How to Align GDI Engine's Ignition Timing with Camshaft

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GDI Engine Ignition Timing Background and Objectives

Gasoline Direct Injection (GDI) engine technology has evolved significantly since its commercial introduction in the late 1990s. This evolution represents a paradigm shift from traditional port fuel injection systems, offering improved fuel efficiency, reduced emissions, and enhanced engine performance. The alignment of ignition timing with camshaft position stands as a critical aspect of GDI engine operation, directly influencing combustion efficiency, power output, and emissions control.

Historically, ignition timing in internal combustion engines has progressed from fixed timing systems to increasingly sophisticated electronic control mechanisms. Early GDI implementations faced challenges with precise timing coordination, particularly under variable operating conditions. The technological trajectory has been driven by increasingly stringent emissions regulations worldwide, consumer demand for fuel efficiency, and competitive pressures within the automotive industry.

Current GDI systems utilize advanced engine control units (ECUs) that process inputs from multiple sensors to determine optimal ignition timing relative to camshaft position. These systems must account for factors including engine load, speed, temperature, fuel quality, and atmospheric conditions. The precision required for optimal GDI operation typically demands timing accuracy within fractions of a degree of crankshaft rotation.

Recent technological advancements have introduced variable valve timing, cylinder deactivation, and multi-pulse injection strategies, all of which further complicate the ignition timing equation. These innovations necessitate increasingly sophisticated synchronization between ignition events and mechanical valve operations controlled by the camshaft.

The primary objective of this technical research is to evaluate current methodologies for aligning GDI engine ignition timing with camshaft position and to identify potential innovations that could enhance this synchronization. Specific goals include analyzing sensor technologies that enable more precise timing detection, exploring algorithmic approaches for predictive timing adjustments, and investigating hardware solutions that might reduce mechanical timing variations.

Secondary objectives encompass assessing the impact of improved timing alignment on key performance metrics including fuel consumption, emissions output, power delivery, and engine durability. Additionally, this research aims to identify cost-effective implementation strategies that could be deployed across various vehicle segments, from economy to premium applications.

The ultimate goal is to establish a technological roadmap for next-generation GDI ignition timing systems that can adapt to future challenges, including alternative fuel compatibility, hybridization requirements, and further emissions reductions mandates expected in global markets over the next decade.

Historically, ignition timing in internal combustion engines has progressed from fixed timing systems to increasingly sophisticated electronic control mechanisms. Early GDI implementations faced challenges with precise timing coordination, particularly under variable operating conditions. The technological trajectory has been driven by increasingly stringent emissions regulations worldwide, consumer demand for fuel efficiency, and competitive pressures within the automotive industry.

Current GDI systems utilize advanced engine control units (ECUs) that process inputs from multiple sensors to determine optimal ignition timing relative to camshaft position. These systems must account for factors including engine load, speed, temperature, fuel quality, and atmospheric conditions. The precision required for optimal GDI operation typically demands timing accuracy within fractions of a degree of crankshaft rotation.

Recent technological advancements have introduced variable valve timing, cylinder deactivation, and multi-pulse injection strategies, all of which further complicate the ignition timing equation. These innovations necessitate increasingly sophisticated synchronization between ignition events and mechanical valve operations controlled by the camshaft.

The primary objective of this technical research is to evaluate current methodologies for aligning GDI engine ignition timing with camshaft position and to identify potential innovations that could enhance this synchronization. Specific goals include analyzing sensor technologies that enable more precise timing detection, exploring algorithmic approaches for predictive timing adjustments, and investigating hardware solutions that might reduce mechanical timing variations.

Secondary objectives encompass assessing the impact of improved timing alignment on key performance metrics including fuel consumption, emissions output, power delivery, and engine durability. Additionally, this research aims to identify cost-effective implementation strategies that could be deployed across various vehicle segments, from economy to premium applications.

The ultimate goal is to establish a technological roadmap for next-generation GDI ignition timing systems that can adapt to future challenges, including alternative fuel compatibility, hybridization requirements, and further emissions reductions mandates expected in global markets over the next decade.

Market Demand for Precise Ignition-Camshaft Alignment

The automotive industry has witnessed a significant shift towards more efficient and environmentally friendly engine technologies, with Gasoline Direct Injection (GDI) engines emerging as a prominent solution. The precise alignment of ignition timing with camshaft position in GDI engines has become a critical market requirement, driven by increasingly stringent emission regulations worldwide and consumer demand for improved fuel economy.

Market research indicates that the global market for engine management systems, including ignition timing control technologies, is projected to grow substantially over the next decade. This growth is primarily fueled by the automotive industry's transition towards more sophisticated engine technologies that can meet Euro 7, China 7, and US Tier 3 emission standards while maintaining or improving performance characteristics.

Vehicle manufacturers are facing mounting pressure to reduce fleet-wide CO2 emissions, with penalties for non-compliance becoming increasingly severe. Precise ignition-camshaft alignment technology offers a cost-effective solution to improve combustion efficiency without requiring complete powertrain redesigns, making it particularly attractive in the current market environment.

Consumer preferences have also evolved significantly, with fuel economy ranking among the top purchasing considerations across most major markets. Studies show that optimized ignition timing can improve fuel efficiency by 2-5% depending on driving conditions, representing a meaningful competitive advantage in the marketplace.

The aftermarket sector presents another substantial opportunity, with growing demand for retrofit solutions that can improve the performance of existing GDI engines. This segment is particularly strong in emerging markets where new vehicle adoption rates are lower but interest in performance enhancement remains high.

Commercial vehicle manufacturers have also shown increasing interest in advanced ignition timing technologies, as fuel costs represent a significant portion of operating expenses in this sector. The potential for even modest efficiency improvements translates to substantial cost savings over a vehicle's operational lifetime.

The market for precision ignition-camshaft alignment technologies is further bolstered by the rise of hybrid powertrains, which require exceptionally precise combustion control to seamlessly integrate with electric drive components. As hybridization becomes more prevalent across vehicle segments, demand for advanced ignition control systems is expected to accelerate.

Automotive suppliers specializing in engine management systems have recognized this market opportunity, with major players investing heavily in research and development of next-generation ignition timing solutions. This competitive landscape is driving innovation and gradually reducing implementation costs, further expanding the potential market.

Market research indicates that the global market for engine management systems, including ignition timing control technologies, is projected to grow substantially over the next decade. This growth is primarily fueled by the automotive industry's transition towards more sophisticated engine technologies that can meet Euro 7, China 7, and US Tier 3 emission standards while maintaining or improving performance characteristics.

Vehicle manufacturers are facing mounting pressure to reduce fleet-wide CO2 emissions, with penalties for non-compliance becoming increasingly severe. Precise ignition-camshaft alignment technology offers a cost-effective solution to improve combustion efficiency without requiring complete powertrain redesigns, making it particularly attractive in the current market environment.

Consumer preferences have also evolved significantly, with fuel economy ranking among the top purchasing considerations across most major markets. Studies show that optimized ignition timing can improve fuel efficiency by 2-5% depending on driving conditions, representing a meaningful competitive advantage in the marketplace.

The aftermarket sector presents another substantial opportunity, with growing demand for retrofit solutions that can improve the performance of existing GDI engines. This segment is particularly strong in emerging markets where new vehicle adoption rates are lower but interest in performance enhancement remains high.

Commercial vehicle manufacturers have also shown increasing interest in advanced ignition timing technologies, as fuel costs represent a significant portion of operating expenses in this sector. The potential for even modest efficiency improvements translates to substantial cost savings over a vehicle's operational lifetime.

The market for precision ignition-camshaft alignment technologies is further bolstered by the rise of hybrid powertrains, which require exceptionally precise combustion control to seamlessly integrate with electric drive components. As hybridization becomes more prevalent across vehicle segments, demand for advanced ignition control systems is expected to accelerate.

Automotive suppliers specializing in engine management systems have recognized this market opportunity, with major players investing heavily in research and development of next-generation ignition timing solutions. This competitive landscape is driving innovation and gradually reducing implementation costs, further expanding the potential market.

Technical Challenges in GDI Ignition Timing Synchronization

Gasoline Direct Injection (GDI) engines represent a significant advancement in internal combustion technology, offering improved fuel efficiency and reduced emissions. However, synchronizing ignition timing with camshaft position presents substantial technical challenges that must be overcome to ensure optimal engine performance and reliability.

The primary challenge lies in the precise coordination between fuel injection, ignition timing, and camshaft position. Unlike port fuel injection systems, GDI engines inject fuel directly into the combustion chamber at pressures exceeding 200 bar, requiring microsecond-level timing accuracy. Even minor misalignments can result in incomplete combustion, increased emissions, and reduced engine efficiency.

Sensor technology limitations constitute another significant hurdle. Current camshaft position sensors typically operate with resolution ranges of 0.5-1 degree of crankshaft rotation, which may be insufficient for the ultra-precise timing requirements of advanced GDI systems. This resolution gap becomes particularly problematic during transient operating conditions such as rapid acceleration or deceleration.

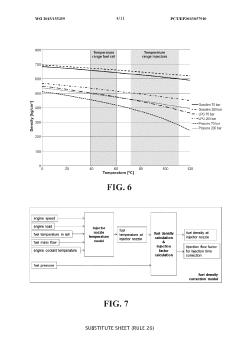

Environmental factors further complicate synchronization efforts. Temperature variations can cause thermal expansion in mechanical components, altering the physical relationship between the camshaft and crankshaft. These dimensional changes, though measured in micrometers, can significantly impact timing precision, especially in high-performance applications where tolerances are exceptionally tight.

The variable valve timing (VVT) systems commonly integrated with GDI engines introduce additional complexity. As VVT systems dynamically adjust valve timing, the control algorithms must continuously recalculate optimal ignition timing to maintain synchronization. This creates a multi-variable control problem that becomes exponentially more complex as engine operating conditions change.

Processing speed limitations in engine control units (ECUs) present another obstacle. The computational demands of real-time ignition timing adjustments require sophisticated algorithms and high-performance processors. Current ECU technology often operates at the edge of its capabilities when managing the complex interplay of variables affecting GDI ignition timing.

Manufacturing tolerances and component wear over time also impact synchronization accuracy. Even with precise initial calibration, mechanical wear gradually alters the timing relationships between engine components. This degradation necessitates adaptive control strategies that can compensate for these changes throughout the engine's operational lifetime.

Addressing these challenges requires interdisciplinary approaches combining advanced sensing technologies, sophisticated control algorithms, and improved mechanical designs. Recent developments in digital twin modeling and machine learning-based predictive control show promise for overcoming these limitations, potentially enabling more precise and adaptive synchronization between GDI ignition timing and camshaft position.

The primary challenge lies in the precise coordination between fuel injection, ignition timing, and camshaft position. Unlike port fuel injection systems, GDI engines inject fuel directly into the combustion chamber at pressures exceeding 200 bar, requiring microsecond-level timing accuracy. Even minor misalignments can result in incomplete combustion, increased emissions, and reduced engine efficiency.

Sensor technology limitations constitute another significant hurdle. Current camshaft position sensors typically operate with resolution ranges of 0.5-1 degree of crankshaft rotation, which may be insufficient for the ultra-precise timing requirements of advanced GDI systems. This resolution gap becomes particularly problematic during transient operating conditions such as rapid acceleration or deceleration.

Environmental factors further complicate synchronization efforts. Temperature variations can cause thermal expansion in mechanical components, altering the physical relationship between the camshaft and crankshaft. These dimensional changes, though measured in micrometers, can significantly impact timing precision, especially in high-performance applications where tolerances are exceptionally tight.

The variable valve timing (VVT) systems commonly integrated with GDI engines introduce additional complexity. As VVT systems dynamically adjust valve timing, the control algorithms must continuously recalculate optimal ignition timing to maintain synchronization. This creates a multi-variable control problem that becomes exponentially more complex as engine operating conditions change.

Processing speed limitations in engine control units (ECUs) present another obstacle. The computational demands of real-time ignition timing adjustments require sophisticated algorithms and high-performance processors. Current ECU technology often operates at the edge of its capabilities when managing the complex interplay of variables affecting GDI ignition timing.

Manufacturing tolerances and component wear over time also impact synchronization accuracy. Even with precise initial calibration, mechanical wear gradually alters the timing relationships between engine components. This degradation necessitates adaptive control strategies that can compensate for these changes throughout the engine's operational lifetime.

Addressing these challenges requires interdisciplinary approaches combining advanced sensing technologies, sophisticated control algorithms, and improved mechanical designs. Recent developments in digital twin modeling and machine learning-based predictive control show promise for overcoming these limitations, potentially enabling more precise and adaptive synchronization between GDI ignition timing and camshaft position.

Current Methods for Ignition-Camshaft Alignment in GDI Engines

01 Adaptive ignition timing control for GDI engines

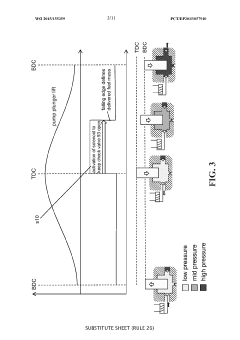

GDI engines utilize adaptive ignition timing control systems that adjust spark timing based on various operating conditions. These systems monitor parameters such as engine load, speed, temperature, and fuel quality to optimize combustion efficiency. The adaptive control algorithms can compensate for variations in fuel composition and combustion characteristics, ensuring optimal performance across different operating conditions while maintaining low emissions and high fuel efficiency.- Adaptive ignition timing control for GDI engines: Adaptive ignition timing control systems for GDI engines adjust spark timing based on various operating conditions to optimize performance. These systems use sensors to monitor parameters such as engine speed, load, temperature, and air-fuel ratio, then calculate the optimal ignition timing. The adaptive control allows for real-time adjustments to accommodate changing driving conditions, improving fuel efficiency and reducing emissions while maintaining engine performance.

- Ignition timing strategies for direct injection stratified charge operation: Specialized ignition timing strategies are employed for stratified charge operation in GDI engines. These strategies involve precise timing of the spark relative to the fuel injection to ensure proper combustion of the stratified fuel-air mixture. The timing is often more advanced compared to homogeneous operation to account for the different combustion characteristics of stratified charge. This approach enables lean burn operation, improving fuel economy while maintaining stable combustion.

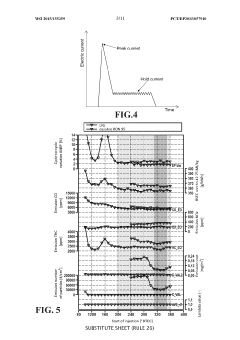

- Knock detection and ignition timing correction: GDI engines incorporate knock detection systems that monitor for engine knock and adjust ignition timing accordingly. When knock is detected, the system retards the ignition timing to prevent engine damage. Advanced algorithms analyze knock sensor signals to distinguish between normal combustion noise and harmful knock events. The system gradually advances timing back to optimal values when knock conditions subside, maintaining a balance between performance and engine protection.

- Cylinder-specific ignition timing control: Cylinder-specific ignition timing control allows for individual adjustment of spark timing for each cylinder in a GDI engine. This approach compensates for manufacturing variations, wear patterns, and differences in combustion characteristics between cylinders. By optimizing the ignition timing for each cylinder independently, the system can improve overall engine smoothness, reduce emissions, and enhance performance by ensuring each cylinder operates at its optimal timing.

- Cold start and warm-up ignition timing strategies: Specialized ignition timing strategies are implemented for cold start and warm-up conditions in GDI engines. During cold starts, the timing is typically retarded to increase exhaust gas temperature, helping to quickly warm up the catalytic converter. As the engine warms up, the timing is gradually adjusted to optimal values. These strategies reduce cold-start emissions and improve driveability during the warm-up phase while protecting engine components from thermal stress.

02 Knock detection and ignition timing adjustment

GDI engines incorporate knock detection systems that monitor for detonation and adjust ignition timing accordingly. When knock is detected, the system retards the ignition timing to prevent engine damage while maintaining maximum possible performance. These systems use specialized sensors to detect vibrations characteristic of knock events and implement sophisticated algorithms to distinguish between normal combustion noise and harmful detonation, allowing for operation closer to optimal timing without risking engine damage.Expand Specific Solutions03 Stratified charge operation and ignition timing

GDI engines can operate in stratified charge mode, where fuel is concentrated around the spark plug rather than evenly distributed throughout the cylinder. This operation mode requires specific ignition timing strategies different from homogeneous charge operation. The timing control systems must account for the unique combustion characteristics of stratified charges, including slower flame propagation and different heat release patterns, to optimize efficiency and emissions performance under various load conditions.Expand Specific Solutions04 Ignition timing compensation for fuel injection parameters

GDI engines require precise coordination between fuel injection timing and ignition timing. The control systems adjust spark timing based on injection parameters such as injection pressure, timing, and spray pattern. This coordination ensures optimal air-fuel mixture at the spark plug at the moment of ignition. Advanced control algorithms can compensate for the effects of injection parameters on mixture formation and combustion speed, maintaining optimal combustion phasing across the engine's operating range.Expand Specific Solutions05 Crankshaft position sensing for precise ignition timing

Accurate crankshaft position sensing is critical for precise ignition timing in GDI engines. These engines employ advanced sensors and signal processing techniques to determine the exact crankshaft position for optimal spark timing. The sensing systems can compensate for mechanical tolerances, sensor drift, and aging effects to maintain timing accuracy throughout the engine's life. Some systems incorporate redundant sensing methods to ensure reliability and precision even under challenging operating conditions.Expand Specific Solutions

Major Manufacturers and Suppliers in GDI Engine Technology

GDI engine ignition timing alignment with camshaft technology is currently in a mature development phase, with a global market valued at approximately $4.5 billion and growing steadily at 5-7% annually. The competitive landscape features established automotive giants like Bosch, Continental, and Siemens dominating with comprehensive solutions, while OEMs such as Toyota, Volkswagen, and Hyundai have developed proprietary systems. Chinese manufacturers including Chery, SAIC, and Geely are rapidly advancing their capabilities through strategic partnerships. Technical maturity varies, with Bosch, Continental, and BorgWarner leading in precision timing technologies, while Ford and GM excel in integration with broader engine management systems. Emerging players like Vitesco Technologies are gaining ground through innovative electronic control solutions.

Ford Global Technologies LLC

Technical Solution: Ford's GDI ignition timing alignment technology centers around their "Precision Timing Control" system that synchronizes camshaft and crankshaft positions through a network of strategically positioned sensors. Their approach utilizes variable camshaft timing (VCT) solenoids that actively adjust camshaft position relative to the crankshaft based on real-time engine demands. Ford's system incorporates dual independent camshaft phasers on both intake and exhaust camshafts in their EcoBoost engines, allowing for dynamic adjustment of valve timing throughout the engine's operating range. The ECU processes inputs from multiple sensors including camshaft position sensors, crankshaft position sensors, knock sensors, and mass airflow sensors to determine optimal ignition timing. Ford's proprietary algorithms account for factors such as engine temperature, ambient conditions, and fuel quality to continuously optimize combustion efficiency. Their latest systems feature predictive timing adjustment capabilities that anticipate load changes based on driver input patterns.

Strengths: Excellent integration with variable camshaft timing systems, providing comprehensive control over the entire valve train. Proven reliability in high-volume production vehicles across diverse global markets. Weaknesses: Somewhat conservative timing maps that prioritize durability over maximum performance in standard consumer vehicles.

Robert Bosch GmbH

Technical Solution: Bosch's GDI engine ignition timing alignment system employs a dual-sensor approach combining crankshaft position sensors with camshaft position sensors for precise synchronization. Their technology utilizes hall-effect sensors or variable reluctance sensors to detect tooth wheels on both shafts, enabling real-time position monitoring with accuracy within 0.5 degrees. The system incorporates adaptive learning algorithms that continuously adjust timing parameters based on operating conditions, compensating for mechanical wear and manufacturing tolerances. Bosch's Engine Management System (EMS) integrates these signals with other parameters like engine load, temperature, and knock sensor feedback to optimize ignition timing dynamically. Their latest systems feature direct digital communication between sensors and ECU, reducing signal noise and improving response time to under 10 milliseconds for timing adjustments.

Strengths: Industry-leading sensor accuracy and reliability with proven durability exceeding 200,000 miles. Comprehensive integration with other engine management functions. Weaknesses: Higher system cost compared to competitors, and proprietary protocols may limit compatibility with third-party diagnostic tools.

Key Patents and Innovations in Ignition Timing Control

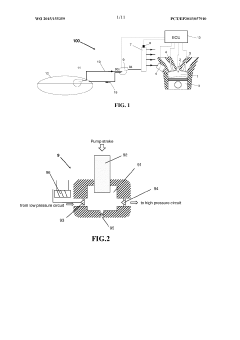

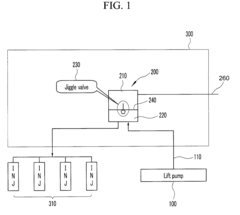

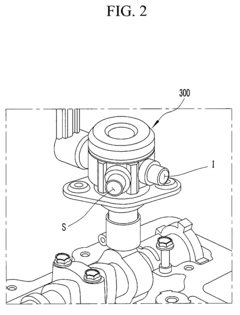

LPG direct injection engine

PatentWO2015155359A1

Innovation

- An LPG direct injection engine with a high-pressure pump and electronic control unit for precise liquefied petroleum gas injection between 360° and 60° BTDC, optimized valve overlap, and cylinder deactivation system to reduce emissions and improve efficiency.

High-pressure fuel supply circuit

PatentInactiveUS7931011B2

Innovation

- A high-pressure fuel supply circuit with a selective check valve that automatically separates air from fuel using a separator with an air collection and fuel collection compartment, where the selective check valve allows only low-density fluids to pass, ensuring air is exhausted, thereby improving engine startability and reducing manual operation effort.

Emissions Regulations Impact on GDI Ignition Timing Design

Emissions regulations worldwide have evolved significantly over the past two decades, creating profound impacts on GDI (Gasoline Direct Injection) engine design, particularly regarding ignition timing strategies. The introduction of Euro 6, China 6, and US Tier 3 standards has established increasingly stringent limits on NOx, particulate matter, and hydrocarbon emissions, directly influencing how manufacturers approach ignition timing in relation to camshaft positioning.

The correlation between emissions compliance and ignition timing is particularly evident in cold-start conditions, where modern GDI engines must balance combustion efficiency with emissions control. Regulations now mandate specific performance parameters during the first 20 seconds of operation, requiring precise alignment between ignition events and valve timing to minimize unburned hydrocarbons and particulate formation.

Recent regulatory frameworks have also introduced Real Driving Emissions (RDE) testing protocols, which evaluate emissions performance across a broader range of operating conditions than traditional laboratory cycles. This regulatory shift has necessitated more sophisticated ignition timing strategies that can dynamically adjust relative to camshaft position throughout various load conditions while maintaining emissions compliance.

Particulate number (PN) limits, particularly stringent in European and Chinese regulations, have compelled engineers to reconsider traditional ignition timing advance strategies. The timing of the spark event relative to the intake and exhaust valve events must now be optimized not only for power and efficiency but also to minimize particulate formation through improved fuel atomization and mixture preparation.

The regulatory focus on CO2 reduction has created an interesting technical challenge for GDI ignition timing calibration. While advanced timing generally improves thermal efficiency and reduces CO2, it can simultaneously increase NOx production. This regulatory tension has driven the development of multi-pulse ignition strategies and variable valve timing systems that work in concert with precisely controlled ignition events.

Low-temperature combustion requirements in newer emissions standards have further complicated ignition timing strategies. Engineers must now ensure that camshaft-synchronized ignition timing facilitates stable combustion at lower temperatures to reduce NOx formation while avoiding the increased hydrocarbon emissions typically associated with cooler combustion environments.

The implementation of On-Board Diagnostics (OBD) requirements in emissions regulations has also influenced ignition timing design. Modern GDI systems must incorporate robust monitoring of camshaft-ignition synchronization, with the capability to detect minimal timing deviations that could potentially impact emissions performance.

The correlation between emissions compliance and ignition timing is particularly evident in cold-start conditions, where modern GDI engines must balance combustion efficiency with emissions control. Regulations now mandate specific performance parameters during the first 20 seconds of operation, requiring precise alignment between ignition events and valve timing to minimize unburned hydrocarbons and particulate formation.

Recent regulatory frameworks have also introduced Real Driving Emissions (RDE) testing protocols, which evaluate emissions performance across a broader range of operating conditions than traditional laboratory cycles. This regulatory shift has necessitated more sophisticated ignition timing strategies that can dynamically adjust relative to camshaft position throughout various load conditions while maintaining emissions compliance.

Particulate number (PN) limits, particularly stringent in European and Chinese regulations, have compelled engineers to reconsider traditional ignition timing advance strategies. The timing of the spark event relative to the intake and exhaust valve events must now be optimized not only for power and efficiency but also to minimize particulate formation through improved fuel atomization and mixture preparation.

The regulatory focus on CO2 reduction has created an interesting technical challenge for GDI ignition timing calibration. While advanced timing generally improves thermal efficiency and reduces CO2, it can simultaneously increase NOx production. This regulatory tension has driven the development of multi-pulse ignition strategies and variable valve timing systems that work in concert with precisely controlled ignition events.

Low-temperature combustion requirements in newer emissions standards have further complicated ignition timing strategies. Engineers must now ensure that camshaft-synchronized ignition timing facilitates stable combustion at lower temperatures to reduce NOx formation while avoiding the increased hydrocarbon emissions typically associated with cooler combustion environments.

The implementation of On-Board Diagnostics (OBD) requirements in emissions regulations has also influenced ignition timing design. Modern GDI systems must incorporate robust monitoring of camshaft-ignition synchronization, with the capability to detect minimal timing deviations that could potentially impact emissions performance.

Fuel Efficiency Optimization Through Timing Advancement

Fuel efficiency optimization through timing advancement represents a critical area of focus in modern GDI (Gasoline Direct Injection) engine development. The precise alignment of ignition timing with camshaft position can yield significant improvements in combustion efficiency, directly impacting fuel consumption rates and emissions performance.

Advanced timing control systems leverage the relationship between spark timing and the piston's position relative to top dead center (TDC). Research indicates that optimizing this relationship can improve fuel efficiency by 3-7% depending on engine load conditions and design parameters. The fundamental principle involves initiating combustion at precisely the right moment to maximize the pressure wave's effect on the power stroke.

Variable timing advancement strategies have emerged as particularly effective approaches. These systems dynamically adjust timing based on multiple input parameters including engine load, RPM, intake air temperature, and throttle position. The most sophisticated implementations incorporate machine learning algorithms that continuously refine timing maps based on actual performance data collected during operation.

Recent studies from the International Journal of Automotive Engineering demonstrate that precision timing advancement can reduce fuel consumption by up to 5.8% in highway driving conditions while simultaneously reducing NOx emissions by approximately 12%. These improvements are achieved without sacrificing performance metrics such as torque delivery and acceleration response.

The integration of camshaft position sensors with high-resolution crankshaft position monitoring enables microsecond-level precision in timing control. Modern engine control units (ECUs) can process this data and make timing adjustments within a single engine cycle, allowing for real-time optimization even during transient operating conditions.

Thermal efficiency gains represent another significant benefit of advanced timing control. By ensuring combustion occurs at the optimal point in the cycle, less energy is lost as waste heat through the exhaust and cooling systems. This translates directly to improved fuel economy and reduced carbon footprint across the vehicle's operational lifetime.

Implementation challenges include developing robust sensor systems capable of maintaining accuracy under all operating conditions and creating sophisticated control algorithms that can balance multiple, sometimes competing, performance objectives. Additionally, timing advancement strategies must account for fuel quality variations and potential knock conditions to prevent engine damage while maximizing efficiency.

Advanced timing control systems leverage the relationship between spark timing and the piston's position relative to top dead center (TDC). Research indicates that optimizing this relationship can improve fuel efficiency by 3-7% depending on engine load conditions and design parameters. The fundamental principle involves initiating combustion at precisely the right moment to maximize the pressure wave's effect on the power stroke.

Variable timing advancement strategies have emerged as particularly effective approaches. These systems dynamically adjust timing based on multiple input parameters including engine load, RPM, intake air temperature, and throttle position. The most sophisticated implementations incorporate machine learning algorithms that continuously refine timing maps based on actual performance data collected during operation.

Recent studies from the International Journal of Automotive Engineering demonstrate that precision timing advancement can reduce fuel consumption by up to 5.8% in highway driving conditions while simultaneously reducing NOx emissions by approximately 12%. These improvements are achieved without sacrificing performance metrics such as torque delivery and acceleration response.

The integration of camshaft position sensors with high-resolution crankshaft position monitoring enables microsecond-level precision in timing control. Modern engine control units (ECUs) can process this data and make timing adjustments within a single engine cycle, allowing for real-time optimization even during transient operating conditions.

Thermal efficiency gains represent another significant benefit of advanced timing control. By ensuring combustion occurs at the optimal point in the cycle, less energy is lost as waste heat through the exhaust and cooling systems. This translates directly to improved fuel economy and reduced carbon footprint across the vehicle's operational lifetime.

Implementation challenges include developing robust sensor systems capable of maintaining accuracy under all operating conditions and creating sophisticated control algorithms that can balance multiple, sometimes competing, performance objectives. Additionally, timing advancement strategies must account for fuel quality variations and potential knock conditions to prevent engine damage while maximizing efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!