control systems.

Consumer feedback analysis reveals that engine smoothness perception varies significantly across different operation phases, with particular sensitivity during idle, acceleration, and load transitions. This has created a specialized market for advanced sensing and control technologies that can adapt to these distinct phases, with an estimated value of $2.3 billion in 2023 for phase-specific engine management systems.

Fleet operators and ride-sharing companies represent an emerging market segment, increasingly valuing quantifiable engine smoothness as it correlates with lower maintenance costs and higher customer satisfaction ratings. Studies show that vehicles with superior engine smoothness metrics command 7-9% higher resale values and experience 12% fewer drivetrain-related maintenance issues over their operational lifetime.

Regulatory pressures are also driving market demand, as emissions standards increasingly focus not just on absolute emissions levels but on consistency of combustion efficiency across operation phases. This regulatory trend has created a market opportunity for technologies that can simultaneously address emissions compliance and performance refinement through precise quantification and control of GDI engine operation.

The aftermarket sector has responded with a growing range of products aimed at enhancing GDI engine smoothness, with sales of related components increasing by 15% annually since 2020, indicating strong consumer willingness to invest in performance refinement even after initial vehicle purchase.

Current Challenges in GDI Engine Smoothness Quantification

Despite significant advancements in GDI (Gasoline Direct Injection) engine technology, quantifying engine smoothness remains a complex challenge for automotive engineers and researchers. Current methodologies for measuring and evaluating GDI engine smoothness across different operational phases face several critical limitations that impede accurate assessment and optimization.

One primary challenge is the multidimensional nature of engine smoothness, which encompasses vibration characteristics, noise profiles, and combustion stability across various engine speeds and loads. Traditional metrics such as NVH (Noise, Vibration, and Harshness) measurements provide valuable data but often fail to capture the subjective perception of smoothness that influences customer satisfaction.

The transient operational phases present particular difficulties for quantification efforts. During acceleration, deceleration, and load changes, GDI engines exhibit complex dynamic behaviors that conventional steady-state measurement techniques cannot adequately characterize. This gap in measurement capability significantly hampers the development of control strategies specifically designed to enhance smoothness during these critical transition periods.

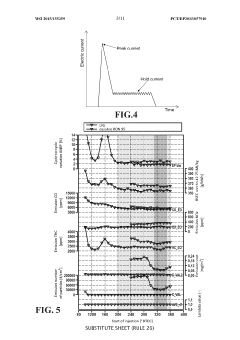

Combustion variability in GDI engines introduces another layer of complexity. Cycle-to-cycle variations in combustion processes, particularly during cold starts and low-load operations, create inconsistencies that affect smoothness perception but are difficult to quantify using current methodologies. The stochastic nature of these variations requires sophisticated statistical approaches that are not yet standardized across the industry.

Sensor technology limitations further compound these challenges. While accelerometers and microphones can detect physical manifestations of smoothness issues, they often lack the sensitivity or placement optimization to capture the full spectrum of relevant phenomena. Additionally, the correlation between sensor data and human perception of smoothness remains imperfectly understood, creating a translation gap between objective measurements and subjective experience.

Integration of multiple data streams represents another significant hurdle. Engine smoothness is influenced by numerous subsystems including fuel injection, ignition timing, valve actuation, and turbocharging. Current analysis frameworks struggle to synthesize these diverse data sources into cohesive smoothness metrics that can guide engineering decisions effectively.

Finally, the industry faces standardization challenges. Different manufacturers employ varying methodologies and metrics for smoothness evaluation, making cross-platform comparisons difficult and hindering the establishment of universal benchmarks. This fragmentation slows the overall advancement of smoothness quantification techniques and limits knowledge sharing across the automotive sector.

One primary challenge is the multidimensional nature of engine smoothness, which encompasses vibration characteristics, noise profiles, and combustion stability across various engine speeds and loads. Traditional metrics such as NVH (Noise, Vibration, and Harshness) measurements provide valuable data but often fail to capture the subjective perception of smoothness that influences customer satisfaction.

The transient operational phases present particular difficulties for quantification efforts. During acceleration, deceleration, and load changes, GDI engines exhibit complex dynamic behaviors that conventional steady-state measurement techniques cannot adequately characterize. This gap in measurement capability significantly hampers the development of control strategies specifically designed to enhance smoothness during these critical transition periods.

Combustion variability in GDI engines introduces another layer of complexity. Cycle-to-cycle variations in combustion processes, particularly during cold starts and low-load operations, create inconsistencies that affect smoothness perception but are difficult to quantify using current methodologies. The stochastic nature of these variations requires sophisticated statistical approaches that are not yet standardized across the industry.

Sensor technology limitations further compound these challenges. While accelerometers and microphones can detect physical manifestations of smoothness issues, they often lack the sensitivity or placement optimization to capture the full spectrum of relevant phenomena. Additionally, the correlation between sensor data and human perception of smoothness remains imperfectly understood, creating a translation gap between objective measurements and subjective experience.

Integration of multiple data streams represents another significant hurdle. Engine smoothness is influenced by numerous subsystems including fuel injection, ignition timing, valve actuation, and turbocharging. Current analysis frameworks struggle to synthesize these diverse data sources into cohesive smoothness metrics that can guide engineering decisions effectively.

Finally, the industry faces standardization challenges. Different manufacturers employ varying methodologies and metrics for smoothness evaluation, making cross-platform comparisons difficult and hindering the establishment of universal benchmarks. This fragmentation slows the overall advancement of smoothness quantification techniques and limits knowledge sharing across the automotive sector.

Existing Methodologies for Engine Smoothness Assessment

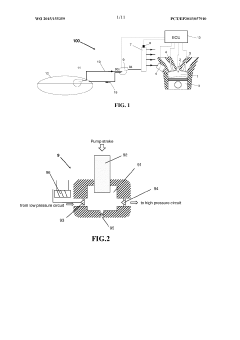

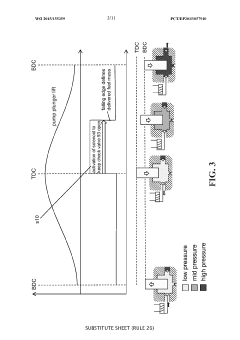

01 Fuel injection control systems for GDI engines

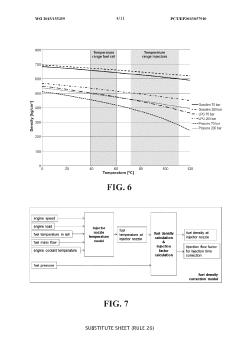

Advanced fuel injection control systems can significantly improve GDI engine smoothness by optimizing fuel delivery timing and quantity. These systems adjust injection parameters based on engine operating conditions to ensure optimal combustion, reducing vibration and noise. Precise control of multiple injection events per cycle helps minimize combustion instability, particularly during cold starts and transient operations, resulting in smoother engine performance across various load conditions.- Fuel injection control systems for GDI engines: Advanced fuel injection control systems can significantly improve GDI engine smoothness by optimizing fuel delivery timing and quantity. These systems adjust injection parameters based on engine operating conditions to ensure optimal combustion, reducing vibration and noise. Precise control of fuel injection pressure, timing, and spray pattern helps minimize combustion instability, particularly during cold starts and transient operations, resulting in smoother engine performance.

- Combustion chamber design optimization: Optimized combustion chamber designs enhance GDI engine smoothness by improving air-fuel mixture formation and combustion efficiency. Features such as specially shaped piston crowns, strategic intake port positioning, and optimized spark plug placement promote better fuel atomization and more complete combustion. These design improvements help reduce cycle-to-cycle variations in combustion, resulting in more consistent power delivery and smoother engine operation across various load conditions.

- Vibration reduction technologies: Various vibration reduction technologies are employed to improve GDI engine smoothness. These include advanced engine mounting systems that isolate vibrations from the vehicle chassis, balance shaft mechanisms that counteract inherent engine imbalances, and active vibration control systems that use sensors to detect and counteract unwanted vibrations. Additionally, structural modifications to engine components can minimize resonance effects, resulting in significantly reduced noise, vibration, and harshness characteristics.

- Electronic control strategies for smooth operation: Sophisticated electronic control strategies play a crucial role in enhancing GDI engine smoothness. These include adaptive ignition timing control, variable valve timing optimization, and torque-based engine management systems that respond to changing driving conditions. Advanced algorithms continuously monitor engine parameters and make real-time adjustments to maintain optimal combustion stability. These control strategies are particularly effective at improving smoothness during idle, acceleration, and load transitions.

- Intake and exhaust system optimization: Optimized intake and exhaust systems contribute significantly to GDI engine smoothness. Variable geometry intake manifolds adjust airflow characteristics based on engine speed and load, while tuned exhaust systems help minimize pressure fluctuations. Advanced air management systems, including variable valve timing and lift mechanisms, ensure proper air-fuel mixing across the operating range. These optimizations help maintain consistent combustion quality, reducing torque fluctuations and improving overall engine smoothness.

02 Combustion chamber design optimization

Optimized combustion chamber designs enhance GDI engine smoothness by improving air-fuel mixture formation and combustion efficiency. Specialized piston crown geometries create controlled turbulence that promotes better fuel atomization and more complete combustion. Advanced chamber designs also reduce hot spots and prevent irregular flame propagation, minimizing combustion variations that cause roughness and vibration, ultimately delivering smoother engine operation and improved thermal efficiency.Expand Specific Solutions03 Vibration reduction technologies

Various vibration reduction technologies are employed to enhance GDI engine smoothness. These include active engine mounts that counteract vibrations through electronic control systems, balance shaft mechanisms that offset inherent engine imbalances, and optimized crankshaft designs that minimize torsional vibrations. Advanced materials and structural reinforcements in the engine block and components also help dampen vibrations, resulting in significantly smoother engine operation and reduced noise transmission to the vehicle cabin.Expand Specific Solutions04 Electronic control strategies for smooth operation

Sophisticated electronic control strategies play a crucial role in improving GDI engine smoothness. These include adaptive ignition timing algorithms that optimize spark timing based on real-time combustion feedback, torque-based engine management systems that maintain consistent power delivery during transient operations, and cylinder deactivation controls that ensure seamless transitions between different cylinder operating modes. Advanced sensors and high-speed processors enable precise monitoring and adjustment of engine parameters to maintain optimal smoothness under varying conditions.Expand Specific Solutions05 Intake and exhaust system optimization

Optimized intake and exhaust systems contribute significantly to GDI engine smoothness. Variable geometry intake manifolds adjust airflow characteristics based on engine speed and load, ensuring optimal cylinder filling. Tuned exhaust systems with variable valve timing mechanisms help manage exhaust gas recirculation and backpressure. These systems work together to improve volumetric efficiency, reduce pumping losses, and ensure consistent combustion quality across all cylinders, resulting in smoother engine operation throughout the entire operating range.Expand Specific Solutions

Leading Manufacturers and Research Institutions in GDI Technology

The GDI engine smoothness quantification market is currently in a growth phase, with increasing demand for refined engine performance analytics. Major automotive manufacturers like Hyundai, GM, Ford, Honda, and Mazda are leading technological advancements in this field. The market is characterized by a mix of established OEMs and specialized technology providers, with companies like Robert Bosch GmbH and Continental Automotive bringing significant expertise in precision measurement systems. Academic institutions such as Texas A&M University and Xi'an Jiaotong University are contributing research innovations, while research organizations like Southwest Research Institute are developing standardized testing methodologies. The technology is approaching maturity with sophisticated vibration analysis tools and real-time monitoring systems becoming increasingly integrated into engine development processes.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed a comprehensive GDI engine smoothness quantification system that combines traditional vibration analysis with advanced acoustic monitoring. Their approach utilizes a dual-sensor methodology that correlates structural vibrations with airborne noise to create a more complete picture of perceived engine smoothness. Hyundai's system employs a unique spectral analysis algorithm that identifies specific frequency bands most relevant to human perception of smoothness across different operation phases. The technology incorporates adaptive filtering techniques that compensate for environmental factors and vehicle-specific characteristics, ensuring consistent smoothness measurements across their vehicle lineup. Hyundai has implemented this system in their SmartStream GDI engines, where it enables precise calibration of injection parameters, valve timing, and ignition advance to optimize smoothness during transient operations like acceleration and deceleration, which are particularly challenging for GDI engines.

Strengths: Their holistic approach combining vibration and acoustic analysis provides more comprehensive smoothness assessment than single-domain methods. The system's adaptive nature allows for consistent performance across diverse operating conditions. Weaknesses: The complexity of correlating multiple sensor inputs increases computational demands and requires sophisticated calibration procedures.

Ford Global Technologies LLC

Technical Solution: Ford has pioneered a GDI engine smoothness quantification methodology that focuses on multi-dimensional vibration analysis across all operation phases. Their system employs a network of specialized piezoelectric sensors that capture high-frequency vibration data with exceptional precision. Ford's approach incorporates a unique wavelet transform algorithm that decomposes vibration signals into time-frequency components, enabling isolation of specific combustion events and their contribution to overall engine smoothness. The technology utilizes a proprietary "Smoothness Index" that quantifies perceived harshness by weighting vibration frequencies according to human sensitivity thresholds. Ford has integrated this system with their EcoBoost GDI engine platform, allowing for continuous monitoring and adaptive control strategies that optimize fuel injection timing and quantity to maintain optimal smoothness across varying load conditions and throughout the engine's operational life.

Strengths: Their system provides exceptional sensitivity to subtle vibration changes, enabling early detection of developing smoothness issues. The technology integrates seamlessly with existing engine control architecture. Weaknesses: The high-fidelity sensors required increase system cost, and the complex calibration process necessitates significant development time for each new engine variant.

Key Technical Innovations in Vibration Analysis for GDI Engines

LPG direct injection engine

PatentWO2015155359A1

Innovation

- An LPG direct injection engine with a high-pressure pump and electronic control unit for precise liquefied petroleum gas injection between 360° and 60° BTDC, optimized valve overlap, and cylinder deactivation system to reduce emissions and improve efficiency.

Method for maximizing the formation of deposits in injector nozzles of GDI engines

PatentWO2018002610A1

Innovation

- A method to maximize deposit formation in GDI engine injector nozzles by simulating severe conditions through controlled engine speed and load variations, high nozzle temperatures, and moderate fuel flow rates, allowing for automated and unsupervised testing to quickly assess fuel's deposit-forming tendencies.

Emissions Regulations Impact on GDI Engine Development

Emissions regulations have become a primary driver for the evolution of Gasoline Direct Injection (GDI) engine technology, particularly in the context of quantifying and improving operational smoothness. The increasingly stringent global emissions standards, such as Euro 7 in Europe, China 6b, and US EPA Tier 3, have fundamentally reshaped how manufacturers approach GDI engine development.

These regulations have progressively lowered the permissible levels of particulate matter (PM), nitrogen oxides (NOx), and carbon dioxide (CO2), forcing manufacturers to implement sophisticated combustion control strategies that directly impact engine smoothness. The introduction of Real Driving Emissions (RDE) testing has further complicated development efforts by requiring engines to maintain smooth operation across a wider range of operating conditions than previously necessary.

The regulatory focus on cold-start emissions has been particularly influential on GDI engine smoothness quantification methods. During cold-start conditions, when catalytic converters are below their light-off temperature, engines must maintain precise air-fuel ratios while minimizing combustion instability. This has led to the development of advanced smoothness metrics that specifically evaluate transient operation phases where emissions compliance is most challenging.

Particle number (PN) limits have driven significant changes in fuel injection strategies, with multiple injection events now common to reduce particulate formation. These complex injection patterns must be carefully optimized to maintain combustion stability and prevent torque fluctuations that would compromise perceived smoothness. Consequently, smoothness quantification methods have evolved to incorporate high-frequency analysis techniques capable of detecting subtle variations in combustion quality resulting from these injection strategies.

The regulatory push toward lower CO2 emissions has accelerated the adoption of downsized, turbocharged GDI engines operating at higher specific loads. These conditions inherently increase the risk of abnormal combustion phenomena such as low-speed pre-ignition (LSPI) and knock, which significantly impact smoothness. This has necessitated the development of more sophisticated smoothness metrics that can distinguish between different sources of vibration and harshness.

Hybridization requirements, driven by fleet CO2 targets, have created additional challenges for smoothness quantification, as engines must transition between on and off states seamlessly. The metrics for quantifying smoothness during these transitions have become increasingly important as the frequency of engine restarts increases in modern hybrid powertrains.

Looking forward, upcoming regulations focusing on durability requirements will likely drive further refinement of smoothness quantification methods, as manufacturers must ensure that combustion stability and NVH characteristics remain consistent throughout the vehicle's regulatory useful life, which continues to be extended with each new emissions standard.

These regulations have progressively lowered the permissible levels of particulate matter (PM), nitrogen oxides (NOx), and carbon dioxide (CO2), forcing manufacturers to implement sophisticated combustion control strategies that directly impact engine smoothness. The introduction of Real Driving Emissions (RDE) testing has further complicated development efforts by requiring engines to maintain smooth operation across a wider range of operating conditions than previously necessary.

The regulatory focus on cold-start emissions has been particularly influential on GDI engine smoothness quantification methods. During cold-start conditions, when catalytic converters are below their light-off temperature, engines must maintain precise air-fuel ratios while minimizing combustion instability. This has led to the development of advanced smoothness metrics that specifically evaluate transient operation phases where emissions compliance is most challenging.

Particle number (PN) limits have driven significant changes in fuel injection strategies, with multiple injection events now common to reduce particulate formation. These complex injection patterns must be carefully optimized to maintain combustion stability and prevent torque fluctuations that would compromise perceived smoothness. Consequently, smoothness quantification methods have evolved to incorporate high-frequency analysis techniques capable of detecting subtle variations in combustion quality resulting from these injection strategies.

The regulatory push toward lower CO2 emissions has accelerated the adoption of downsized, turbocharged GDI engines operating at higher specific loads. These conditions inherently increase the risk of abnormal combustion phenomena such as low-speed pre-ignition (LSPI) and knock, which significantly impact smoothness. This has necessitated the development of more sophisticated smoothness metrics that can distinguish between different sources of vibration and harshness.

Hybridization requirements, driven by fleet CO2 targets, have created additional challenges for smoothness quantification, as engines must transition between on and off states seamlessly. The metrics for quantifying smoothness during these transitions have become increasingly important as the frequency of engine restarts increases in modern hybrid powertrains.

Looking forward, upcoming regulations focusing on durability requirements will likely drive further refinement of smoothness quantification methods, as manufacturers must ensure that combustion stability and NVH characteristics remain consistent throughout the vehicle's regulatory useful life, which continues to be extended with each new emissions standard.

NVH Standards and Consumer Perception Analysis

The quantification of engine smoothness requires adherence to established NVH (Noise, Vibration, and Harshness) standards that serve as benchmarks for automotive manufacturers. Industry standards such as ISO 2631 for whole-body vibration and SAE J1060 for subjective rating of vehicle ride and handling provide frameworks for evaluating GDI engine performance. These standards establish acceptable thresholds for vibration frequencies and amplitudes that impact human comfort, typically focusing on the 1-80 Hz range where human sensitivity to vibration is highest.

Consumer perception analysis reveals that vehicle occupants are particularly sensitive to vibrations during specific operational phases of GDI engines. Research indicates that consumers can detect vibration changes as small as 0.2 m/s² in the frequency range of 4-8 Hz, which often corresponds to engine idle and low-speed operation. During cold starts, consumers report heightened awareness of engine roughness, with satisfaction scores decreasing by up to 15% compared to smooth operation.

Market studies demonstrate a direct correlation between perceived engine smoothness and overall vehicle quality ratings. Premium vehicle segments show that consumers are willing to pay 5-8% more for vehicles with superior NVH characteristics. This price premium underscores the economic value of refined engine operation across all operational phases.

Psychoacoustic research further indicates that the human perception of engine smoothness is multisensory, combining tactile vibration feedback with auditory cues. The harmonics of engine sound significantly influence perceived quality, with even-order harmonics generally perceived as more pleasant than odd-order harmonics. GDI engines present unique challenges in this regard due to their characteristic combustion profile.

Regional variations in consumer expectations also emerge from global market analysis. European consumers typically prioritize refinement at highway speeds, while North American consumers place greater emphasis on smoothness during acceleration. Asian markets show particular sensitivity to idle quality, especially in urban driving conditions with frequent stops.

Manufacturers increasingly employ consumer clinics and blind comparison tests to quantify subjective perceptions of engine smoothness. These methodologies have evolved to include biometric measurements such as galvanic skin response and eye-tracking to capture unconscious reactions to NVH stimuli, providing more objective data on subjective experiences.

Consumer perception analysis reveals that vehicle occupants are particularly sensitive to vibrations during specific operational phases of GDI engines. Research indicates that consumers can detect vibration changes as small as 0.2 m/s² in the frequency range of 4-8 Hz, which often corresponds to engine idle and low-speed operation. During cold starts, consumers report heightened awareness of engine roughness, with satisfaction scores decreasing by up to 15% compared to smooth operation.

Market studies demonstrate a direct correlation between perceived engine smoothness and overall vehicle quality ratings. Premium vehicle segments show that consumers are willing to pay 5-8% more for vehicles with superior NVH characteristics. This price premium underscores the economic value of refined engine operation across all operational phases.

Psychoacoustic research further indicates that the human perception of engine smoothness is multisensory, combining tactile vibration feedback with auditory cues. The harmonics of engine sound significantly influence perceived quality, with even-order harmonics generally perceived as more pleasant than odd-order harmonics. GDI engines present unique challenges in this regard due to their characteristic combustion profile.

Regional variations in consumer expectations also emerge from global market analysis. European consumers typically prioritize refinement at highway speeds, while North American consumers place greater emphasis on smoothness during acceleration. Asian markets show particular sensitivity to idle quality, especially in urban driving conditions with frequent stops.

Manufacturers increasingly employ consumer clinics and blind comparison tests to quantify subjective perceptions of engine smoothness. These methodologies have evolved to include biometric measurements such as galvanic skin response and eye-tracking to capture unconscious reactions to NVH stimuli, providing more objective data on subjective experiences.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!